Unscheduled repairs are unlikely to please anyone. Especially when an apartment or country house is flooded with waste water from a sewer pipe. A sewer check valve can prevent a local disaster. All you need to do is choose the right model and install it.

We will tell you how the device works and why it will become the best protector against backflow of sewage for the next 5 years or more. We describe in detail the types of valves, their design features and operating rules. Taking into account our recommendations, you can choose the ideal device that solves your problems.

Types of check valves

All sewer shut-off devices can be divided according to the installation location:

- for the street;

- for the premises.

If the device is to be installed in a street sewer pipe, then you should choose a frost-resistant model with high throughput.

For indoor installation, simpler options are suitable. Moreover, these can be either plastic or steel models

Depending on the installation method, there are:

- flanged;

- wafer;

- coupling

The second option requires the use of welding and is used in metal pipelines. But this is a quick and easy method that does not require much time to install.

The flange method is used to install a check valve on large diameter pipes. Most often on the street. The coupling method is more convenient for installing devices of small diameter. This option is mainly used indoors. The main thing is that when installing, choose a place where you can safely remove the cover and clean the valve if it is clogged.

Image gallery

Photo from

Check valve for cold welding

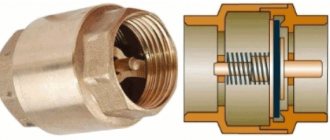

Structure of a simple check valve

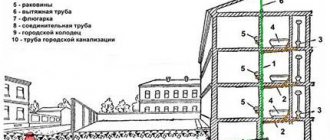

Discharge of wastewater into a collector well

Disposal of water into the drain

Also, according to the type of locking device, there are rotary, lift and ball valves. This is a difference in the way the locking mechanism is attached to the device itself. In a rotary valve, a damper is used; in a ball valve, the working body is a ball that closes the cross-section of the pipeline.

A model of a check valve for sewerage, which uses a ball as a working element, is most often used in industrial premises

In the lifting model of the shut-off valve, there is a special lock - a spool that moves under the influence of a spring or under its own weight.

Sometimes home craftsmen offer their own version of a homemade device - this is not always justified. Such a device may not withstand the pressure, and subsequent repairs will cost a pretty penny.

Briefly about the main thing

Installing a vacuum valve greatly improves the operation of the sewer network and protects the room from foul odors. But it will not protect against all problems associated with interruptions in the drainage system. It is important to take into account the purpose of the aerator, its main advantages, and use it only for its intended purpose. It is worth choosing a valve based on the characteristics of the pipeline in the room. Installing a protective mechanism, with the proper skills and knowledge, will not take much time and effort.

Ratings 0

Nuances of choosing a check valve

Before purchasing a shut-off device for personal use, you should carefully analyze the features of your sewer system. Based on its specifics, you have to choose.

When choosing the best option, you should pay attention to the following characteristics:

- diameter of sockets;

- material;

- fixture size;

- installation complexity;

- quality and guarantee;

- price.

Moreover, price is clearly in last place - the reliability and functionality of the valve do not depend on it. Here you should focus on your financial capabilities. For example, there is no point in buying a sophisticated model of a locking device with an electric motor for more than 120 thousand for a modest dacha with cheap plastic sewer pipes.

For the installation of sewer systems, models of check valves with horizontal and vertical installation methods are produced. Horizontal ones are mounted on main lines, vertical ones on risers

The most important parameter is the diameter of the sockets. This is the key characteristic and must match the diameter of the sewer pipe into which the check valve is to be installed.

Taking a smaller or larger cross-section of the device and buying special adapters would be the wrong decision. This will disrupt the smooth functioning of the system and may disrupt the throughput of installed pipes.

The material from which check valves are made is the same as the material of sewer pipes:

- plastic;

- steel, including stainless steel;

- cast iron;

- bronze;

- other materials, less common.

From the available options, it is best to choose the same one as the installed sewer pipes in a house, cottage, or apartment. It is not advisable to embed a plastic valve into a cast iron pipeline and vice versa. Moreover, plastic models are the most affordable.

Models of shut-off devices made of metal must be correctly installed in the same pipeline made of similar material

As for the size, the locking device should be selected based on the availability of space for its installation. Do not forget that there are valves for vertical and horizontal installation.

Most often the second option is chosen. But if there is not enough free space in the bathroom, kitchen, behind the toilet or in the utility room, take the vertical option.

If there is very little space, then a reasonable solution would be to use wafer check valve models, for installation of which only seals are required

The cost of installation work depends on the ease of installation if you plan to invite a plumber. If this is a simple plastic model, then a home craftsman with a minimum set of tools can install it.

Also, before purchasing, it would be a good idea to look at the model you like and check it so that nothing dangles or creaks under your fingers. You need to pay attention that there is an arrow on top, marked by the manufacturer.

Each high-quality product must indicate the direction of movement of sewage, which eliminates errors during installation.

You need to ask the seller for a manufacturer's warranty for this product. A high-quality product produced at the factory always has warranty documents and installation recommendations.

In private homes and cottages, the shut-off valve can also perform the function of protecting against rodents

Causes of blockages

Sewage back up can be caused by a variety of reasons, including:

- Improper operation of the sewer system, as a result of which rags, plastic bags and other things end up in it, blocking the lumen of the pipe.

- of sediment on the internal walls of pipes during long-term operation . In this case, not only the clearance decreases, but also roughness appears on the walls, which contributes to the settling of solid particles and even faster formation of a plug.

- Incorrect slope of sewer pipeline . Moreover, both too large and too small a slope contributes to blockages. To prevent solid particles from settling on the internal walls, the water flow driving them must move at a certain speed. The tilt can only be changed by completely redoing the system.

- The presence of outlets located at right angles causes the water flow to sharply change its speed, while large inclusions can be delayed, forming a plug over time.

Features of installing a locking device

The best option for installing a shut-off valve is renovating an apartment or building a house. It is at this stage that it is easiest to design the location of its placement and calculate the required length of pipes. In this case, the shut-off device will be installed during the assembly of the entire sewer system.

Plastic check valves for the installation of internal sewer networks are produced with shaped elements that facilitate installation and decorate passages through building structures

Most often it happens that no one plans to do repairs, but the valve needs to be installed. Then you should choose this device based on the realities of your sewer system. If the shut-off valve has already been selected and purchased, you can deal with the issue of its installation.

There are 2 options:

- do everything yourself;

- invite a plumber.

Depending on the material of the pipes in the apartment/house, the installation methods and the list of work required will differ. The price of the issue will also differ - for cast iron fittings, removing a part to install a shut-off valve in this place is much more expensive than a similar amount of work with plastic materials.

When you choose the option of inviting a master, you will only need funds to pay for his services. It is also advisable to monitor the work and check the quality of the installation so that problems do not arise later. It is best to contact a plumber who services your home/is assigned to a specific area.

The check valve is connected to the plastic sewer pipeline using a connecting element designed to exceed the standard pressure in the network. It does not allow leaks

If you decide to do everything on your own, then you need to first look at the installation theory or read a short instruction on installing a check valve on a sewer system.

Firstly, you will need to check the purchased device in action before installing it. To do this, you can use, for example, a stream of water from a tap. Having tested the functionality of the valve and made sure that it only allows water to flow in one direction, you can proceed to the next stage.

The second step is to measure the length of the return device and mark its installation location taking into account these dimensions. It is important here that there is free access to the valve - periodic inspection will be necessary.

When everything is marked, you have to remove/cut off a section of the pipe, in whose place a shut-off device will be installed. During installation, you need to use an O-ring and sealant or fum tape to ensure a reliable connection and prevent leakage.

To connect the check valve at the point where the direction of the sewer line changes, elbows with seals are used. They allow you to create an optimal bending angle and ensure reliable connection

The same should be done with the remaining shut-off valves if you plan to install separate shut-off devices on each plumbing fixture.

You should correctly position the valve using the instructions included with the device, or you can look at the red arrow indicating the direction of movement of the sewer.

When all the joints of the sewer pipe with the shut-off valve are securely insulated, you should check the work done in action by opening the tap or draining the water in the drain tank. If nothing leaks at the installation site, it means everything was done efficiently and you don’t have to worry.

The option with separate blocking devices on each plumbing fixture is more convenient - this way the apartment will be more reliably protected in the event of a sewer blockage

When installing a shut-off valve in a common sewer pipe in a country house/cottage, you should also ensure free access to it, even if it is located on the street. The outer part of the sewer system, together with the device and other fittings, should be equipped with a heating cable or thermal insulation system.

The principle of operation of ventilation in the sewer system

Drain outlets of plumbing fixtures are connected to the general sewer system. Wastewater is discharged spontaneously into a riser, which is a vertically located pipe, the diameter of which is most often 110 mm. It passes through several apartments, at the bottom it opens into a collector. From the reservoir, wastewater enters a centralized system.

The top hole is located above the roof level. The plug is not installed here. The ventilation hole allows air to pass through, which is needed to maintain the required pressure in the public sewer system.

This system is called a fan pipe. It is installed in all multi-storey buildings. Sometimes it is impossible to arrange such a structure. If the vent is located a short distance from the windows, the apartments will smell like sewage.

Rules for using the device

In order for the non-return valve to protect the house/apartment from the reverse flow of sewer water for a long time, it must be serviced in a timely manner. Therefore, it is important to provide convenient access to it.

Every 6-12 months you will need to open/unscrew the inspection cover and, if necessary, remove debris accumulating on the valve

It is possible that during the process of removing used water, noise, creaking and other unpleasant sounds occur. In this case, it is necessary to check the shut-off valve ahead of time - breakdowns in the form of worn parts or unexpected clogging are possible.

If you do not check everything in time, then when the sewage flows back, the device will not be able to fulfill its purpose and dirty water will begin to come out of all plumbing fixtures.

It is advisable to install check valves on each plumbing fixture so that if one of them breaks down, the rest will work

In the case when an automatic device with an electric motor is used, you must strictly adhere to the recommendations for its maintenance and change spare parts in a timely manner. The wear periods of individual elements of the device are indicated by the manufacturer in the instructions.

It is important to follow the recommendations and maintenance schedules for shut-off devices with an electric motor to ensure maximum protection of your home/apartment from flooding

It happens that during the audit, wear of certain parts was discovered, which cannot be replaced - the manufacturer does not produce the necessary spare parts.

In simple models with valves, if the locking part fails, it is better to buy and install a new valve to replace the damaged one

You should not repair a damaged part with improvised materials - there is no guarantee that, if necessary, a homemade damper will cope with the pressure of wastewater from the pipeline in the opposite direction.

Conclusion

Now you will certainly be able to choose a suitable air valve for sewerage 110. However, if you could not understand all the details, then do not be discouraged (see also the article “Why do you need cable ducting and how is it laid”).

In the video presented in this article you will find additional information on this topic, which will help you understand everything.

Did you like the article? Subscribe to our Yandex.Zen channel

Pros and cons of aerators

The positive qualities of the aerator include:

- Normalization of sewerage work. Installing an auxiliary part prevents the spread of an unpleasant “aroma” that is dangerous to the human respiratory system.

- Possibility of refusing to install a drain pipe. The placement of the aerator allows you to avoid creating an exit in the roof of a private house.

- Possibility of installation in a non-ventilated riser. In this case, the valve only works effectively in a low-rise building. In multi-storey buildings, the part is used in combination with a fan structure.

The disadvantages include the possibility of the rod jamming. This is caused by membrane wear or clogging of the aerator. The second is unlikely; debris gets into the case only when the lid is opened.

Technical characteristics, diameters and manufacturers

Important technical parameters of the device are:

- Diameter. Selected according to pipe dimensions. The diameter can be 5, 7.5 or 11 cm. The first 2 types are installed on intra-apartment systems, the last - on the riser. Some valves can be placed on sewer elements of different sizes. This becomes possible thanks to the introduction of a stepped pipe. On pipes of non-standard sizes, tees with a ventilation valve are installed.

- Bandwidth. This parameter reflects the volume of air entering per second. For 1 l/s of wastewater, up to 25 l/s of gas is required. The valve capacity can reach 37 l/s.

In our country you can purchase vacuum valves manufactured by HL (Austria), McAlpine (Great Britain), Wavin (Poland), Europlast (Ukraine), Ostendorf (Germany).