One of the problems faced by owners of country houses and private households is the difficulty of igniting stoves. This usually happens due to poor fuel quality (high moisture content of the wood) or poor draft in the chimney. The last condition is a necessary process, the maintenance of which can occur naturally (due to the pressure difference). In some cases, poor draft as a phenomenon can be eliminated by installing forced means of increasing the aerodynamic effect or by revising the design of the room ventilation system.

What is traction

Draft is the movement of flue gases up the chimney of a house, from an area of high pressure to an area of low pressure.

In a chimney (in a pipe) of a set diameter, with a height of at least 5 m, a vacuum is formed, this means that the required minimum pressure difference is formed between the lower part of the chimney and the upper, the air from the lower part, entering the pipe, goes up. This is called traction. The draft can be measured with special sensitive instruments, or you can take a piece of fluff and bring it to the pipe. Accordingly, if you take a pipe of sufficient diameter in which air has the opportunity to move, and stretch it high up, then air from the ground will begin to constantly flow upward. This happens because the pressure is lower at the top, and the vacuum is greater, and air tends there naturally. And in its place will come air from other sides. In the “firebox + chimney” system, the draft operates even if the stove in a private house is not working. When burning wood, increased pressure is formed in the internal combustion chamber and the flue gases generated during combustion require exit. All fireboxes and stoves are designed to exhaust flue gases into a chimney.

The height of each chimney is selected so that draft is created, an initial vacuum is created. When burning in the combustion chamber, heat and gases are released and excess pressure occurs. Gases move in the chimney under the influence of draft, tending to move from an area of high to an area of low pressure. The laws created by nature work.

Supply ventilation systems

offers a wide range of different types of ventilation equipment:

- Devices for forced air supply and purification. Models of different sizes and power with a different set of functions are presented: heating, passive ventilation, ionizer, UV radiation, CO2 level measurement, etc.

- Supply and exhaust ventilation - equipment for ventilation, cleaning and heating of air.

- Supply valves - provide ventilation without the use of electricity, a high level of cleaning and protection against freezing.

- Dust filters are high-quality consumables for the equipment presented in the online store.

The AEROS company is Tion No. 1 dealer in Russia . We create comfortable conditions for our clients:

- We provide a two-year warranty on all equipment.

- Professional in-house teams of installers are available to customers.

- Delivery throughout Novosibirsk and the region is free.

You can get advice on the presented range and technical characteristics by contacting the company’s specialists by phone listed on the website or via online chat.

Why does backdraft occur in a stove or chimney?

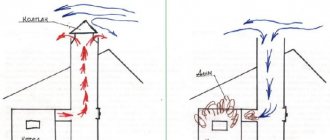

Reverse draft is the movement of flue gases from an area of high pressure to an area of low pressure, but not upward (as described earlier), but downward. Reverse draft occurs when pressure is inverted - when the pressure at the top is higher than at the bottom.

The reasons are the most ordinary things: if a private house or room is sealed, there are double-glazed windows, and an exhaust hood works together with the chimney, drawing air out of the room. This is where low pressure is created relative to the surrounding area. Therefore, during kindling, when the chimney is still cold, the air in the upper part of the chimney has greater pressure than in the room. The smoke will of course go where it is easier for it. This phenomenon is called a “cold column”. When the chimney cools, a low-temperature air mass forms inside, which presses down, causing reverse draft. If the pressure in a private house is not reduced, then warm air will go up into the chimney.

Thus, if the house does not have a kitchen hood and it is not airtight, there will be no stagnation of cold air in the firebox.

Check: if in winter, before lighting the fireplace, you first set fire to a newspaper and put it into the chimney (bypassing the combustion part), then the fire will not go into the room, no matter what the column of cold air is. The fire will burn and come out only into the chimney. This indicates that the pressure in the room is not low and warm air normally tends to rise.

When lighting a stove or fireplace in a private home, sometimes smoke comes into the room. This is due to the fact that the flue gases formed during the initial kindling have not yet had time to heat up, and, when rising upward, coming into contact with the cold walls, they immediately cool down. After that, they will naturally rush down. Again, reverse draft occurs in the chimney ventilation. To normalize the draft in the stove, it is important to melt correctly, understanding the processes occurring there.

What threatens the lack of normal vacuum in the furnace?

Modern, even the simplest gas heating equipment does not allow combustion with reverse draft or its complete absence. However, with insufficient, poor draft, not all boiler models interrupt combustion, and this is fraught with:

- the spread of natural gas throughout the room due to its under-combustion due to lack of oxygen. In this case, there is always a characteristic smell of gas;

- the entry of toxic combustion products into the room, sometimes, especially in small quantities, they are not noticeable by smell;

- increased soot formation, which leads to accelerated clogging of the chimney, heat exchanger and combustion chamber of the boiler.

How to choose a room thermostat and save up to 30% per month on heating

Rollover traction

Another issue that arises is the tipping of the draft. In what cases does this happen?

If the chimney is long and cold (often brick), and the pressure is reduced. If the ratio of the dimensions of the firebox and the cross-section of the chimney correspond, if there is normal pressure in the house, a situation still arises when, when lighting the flame, there is not enough strength and the exhaust flue gases manage to cool in the chimney and collapse down. Why is there no draft in the chimney? This happens in cloudy weather and wind. It happens that the fire flares up normally, but then smoke pours into the house. Why is there no draft in the furnace? Why does back draft form in the chimney? Air is taken from the house and the pressure decreases, there is no air flow. As the flue gases rise, they cool and fall down. What do you need to know in such situations? Open the window slightly if the room has double-glazed windows and is sealed. The preparation of firewood and its quality are important.

Methods for determining hood malfunction

checking the operation of the hood using fire

If a malfunction is suspected, it is worth checking the draft. It's easy to do it yourself. Algorithm of actions:

- Open the window (window sash 6-9 cm).

- Place a lit match in front of the ventilation grille (use lighters or candles). The distance from the flame to the hood is 1 cm.

- Determine which direction the flame is leaning - towards the ventilation or into the room. In the first case, the system works properly, in the second, the hood in the apartment does not work; measures must be taken to restore the draft.

If the flame experiment does not give concrete results, you can use another test method using paper. Without closing the window, you need to bring a thick napkin (its size is equal to the area of the ventilation channel) to the grille, press it and pull your hand away. If the napkin is held tightly, traction is present, ventilation is working properly. Falling paper indicates otherwise. It is recommended to check the hood in residential premises at least once a year.

How to assemble a chimney correctly?

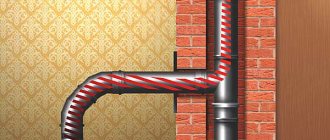

Sandwich chimneys (prefabricated), collected by smoke and condensate.

There is an opinion that it is more correct to collect by smoke. The explanation is that there are gaps at the pipe joints where the flue gases escaping into the pipe get clogged. In contrast, it is believed that if you collect the smoke, the smoke will stop coming out.

Such a dispute can be resolved if you drill a hole in the existing stove at home anywhere in the chimney and see what happens. It's most interesting to do this at the bottom. Drill any hole, at least a centimeter in diameter. What will you see? No smoke will come out of this hole (unless you close the chimney tightly from above).

Precautions when working in a ventilation duct

If the air outflow is disrupted, an accumulation of flammable gases and combustible debris may occur in the ventilation shaft, so during operation, take the following precautions:

- Do not use open fire to illuminate the ventilation shaft and do not try to set fire to debris accumulated in the chimney, as this may lead to a fire.

- Do not place heavy objects into the ventilation duct.

- Do not use aggressive solvents or other chemicals to clean pipes. It is permissible to use dry ice, which when melted leaves no traces.

Ways to normalize cravings

The main thing is to take into account that condensation may occur in every chimney of a house, especially when it is still cold and warm flue gases are greatly cooled as they rise. Condensation may settle on the walls and flow down the pipe.

If the chimney is assembled according to smoke, then condensation easily penetrates into the cracks and moistens the insulation, completely depriving it of its heat-insulating properties. It's not far from the fire here. Therefore, the assembly of modular chimneys is carried out only using condensate. The chimneys are assembled at a clear joint, with sealant along the inner pipe. However, the chimneys themselves must be of high quality so that no extraneous cracks remain. If the gaps remain, air will enter through them, and it turns out that there will be no draft anyway.

But the chimney is big and tall! Not understanding the reason, they call the experts. Craftsmen use a simple method: they cover the top of the chimney and watch where the smoke comes from. Here all sorts of inconsistencies in the chimney are discovered, which lead to air being sucked into the chimney. Remember? The air tends upward, to where the pressure is lower. Therefore, the more cracks, the worse the traction below. The smoke assembly, unfortunately, does not take into account the very essence of draft. As a result, the fire burns and smoke rushes in all directions. Although the logic here is not complicated - smoke goes from an area of high pressure to an area of low pressure, where it is easier for it.

What are the dangers of non-functional ventilation?

During human life, excess heat, dust, gases and vapors, moisture and other harmful emissions accumulate in the air masses of an apartment. They pollute the air and make it unfit for inhalation. The ventilation system of an apartment building is designed in such a way as to eliminate harmful substances by removing them and replacing them with clean street air. Its installation is carried out in accordance with legislative, SanPiN and building codes. They determine the speed and frequency of movement of air masses through ventilation ducts.

If the system is not designed correctly and is not regularly maintained, or if the channels are clogged, the air exchange process is disrupted. It leads to:

- jump in indoor air humidity;

- deterioration of health: allergies, frequent respiratory diseases, headaches, insomnia, lethargy, sore throat and cough, lacrimation, shortness of breath, etc.;

- the appearance of condensation (water droplets) on the windows;

- the formation of moldy fungi on textile upholstery and wallpaper;

- the appearance of unpleasant, corrosive odors.

consequences of faulty ventilation

High humidity and excess heat are a favorable environment for the active reproduction of viruses, mold, bacteria and insects. If ventilation is faulty, a favorable microclimate turns into an unfavorable one in 14-24 days. It is quite difficult to restore sanitary and hygienic conditions in the apartment. Excess moisture also has a bad effect on furniture, decoration, and household electrical appliances. Their service life is reduced by 25%.

Unpleasant consequences can be easily avoided by regular system checks and installation of equipment for forced removal of contaminated air. It is most often used in the kitchen and bathroom. If the system check gives an unsatisfactory result, action must be taken.

What else affects the amount of thrust?

First of all, the height of the chimney. The minimum required height is 5 meters. This is enough for a natural vacuum to occur and the upward movement to begin. The higher the chimney, the stronger the draft. However, in a brick chimney with an average cross-section of 140x140mm, at a height of over 10-12 meters, the draft no longer increases. This is because the wall roughness value increases with increasing height. Therefore, excess height does not affect traction. A similar question arises among those who want to use ducts for chimneys in their homes. They come in large heights and narrow cross-sections, so a serious fireplace is rarely connected to such a chimney.

Reasons affecting cravings:

- Flue gas temperature. The higher the temperature, the faster the flue gases rush upward, creating a greater draft.

- Chimney heating. The faster the chimney warms up, the faster the poor draft normalizes.

- The degree of roughness of the chimney and internal walls. Rough walls reduce traction, while smooth walls have better traction.

- The cross-sectional shape of the chimney. The circular section is a sample; oval, rectangular and so on. The more intricate the shape, the more strongly it affects traction, reducing it.

- It is important to note that the ratio of the size of the firebox, the diameter of the outlet pipe and the diameter of the chimney pipe also influences. If the height of the designed chimney is excessive, you should consider reducing the cross-section of the chimney by an average of 10%. Install an adapter on the firebox, on the smoke pipe (for example, from a 200-diameter to a 180-diameter) and take the 180-diameter pipe itself. This is allowed by the manufacturers. If we talk about “EdilKamin” as an example, you can see that in the instructions for the fireboxes he describes what diameter the chimney should be depending on the height.

For example:

- height up to 3 m – diameter 250,

- height from 3 m to 5 m – 200,

- height from 5 m and above – 180 or 160. Strict recommendations.

Other manufacturers (such as Supra) admit that changes are possible. Some don't allow it at all. Therefore, following the instructions, you should not forget about the processes occurring in the chimney.

Other ways to fix the problem

To ensure that the hood in the bathroom, toilet or kitchen effectively copes with the task, you can install forced ventilation. Such a system works passively by switching on. In the toilet, as a rule, the switching on occurs simultaneously with the light switching on. However, you can also make a separate switch for the hood.

In the kitchen, ventilation is installed above the stove in the form of a socket. This system eliminates unpleasant odors and smoke. In addition, it reduces the accumulation of grease on walls, furniture, ceilings and other surfaces. How to clean the kitchen from grease, read here.

To keep fresh air in the apartment, supply valves are installed. To do this, additional holes are made in the wall between the battery and the window. Such openings operate on the principle of cracks in windows and provide regular access to fresh air from the street.

The valves are placed at an angle to the wall and covered with a grille; a soundproofing box is installed inside. At the same time, they are more effective and less noticeable than the cracks of a slightly open window.

To install supply valves, it is important that the holes in the wall match the diameter of the air duct. A suitable diameter would be 6-10 centimeters.

In addition, air humidifiers will provide the necessary humidity in the apartment. For more information about the operation of this device and which humidifier is better to choose, read the link.

Rose of Wind

A situation when the prevailing winds blow directly into the chimney and reduce the draft or reverse it. The chimney is installed on the windward side, of course, if the wind directions are determined. If the chimney is located far from the ridge and below, the leeward side cannot be used. Multi-storey buildings and trees also affect traction. To compensate for gusts of wind and poor placement of the chimney, anti-wind deflectors are used. According to the standards, the chimney is installed half a meter above the ridge. If the distance from the ridge is 1.5 m - 3 m, then it is brought to the same level as the ridge. If the distance is more than 3 meters, then proceed according to the formula: from the horizontal drawn from the ridge, 10 degrees down. In practice, the chimney is made higher than the ridge, or at the same level as the ridge. It is important to use one chimney for one stove in the house.

Where to go if the ventilation doesn't work?

ventilation repairman

In order not to pay a fine , it is wiser to immediately resort to the help of the organization responsible for the apartment building and the provision of services to its residents - a management company , HOA or housing office. The claim is submitted in the form of a statement with a detailed description of the problem. After reviewing the document, a team of specialists will be sent to the site. They will diagnose the channels, clean them and issue a conclusion in the form of a work report.

In practice, submitting an application to the management company and the subsequent cleaning procedure gives only minor results.

Therefore, experts advise selecting equipment in advance to ensure forced air circulation (described above).

Do-it-yourself stove and chimney cleaning

You can clean the chimney yourself or call a specialist with professional tools

. If the stove is used for seasonal heating and cooking, the chimney should be cleaned once a quarter. This should be done more often if resinous or damp firewood is used. This causes excessive deposits and narrowing of the lumen. Mechanical cleaning can be done independently using traditional techniques that have not changed over the past centuries. Work is carried out wearing protective glasses and gloves. For activities at heights, you need non-slip shoes and insurance.

From the roof side

You will need a cable on which hard brushes are attached to clean the chimney from soot, and a heavy round weight with an eye. A brush can be made from an old plastic bottle.

Cleaning is carried out in five stages:

- To prevent soot from entering, cover the firebox and hatches with a wet rag.

- Remove the head and inspect the canal.

- Clean with a broom to remove cobwebs and debris.

- Use a weight to break through the blockage several times.

- Clean the chimney walls with brushes.

Finally, you will need to clean up the soot from the roof and inside the firebox.

From the oven side

Cleaning the chimney from the stove side

You need a special brush with a rigid but flexible fiberglass cable. It can be purchased at a hardware store.

Cleansing also takes place in five steps:

- Unscrew the hatch plug for cleaning,

- Clear the entrance of debris.

- Attach a suitable brush (for metal pipes only a plastic one).

- Clean the canal, slowly moving the instrument upward.

- The firebox is cleaned in the same way.

All that remains is to remove the soot and return the plugs to their place.

Cleaning a chimney is not a complicated procedure, but it is dirty and tedious. To make your task easier, you need to carry out preventive measures using special fuel. It is impregnated with chemicals, with the help of which the deposits themselves fall off into the firebox or turn into gas and fly away into the chimney. Be sure to read the instructions carefully. Some of these products are toxic; measures can only be carried out by tightly closing the firebox with an iron damper.

You can use traditional methods. Periodically complete the kindling with a few alder or aspen logs. This prevents the formation of soot. But you should not add any powders to the firewood, since some of these methods can lead to an explosion.

To prevent the stove from smoking, check the draft periodically. Do not use coniferous or wet firewood or garbage. From time to time, carry out preventive inspections of the chimney, because most often the stove smoke occurs due to its clogging. However, other problems can also lead to this. If you correctly determine the cause, you can quickly correct the situation yourself or with the help of a specialist.

Rotary damper device for a sauna stove chimney

An important role in regulating the draft force is played by the damper device, which is a special horizontal plate, which, due to its position, increases or decreases the cross-section of the chimney. There is a small hole in this plate that does not allow the damper to completely seal the chimney. This is necessary to comply with fire safety regulations. Often, a horizontal damper is installed in brick stoves, but can also be installed in steel chimneys. The rotary damper for the chimney is a plate that is attached along the axis. Its adjustment is made by turning it. The only drawback is that the welding burns out at the rotary gate, and this unpleasant phenomenon has been observed very often lately.

Both types of damper have certain differences: the damper on the chimney, i.e., a horizontal damper, allows you to adjust the flow area, and the throttle only shows whether the chimney is open or closed. As a last resort, you can fix it using a chain.

In order to choose the right damper for the chimney, you need to decide on the type of stove and take into account some other features. The damper is installed on all types of stoves, except for some new models, where the combustion process is already regulated by controlling the supply of supply air, for which a deflector is used. In a gas stove, it is recommended to use a rotary damper, which can completely eliminate the risk of completely closing the chimney, and the flame will not accidentally jump out through the ash pan. If a damper is still used, then it is necessary to ensure that there is always a gap of at least 30-40% of the cross-sectional area of the chimney. You should not install rotary dampers for a sauna stove with intermittent operation, because the damper always allows steam to pass through when closed when supplied. But there is an opinion that when the rotary gate is in the open position, the pipe located below is quite difficult to clean subsequently.