Insulation is a structural element or material that reduces the transfer of heat to the environment. Insulation of steel pipes is the main method of increasing the service life of pipelines, and also helps to reduce heat transfer from plumbing and heating systems.

It is worth noting the fact that pipes with insulation are able to maintain their performance characteristics longer.

This is especially important for external systems that are most exposed to environmental factors. As for the thermal insulation of rolled steel pipes, it makes it possible to keep them from freezing, protects them from ruptures, and thereby avoids emergency problems. It turns out that purchasing protection in advance is much more economical than dealing with emergency repairs in the winter.

All protection materials are produced in strict accordance with regulatory requirements and are allowed for installation in the following networks:

- gas and oil;

- various engineering communications;

- with high humidity in the soil;

- with low temperatures and frequent changes.

Insulated steel pipe materials are used in the following areas:

- Water supply. Insulation of such hot systems is done not only for reasons of economy, but also for the purpose of safe use.

- Heating system. Thermal insulation of such networks protects against breakthrough. It can occur due to a large difference between internal and external temperatures.

- Chimneys. When insulating a chimney, you need to use non-toxic and heat-resistant materials. Because the temperature in front of the firebox is approximately -25 degrees or more, and near the firebox itself it rises to more than 55 degrees.

The cost of insulating materials depends on its type. The price for them starts at a threshold of 160 rubles for pipes with a volume of 5.7 cm.

Calculation procedure

Without performing calculations, it is impossible to select the optimal material or determine the appropriate thickness. Without this, it is impossible to determine what density the thermal insulation of equipment and pipelines will have. Among the factors influencing the final result of the calculations:

- conduction of heat.

- Ability to protect against deformation.

- Impacts of mechanical type.

- What is the temperature on the insulated surfaces.

- Vibration on equipment and the possibility of its occurrence.

- Temperature indicator in the environment.

- Permissible load limit.

One cannot do without taking into account the load that occurs when equipment or pipelines interact with the surrounding soil and vehicles that pass along the surface. Special formulas are used for any heat transfer systems, which can be stationary or non-stationary.

We present a series of formulas for independently calculating the thickness of thermal insulation.

The calculation for thermal insulation is artificially adapted to all operating conditions characteristic of a particular pipeline or equipment. The conditions themselves are formed with the participation of:

- Building materials to prepare for the changing seasons.

- Humidity, which accelerates heat transfer.

Professional companies provide performers with engineering data for future construction. Which specific requirements have the greatest impact on the selection of suitable insulation coatings?

- Thermal conductivity.

- Soundproofing.

- Ability to absorb or repel water.

- Vapor permeability level.

- Non-flammability.

- Density.

- Compressibility.

Tape protection

Reinforced insulation of steel pipes according to GOST refers to 9.602-89. This polymer tape-based protection effectively copes with its function on the outer surface.

This insulation is applied by winding the tape using the overlapping method. This is done after priming with a bitumen-polymer layer.

There is a whole list of requirements for such external insulation:

- Highly reliable and permanent adhesion to steel pipes.

- High level of mechanical characteristics.

- UV resistance.

- Great indicator of dielectric capabilities.

- Resistant to cathodic disbondment.

Enhanced protection based on these tapes has the following advantages:

- manufacturability;

- high security.

Video: thermal insulation of pipelines

Thermal insulation of pipes

The thickness of the coating in this case is at least 0.18 cm for a pipe with a volume of 5.7 to 53 cm.

It is of high quality and helps prevent external corrosion formations and the possibility of mechanical damage. It also allows the use of steel pipelines in places of high humidity and in a wide range of temperatures.

This reinforced coating has become the most common type of insulation. Nowadays, adhesive tapes made of polyethylene are often used, which can create a long-term level of protection for steel pipes.

Pipes with such a shell are widely used when laying utility lines (water supply systems, storm drains). Such materials can also be found in oil pipelines.

Thermal insulation of pipelines and its essence

By using thermal insulation, manufacturers make it easier for themselves to carry out certain technological processes. This solution is widely used in many industries:

- Metallurgical.

- Food.

- Oil refining.

- Chemical.

But insulation receives more attention from energy representatives. In this case, the thermal insulation objects have the form:

- Smoke pipes.

- Heat exchange devices.

- Accumulator tanks where hot water is stored.

- Turbines with gas and steam.

Thermal insulation of pipelines is used on devices that are located in both vertical and horizontal planes. This is a current solution for thermal insulation of equipment, such as tanks in which water is stored along with coolants. A number of stringent requirements are imposed on the effectiveness of insulating coatings.

Requirements for thermal insulation materials

An ideal heat-insulating layer should have a set of the following characteristics:

- low thermal conductivity coefficient is the main requirement based on the purpose of the material;

- heat resistance - a sufficient degree of resistance to temperature influences while maintaining the main characteristics;

- low flammability - the insulator should not support fire and, moreover, be a means of its spread if a fire occurs in the room;

- dielectric properties - if the grounding device of an electric heating boiler fails, the thermal insulation shell of the pipeline should not become a conductor of electric current;

- acceptable specific gravity - the thermal insulation shell should not create significant additional loads on the pipeline supports;

- lack of hygroscopicity - the material should not absorb and accumulate water from the environment;

- waterproof - the insulating coating must protect the pipeline from corrosion;

- vapor permeability - in case of abnormal wetness, the insulator must dry quickly and restore its thermal insulation properties.

In practice, the materials used to insulate heating pipes outdoors and indoors meet all these requirements to varying degrees, and therefore have both advantages and disadvantages.

When choosing a heat insulator, it is necessary to take into account the conditions of its upcoming operation in order to purchase a shell with the most required properties.

Why can't you save on insulation?

The main communications, constructed independently, are often assembled from pipes with a high thermal conductivity coefficient. Such materials give off heat quite easily, readily accepting the temperature of the external environment. This operation corrects this behavior of the pipes. Pipeline insulation technology requires detailed consideration, since this stage cannot be skipped. Otherwise, the owners will subsequently face very unpleasant facts.

- DHW pipelines. An uninsulated system will cause a serious drop in water temperature. The consequence will be inconvenience in using the networks and high costs arising from the need for additional water heating. In addition, the lower temperature will turn the liquid into an ideal environment for the growth of bacteria in autonomous systems, where the water is not protected from microorganisms by “improvers”.

- Cold water supply systems. Heating cool water in summer is the first thing thermal insulation protects against. The appearance of condensation threatens metal pipelines, which become damaged due to contact with liquid, which means that a leak may occur in the system at any time. Freezing water often causes burst pipes.

- Gravity sewerage. In this case, insulation is usually not required. However, there is an exception: these are systems laid shallowly, with a slight slope. If the sewer system is long or has many turns, the risk only increases. Such pipelines are always at risk of traffic jams and blockages.

- Heat generators in the boiler room. If you neglect the insulation of the device piping, you may encounter significant heat losses. In addition, there is always a risk of burns for owners.

Thus, thermal insulation solves two main problems: it prevents emergency situations and makes it possible to reduce the cost of energy used to heat the coolant. Therefore, no one will dispute the need for this operation. Pipe protection is an integral undertaking. It allows you not only to increase the efficiency of systems, but also to avoid unplanned expenses for repairs that will require time and effort. In addition to the two main tasks, there is also a function that thermal insulation can perform. Sometimes it is organized to reduce the noise of the system.

Glass wool, mineral wool

Insulating materials proven by practice. Meet the requirements of SP 61.13330.2012, SNiP 41-03-2003 and fire safety standards for any installation method. They are fibers with a diameter of 3-15 microns, close to crystals in structure.

Glass wool is made from waste from glass production, mineral wool from silicon-containing slag and silicate waste from metallurgy. The differences in their properties are insignificant. Available in the form of rolls, stitched mats, plates and pressed cylinders.

Installation

The pipe is wrapped or lined with cotton wool, ensuring uniform filling density over the entire surface. Then the insulation, without too much pressure, is fixed using a knitting wire. The material is hygroscopic and easily gets wet, so insulation of external pipelines made of mineral or glass wool requires the installation of a vapor barrier layer made of a material with low vapor permeability: roofing felt or polyethylene film.

A covering layer is placed on top of it to prevent the penetration of precipitation - a casing made of roofing tin, galvanized iron or sheet aluminum.

Materials for insulation of chimney pipes

It is advisable to start a project for insulating chimney pipes at the time of construction of a house or cottage, but thermal insulation work can be carried out at any stage, even if the dwelling has already been built. Next, we will consider the main methods, methods and materials that are suitable for carrying out this procedure.

How can you insulate a chimney duct?

The integrity of the chimney pipe is affected by two main factors that must be taken into account during insulation work:

- Dew point. This point concerns the release of condensate, the negative impact of which was discussed above. The fact is that in the absence of proper thermal insulation, the dew point moves inside the pipe. That is, the warm air that rises during the heating of the room rises up from the direct heating source, reaches a certain point inside the chimney, and settles there in the form of condensate drops. This is especially dangerous for metal and brick products, since excess moisture is absorbed by the material and destroys it from the inside, freezing and turning into ice;

- aggressive negative impact of gases released from combustion. During the heating process, harmful chemical compounds inevitably appear, which destroy the entire home heating system. This especially applies to weak acidic solutions of nitrogen or sulfur. With prolonged exposure, they can destroy a chimney made of almost all materials.

To protect yourself from such harmful factors, you can choose one of the following insulation materials:

- non-flammable insulation for chimneys made of slag wool;

- glass wool;

- basalt wool.

The most popular and widely used are thermal insulators made of basalt wool.

Non-flammable thermal insulation materials made from slag wool

This version of fire-resistant insulation for chimney lining is available in two forms: in rolls and mats. It also varies in density and size, depending on the individual characteristics of the pipe, the purpose of the lining and other design factors, which are taken into account separately in each specific case.

Their main feature: preservation of structure and properties even with strong heating up to +400 o C. They are fire-resistant and non-flammable, therefore they reduce the risk of fire to a minimum.

Metallurgical slags are used as raw materials for production.

The disadvantages of this material include:

- presence of residual acidity;

- the possibility of a hostile environment occurring when moisture gets on the material.

Despite these negative aspects, this fire-resistant chimney insulation is widely used in repair and insulation work, as it maintains an ideal price-quality ratio.

Glass wool insulation materials

Glass wool is an insulating material with a fibrous structure. It is produced from broken glass or raw materials used during glass melting.

Depending on the manufacturing method, glass wool is divided into:

- thin, which is obtained by spunbonding (pulling) from glass melt;

- rough through the blowing method.

Glass wool is sold in the form of rolls or slabs.

Insulation for pipes made of basalt wool

Basalt rocks are used as raw materials for the production of insulation.

- The method of using inorganic elements provides complete resistance to rotting and fungi.

- Basalt wool for chimneys has high strength and heat resistance, so it is preferred to be used as non-combustible thermal insulation to prevent fire inside the chimney.

- The insulator fits well and adapts to the insulation surface. Has a long service life. After installation, it serves without loss of its characteristics for 30-40 years.

- Based on strength, basalt wool is divided into: soft, semi-rigid and hard.

Basalt wool has an additional useful property in the form of protection against moisture, therefore it is a more universal method of thermal insulation in comparison with glass wool or slag fiber.

Is it necessary to insulate pipes in the basement of a house?

Is it necessary to insulate polypropylene pipes in the basement? If you did not insulate the strip foundation during construction. then it is simply necessary to protect communications from heat loss. If a country house is rarely used in winter, then communications may freeze, regardless of what material is used for the water supply pipe - metal-plastic, HDPE pipe or galvanized steel.

When a cold water pipe enters a warm room, condensation will always form on it. If the pipe is insulated, you will protect the room from possible dampness. Heating pipes in the basement also need thermal insulation so as not to waste excess heat in this room, but to redirect it as much as possible to the living quarters, reducing your heating costs.

PPM pipe insulation

Foam-polymer-mineral insulation is another method of insulating metal structures, which is used in the construction of hot water supply systems. The material is obtained by mixing foamed polymer and mineral filler (sand, ash, etc.). Has good strength.

The laying of pipelines in PPM insulation is carried out in accordance with GOST. The insulation is characterized by excellent maintainability. If necessary, it is opened and changed in the field.

Characteristics of foam-polymer-mineral pipe insulation

PPM consists of three layers:

- outer cortical;

- thermal insulation;

- internal anti-corrosion.

The weight and thickness of the coating depend on the diameter of the pipeline, the requirements of regulatory documentation, and operating conditions.

Production of PPM insulation

A monolithic shell made of foam-polymer-mineral material is applied to rolled metal in the factory. The production of cement-based PPM insulation pipes increases the anti-corrosion properties of the coating. Involves the use of special equipment. The product to be coated is placed in a cylinder into which the finished mineral composition is fed. The product is ready after the composition has hardened.

The rules for long-term storage of pipes in PPM insulation require the use of a flat area cleared of stones and other debris. Products are stored in stacks strictly according to their diameter.

During installation, the following components are used to insulate PPM joints: ISOLAN 345PB, polyisocyanate, quartz molding sand.

Types of insulation materials

Thermal insulation of heating pipes is carried out after purchasing the material, but before this moment it is necessary to learn about the characteristics and advantages of the insulation, as well as its scope. After this data, you will be able to select the most suitable and effective option.

Polyurethane foam

This insulation consists of ribs and walls that form a solid solid structure. It creates a heat-insulating shell that has a high level of strength, while quite effectively retaining heat inside the heating network. Polyurethane foam has the following positive qualities:

- odorless and non-toxic;

- does not rot;

- it is environmentally harmless to the human body;

- has excellent dielectric properties;

- the material is resistant to various types of climatic influences, favorably suitable for outdoor use;

- sufficiently strong insulation, eliminating the possibility of pipeline breakdowns under the influence of mechanical loads from the outside.

Its only noticeable drawback is its high cost.

Minvata

Possessing a significant level of efficiency, it is quite popular among heat insulators. It consists of mineral wool and has a number of its own features:

- cotton wool has low moisture absorption due to treatment with special compounds during the manufacturing process;

- high degree of thermal stability, which, when heated, ensures the preservation of thermal insulation and mechanical parameters at the primary level;

- is environmentally friendly and does not contain toxic substances;

- it is not afraid of exposure to acids, solvents and other chemical solutions.

Mineral wool is excellent for use as a heat insulator for heating pipes. It is quite often installed on pipelines that are subject to continuous heating of great force.

Foamed polyethylene

Does not harm the human body. It is not afraid of significant temperature changes and is resistant to moisture. The insulation is quite popular among buyers. It has the shape of a tube with a specific thickness in which an incision is made. It is used as a heat-insulating material for heating network pipes, and also for insulating warm and cold water pipes.

It retains its properties when used together with other building materials, including concrete, lime and others.

Penofol

This insulation for heating pipes has appeared on the market quite recently, being a reflective heat insulator, which consists of aluminum foil and cellular polyethylene. Thanks to 2 layers, the material has excellent thermal performance, which is why it is quite in demand among buyers. Folgoizol has a number of features:

- fairly easy installation that does not require special protective equipment;

- it is environmentally friendly and does not emit toxic substances;

- has a long service life;

- has a wide range of uses, suitable for both indoor and outdoor use.

Penofol is distributed in rolls with varying levels of density of the polyethylene layer. When choosing thickness, you should take into account the future conditions of use of the heat insulator. The double layer helps retain heat in a closed space, achieving the maximum permissible efficiency.

Polyurethane foam (PPU) coating

Steel pipe in polyurethane foam insulation is used for laying heating networks in a ductless and above-ground way. PPU insulation is manufactured using the latest technologies and high quality materials.

Polyurethane foam (PPU) is created by pairs of environmentally friendly components. These are Voratec CD 100 and Izolan-345. A distinctive characteristic of this product is its high (97%) thermal insulation properties.

Compared to mineral wool, which is used very often, polyurethane foam loses less heat. At normal humidity, the thermal conductivity coefficient of polyurethane foam is much lower than that of mineral wool.

If we consider the advantages of PPU, they are:

- The temperature at which it can be used is from 85 to 135 degrees.

- Long period of use (up to thirty years).

- Thermal insulation properties up to 97 – 98%.

- Reducing the cost of installing heating mains.

- Reduced costs for repair work of the water supply network.

- Possibility of use in different climatic conditions.

- Ease of identifying the emergency area.

And the most important advantage is that polyurethane foam does not have a harmful effect on the environment. This also reduces leakage of the working medium, because additional anti-corrosion protection increases.

The wall thickness of steel pipes and the height of the surface coating made of polyurethane foam at companies selling these products are adjusted in accordance with the wishes of customers.

Video: pipe insulation, comparison of types

Thermal insulation of pipes: comparison of types

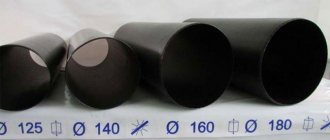

The length of steel options in thermal insulation corresponds to the specifics of the manufacturer and has an indirect connection with volume. Steel pipes that are installed in heating networks with a volume of up to 10.8 cm and a length of 10 meters. Products with volumes from 13.3 to 72 cm have a non-standard length, from 114 to 118 cm.

Today, options using polyurethane foam insulation are recognized as the most modern and effective type of solution in the field of reducing energy costs and protecting pipe materials from the aggressive influence of the environment.

Steel pipes in polyurethane foam insulation are used for the construction of various heating mains.

Manufacturing standards are determined by GOST 30732-2006. Let's consider their technical features:

- The density index is not less than 60.

- Compressive strength of at least 0.3.

- Water absorption during one and a half hour boiling is no more than 10.

- At a temperature of +50 degrees, heat conductivity is no more than 0.033.

These options are suitable for the following coolant parameters:

- Working pressure within 1.5 MPa.

- The temperature of the coolant is not higher than 140 degrees.

The main advantages of products with polyurethane foam:

- Long time of use, more than 30 years.

- Reducing heat loss.

- Ability to work at high temperatures.

- Reducing waste on the use of heating networks by 10 times.

Thermal calculation of the heating network

For thermal calculation we will take the following data:

· water temperature in the supply pipeline is 85 ° C;

· water temperature in the return pipeline is 65 °C;

· average air temperature during the heating period of the Republic of Moldova +0.6 °C;

Let's calculate the losses of uninsulated pipelines. An approximate determination of heat losses per 1 m of an uninsulated pipeline, depending on the temperature difference between the pipeline wall and the surrounding air, can be made using a nomogram. The heat loss value determined from the nomogram is multiplied by correction factors:

where: a

— correction factor taking into account the temperature difference,

a

= 0.91;

b

— radiation correction, for

d

=45 mm and

d

=76 mm

b

=1.07, and for

d

=133 mm

b

=1.08;

l

— pipeline length, m.

Heat losses of 1 m of uninsulated pipeline, determined according to the nomogram:

for d

=133 mm

Q nom

=500 W/m;

for d

=76 mm

Q nom

=350 W/m;

for d

=45 mm

Q nom

=250 W/m.

Considering that there will be heat losses on both the supply and return pipelines, the heat losses must be multiplied by 2:

kW

For heat loss from suspension supports, etc. 10% is added to the heat loss of the uninsulated pipeline itself.

kW

Standard values of average annual heat losses for a heating network when laid above ground are determined by the following formulas:

where: , - standard average annual heat losses, respectively, of the supply and return pipelines of the above-ground installation sections, W;

, - standard values of specific heat losses of two-pipe water heating networks, respectively, of the supply and return pipelines for each pipe diameter for above-ground installation, W/m, determined by ;

l

— length of a section of a heating network characterized by the same diameter of pipelines and type of installation, m;

— local heat loss coefficient, taking into account the heat losses of fittings, supports and compensators. The value of the coefficient in accordance with is taken for above-ground installation as 1.25.

The calculation of heat loss of insulated water pipelines is summarized in Table 3.4.

Table 3.4 - Calculation of heat loss of insulated water pipelines

| dн, mm | , W/m | , W/m | l, m | ,W | ,W |

| 133 | 59 | 49 | 92 | 6,79 | 5,64 |

| 76 | 41 | 32 | 326 | 16,71 | 13,04 |

| 49 | 32 | 23 | 101 | 4,04 | 2,9 |

The average annual heat loss of the isolated heating network will be 49.12 kW/an.

To evaluate the effectiveness of an insulating structure, an indicator called the insulation efficiency coefficient is often used:

where Q g

, Q and

are the heat losses of uninsulated and insulated pipes, W.

Insulation efficiency factor:

Insulation of a chimney pipe with basalt wool

The technology and mechanism for installing the casing is influenced by many factors, including the material from which the pipe is made, its diameter and others.

Basic rules for high-quality thermal insulation

Compliance with the following standards is mandatory when lining a chimney with a heat insulator:

- for a wooden covering, the layer of wool should be no less than 50mm and no more than 100mm;

- in passages through wood this layer should reach at least 5 cm;

- if mats of material are laid in several layers, then their joints must be covered with upper layers;

- for heat insulators in a cylindrical release form, when they are applied in several layers, each subsequent one must be laid with an offset of 180 o;

- for boilers with liquid fuel or gas heating technology, it is advisable to use high-temperature cladding materials with a range of up to 300 o;

- a protective screen is a mandatory insulation measure if materials without a foil layer were used during the work.

Insulation of a ceramic or asbestos chimney

For asbestos chimneys, the outer cladding procedure is carried out, and the layers of material are secured with special staples. To simplify and speed up the work, you can use basalt cylinders, the thickness of which should not exceed 5 cm.

Important! You will also need to additionally install an external steel casing (the best option is stainless steel or galvanized materials), and insulate the upper end of the chimney with a cement mortar.

Methods for insulating a steel chimney

The mechanism for carrying out the procedure is almost completely similar to the method for a ceramic chimney, and looks like this:

- 2 pipes of different diameters are used: a large one for the external surface, and a smaller one for interior decoration.

- One pipe is inserted into another.

- The resulting gap between the products is filled with the selected non-combustible insulation to insulate the chimney.

- If the material has a foil layer, it is not necessary to install a protective casing.

- The structure at the end must be additionally insulated.

The instructions themselves are quite simple, but they can be simplified by using ready-made sandwich pipes that replace the first 3 points of the manual. Such ready-made consumables for insulation have high heat resistance and help achieve high insulation characteristics.

Brick pipe insulation technology

Insulating a brick pipe is not an easy task.

To carry out the procedure, 2 methods are used:

- plastering;

- lining with mineral wool.

To plaster a pipe you need:

- a special reinforced mesh is installed on its outer surface;

- the first layer is applied directly to it in a small amount;

- after drying, make a thicker mixture and lay it on a mesh in several layers;

- To achieve an aesthetic appearance, after the substance has dried, it is rubbed, leveled, whitened or painted over.

For the second method - sheathing - use basalt wool in rolls or mats:

- the required amount of material is cut depending on the size of the insulated surface.

- the resulting layers of material are attached to the chimney using thick tape.

- A protective casing made of brick or slabs (optional) is mounted on top of the wool.

- The surface can be plastered or painted to achieve the desired external characteristics.

Basalt wool is the best option for insulating chimneys. It can be used for any premises: residential and industrial. It also has the necessary characteristics for these purposes - it is fireproof, resistant to moisture and vibration, and easily tolerates high and low temperatures.

Thermal insulation of pipelines of various types is one of the priority areas of modern energy saving. Through the use of high-quality materials with unique characteristics and the best technologies, it is possible to significantly reduce heat loss, as well as protect the pipes themselves and, accordingly, the transported substances from the negative effects of significant temperature changes.

The structure of the substance that is part of the insulation

How to insulate pipes in the basement with your own hands

You should think in advance about how and with what to insulate pipes in the basement of a private house, how to insulate a columnar foundation, and what thermal insulation material to use for various materials. Requirements for the materials used should take into account the ease of installation of insulation, long service life, water-repellent characteristics, environmental and fire safety of the material.

You should not have any difficulties in your work; anyone can handle this issue. No special skills or special tools are required to insulate pipes in the basement. Read the video instructions at the end of the article on this topic, and you will understand the stages of sewer insulation. The main thing is to be careful when performing all repair work.

Spray polyurethane foam

Convenient form of release - a two-component mixture is sprayed from a special device through a nozzle. It is used on any inclined surface or in hard-to-reach places in warehouses, attics and other auxiliary rooms. The use of foam materials such as sprayed polyurethane foam when laying underground communications is not advisable. The porous material is compacted under soil pressure, therefore losing its properties and becoming ineffective

Installation: Thermal insulation by spraying in the form of snow foam can be performed not only on the surface of pipes, but also on any freezing surface. Dense white foam forms excellent adhesion to metal (steel) pipes.

Advice! You can do this work yourself (if you have basic skills) or entrust it to a specialized company. In the absence of experience, there will be a large consumption of foam and an uneven layer during application. It is advisable to practice on a few square meters of area before fully thermally insulating the pipeline.

Types of insulation

Let's consider the most popular and frequently used materials for thermal insulation:

- Fiberglass. Glass fiber materials are often used for above-ground piping because they have a long service life. Fiberglass has a low application temperature and is characterized by low density. High-quality fiberglass has high vibration, chemical and biological resistance.

- Mineral wool. Insulation of pipelines with mineral wool is a very effective heat insulator. This insulating material is used in different conditions. Unlike fiberglass, which has a low application temperature (up to 180ºC), mineral wool can withstand temperatures up to 650ºC. At the same time, its heat-insulating and mechanical properties are preserved. Mineral wool does not lose its shape and is highly resistant to chemicals and acid. This material is non-toxic and has a low degree of moisture absorption.

In turn, mineral wool comes in two forms: stone and glass.

- Polyurethane foam has a wide range of applications, but is a fairly expensive material. According to SNiP standards, thermal insulation of pipelines is environmentally friendly and does not affect human health. Polyurethane foam is resistant to external factors, non-toxic and quite durable.

- Expanded polystyrene. In some areas of industry, foam plastic is an indispensable material, as it has low thermal conductivity and moisture absorption and a long service life. Expanded polystyrene is difficult to ignite and is an excellent sound insulator.

- In addition to the above materials, pipeline insulation can be carried out using other less well-known, but no less practical insulation materials, such as foam glass and penoizol. These materials are durable, safe and are close relatives of polystyrene foam.

Thermal insulating paint can also provide protection against corrosion and high thermal insulation of pipes.

Stages of thermal insulation of heating pipes

Mineral wool

Processes for insulating a heating pipeline with mineral wool must be carried out while wearing gloves.

- First of all, the material is cut according to the required dimensions.

- It is wound onto the pipe without the need to tighten it too much.

- At intervals you should stop, fixing it with electrical tape, wire or a solid rope.

- Having finished covering the pipeline with mineral wool, it is necessary to prepare a protective sheathing, which is made of roofing felt or corrugated foil, which is pre-cut into pieces.

- Having installed a shell of foil or roofing felt, it is secured using plastic ties or ropes.

Polyurethane foam shell

For small diameters, you can use a cylindrical or semi-cylindrical shell shape.

- Thermal insulation material is placed on the pipeline.

- It is fixed using glue, tape, wire or self-adhesive tape.

If the pipes have a large diameter, then it is necessary to select a shell, which consists of several parts. This type of material is fixed using the tongue-and-groove principle.

By making high-quality insulation of heating networks, it will be possible to retain a significant amount of heat indoors. Therefore, the choice of insulation should be approached responsibly, having weighed all the advantages of thermal insulation building materials available on the market before making a purchase.