Home / Articles

How to organize an autonomous water supply system in a country house so that it works accurately and reliably?

First of all, it is important to follow the rules and regulations. Let's start with SNiP 2.04.01-85 “Rate of water consumption by consumers,” which regulates the average water consumption per person ranging from 80 to 230 liters per day. To ensure the supply of such a quantity, pumping equipment is forced to work intensively, which causes premature wear of parts and regular repairs.

However, there are methods that reduce the number of switches on/off of devices. In this article we will look at the intricacies of proper water supply to a country house.

Where to begin?

The arrangement of water supply in an automatic or semi-automatic mode begins with planning and project development and ends with periodic maintenance. At the first stage, it is important to analyze:

- What is the source of water supply (well, well)?

- What plumbing fixtures are planned to be installed in the house (number of toilets, sinks, bathtubs, showers, swimming pools)?

- What problems should the water supply system solve (dependence on electricity, minimum water supply, ensuring stable pressure on all floors, etc.)?

- Where is the equipment planned to be installed (in the technical room or outside the house)?

To ensure uninterrupted operation, it is important to use storage tanks that are needed to store water. A reserve supply is important in emergency situations, such as when the power goes out temporarily. This is the second advantage of installing storage tanks.

Installation of external water supply network

Installing an autonomous water supply for a private house with your own hands begins with digging a trench from a well or borehole to entering it into the building. Ideally, the depth of the pipeline should be 30 cm below the soil freezing line. The trench is dug 100 mm deeper than this mark in order to create a sand cushion.

When digging and laying pipes, it is necessary to maintain a slope of the water main towards the well of 3-5 mm per 1 m of length (what is a heating cable for a water supply system). It serves to empty the pipeline.

If it is laid above the standard depth, then insulation is performed with half-cylinders of polystyrene foam or expanded polystyrene with a thickness of 40-60 mm (how to insulate water supply pipes in a private house). You should not use mineral wool in the ground; it will become saturated with moisture and cease to perform its functions.

Methods for supplying water to the tank

Start selecting the necessary equipment by answering the question: where will the storage tank be located?

There are 2 options: location at the top or bottom.

Let's take a closer look.

Tank at the top. Mounted on the 2nd, 3rd floor of the house or in the attic. Then the water flows by gravity through pipes to water sources.

This option is cost-effective, since there are no costs for purchasing a pumping station and subsequent payment for electricity.

However, it is important to meet 2 conditions when organizing space for the container:

1) the room must remain at a positive temperature, 2) ventilation is required.

And also in such a scheme, the amount of pressure directly depends on the height at which the container is located. Every meter the tank rises increases the pressure by 0.1 atmosphere. For a private house with a height of up to 10 m, it is enough to provide a pressure of 1 atmosphere. However, if you plan to install a washing machine or dishwasher, the minimum required pressure increases to 2 atmospheres. Therefore, you think over the necessary equipment in advance, and also follow the standards of SP 31.13330.2010 and the passports of household appliances.

The container is placed below , in the ground, when there is no available space in the house. The tank is buried in such a way that a layer of earth about 0.5 m thick remains on top. To prevent the effects of frost heaving, the soil located next to the tank is insulated.

This system has its own drawback: to supply water to the house, you will need to install a pumping station.

When choosing a container, pay attention to the material .

Plastic structures are not limited in terms of installation method, volume, or operating temperature. Environmentally friendly and light weight. See what such a product looks like in a video review from a Europlast specialist.

When installing stainless steel products, it is necessary to use lifting equipment, since such elements are heavy.

There is a third way to arrange a tank outside the house - concrete containers. However, we do not recommend it, since the water resistance of such structures decreases over the years and requires additional measures to restore the waterproofing. Professional cleaning of the inner surface of the tank is also necessary.

The volume of the container is selected depending on the thickness of the aquifer from which the water comes, as well as the needs of the subsidiary farm.

We examined the installation of non-pressure tanks. Now let's talk about hydropneumatic tanks , which consist of two chambers separated by a membrane and serve to create the required pressure in the water supply system.

When choosing such a hydraulic accumulator, it is important to correctly select the volume, which is affected by the permissible interval between pump starts. For example, with submersible pumps the time between starts is longer, so the tanks are selected to be more spacious compared to surface water intake devices.

Hydraulic accumulators are located underground in caissons, basements, utility rooms and technical rooms.

If you are not yet familiar with caisson installations, then a small digression is for you. A caisson is a waterproof chamber in which the necessary equipment is installed. You can go down into it to check, repair or service the unit. Caissons are also used to isolate the well head from external groundwater.

Watch a video review of the installation of the caisson on site.

Design of polymer storage tanks

Plastic tanks for storing water resources come in various volumes (up to 10,000 liters) and shapes. They can be square, cylindrical, vertical and horizontal, flat, angular.

Tanks are produced in two designs. The first is ordinary containers with smooth walls and a sealed lid equipped with a breathing valve. Any storage tank requires access to air, otherwise it will be flattened by atmospheric pressure when emptied. Conventional tanks are designed for storing water resources, extracting them with an electric pump or using a self-installed tap.

The second option is special tanks for use in individual water supply systems. They have four holes in the body on one side - two at the top and two at the bottom. One top and one bottom hole are equipped with a 1-inch male thread. These bends are used to connect the inlet and outlet pipelines of the water main to them.

There is also a hole with a diameter of 28 mm at the top. It is usually used to organize emergency drainage by connecting a pipeline directed to the street or to the sewer.

It is worth noting that any installer can use the top threaded pipe and hole at his discretion. For example, in a 28 mm cutout you can install a float valve that turns off the water supply when the tank is filled, and a 1-inch threaded pipe can be used for emergency draining.

The 3/4 inch pipe at the bottom is used to empty the tank. The need for this arises when dirt accumulates at the bottom of the container in the form of sand and clay deposits, products of decomposition of metal oxides.

There is a different design for storage tanks for underground installation than the traditional one. Since the soil pressure on the tank walls is quite high, they are equipped with stiffeners. In addition, they have a high neck, which allows them to be immersed underground to a depth below the freezing point.

Rice. 4 Storage tank for water supply - examples of use in the home

Connecting pipes from the caisson and tank to the house

Now let's move on to other elements of the autonomous water supply system. In addition to the pump or pumping station, storage or control tank, you will need:

- filters for water purification;

- pipes for internal and external installation;

- devices that ensure automatic operation of the system.

Filters

The selection of necessary filters depends on the quality of the water in your source. In some situations, water treatment stations are installed. However, to protect against mechanical impurities, filtration installations are necessary for all systems.

If the water is not very polluted, then we recommend installing a mesh filter due to the low cost of the product and its sufficient efficiency.

Water source requirements

If there is already a ready-made well on the site, you can try to establish a water supply system in a country house from it. But it should be borne in mind that such a source of water has certain requirements that must be observed.

When choosing a container for autonomous water supply, you should take into account the number of people living in the house

So, what should the well be like:

- Airtight and not prone to shedding;

- Equipped with a bottom cleaning filter (if it does not exist, it is advisable to do so by pouring a 15-centimeter layer of quartz sand onto the bottom of the structure, and river pebbles on top of it);

- Does not contain membranes or bitumen mastics on its surface (it is better to use fiberglass or polymer additives instead);

- With clean water (the presence of small crumbs of bricks or concrete will make it difficult for the pump to work, and then may even cause it to break);

- Insulated (in this case the ground part of the structure is insulated);

- The materials used to insulate the joints of the structure should not in any way affect the taste or smell of well water.

Before installing the system, the structure should be thoroughly cleaned and the water should be disinfected. Ideally, you need to check for compliance with accepted sanitary standards.

Centrifugal and cyclonic filtration systems are used for contaminated waters.

Pipes

The service life of the entire system depends on the quality of the pipeline and its connection. In practice, 4 types of pipes are used to lay the main line. Let's take a closer look at each variety.

- Copper

Such pipes can easily withstand multiple pressure drops in the system and are resistant to corrosion and ultraviolet radiation. The only drawback is the price.

2. Steel

Durable, affordable, but susceptible to rust. And also the connection of such pipes is labor-intensive: the joint is either welded with subsequent protection of the weld, or a thread is cut at the end of each element.

3. Metal-plastic

The basis of such pipes is aluminum, coated on the inside and outside with a layer of polyethylene. They do not rust, do not form condensation, are not destroyed by ultraviolet radiation, and do not accumulate dirt and mineral deposits. However, they are deformed at low temperatures and heating above 95 degrees.

4. Plastic

Plastic pipes for water supply are the most popular due to their properties and easy installation. Let's consider 2 main materials: polypropylene (PP) and low-density polyethylene (HDPE).

Polypropylene pipes are light, durable, resistant to temperature changes, and are not susceptible to rust or other external influences. However, they do not bend, so connecting elements must be used to turn the line and drain the pipe.

HDPE pipes and fittings for water supply have the same advantages as polypropylene pipes, in addition they are also elastic - they can withstand external dynamic influences and water hammer. Service life is at least 50 years.

HDPE water pipes for cold water supply can be used when organizing automatic watering of a suburban area, equipping wells, and arranging fountains. You can select the required pipe yourself using the table.

For drinking water supply, choose products with a blue stripe.

Circuits and equipment for hot water supply

It would be a mistake to assume that heating and autonomous water supply of a house with hot water are the same thing. Of course, you can install a single-circuit system, but this is inconvenient. In the summer, when heating is not needed and will be turned off, there will be no hot water either. But even in warm weather, in addition to a summer shower, a hot water system is needed. Therefore, the organization of hot water supply is carried out using special equipment.

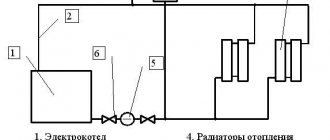

Electric boiler

This is a tank with heating elements. Its volume is calculated based on the needs of the family and the number of residents. The operating principle is as follows:

- The tank is filling.

- The heating elements heat it up to the set temperature.

- When used up, the supply is automatically replenished from the cold water system.

- As soon as the temperature drops, the heating turns on.

Modern models have 2 heating elements. One of them is the main one, and is responsible for maintaining the temperature regime. The second is auxiliary, which turns on when you need to quickly heat the entire volume.

Indirect heating boiler

Instead of heating elements, a tubular heat exchanger is used, through which a coolant heated by a heating boiler circulates. The advantage is cost effectiveness. There are no energy costs. The downside is that hot water is only available in winter when the heating is on. In warm regions this method is unlikely to be suitable, but in places where cold weather is normal all year round, this is an excellent method of providing hot water.

Gas water heater, double-circuit boiler

The main difference is that the column is a flow-type heater. Heating is performed by burning gas. Heat passes through a chamber with a heat exchanger. This system is suitable for a dacha, apartment, cottage. An alternative is a double-circuit boiler. This is a single installation operating in two modes: heating, hot water.

About other important devices

If water is taken from its own source, then the tank must be equipped with a float mechanism that will turn off the liquid supply when the required volume is reached. In the event of a failure of the float valve, it is important to install an overflow pipe that will insure the system against overflow.

We recommend filling the tank through a diffuser. This precaution is necessary to prevent sediment from rising from the bottom of the container if for some reason the filters do not cope with their work and impurities enter the reservoir. And also don’t forget about installing other components.

Any system is equipped with a pressure gauge and a safety valve.

Main nuances and mistakes

When installing it yourself, mistakes can be made already at the design stage. Without special knowledge, it is difficult to correctly calculate all parameters and select electrical equipment. Installation of a pipeline from source to home also has a number of features that need to be taken into account.

If the route is shallow (above the soil freezing level), it needs to be insulated. A waterproof film and a protective shell are laid on top of the insulation. In places where pipes are turned, inspection wells are installed. This is in case the water supply becomes clogged and you have to clean it mechanically.

It is necessary to select the correct pipe diameter and material. Combination is allowed, but in this case you need to buy adapters. Plastic pipes cannot be used to transmit hot water. Joints and connections become depressurized. Iron ones need to be looked after (painted). Metal-plastic does not require maintenance.

Water collection for technical needs

Have you ever thought that rainwater can be collected for technical needs using storage tanks and plastic pipes for water supply already known to you?

To do this, it is enough to install the tank above or below the ground and connect plastic pipes to it for water supply from the drains. An alternative to pipes is drainage trays. However, it is important to ensure that excess water is drained from the container.

Choose a tank material that is safe, durable, lightweight and does not require special care. Plastic tanks have these properties, take a closer look. When choosing polyethylene pipes for water supply, you avoid fakes. Thus, Europlast offers only high-quality and proven products that meet the requirements of GOST 18599-2001.

In the article, we gave general recommendations for organizing water supply at home using a container. For detailed information, as well as selection of the necessary equipment, please contact us. We will help in any situation.

Launching a water supply system for a private home

A prerequisite for the system to operate before the first start of the pump, in cases where the reservoir is completely empty, is the presence of water in the turbine chamber and suction line. If this requirement is not met, the liquid will not flow to the disassembly point, and the pump elements will overheat and fail.

Procedure for filling the suction line.

Step 1

A plug is unscrewed from the upper part of the turbine housing, and a watering can is inserted in its place (photo 7).

Step 2

A dry cloth is placed under the body to catch liquid during the filling process.

Step 3

Water from a plastic bottle, in small portions, is fed into the suction line until it flows out from under the watering can.

Step 4

The watering can is removed and a plug is installed.

After the above activities, the station is ready for launch.

The suction can be filled in a reverse way, that is, if there is water in the main pipeline, to avoid water hammer on the blades, smoothly open valve 23 or 24 and do not close it until the readings appear on pressure gauge 6.