The main causes of air jams

The appearance of bubbles in water supply lines is associated with an internal physico-chemical reaction or penetration from the outside. In the first case, gas escapes from the water flow itself, because approximately 30 grams of air are dissolved in 1000 liters of water. The release of a gaseous substance occurs faster if the liquid flows slowly and if it is heated. It is for this reason that voids and cavities occur much more often in hot water pipes. In the second case, air from the external environment leaks into the main networks.

The main reasons for the appearance of air from outside in the water supply system of a private home:

- when the liquid level decreases, air can be sucked in through the non-return valve;

- the fitting elements with rubber sealing parts are poorly covered, depressurization occurs at the joints;

- the air in the water supply lines was not removed from the first start-up of the system.

In vertically directed pipes, air rises upward or is absorbed throughout the cavity. In horizontal ones, it accumulates in the highest places, which is unfavorable for the entire system.

The destruction of air bubbles occurs at a flow speed of a quarter of a meter per second. If it is smaller, the traffic jams may remain in one place for a long time.

Maybe the Venturi effect is at work?

The Venturi effect is a rather interesting effect, which lies in the fact that water moving at high speed and under certain conditions may not pour out through a hole, but suck air into this hole. This effect is used in self-priming pumps. It also works in so-called ejectors, and not so long ago I came across its use in a gas water heater. It turns out that it is precisely due to this effect that the gas turns on when the water is turned on. There are models of water aerators that also use the described effect. There is Venturi in washing machines in the drain system. The spray gun also exploits the Venturi effect. A car carburetor is similar.

But this effect can also be detrimental. For example, if you want to remove air from a surface water pump, you cannot remove it by unscrewing the inlet line while the pump is on. The air will not leave the pump, but will be drawn into it even more.

For the Venturi effect to work, there must be some narrowing of the fluid flow and a very high speed of its movement. This is clearly not the case with heating. In addition, you can turn off the circulation pump and the fluid flow will stop, but the pressure will remain. At the same time, water should come out into the hole, if there is one. This was not observed on my system.

Danger of air bubbles in the pipeline

Bubbles, especially large ones, can destroy even strong elements of the highway. The main troubles they cause to owners of private houses:

- They accumulate in the same areas, leading to breakdowns of pipe sections and adapters. They also pose a risk for turning and twisting pipe sections where air is trapped.

- They break the water flow, which is inconvenient for the user. The taps “spit out” water all the time and vibrate.

- Causes water hammer.

Water hammer leads to the formation of longitudinal cracks, which causes the pipes to gradually collapse. As time passes, the pipe breaks at the point of cracking and the system stops functioning. Therefore, it is important to equip additional elements that allow you to quickly get rid of dangerous bubbles.

How to get rid of air in a water supply

If air bubbles are interfering with the operation of the pipeline, but the bleeder elements have not yet been installed, turn off the pumping station that pumps water from the well.

Then open all the drain taps and drain the water along with the bubbles from the network. After this, connect the pressure equipment and let the water flow. Bleeding and draining devices will help you get rid of air locks in the water supply of a private house forever:

- mechanical valves, such as Mayevsky's device;

- ball valves and valves;

- automatic air vents.

You have to bleed air using shut-off valves manually, which is quite labor-intensive. Therefore, it is better to choose alternative options.

Mechanical valve

The device is not complicated, but the device is able to quickly and effectively rid the line of bubbles. The operating principle of a mechanical valve is as follows:

- A hollow cylinder with a lid, in which a threaded plug is mounted, is connected to the water supply with a threaded connection.

- A plastic float ball is suspended inside the cylindrical box. When there is only water in the pipeline, the float rises to the plug hole and, thanks to the pressure of the water flow, tightly blocks it.

- As soon as air leaks into the device, the ball goes down and releases the air plug.

Devices capable of removing air are installed in the highest, turning and curved places of the highway - where there is a high risk of air accumulations.

Automatic air vent

There are three types of automatic machines for removing air from water supply networks:

- float valves;

- starting devices;

- combined type devices.

When choosing a diverter, they look at the volume of potential plugs, operating pressure in the network and water quality indicators. These data can be found in the technical manual of the device. You should not take a machine with maximum power. When working at a minimum, it is more likely to wear out.

Homemade air accumulator

Automatic devices do not always cope with air removal in country houses. Usually there are a lot of air bubbles in such lines, and water gushes out of the valve device.

Instead of an automatic air vent, a storage tank is installed, which is a tank with a tube and a tap.

You can build the device yourself. For effective operation, the cross-section of the air accumulator must be five times larger than that of the pipeline. The storage tank is installed at the highest point of the aquifer.

When installing water supply networks in a country cottage, it is important to provide for the installation of air elimination devices. They protect the operating system from water hammer and rapid destruction.

Mayevsky crane

Design of the Mayevsky crane

It is designed to eliminate air lock in the heating battery. Despite its small size, the Mayevsky faucet helps to effectively remove accumulated steam not only in radiators, but also in pipes.

Structurally, it is a needle valve enclosed in a metal housing. How to remove an air lock from a heating system using it? First you need to decide on the device model.

Manual taps

After installation in the upper radiator pipe, air is released after turning the union nut on the tap. Removing an air lock from the heating system using a Mayevsky manual tap is carried out according to the following scheme:

- Filling the system with coolant. The taps on the radiators are closed;

- When the maximum level is reached, the water supply stops;

- Having set the required gap of the needle limiter in the devices, the taps are opened;

- At the same time, the coolant supply is restored.

Water is added to the system until liquid begins to flow from all Mayevsky taps. Be sure to check that there is no air flow. This method is effective for removing air locks in heating radiators when starting the system for the first time, before the season, or when airiness appears during operation.

Manual models will effectively eliminate air lock in the radiator for both autonomous and central heating. The main thing is to choose the right mounting thread. In most cases it is 1/2", but there are models with a non-standard size of 3/4".

Automatic taps

Mayevsky automatic crane

Unlike the model described above, in their design, a seat with a certain surface area is installed on the end of the needle valve. In combination with a return spring, the degree of pressure of which determines the critical pressure value at which the valve opens. A detailed device is designed to automatically break through a heating plug when a critical temperature value and, as a result, pressure is exceeded.

However, before installation you should familiarize yourself with the specifics of this model:

- To prevent water from getting onto the floor, the structure must have a pipe to drain excess water into the sewer;

- If it sits for a long time, the valve seat may become covered with limescale, which will make it difficult to open. Therefore, it is recommended to open the tap manually once every 2-3 months. The steps of the procedure must be done before starting the heating for the first time;

- The set maximum opening pressure should not exceed the critical pressure of the entire system. In order to remove an air lock from the heating in automatic mode, the pressure value on the tap should be 5-10% less than the maximum.

What is better to install: an automatic or manual Mayevsky crane? If the operation of the system does not involve sudden pressure surges, manual models can be installed on the radiators. For autonomous heating, preference is given to automatic ones.

It is best to choose models made of brass. During the expulsion of an air lock from the heating, they can withstand not only a critical pressure value, but also a temperature. The steel body is subject to destruction and rusting.

What is water hammer

Water hammer ( hydraulic hammer ) is a short-term, but sharp and strong increase (decrease) in pressure in a pipeline (in a water supply system) due to sudden braking (acceleration) of the fluid flow moving through it.

Water hammer in the water supply system

In simple words, water hammer is a sharp increase in pressure in pipes

Water hammer occurs:

- Positive - when the pressure in the pipeline increases very sharply. This can happen when a tap (valve, valve) is quickly closed or a pump is turned on.

- Negative - when, on the contrary, there is a decrease in pressure in the water supply due to the fact that the tap was opened or the circulation pump was turned off.

The greatest danger to the water supply system is positive water hammer. Let's say you turned on the tap and washed the dishes. Finished washing, you don’t need water, turn off the tap.

In this case, the following happens in the water supply. The water flow for some time, by inertia, flows at the same speed. Then he encounters an obstacle (the tap was closed). And “hitting” against this barrier, a reverse wave is formed. And since the entire water supply system is sealed. This backward wave collides with the water flow coming towards it. The result is water hammer.

The very first signs of water hammer are dull knocks and clicks heard when opening or closing a tap. The appearance of leaks at the junction of water pipes or leaking taps.

Causes of water hammer

The main reasons for the occurrence of water hammer in the water supply system are:

- Abrupt closure of shut-off valves (taps, valves, gate valves.

- Breakdown or shutdown of the circulation pump or pumping station.

- Air locks in the water supply system.

- Variations in the cross-section of water pipes.

Basically, water hammer occurs when the shut-off valves are suddenly closed. Water passes through pipes with constant pressure, but when the water flow suddenly stops. The water pressure on the pipe walls increases several times.

As a result, pipes may burst or seals of threaded connections and locking elements may become unusable.

Crack in a pipe after a water hammer

Of course, a sharply closed tap is not the only cause of water hammer. A similar situation occurs when air remains in the system. The moment the tap opens, the water encounters a plug of air.

And this air plug in a confined space acts as a shock absorber. As a result, the water is pushed out with enormous force and an impact occurs.

Also, the appearance of water hammer can be caused by pipes of different diameters. Pressure drops, if the pipes are not reduced to a common denominator, are guaranteed

Consequences of water hammer

Pressure above the permissible limit is critical for pipes and their connections. Shut-off valves can also fail.

The first water hammer usually does not cause damage to the water supply system. After all, water supply products are manufactured with reserves in case of increased pressure. But subsequent water hammers will hit the same weak spot. And at some point the pipe or shut-off valve will fail.

Fixing the problem

You can solve the air lock problem yourself. The main thing is to identify the reason for its formation.

- First, it is worth inspecting the pipeline along its entire length for cracks or depressurization (provided that the sewerage system has a water seal). If any are found, it is worth replacing the collector section with a whole one. In this case, the air will freely flow into the drain pipe during a volley discharge of water into the system. That is, the water seal cover will close when the pressure in the pipeline increases and thereby prevent stagnation of water.

- If an air lock is observed in the area of a specific plumbing fixture, then perhaps the slope of the pipes towards the riser was not observed during installation. To do this, you need to reposition the pipeline section to create the required slope or, if possible, raise the plumbing fixture to create the optimal level of slope for the drains.

- If the sewerage system basically does not have a drain pipe, then it will have to be installed with the installation of water seals near each plumbing fixture.

And always remember that if you are not confident in your abilities and think that you are prone to make mistakes when installing sewerage in your home, it is better to use the services of professionals. The craftsmen will create a reliable drainage system with a properly functioning drain pipe,

Most often, clogged sewer systems occur in old houses, and the reasons for this phenomenon can be completely different.

For example, due to the owner’s negligence, a rag or some hard object may get stuck in the system. Over time, the diameter of the pipe narrows as fat deposits form on its walls. Therefore, a minor blockage can cause a big problem.

Depending on the nature of the problem, there are several solutions that can be used to effectively clean the sewer with your own hands without calling a professional

Therefore, a minor blockage can cause a big problem. Depending on the nature of the problem, there are several solutions that can be used to effectively clean the sewer with your own hands without calling a professional.

How to avoid water hammer in a water supply

There are several ways to prevent water hammer in an apartment and private house.

- increase the diameter of the water pipe to reduce the flow rate of water

- smooth shut-off of the water flow. pipes

How to avoid water hammer

Smooth shut-off of the water supply system

The elasticity of pipes also plays an important role, as they can deform under pressure. But it is worth noting that these measures only prolong the process, reducing its power and, accordingly, the impact on the water supply system..

All starts and stops of the pipeline must be carried out smoothly. In order to ensure a uniform change in pressure in the pipes.

Old-style valves and taps are much safer in terms of water hammer. In order to shut off the water, you will need to make several turns. Accordingly, the pressure will drop more slowly. It won’t be possible to close it abruptly even with the greatest desire,

Recently, ball valves are often used in apartments. To shut off the flow of water, just turn the tap once. Not everyone knows that the overlap must be done smoothly.

In this case, hydraulic shock will still occur. But it will break into several blows, insignificant in strength. Therefore not so dangerous.

Types of sewer clogs

If the sewer system in a house is operated in violation of all the rules for its use, then over time, blockages and plugs inevitably appear in the collector, which impede or completely stop the flow of wastewater. As a result, either someone from an apartment building or the owners of a private building will suffer from at least an unpleasant odor in the living space. The maximum possible flooding of the kitchen or bathroom with fecal water. This is not very pleasant, so to avoid such situations you need to use the collector correctly, namely:

- It is strictly forbidden to flush used personal hygiene items, such as pads, diapers, tampons, etc., down the toilet. Only flushing toilet paper is allowed.

- It is prohibited to flush bulk construction mixtures such as cement, sand, chalk, clay, etc. down the drain.

- Accidental flushing of rags and other similar items down the drain should be avoided.

- It is advisable to install grease traps in the kitchen, which will prevent the deposition of heavy greasy deposits on the walls of the collector. This, in turn, can create fecal growths-stalactites in the system and impede the flow of gray water.

It is always worth remembering that a traffic jam can form either in a specific place in the sewer system in an apartment or in a private house, or at any point in the central riser. If the last option is checked, then the drains will have nowhere to go but to return back from the blockage under the influence of hydraulic force. As a result, fecal or gray water will try to escape through the unoccupied openings of the bathtub, sink, and other plumbing fixtures.

Protection against water hammer in the water supply system

Proper protection against water hammer should be aimed at reducing its intensity. And competently neutralize the effects of high blood pressure.

The water supply system of an apartment and a private house must be protected from improper operation and untimely maintenance. There are a number of technical solutions that can minimize the consequences of fluid pressure drops in the water supply and prevent their occurrence.

Using expansion joints

Compensators are cylinder-shaped containers with a spring inside. One side of the spring rests against the top of the cylinder, and the other against a plastic movable disk.

Water hammer compensator

When the pressure in the system increases, the water compresses the spring and puts pressure on the disk. If the pressure decreases, the spring, due to its elasticity, makes up for the loss of pressure.

Membrane compensators and hydraulic accumulators are also used to protect against water hammer.

Why and how to choose a hydraulic accumulator for water supply systems

The capacity of the compensator is separated by an elastic membrane. One part is filled with air, the other is empty. The air is pumped under the required pressure. Basically the pressure is 3 bar.

If necessary, the pressure can be changed to the desired one by connecting the pump. Typically 20-30% higher than a worker in a water supply system.

In the event that excess pressure arises in the pipes, it will be released into the tank due to stretching of the elastic membrane and a decrease in the volume of air inside the tank.

Shock-absorbing devices

Inserts made of reinforced plastic or heat-resistant rubber can be used as a shock absorber.

These inserts are capable of both stretching and contracting during sudden pressure changes, which will reduce the impact on water supply pipes.

If a hydraulic shock occurs, this section will stretch and the impact force will be partially absorbed. Recommended length is from 20 to 40 centimeters. Inserted in front of the water hammer source.

Safety thermostat

A thermostat is also used to protect against water hammer. This device has a spring mechanism located between the valve and the thermal head.

When the pressure increases, the spring is activated and prevents the valve from closing completely. As soon as the pressure decreases, the valve begins to close smoothly.

Important! The thermostat is always installed only in the direction indicated by the arrow on the body.

Possibility of bypass

If you have a good understanding of how a thermostat works, you can install a shunt with a clearance of 0.2-0.4 mm or make a hole of the same diameter.

The main task of this element is to gradually reduce the pressure if overload occurs. It is installed in the direction of the water flow.

Safety valve

These devices work very simply. If the pressure at the installation sites of the safety valves is higher than the permissible parameters. The valve opens and pressure is quickly released. When the pressure drops to normal, the valve closes slowly.

Also protects the pump or pumping station in cases of unexpected shutdown, such as a power outage. Install it after the check valve, at the outlet from the pipeline, next to the pump.

Water hammer in a water supply system is a common occurrence. And if you do not conduct regular preventive inspections of the system and do not take the necessary actions. Water hammer can cause serious damage.

How to eliminate water hammer

To prevent water hammer from occurring in heating pipes and water supply systems, several methods are used.

Smoothly close the tap

If the valve moves slowly, then it is permissible to move it in small jerks.

The impact occurs, but is broken into several weak ones. Which has no consequences.

Depreciation

Mechanical shut-off can be done safely, but systems equipped with automation (heating) do not have this.

To soften the impact, a shock absorption device is installed in the line. A piece of elastic pipeline (reinforced plastic or rubber resistant to high temperatures) is installed in front of the thermostat.

Due to stretching, during a pressure surge, the pipe temporarily increases and relieves pressure.

0.2-0.3 m is a sufficient length of shock absorption.

Bypass surgery

This is a manual modification of the thermal valve.

A tube with a diameter of 0.2-0.4 mm is inserted into the valve in the direction of travel. It does not affect the performance of the system, but if there is a pressure surge it can transfer it over the valve into the pipeline.

For your information

The method is productive only in a new system and not made of metal. The presence of corrosion is all gone.

Compensators

The lower part contains liquid, the upper part contains air under pressure. A similar system is installed on automatic pumps to regulate pressure.

In a heating system, the compressor is installed at a weak point where shock is possible. When there is a pressure surge, the water presses on the membrane and displaces it towards the air, as a result the pressure is extinguished.

When the pressure returns to normal, the water hammer stops and the membrane returns to its original place.

Special dampers are also used in the water main.

Safety valves

In the old days, the patient's blood pressure was lowered by bloodletting. The operation of the safety valve is similar.

Installation takes place in potentially hazardous locations. They work autonomously or from a controller.

When the pressure increases, the valve releases water; of course, the liquid is discharged in permissible places.

After the pressure returns to normal, the tap closes.

Automatic adjustment

Turning pumping equipment off and on is an “excellent” provocateur of water hammer.

The pump creates pressure, which is directly related to the rotation speed. Acceleration occurs at lightning speed. Forced slowing down of the process of increasing speed in the pump stops the occurrence of water hammer.

It will not be possible to regulate the speed; it is possible to change the frequency, which will give the required result.

This function is performed by the UUE (electric motor control device), frequency converters and soft starters. Water hammers disappear when installing the UUE.

Pursuing this goal, a pressure sensor is connected to the converter; it will change the pump rotation speed depending on the specified indicators. As a bonus, energy savings occur.

Why is there air in the water from the well and what to do

Let's find out the causes of a common problem when water from a well comes with air when the pump is running and how to eliminate this cavitation.

Water is needed at the dacha, in the garden or in the garden throughout the warm period, but not everywhere there is a main water supply. Therefore, to obtain water, a well is sometimes drilled, but there are certain problems in its operation.

The problem of cavitation in well water

- What is cavitation

- How to eliminate cavitation

- Other causes of air bubbles in water

For example, when a certain amount of air appears in the water from a well, as a result of which the pump’s operation is disrupted, and therefore the water supply is interrupted, the pressure drops and other difficulties arise. All this reduces the quality of the supplied water, shortens the life of the pump and all hoses.

What is cavitation

The appearance of varying numbers of air bubbles in the water flow (interruption of water flow) is called cavitation. This happens with a strong decrease in pressure, which can occur for various reasons. In this case, the number and volume of bubbles can increase and combine, resulting in rather large volumes of air that are located in the water flow.

The destruction of such air voids and bubbles occurs only under the influence of very high pressure. During this process, which occurs very quickly, a kind of hissing appears. It always accompanies cavitation.

Typically, the process of bubble formation (cavitation) occurs in wells more than 8 meters deep under the influence of high pressure and long pipes. At this depth, the water begins to turn into a gaseous state, and the water flow is filled with air.

Most often, this process appears in water sources that have a telescopic structure. This means that the well consists of several pipe sections (from 2 to 4-5), each subsequent one is smaller than the previous one. Remember a children's folding telescope (they have the same structure).

As soon as air bubbles and voids begin to appear in the water flow, you need to begin to act, since as a result of cavitation, vibration and water hammer can occur, which in turn leads to a decrease in water pressure, a decrease in pump performance, destruction of parts, their corrosion, and breakdown pumping stations (or simply pumps).

Determining where the formation of air bubbles occurs is quite difficult without special equipment. But let’s try to name the main reasons why this process occurs, as well as the requirements that must be met so that cavitation does not appear.

Ways to solve the problem

In order to prevent the heating system from becoming airy, it should be properly designed and installed, periodically cleaned and filled with coolant without undue haste. Let's consider the main ways to help avoid such negative manifestations.

Correct installation

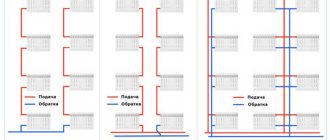

In heating systems in which the coolant circulates naturally, with the upper type of wiring, air is removed through the cover of the expansion tank. When installing such a system, the supply line is installed so that it approaches the tank vertically.

The tank, which provides free space for the expansion of the heated coolant, must be installed at the top point of the entire system to ensure the natural flow of liquid into the system circuit.

The return line is also installed with a slope along which the liquid moves freely.

Correct installation will help prevent air from entering the heating system.

If the installation of the heating system is carried out without errors, then the air appearing inside the circuit will be gradually squeezed out by the hot liquid to the top point, leaving the pipes through the open cover of the expansion tank.

Installation of air vents

How to promptly remove air accumulated in the heating system?

An open expansion tank must be installed in the upper part of the heating system, and a hermetically sealed one must be placed in the place where the return flow enters the boiler (before the pipe enters).

In such a system, supply pipes can be mounted without tilting, and the coolant will move under the influence of a circulation pump. In addition, other devices are installed through which air is discharged.

Air can be vented from the heating system itself through special air vents operating in automatic mode, installed on the rotating sections of pipes and at the highest point of the system. The plugs are removed from the radiators using a Mayevsky tap. Using the same principle, air is removed from the circuit through which water circulates naturally, but in this case, lower pipe routing must be done.

If everything is installed correctly, then there will be no problems with how to expel air from the heating system. It is enough to open the necessary taps, and as soon as the air leaves the system, close them again. Air vents operating in automatic mode do not need to be opened at all - their operating principle is based on changes in pressure.

If a closed heating system is installed, an automatic air vent must be installed in it. They are installed along the contour in certain places so that air pockets are removed locally. The idea is that each part of the heating system circuit must have the ability to vent air. An example of this is Mayevsky taps, which are installed on all radiators. Open them with a key or a screwdriver, allowing air to escape from the system. The procedure is quite simple, but with its help you can distribute the coolant evenly throughout the radiator.

An air vent can solve the problem with air in the heating system

To extend the operational life of the automatic air vent, it is necessary to install good filters and regularly flush the system.

Coolant heating

Sometimes, in order to remove excess air naturally, the coolant is simply heated strongly. An increase in temperature stimulates the release of air and its movement along the system circuit. It is allowed to heat the liquid in the pipes up to one hundred degrees.

If after such an operation air pockets appear again, it is necessary to check all connecting areas for leaks. Almost always, near the place where the air jam forms, there is a small gap from which water oozes out in small drops and into which air gradually penetrates. By sealing such a gap, you will immediately get rid of the annoying problem.

Radiators made of aluminum material are considered the most vulnerable places through which air passes. When an alloy is exposed to hot water, corrosion processes develop, accompanied by gas emissions.

If such radiators often become airy, it is recommended to simply replace them.

Air vent in a water supply system: purposes of application, installation location, alternative solutions

Automatic vent for hot water supply

Today we have to find out why we need to install an air vent in the water supply system. In addition, we will find out in which part of the water supply circuit it can be installed, what kind of air vents can be used there, and how to solve the problem of air in the water supply without an air vent. Let's get started.

Video description

For an example of protective equipment for damping water hammer in a water supply system, see the video:

Pressure surges or water hammer are a dangerous phenomenon inherently associated with the operation of plumbing or heating systems. Their number and negative impact can be minimized using preventive measures and technical solutions. In order to comprehensively solve this problem, to prevent as much as possible the risks of danger to people and material damage, it is better to turn to professionals.

About hot water supply

First, let's find out why airing of the water supply system occurs and how it interferes. Let's start from afar.

The cold water supply of an apartment building or private building always has a dead-end distribution: the bottling goes into risers, they branch into connections, and the connections end with taps of plumbing fixtures. Water moves in a dead-end circuit only due to water intake.

Dead-end DHW circuit

Until about the 70s of the last century, hot water supply systems (DHW) in all houses under construction were organized in the same way.

Dead-end hot water distribution

However, this wiring has two serious drawbacks:

- Having opened the hot water tap, the homeowner is forced to wait for several minutes for it to heat up. The wait is especially long at night and in the mornings, when in the absence of water supply the risers and hot water outlets cool down. This is not only inconvenient, but also contributes to unreasonably high water consumption;

Please note: when recording hot water consumption using a mechanical water meter, you are forced to pay for the entire volume passing through it. In fact, a significant part of this volume does not meet the requirements of current operational standards: the DHW temperature must be within the range of +50 - +75°C.

The mechanical meter in the photo records water flow through the hot water pipeline, regardless of its temperature

- Heating of bathrooms and combined bathrooms in apartment buildings is provided by a heated towel rail powered by a hot water supply system. It is clear that in the absence of water intake in the dead-end system it will cool down. For the apartment owner, this means dampness and cold in the bathroom, and in the long term, a greater likelihood of fungal damage to the walls.

The heated towel rail is mounted in the gap of the hot water supply line, and heats up only when drawing water

Circulation scheme

Since the late 70s - early 80s, hot water supply in new buildings gradually began to become circulating.

How it's implemented:

- Two hot water supply outlets are laid in the basement or subfloor of the house;

- Each bottling has an independent insertion into the elevator unit;

- The hot water supply risers are connected alternately to both dispensers and are connected by jumpers on the top floor or in the attic. From 2 to 7 risers can be combined into groups connected by circulation jumpers.

Manual and automatic air vents

How to remove air from a water supply system after it has been reset? The most logical solution is to bleed the air through an air vent installed directly on the jumper between the risers.

There you can find an air vent belonging to one of two types:

| Image | Description |

Mayevsky brass tap | Manual (Mayevsky faucet) - a plug with a screw-in valve using a key or a screwdriver. To eliminate air from the hot water supply system, just unscrew the valve a couple of turns, wait until the air coming out of the hole on the tap is replaced by water, and screw the valve back on. Sometimes you have to bleed the air two or three times as the water displaces new air bubbles into the upper part of the circuit. |

Automatic air vent device | An automatic air vent for water supply does the same without the intervention of the owner. When its chamber is filled with air, the float connected to the spool lowers - after which the water pressure displaces the air plug. The floating float hermetically closes the spool. |

The photo shows a brass water tap that can successfully replace the Mayevsky tap

The obvious advantage of the Mayevsky crane is its low cost. That is why, in Soviet-built houses, exclusively manual air vents were used.

However, from the point of view of ease of use, they are much inferior to automatic air vents:

- Some residents of the upper floors are simply afraid to use shut-off valves that are unfamiliar to them;

- Keys to Mayevsky taps with valves of complex shapes are constantly lost;

Key to Mayevsky's tap

Manifestations of excessive enthusiasm by residents, coupled with technical illiteracy, often lead to flooding of apartments. The fact is that a completely unscrewed valve (and even more so the tap itself) is almost impossible to screw in under pressure. Especially when scalding hot water is gushing out of the hole.

Enthusiasm + illiteracy = accident

Why does water from the well come with air when the pump is running?

A water well is a convenient alternative to autonomous water supply in the private sector. Having a number of advantages, the design requires not only proper installation and equipping with a filtration system, but also timely cleaning, as well as preventive maintenance and rinsing. Failure to comply with at least one point may result in disruptions to the operation of the entire station. For example, water from a well often comes with air. The life of the pump, water quality and much more depend on the timely identification of causes and their elimination.

Important Takeaways

First and foremost. There is a lot of air in the water! It actively leaves the water for about six months. But probably this should depend on the capacity of the system. I use a boiler with a decent-sized tank of about 60 liters. But I don’t think that there will be more than 100 liters of water in my system.

Water without air must be protected in every possible way and the heating must not be drained without very serious reasons. And if you drain it, then not all of it. To do this, it would be nice to have a bunch of intermediate taps that would allow water to be drained not from the entire system, but only from the areas being repaired.

If you have an open expansion tank, you urgently need to replace it with a closed one. By doing this, you will not only increase your personal comfort, but also increase the service life of your system, because water without air does not cause metal corrosion. And yes! A closed expansion tank can be placed in a gravity system. There is nothing incompatible here!

As Karl Marx said (I’m not a fan of his ideas, if anything), the criterion of truth is practice. In this case, practice has proven the truth of a very controversial cause of water in the heating system. This allows the issue to be closed.

Thank you all for your attention! Dmitry Belkin.

Source

Cavitation as a cause

Before you start clarifying the issue, it is important to know: pumps are installed depending on the diameter of the well! For sizes of 100 mm, a submersible pump is suitable; smaller diameters require a circular or plunger pump.

What is cavitation? This is a violation of the continuity of the fluid flow, otherwise it is the filling of water with bubbles. Cavitation occurs in those areas where the pressure drop reaches a critical level. The process is accompanied by the formation of voids in the flow, the release of air bubbles that appear as a result of vapors and gases released from the liquid. Being in an area of reduced pressure, bubbles can increase and collect into large empty cavities, which are carried away by the flow of liquid and, in the presence of high pressure, are destroyed without a trace, and in the conditions of an ordinary domestic well, they often remain and it turns out that the pump pumps air bubbles from the wells without producing the required volume of water.

Identifying a cavitation zone is sometimes impossible due to the lack of special instruments, but it is important to know that such a zone may be unstable. If the deficiency is not eliminated, the consequences can be devastating: vibration, dynamic effects on the flow - all this leads to breakdown of the pumps, because each device is characterized by a specified value of the cavitation reserve. Otherwise, the pump has a minimum pressure within which water entering the device retains its density properties. When pressure changes, cavities and air voids are inevitable. Therefore, the selection of a pump should be carried out depending on the volume of water needed to meet economic and domestic needs.

The destruction of air bubbles occurs only when they are transferred by a flow to an area of high pressure, which is accompanied by small hydraulic shocks. The frequency of impacts leads to the appearance of a hissing sound, by which the presence of air in the well can be determined.

Elimination of cavitation

What can be done to avoid the appearance of air in the well and the entry of water with bubbles:

- Replacing a small-diameter suction pipe with a larger one;

- Moving the pump closer to the storage tank.

Attention! When moving the pump, follow the established standards: the distance from the pump to the tank cannot be less than 5 diameters of the suction pipe!

- Reduce the pressure of the suction element by replacing it with a smooth pipe, and the valve can be replaced with a slide valve, and the check valve can be removed altogether;

- The presence of a large number of turns in the suction pipe is unacceptable; they must be reduced or the bends with a small radius of turns must be replaced with large ones. The easiest way is to orient all the bends in one plane, and sometimes it’s easier to replace rigid pipes with flexible ones.

If all else fails, you will have to increase the pressure on the suction side of the pump by raising the reservoir level, lowering the pump installation axis, or connecting a booster pump.

Note that all manipulations are shown based on a large volume of water consumption and the installation of powerful pumping devices. And, it is important that cavitation can only occur at a depth below 8 meters. It is with this length of all elements and the presence of high pressure in the pipes that the liquid turns into a gaseous state and the water comes with air.

Other reasons for the appearance of air bubbles in the well and ways to eliminate them

When using a well to pump out small volumes of water or seasonal operation of the structure, several possible causes and ways to eliminate them are possible. So, why does the pump pump not only water, but also air:

- Suction of air mass in the suction section. In this case, water and air flow for a long time, but the problem can only be “cured” by completely replacing the pipeline and all related elements. You can check by removing the pipeline from the well and pumping water, for example, in the bathroom.

- Low filling of the aquifer with large pumping. Reducing volumes or drilling a new well would be the best solution. It is only important not to break through to the old thin aquifer, so as not to get water again with air from the well.

- Pump failure when the gland seal is weak, as a result of which air bubbles end up in the discharge chamber and water flows with the air. You will have to disassemble the device yourself or it’s easier to take it to a repair shop.

Hydraulic systems are similar to electric systems - the laws are the same. Understanding the problem of why a pumping station pumps air is sometimes only possible with a series of technical measures. And if the proposed options for identifying the problem and eliminating deficiencies did not help and the water also comes with air, it is better to contact the professionals who service the pumps. The cost of the service starts from $50, but you will be freed from the problem and will be able to find out exactly why your pump does not pump water as you would like.