How much is a linear meter? This is analogous to a regular meter. The linear meter is used when measuring length in situations where the indication of width or height can be neglected for one reason or another.

In construction there is such a thing as a “linear meter”. For many, this measure of length remains a mystery for a long time. We hasten to reassure you, there is nothing scary here except the expression itself.

Let's try to understand this concept and learn how to correctly calculate the required number of linear meters.

Is it important to calculate the mass of pipes or not?

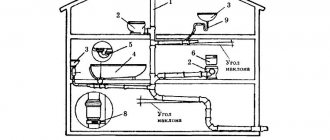

Know at what distance to place metal supports to prevent the line from sagging. When calculating the mass of a pipeline, the following parameters are taken into account: pipe mass; the weight of the liquid that is transported.

When it comes to constructing metal for a building, you have to make calculations. Calculating the weight of metal is a responsible task. The foundation of a structure with supports is subject to pressure from people, equipment, other room contents, and a steel frame. The last element for the mass of the building is the main one. For the construction of floors, a pipe with an I-beam or channel is used. These metal parts are highly durable.

Calculation of metal structures

Design documentation necessarily includes strength calculations of metal structures. It is represented by drawings, assembly diagrams and other related documents. In order for the structure to be durable, professional specialists determine the configuration and characteristics of metal structures. Only engineers can correctly calculate the mass of a steel frame. They take into account factors that can affect the value of the building. The employees of the company you contact will select materials with the required dimensions and a technology suitable for connecting the nodes for the project: using bolts or welding.

Calculating the strength of metal structures is indispensable for determining the reliability of a structure in the future. Metal structures are divided into the following types:

- agricultural;

- industrial;

- construction;

- lungs;

- heavy.

To calculate the strength correctly, mating, product dimensions, load and cross-section are required. Pipeline strength calculations are carried out by professionals using special programs. The use of online “assistants” allows you to obtain accurate results.

If we consider static loads simultaneously with dynamic ones, then the former are considered constant. They have another name: “gravitational”: their action is directed vertically. As for dynamic ones, their character is changeable. Strength waxes and wanes. The location for applying the load varies. This includes hail, rain, snow, wind, and temperature changes.

Thanks to the technical conditions, the maximum possible value of the force acting on the construction site is determined. Next, the force is multiplied by the safety factor. However, the use of such a formula is limited only when there are no vibration loads.

To carry out calculations, the limit state method is used. The load-bearing capacity of metal structures is the first limit of conditions. The structures resist external influences. They may change.

When planning a facility, a construction company evaluates individual elements for strength. At the same time, an increase in corrosion is added. This value represents the safety factor. It allows you to accurately determine what the effect of rust will be on metal parts. To make comprehensive corrosion protection effective, the characteristics of the steel and the operating conditions of the construction site are taken into account:

- temperature regime;

- humidity level;

- pressure;

- presence of an aggressive environment.

The calculation of metal structures must be entrusted to professionals: only in this case it is possible to adjust the strength and increase the service life of the object.

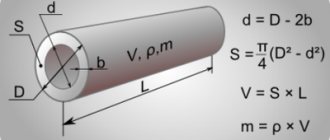

Calculation of the mass of a round pipe

How to calculate a linear meter: its differences from a square meter, how to calculate the cost of goods by length

In everyday life, when purchasing various building materials and carrying out work, everyone is accustomed to using metric units of measurement. Therefore, when purchasing long materials, the size of a linear meter leads to misunderstanding for some. But in some cases the use of this term is convenient and necessary.

What is a linear meter

The linear meter is a derivative of the meter, which, in accordance with the International System of Units (SI) and other metric systems, is a measure of length and distance and is not a measure of quantity. Numerically, these measures are equal to each other.

Where is this term used?

A linear meter is a unit of measurement for the number of molded products (moldings). This name was given to products that have a relatively small cross-section and significant length.

The concepts of the phrase “molded product” and the word “molding” were formed from the name “linear meter”, which is their unit of measurement.

Molded products include the following:

- fabrics;

- ribbons;

- pipes;

- rolled materials;

- profiles made of polymer materials;

- various cables;

- wood products (plinths, platbands, lining), etc.

Thus, a linear meter is a unit of measurement for molded products, which is used to facilitate their measurement and calculation when purchasing and designing.

How to calculate a linear meter

Using this measurement parameter makes it easier to measure and determine the quantity of goods purchased.

To correctly calculate and select the optimal option, you must:

- Take measurements of the area of the room. Correct calculation will allow you to avoid large surpluses or shortages of flooring material in the future and avoid additional costs.

- Select the required width of the linoleum roll, which is equal to the selected side of the apartment, and the other side of the apartment will determine the length of the roll in m\n, while sufficient dimensions of the material are selected taking into account allowances.

It should be noted that linoleum of the same type has different widths: 1 m, 1.5 m, 2 m, 3 m and so on. Hence the different area of a roll of 1 linear meter in length.

The area of a segment of 1 meter will be:

The area of a segment of 2 m will be:

- for a width of 1 m - 2 square meters. m;

- for a width of 2 m - 4 square meters. m.

Thus, when calculating, we multiply the width by the number of linear meters and get the area of the flooring material.

Approximate calculation of the choice of linoleum for a room with dimensions of 2 m × 3 m:

- if we choose a linoleum width of 2 m, then the length of the roll will be 3 m;

- if we choose a width of 3 m, then the length will be 2 m.

In both cases, the area will be 6 square meters. m.

Approximate calculation of the choice of linoleum for a room with dimensions of 4 m × 1.8 m:

- choose a linoleum width of 4 m (if there is no material with a width of 1.8 or does not exist) with a roll length of 1.8 m;

- the area will be 4 m x 1.8 m = 7.2 sq. m.

How to calculate the number of pipes when purchasing?

Today on the Internet it is easy to find special online programs that remove the question from the agenda: “How to calculate?” If the project is drawn up correctly, then the purchase of materials should be carried out taking into account the calculated values. For example, for the construction of a metal structure or pipeline, the owner of the future structure will have to purchase 1,200 meters of pipes. The value of the wall thickness of the products should be 4 millimeters, and the outer diameter should be 100 mm. This is where the buyer faces a problem. Wholesale batches are sold exclusively by tonnage. The question arises: “How to calculate mass?”

A conversion from tons to meters is required; this will help you quickly make a free online pipe calculator.

On the website of the manufacturing company, product consumers make various calculations, depending on the project being implemented:

- Determine the weight for a profile, electric-welded steel pipe with different shapes - round, square or rectangular;

- Calculate the weight of a pipe made not of steel, but of other metals;

- Enter the pipe length in m.

At the same time, the density of the material remains unchanged: 7.850 kg/m3. But this value is only suitable for steel. The calculation of the weight of the metal by size is made after entering the required material and grade, pressing the button with the image of the desired rolled product, entering the dimensions of the sides in mm. In addition to weight, length is calculated.

You can calculate the mass of the pipe yourself. This will require knowledge of geometry. The multiplication operation is performed using an offline calculator. It is important to have an idea of how to find mass from volume. A special formula is used: Mass equals density times volume.

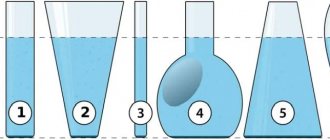

For a person who is far from construction work and does not know how to calculate the volume of a pipe, special online calculators will help. They allow you to calculate the volume of liquid inside the pipeline. For heating, you will need to additionally add the volume of batteries and boiler. Such information is available in the passport. The calculation results are the total V, the surface area of the pipes and the volume per 1 linear meter. Using an online calculator is a convenient way to calculate what a linear meter is equal to. The calculations will be useful later. When you plan to paint a pipeline, it is better to know in advance how much paint will be needed. To perform calculations, you will need to indicate the diameter: internal and external, and the length of the pipeline. Parameters are indicated in mm. The formula allows you to calculate the volume of the pipe: V=∏*R1*R1*L. R1 means the inner radius, and L is the length of the product. The surface area is calculated using the following formula: P=2*∏*R2*L, where R2 denotes the outer radius.

If the client wishes, the calculator-informer is installed on his website. This version is practically no different in functionality from the larger version. The client program is smaller in size. Therefore, it does not require much space. The calculator is installed on the site panel on the left or right side. The customer allocates a separate page for the program on his Internet resource, if he needs it.

When the calculator-informer does not work, the problem is easy to deal with. Press F5 or the key combination Ctrl+F5. You can also clear your browser cache of temporary files or enable support for Java Script.

ESW pipe weight 1 meter table - Prof. Bur

21.05.2021

Electric welded pipe GOST 10704-91 is made of carbon and low-alloy steel. The principle of its manufacture is the formation of a sheet or strip and subsequent robotic welding using a single seam. Several types of welding are used: arc, laser, plasma and induction currents.

Afterwards, the welding seam undergoes mandatory processing. The main advantage of this type of production is that it is possible to produce various cross-sectional shapes of electric-welded pipes: round, oval, square, rectangular.

Figure 1. Oval Figure 2. Square Figure 3. Rectangular

electric welded pipe. electric welded pipe. electric welded pipe.

Weight of the profile pipe. Table.;

Seamless pipe weight. Table.;

Pump and compressor pipes GOST. Weight of tubing;

Installation of pipeline supports. Roller and spring bearings.

There are electric welded pipes with a straight seam (straight-seam) and with a seam in the form of a spiral (spiral-seam).

Figure 4. Electric welded Figure 5. Electric welded pipe

straight-seam pipe. spiral suture

If the pipe is a straight-seam steel pipe , then you can calculate the width of the strip or sheet by multiplying the number π (3.14) by its diameter. Particular attention should be paid to the diameter, namely whether it is external or internal. If the diameter is internal, then when unfolding, you need to add a value equal to the thickness of the sheet to its width.

Electric-welded pipes are standardized in length sizes ranging from 4 to 12 meters.

Its use has found application in various fields of human activity. Such pipes are used to make construction and mechanical engineering structures, water supply lines, etc.

- The weight of electric-welded pipes differs from the weight of seamless pipes and is standardized by GOST.

- Table

- Theoretical weight of 1 linear meter of electric-welded steel pipe.

Weight table for profile pipes: square and rectangular

The scope of application of profile pipes is very wide; corrugated pipes are most in demand in the construction and industrial sectors, for creating durable frames of buildings or industrial structures, hangars and warehouses.

To do this, it is necessary to use different types of pipes, in width and height depending on the cross-sectional shape: square or rectangular, as well as different wall thicknesses so that the pipe can withstand the required load.

- When purchasing these metal products, customers often have questions:

- — How much does 1 linear meter of steel profile pipe weigh?

- — How to convert linear meters into kilograms and tons?

- — Number of linear meters of pipe in 1 ton?

The weight of the profile pipe primarily affects the cost of the product. The fact is that the price of a profile pipe at a metal warehouse is often indicated in tons, and not in linear meters.

Cost calculation is not the only reason why it is important to know the weight of a profile pipe. Because after purchasing the material, it must be delivered to your facility or production site. Knowing the weight of metal products, you can determine the necessary transport for delivery of corrugated pipes.

Important : to make the process of delivering profile pipes simple, quick and comfortable for you, we recommend using our delivery of rolled metal products.

What parameters affect the weight of a profile pipe?

- The rolled metal market offers a large selection of standard sizes of profile pipes; according to GOST, they have sizes from 15 to 300 millimeters, wall thickness from 1 to 12 millimeters.

- It is obvious to everyone that the greater the side length and wall thickness, the greater the weight, because more metal is contained in 1 linear meter, therefore, the weight increases, but let's look in detail at what the weight of 1 linear meter of profile pipe consists of.

- What you need to pay attention to:

- Shape: the most commonly used basic shapes of professional pipes are square and rectangular.

- Geometric parameters: height, width, wall thickness. Height and width - everything is clear here, the larger the size, the greater the weight.

- Wall thickness - the more massive (wider) the walls, the greater the weight. Thin-walled pipes are most often used, as a rule, for furniture or decorative elements of gratings and fences. Thick-walled - most often used for various metal structures.

- Material Density

In our article we are talking about steel pipes, where the average density of ferrous metal is adopted. At the same time, the density of the material is an important value and must be taken into account if you are calculating metal products, for example, from aluminum instead of steel.

Calculate the mass of a round pipe

Calculation of mass for products with a round cross-section is done as follows:

- Calculate the circumference. To do this, multiply pi and the outer diameter of the pipe;

- Determine the surface area of a linear meter of pipe. Multiply the circumference by the linear meter;

- Calculate the volume of liquid that is available in one linear meter. Multiply the area and wall thickness;

- Calculate the mass of one linear meter for the pipe. How to calculate a linear meter? You need the exact density of the material from which the product is made. Multiply the density by the volume to get the mass per linear meter.

- Multiply the mass per linear meter by the length of the pipeline. We get the value in meters.

With the help of an online calculator, the results of actions appear on the monitor in a matter of seconds. You enter the required data and press the “Calculate” button. After a second, the result appears. Using the online calculator is not difficult for novice users.

Areas of application (activities, materials)

The following materials, which are sold in rolls, are often measured in linear meters:

- linoleum, carpet;

- various types of fabrics;

- natural, artificial leather;

- cables, electrical wires;

- seals for windows;

- polyethylene film;

- oilcloth for household needs;

- plastic, metal mesh for vegetable garden;

- curtains, curtains, tulle;

- rope.

In addition, the price for moldings is set for the following types of products:

- metal pipes of various sections;

- rails, channels, angles;

- edged board;

- profiled sheet;

- many types of furniture (kitchen wall);

- baseboards;

- finishing border made of decorative rope, paper, foam.

Also, this unit of measurement is often found in the work of builders, in calculations when providing the following services:

- production of gazebos, canopies, pergolas;

- wallpapering, wall painting;

- installation of a fence made of corrugated sheets, slate, polycarbonate;

- finishing slopes around windows;

- filling mesh under plaster;

- covering the walls with a primer.

When ordering furniture for a kitchen, bedroom or living room, many are faced not with the final cost of the product, but with the price of the moldings. There's nothing wrong with that. On the contrary, sizing calculations are much easier to do.

Calculate the mass of a square pipe

Calculating the mass of several pipes in a bundle

A product with a square cross-section makes its own adjustments to the calculation algorithms:

- Calculate the cross-sectional perimeter for the pipe. Multiply the wall value of the product by 4;

- Calculate the area of a linear meter. The length of the perimeter is multiplied by 1 m. The result is a number showing how many linear meters are in a square meter;

- Find out what is contained in one linear meter. Multiply the surface area of 1 linear meter and the value of the wall thickness of the product;

- Multiply the resulting volume by the steel density value if the mass of the steel pipe is determined;

- Find the weight of the pipe. Multiply the mass of 1 linear meter and the footage.

Examples of calculating linear meters in everyday life

Let's look at several examples of how to correctly calculate linear meters for different materials and products.

Linoleum for the room

For example, the dimensions of the room are 4*5 m, the total area is 20 sq. m. To calculate the length, you will need to divide the area by the width. That is, this will mean that if you decide to take a strip of linoleum 2.5 m wide, you will need 8 linear meters. m of material (20/2.5 = 8 linear meters).

Corrugated sheeting for fence

First, the required width of the sheet is determined, which, in combination with the foundation protruding above the ground, will form a certain height of the fence. The perimeter of the site is measured. The required corrugated sheet moldings are purchased.

Kitchen countertop

To determine the required length of the kitchen countertop, it is important to know that the standard depth is 0.6 m. The exact length depends on the number and dimensions of the kitchen unit (cabinets, sink, built-in oven, cutting table). That is, if you need to close 2 cabinets 0.6 m wide, a built-in stove - 0.5 m, a double-type sink - 0.8 m, then you will have to order 2.5 linear meters. m countertops.

Having understood the term linear meter, it will be easier to understand the estimate drawn up by the builders and make your comments and adjustments to it. The same applies to the independent purchase of materials and other household payments.

Calculate the mass of a rectangular pipe

The difference with previous calculations is also present here:

- The perimeter of the section is the sum of the sides multiplied by 2;

- To get the surface area of a linear meter, multiply the perimeter of the product by one;

- The volume of a substance is calculated using the following action - by multiplying the surface area and wall thickness;

- Let's calculate the mass of one linear meter. Multiply the resulting volume by the density of the steel;

- Multiply the result of calculations in kg by the length of the pipeline. The resulting number is the total weight of the product.

The geometric method is not as convenient to use as an online calculator. This is a cumbersome method. Metallurgists use specialized formulas. They are used to calculate the mass of pipes with given dimensions. However, the results differ from previous ones. When referring to GOSTs, differences with the results of the calculations become obvious. Conclusion: it is better to purchase pipes for construction based on figures from generally accepted standards, which are the norm when it is important for the customer to have enough materials. Focus on the minimum value from the calculations, when purchasing an additional pipe will not be a problem.

If you figure out how to find the mass, knowing the weight, then it will not be difficult for you to determine how much materials you need. This will allow you to calculate future costs. If you know how many pipes will be needed for construction, it is easy to determine how much the project will cost.

If you need to find out the weight of a linear meter of pipe, fittings or other rolled products, then the most convenient and simple solution is our metal calculator.

First, you select the nomenclature by which you want to calculate meters into tons.

Why do you need to know specific gravity?

The total weight of steel pipes is important and necessary quantitative information

in any area where this rental is used. At a plant that produces pipes, it is necessary to know how much raw material is needed to fulfill an order to produce a batch of a certain product. In this case, it is impossible to do without information about the total weight of the delivery of the finished pipeline to the consumer. Financial reporting, accounting, road transport, warehouse and other documents reflect the movement and accounting of metal products in kilograms and tons.

You need to know the weight of the rolled pipe in order to choose the option of transporting it to your destination and select the necessary type of transport. This indicator is used during purchase and sale, as well as during financial settlements for pipe products. The weight of steel pipes is an integral indicator of calculations of strength, reliability, and weight of manufactured metal structures and is included in the relevant technical documentation. And in any case, it can be quickly determined

, knowing the general dimensional data and the length of the rolled product used, using the corresponding specific gravity of one linear meter of pipe.

Next, you select the product size.

To make the calculator easier to use, we have developed an interactive search bar that will make it easier to select product sizes

If it is round steel, then the list shows the diameters (rebar 10, 12, etc., circle).

If you want to know the weight of the pipe, then pay attention to the wall thickness.

To find out the weight of the sheet, you need to select the thickness, and then the weight will be calculated per square meters.

What is this unit of measurement?

If we define a linear meter, then this is the measurement value of long materials, molded products.

Equal to one linear meter to a regular meter (m). So in everyday life it is customary to measure the length of structures, raw materials, products, regardless of their width or height.

Calculating the cost of long goods using linear meters is easier than taking the price per square meter as a basis.

The ability to independently draw up an estimate, perform correct calculations, and understand the definition of a linear meter will eliminate the risk of being deceived and prevent errors of overexpenditure or shortage of materials.

Then data in meters or tons is entered into one of the fields

If you enter values in the "meters" field ("square meters" to find out the weight of the sheet), then you will know the total weight of the entire length (for example, the weight of the reinforcement).

If you are interested in calculating length by weight, then you need to enter data in the “tons” field.

What does the term "square meter" mean?

This unit is designed to calculate the area of a square, each side of which will be 1 meter. To determine the size of the area, you need to multiply the height and length of the product. The short form used for designation is square. m.

Today this unit is found almost everywhere in our lives. The most obvious example is the dimensions of a living space. In other words, if we are talking about an apartment of 16 m2, then the floor area is equal to this value.

The square meter is most often found in the construction industry. To determine the area of a wall that is 6 m long and 4 m high, you simply need to multiply six by four. It turns out that the wall area is 24 m2.

You can record and print the results obtained

Our calculator allows you to record your calculations in a special field so that you can easily see your latest calculations. To do this, you need to click on the “Write” button, and the result of your calculations will appear in a special field.

Also, after you have calculated all the necessary data, you can click on the “Print” button and receive a printout of the results in a convenient form.

You can compare prices for selected items from all suppliers.

To do this, you need to write down your calculations. Please note that the field with the recorded results contains positions that are of interest to you. Next, click “Calculate the entire application online”, and the system will take you to a page where the results of processing supplier prices will be shown.

The range of water and gas pipes is often needed for online calculation of the weight of pipes of water and gas pipeline systems during construction, laying communications, when laying water and gas pipelines. The full range of pipes is used in the installation of heating systems and pipeline parts, in external drinking water supply networks. GOST 3262-62 for water and gas pipes allows the production of rolled pipes without threads at the ends or with threads, while the length of black pipes without threads ranges from 4 to 12 m, and black and galvanized pipes with threads - from 4 to 8 m. Steel water pipes GOST 3262-75 pipes with increased manufacturing precision are used for parts of water and gas pipeline structures.

When welding pipelines, when water and gas pipes are used, manual welding or a coupling connection is used. Couplings are used for VGP pipes with normal wall thickness; welding is possible in all cases: light, regular, reinforced VGP types. The range of steel water and gas pipes of normal precision allows for production from steels in accordance with GOST 380 and GOST 1050 without standardization of mechanical properties and chemical composition. The most popular range of pipes is black rolled pipes, used for water pipelines, gas pipelines and heating systems. High-precision VGP pipes are made from steels in accordance with GOST 1050. The range of galvanized pipes is used for parts of water supply and gas pipeline structures with high requirements for durability and corrosion resistance.

A round pipe is a type of rolled metal product produced by electric welding. The technology for the production of rolled pipe products is that steel sheet blanks from strips (steel sheets in rolls) undergo the process of unwinding and straightening on rolls, are cut to size of a given length and width, after which the edges of the strips are processed by chamfering. Next, the strips are butt welded, the sheet blanks enter the storage tank to supply the material to the forming machine, where they are profiled into a round pipe of the required diameter size. The thickness of the pipe wall (thin-walled, thick-walled) depends on the thickness of the sheet strip. At the next stage, a longitudinal seam is welded (either in a straight line or in a spiral) by melting the edges of the metal with high-frequency currents, closing them into a permanent connection to obtain solid metal over the entire cross-section of a round pipe. At the final stage of the technological process, the burr on the finished product is removed and the electric-welded pipe is cooled, calibrated to comply with GOST diameters within tolerances and cut to the required length.

1 inch = 2.54 cm

Quarter inch – 8 mm; half inch - 15 mm; three quarters of an inch - 20 mm; inch – 25 mm; inch and a quarter – 32 mm; one and a half inches - 40 mm; two inches - 50 mm; two and a half inches - 65 mm; 4 inches - 100 mm.

This ratio between inches and millimeters greatly simplifies the selection of imported pipeline fittings for Ukrainian pipes, however, it is important to understand that these dimensions are also suitable for domestic branches, transitions, water taps, and gas valves. Imported couplings, taps, bends, tees, bends (and now imported stainless pipeline fittings are often used) have actual inch dimensions, which are slightly different from the connecting dimensions of VGP pipes.

Why the name "running"

But this is a more interesting point. It is believed that the word "running" comes from the Polish "pogon". Translated, this means a cord or harness.

It can be assumed that since in the case of a linear meter we are talking about measurements in length, there was a certain cord that was the standard of measurement. And, most likely, it was exactly 1 meter long.

Interesting fact. The word “running” is also found in ancient Russian measurements. So there was a linear fathom, that is, one that is measured in length. And this is how it differed from the square and cubic fathoms.

So manufacturers of building materials did not come up with something fundamentally new, but simply modernized the forgotten old.

By the way, some believe that army shoulder straps originated from the same Polish “lace”. Apparently, ancient warriors used some kind of bandages as insignia.

True, according to another version, the etymology is completely different. And shoulder straps come from the word “gonar”, which means “honor” and “dignity”. Which is undoubtedly characteristic of the military.

Table of pipe diameters - How many kilograms (kg) are in one meter (m) of pipe

| Diameter mm - inch | Outer | Lungs | Regular | Reinforced | ||||

| Wall thickness s, mm | Weight 1m, kg | Meters per ton | Wall thickness s, mm | Weight 1m, kg | Meters per ton | Wall thickness s, mm | Weight, kg/m | Meters per ton |

| 8 — 1\4 | ||||||||

| 15 — 1\2 | ||||||||

| 20 — 3\4 | ||||||||

| 25 — 1 | ||||||||

| 32 — 1 1\4 | ||||||||

| 40 — 1 1\2 | ||||||||

| 50 — 2 | ||||||||

| 65 — 2 1\2 | ||||||||

| 100 — 4 | ||||||||

| 46,2 |

The weight of a linear meter of steel pipe in the table is the theoretical weight. Actual value may vary by 4-8%

To convert meters to kilograms of pipe, you need to multiply the weight of a linear meter in the assortment table by the total length of rolled pipe.

Standard designation of pipe diameter in the range (see table):

- Internal diameter is the main dimensional characteristic of pipes and connecting parts (fittings) to them.

- Outer diameter of pipes (in the table - dn). Rolled steel pipes are classified according to their outer diameter: small pipe sizes - 5-102 mm; average sizes – 102 – 406 mm; large sizes 426 mm and more.

- The nominal pipe diameter (in the table - Dy, Du) is the nominal size of the internal diameter in millimeters or its rounded value in inches.

- Nominal diameter (in the table Dn, Dn)

- Wall thickness, mm (in table S).

Maximum deviations in the mass of pipes in the table of diameters and weight data should not exceed +8%

Linear value for fencing

Scheme for marking the territory for measurements

This is the size of a traditional fence, the canvas of which is a profile sheet or wood. It will be equal to a simple meter if the height of one sheet is also equal to 1 m. Just as when calculating the amount of rolled material, the width is not taken into account, since it is standard, when constructing a fence, the height is not taken into account. It must also be permanent. But it should be borne in mind that the height of the fence does not always coincide with the dimensions of the sheets of building material.

If, for example, a fence is built a meter high, and profiled sheets 1 m high are used, then the linear value of the fence will be equal to a meter of building material. But if the fence is higher, and the same profiled sheets or boards are used, more of them will be required. Therefore, before purchasing raw materials, you should calculate everything correctly.

How much does 1m of steel pipe weigh? Weight calculation

If there is no pipe table, then you can calculate the mass of 1 linear meter using the calculation formula on a regular calculator and find out how many kg are in a meter of pipe:

Calculation of the weight of stainless steel pipes: m = Pi*(d - s)*s*R/1000

Formula for calculating the weight of the “black” pipe: m = (d - s)*s/40.55

where: m

- theoretical mass of one linear meter of pipe (specific gravity) in kg,

Pi

= 3.14 (constant value in our calculation),

d

- outer diameter in mm,

s

- wall thickness in mm,

R

- specific gravity of steel in g / cubic meter . cm.

The weight of 1 m of VGP pipe in the assortment is calculated at a specific gravity of steel equal to 7.85 g/cm3. Galvanized steel pipe products are 3% heavier than non-galvanized steel. To automate the process of calculating pipes, you can use the online pipe calculator (round, VGP, seamless, electric-welded), presented in the section of the website “Rolled Metal Assortment”. In this pipe metal calculator, you can select the material from which the pipe is made for a more accurate calculation of weight.

Steel pipes, depending on their parameters and cross-sectional dimensions: diameter and wall thickness, have different areas of application:

• installation of heating systems, laying water communications, gas pipelines, installation of sewerage, water disposal and gas supply; • production and construction of fences and enclosures, protection of electrical cables from damage; • transportation of substances under pressure over long distances: oil, chemicals and gas; • production of wells, casings in mining; • production and installation of simple and complex metal structures of buildings and structures; • distribution of tap water, supply of process water in irrigation systems; • production of furniture frames; • exploration and development of oil, gas fields, etc.

The table is a handy hint

To make it easier to calculate and quickly understand units of measurement, it is more convenient to convert them into one table. It will look like this:

| Unit | Pog. m | m2 | m3 |

| Pog. cm | 100 | 400 around the perimeter | 1200 around the perimeter |

| Sq. cm | ‒ | 10 000 | 60,000 in area |

| Cube cm | ‒ | ‒ | 1 000 000 |

This cheat sheet will be useful when purchasing building materials, making a fence, stairs, etc.