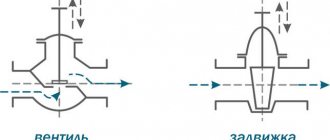

A control valve is a fragment of pipeline shut-off and control valves that serves to control the flow and pressure of gas or liquid in a pipeline. It is actively used in everyday life and other areas. There are several types of devices that differ in design elements, type of fixation, and type of locking.

Areas of use and design features

Control valves are used in domestic or industrial gas and water supply systems. They are also installed on main transport pipelines carrying oil and gas. The flow is adjusted by changing the diameter of the passage hole. In this case, the system capacity increases or decreases.

The simplest is the straight-through valve. It contains the following parts:

- a tee body, inside of which there is a passage hole;

- flanges on the pipes (threads may be present in this place);

- seals ensuring the tightness of the device;

- gate;

- rod (a fragment with the help of which the position of the shutter changes).

The cost of the product depends on the material of manufacture, type, size and technical characteristics. The price ranges from 1000−99000 rubles.

Operating principle and advantages

The rod transmits the force coming from the actuator to the plunger. It lowers and changes the cross-section of the throughput hole. As a result, the volume of liquid or gas passing inside the pipe increases or decreases. The speed of movement of the working medium, as well as the pressure inside the system, changes.

A manual shut-off valve can completely close the bypass hole. In this case, the pressure indicator drops to zero. But this is only possible if the contacting units are completely sealed.

The control valve is used on all pipelines without exception. It has the following advantages:

- Durability and reliability. The body of the device can be made of cast iron, stainless steel or metal alloys. All of them are treated with special substances that prevent the negative effects of aggressive components.

- Simplicity of design. The product fully performs its function, and does not contain complex components.

- Possibility of reducing coolant consumption.

- Wide variety of types and designs.

- Reasonable price.

- Significant adjustable range.

The valve has increased tightness.

Differences

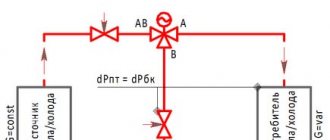

In saddle devices, the locking element is made in the form of a rod, disc or needle plunger. In small cross-section pipes, single-seat fittings are installed; in networks with a diameter of up to 300 mm and a pressure of up to 6.5 MPa, double-seated fittings are installed, which have better tightness and a more balanced plunger.

A feature of cage-type structures is their shutter, made in the form of a cylindrical piston located in the cage. This design reduces noise and vibration when the valve is turned on.

The difference between membrane fittings is the limitations in control methods: their devices are equipped only with pneumatic or hydraulic actuators. The membrane serves as a shutter in them.

In spool valves, the flow level is regulated by turning the valve, that is, the spool, as a result of which the flow hole is partially opened or closed. The mechanism of operation of this fitting is in many ways similar to the operation of an ordinary ball valve.

Device classification

Regulators can be classified according to several parameters:

| Characteristic | Types |

| In the direction of flow |

|

| By control method |

|

| By mounting method |

|

What type of valve will be used depends on the scope of its application and the required design features.

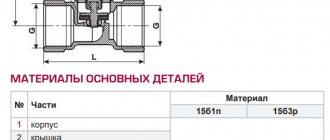

Compression fittings

Compression fittings are used to connect polyethylene pipes in water supply and irrigation systems. They allow you to quickly and reliably install pipes without the use of welding equipment. Compression fittings are most often used for installing small diameter pipes.

Compression fittings have many advantages : they are easy to install, provide a reliable and durable connection, are resistant to corrosion and are airtight.

Fittings consist of:

- housings;

- clamping ring;

- o-ring;

- bushings;

- cover nuts.

The Santekhkomplekt catalog presents a wide range of compression fittings for the installation of HDPE pipes, in particular bends, plugs, tees, flanges, couplings, etc.

Valve types

The valve is the main fragment of the product, with the help of which the cross-section of the passage opening is changed. There are the following types of valves: saddle, spool, cage, membrane.

Saddle and cage

The design of such a device contains a seat and a plunger. The last element is a cylindrical piston, the length of which significantly exceeds the diameter. The seat is a valve component that is located between the passage hole and the internal components of the product.

As soon as the piston begins to move through the seat, the diameter of the bore changes. There are single and double seat valves. The first type of fittings is used in small diameter pipelines.

The cellular product has a seat in which there are radial holes. With their help, the flow of the working medium is regulated. Inside the cell there is a cylinder that moves. It changes the capacity of the hole. The advantage of the product is that it reduces cavitation, vibration and noise .

Diaphragm and spool

The diaphragm valve also has a seat, but a flexible membrane is used to close the hole. It performs several functions. The first of them is monitoring and adjusting the pressure of a liquid (gaseous substance). The second function is to protect the internal components of shut-off valves from the effects of aggressive chemical components.

The advantage of the device is the high reliability and tightness of the moving elements. The membrane is also made from materials that are resistant to corrosion. To ensure that the quality of the valve does not deteriorate over time, the design will have to be additionally equipped with positioners, with the help of which the position of the rod is controlled. These elements will prevent the accuracy of the adjustment.

The last type of valve is a spool valve. Adjusting the flow of liquid or gas in this case depends on the angle at which the valve is turned. Most often, devices of this type are used in the energy sector. According to the principle of operation, a spool valve can be classified as a faucet.

Example of control valve markings

The marking of manufactured control valves is carried out in accordance with GOST R 52720-2007 and tables of figures, which provide data on designations by type of valve and its design nuances. In addition, the regulatory documentation specifies the material used for the production of the housing and sealing elements.

Example decoding for 25s947nzh:

- the first two digits indicate the type of fittings: 25 - control valve;

- the letter indicates the material of the case: c - made of carbon steel;

- if there are three digits, the first indicates the type of drive, and the next two indicate the model number: 947 - model 47 with electric drive;

- the last letters indicate the material of the seals: nzh - the sealing surfaces of the valve are overlaid with corrosion-resistant steel.

Control valve 25s947nzh

If the fittings for regulating the pressure and flow of the medium are manufactured without directional or insertable sealing rings, then on its body or valve this is reflected in the form of two letters - “bk”. If there is a coating on the internal surfaces of the valves, it is indicated according to the last table of figures.

is the main supplier of valves for regulating pressure and other parameters of the working environment in Russia. We offer control valves that are reasonably priced and comply with GOST requirements.

Stary Oskol:

- Telephone: +7

,

46-94-70- Email,

- Address: Boiler, Promuzel, Montazhnaya site, Sh-6 passage, building 19

- Opening hours: From Mon. to Fri: from 8:00 to 17:00, Friday - reduced day by 1 hour.

Moscow:

- Telephone: +7 (495) 229-45-77

,

648-91-91- Opening hours: From Mon. to Fri: from 9:00 to 18:00, Friday - reduced day by 1 hour.

Features of product selection

In order for the valve to work effectively, it must be correctly selected and installed. To make the right purchase, you need to consider the following parameters:

- Diameter of pipe and through hole. This takes into account the type of medium with which the pipeline will work and its size. The larger the diameter of the orifice, the wider the range it can operate. But when choosing large indicators, the pressure inside the system is taken into account.

- Locking type. The valve can be a control valve or a shut-off valve. In the second case, the pipe lumen may be completely blocked.

- Range of application.

- Material of manufacture. Here the choice depends on the conditions of use of the device.

- Type of fixation on the pipe.

- Product control method. For automatic valves to operate, they must be connected to an electrical outlet.

- Type of adjustment mechanism.

The size of the housing and the diameter of the pipes must match the size of the pipeline.

A control valve is an essential element of shut-off valves. It allows you to reduce the consumption of liquid coolant or gaseous substance. In the event of a pipeline failure, the shut-off element will allow only a certain part of the system to be stopped for repairs.

Communication modules

Modern homes use high-tech water supply, heating and sewerage systems. There are special control devices connected to the building’s life support systems, which are capable of regulating the operation of these systems, bringing them into compliance with preset parameters.

a communication module becomes an indispensable element , which makes it possible to communicate between an external device and the electronic controllers of the system. By connecting to control devices via the RS232 interface, the communication module provides access to information about the operation of the system or its individual elements.