- Features Composition

- Technical characteristics of PE 100 pipes

- Production of PE 100

- Certificate of Conformity – what is it?

- Advantages

- By purpose

- Methods for installing HDPE pipes

The popularity of polymer materials in households, industry and everyday life is explained simply: versatility of use, a number of excellent characteristics and, most importantly, low cost. For the transportation of gas, drinking water, process water and other liquids, polyethylene pipes are most often used - non-toxic, strong and durable. Moreover, the most popular product for communication systems is the PE-100 brand. What does the abbreviation “PE-100” mean and what is its meaning?

Peculiarities

PE-100 is the grade of material from which pipes are made. The digital designation after the letters “PE” (polyethylene) indicates its density, which directly determines the strength and weight of the pipe, and therefore its scope of use. Polymer pipes marked in this way have features and technical indicators that have led to their high popularity when laying water supply lines and other communication systems.

Compound

What are PE 100 pipes in structure? These are products made from high-density polymer (HDPE - low-density polyethylene). This polyethylene is produced by polymerization at high temperatures and low pressure using catalysts. As a result, large polymer molecules with free branches are created based on ethylene, the connection between which determines the degree of density of the product. The higher the crystallinity, the greater the digital value of HDPE.

Thanks to the grouped crystal structure, that is, strong intermolecular bonds, PE-100 pipes have high technical performance in comparison with similar products with a lower density, allowing them to be used in the most severe operating conditions. In terms of their properties, these products are inferior only to steel pipes in terms of mechanical strength.

Technical characteristics of PE 100 pipes

The HDPE material PE-100 has unique technical properties that make it possible to create high-quality, reliable products. PE-100 pipes are manufactured in various sizes: diameter - from 10 to 1600 mm, wall thickness - from 2 to 60 mm. Products are sold wound into coils or in lengths of 3-12 m. Pipes of this marking have the following technical properties:

- possibility of use in a temperature range from -60 to 130⁰C;

- when transporting contents, they can withstand pressure up to 20 atmospheres;

- the shell has high resistance to cracking;

- low modulus of elasticity, reducing the risk of water hammer when transporting liquid;

- the smallest weight per linear meter of product from all types of pipes for transportation;

- low thermal conductivity, which reduces the appearance of condensation on the outside of the pipe;

- low deformation modulus, providing compressive and tensile strength (tensile strength - about 1000 hours);

- resistance to chemicals, weather and biological destroyers.

This is interesting!

The production of PE-100 pipes is more expensive than similar products with a lower density, however, due to lower material consumption (the walls of PE-100 pipes are thinner), as a result, the finished products are cheaper for the consumer.

Production of PE 100

PE 100 is produced from ethylene by polymerization by exposure to catalysts under low pressure and high temperatures. The result is a high-density polymer with strong molecular bonds, the structure of which is a rigid and durable thermoplastic. PE 100 is used for molding or blow molding of various containers for high loads used in industry and the national economy:

- pressure pipes for transporting technical liquids, water supply, gas and sewerage communications;

- mounting elements (taps, fittings) for pipelines;

- production of hoods and air ducts resistant to chemical environments;

- parts for technical units, etc.

Important!

It is a mistaken belief that the high density of the material makes it difficult to join products made from it by welding: the orderliness of the molecular structure of PE-100 simplifies this process. If you slightly increase the soldering temperature, the seam will be smoother and neater than in products made from lower density polyethylene.

Certificate of Conformity – what is it?

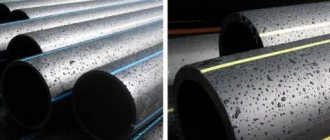

The quality of all products made from PE-100 polyethylene must be confirmed by a certificate of conformity issued by technical regulation and metrology authorities. In addition, each product indicates the GOST to which it corresponds, along with the number of the specific document. For example, for PE-100 drinking water pipes this is GOST No. 18599-2001 (plus color designation - longitudinal blue stripes along the products). The manufacturer applies the inscription GOST R 50838-2009 (starting from 2019 - GOST R 58121.2-2018) and marking with an orange or yellow stripe to gas pipes.

Important!

The absence of a color designation and GOST number indicates that the pipe does not meet the standards, which means it is made from recycled materials and can only be used for technical purposes. You can read more about GOST standards for HDPE pipes in our article “GOST standards for polyethylene (HDPE) pipes”

The difference between the polyethylene brand PE 100 and PE 80

In modern conditions, when carrying out communications and constructing pipelines, the choice falls on PE 80 and PE 100 pipes: their properties are optimal for these purposes. However, the latter type of HDPE pipes is still more in demand. How do HDPE pipes with an index of 100 compare favorably with similar products of PE 80?

Advantages

Factors that influence the choice in favor of pipes marked PE-100 are the following:

- the products have a higher density than similar PE-80, so the pipe wall thickness is smaller, but this does not reduce the ability to maintain the required pressure;

- PE-100 of the same nominal diameter as a PE-80 pipe has a throughput capacity that is 20% higher and a pressure loss that is a third lower;

- a linear meter of PE-100 pipe is 20% lighter than the same size of a PE-80 product, which simplifies transportation and installation of communications;

- the resistance to cracking of pipes made of PE-100 is several times higher;

- PE-100 material tolerates low temperatures better and is resistant to mechanical damage, so pipes made from it can be used in more severe conditions;

- PE-80 polyethylene is usually used for the production of small diameter pipes.

Are you interested in PE-100 polyethylene pipes?

Ours offers a wide selection of pipes of our own production for cold water supply of all required sizes at low prices!

Interesting? Click on this text and see what pipes we have!

Flaws

Among the disadvantages of the PE-100 brand, one can note its higher cost compared to similar material with index 80 due to better quality indicators. In addition, PE-80 pipes have better flexibility than products with an index of 100.

And one more point: PE-100 has a higher melting point. On the one hand, this expands the scope of its use, on the other hand, it complicates installation work.

About care

Polyester does not take much time to care for. Products made from polyethylene are recommended to be washed by hand, on a delicate or synthetic cycle. Use cold water or heated water no higher than 40°. Products made from polyester and natural fibers should be sorted into different bins.

Important! After washing in hot water, unsightly creases appear on the polyester. And bleach can ruin clothes.

For light-colored fabrics, universal detergents are allowed; colored ones require powders and gels for fine textiles. Adding an antistatic agent to the rinse water will prevent “sparking” and cracking when worn.

The material is afraid of intense spinning and twisting. The speed when washing in the machine should be minimal.

Shake the washed items and hang them to dry, which will not take much time. It is necessary to iron polyester infrequently, and this is done at a minimum temperature on the reverse side.

Stains from the material can be easily removed with a soap solution. You need to moisten a cloth in it and treat the stain. Rinse with clean water and dry. Greasy marks on polyester materials can be easily removed using dish gel. It is applied to the contaminated area and left for 7-10 minutes. All that remains is to rinse off the composition and wash the item in a basin of soapy water.

You can try to get rid of shine and wear on fabric by steaming. It is necessary to restore the fibers crushed by monotonous movements. The operation is carried out using an iron and ironing iron moistened in a vinegar solution.

Classification and types of pipes made of PE-100

Pipes made of PE-100 polyethylene, produced under low pressure, are classified according to their purpose and properties.

By purpose

Depending on the type of use, PE-100 pipes are divided into various categories.

- Tap water.

They are marked completely blue or black with blue longitudinal stripes. If drinking water is transported, GOST 18599-2001 imposes additional requirements for production. - Gas.

The color of communications is yellow or black with yellow/orange stripes along the pipe. Manufacturing is regulated by GOST R 50838-2009 (However, starting from 2021, the latest GOST for gas pipes is GOST R 58121.2-2018); - Sewer.

They can be manufactured immediately together with sockets, which facilitates their installation. This type of pipe is also used for collectors. - Drainage

- for draining groundwater from buildings, they have a corrugated design. - Irrigation.

Used for uniform watering of plantings. - Casing.

Using this type of HDPE pipes, water wells are installed: no soil shifts will destroy them.

PE-100 technical pipes have reduced requirements, are not marked with color, can be made from recycled materials, may contain air bubbles, foreign inclusions, and are used for transporting technical liquids.

By properties

The high density of the HDPE material, tensile strength and deformation, at the same time flexibility and ductility make it possible to manufacture pressure pipes of various loads from PE-100. The following properties stand out:

- High-pressure products. Having a wall thickness of up to 7 cm, they can be used with pressures of up to 20 atmospheres.

- Low pressure pipes. Must withstand pressure up to 6 atmospheres.

- Non-pressure communications for which there are no special load requirements - usually these are technical systems.

Marking of HDPE pipes

PE-100 pipes are necessarily marked at the final stage of production: full information about a specific product is applied to them. The pipe indicates:

- name of the manufacturing company (company logo is possible);

- manufacturing material – polyethylene (PE);

- PE density index – 100;

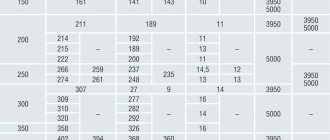

- SDR index – the ratio of the outer diameter to the pipe wall thickness, an indicator of permissible load: a pipe with a thin wall has a higher SDR;

- outer diameter of the pipe, wall thickness (in mm);

- GOST to which the product corresponds.

In addition, pipes are marked along the entire length with colored stripes that reflect the purpose of the product.

By the way, you can read more detailed information about SDR marking in another article “What is SDR in the marking of polyethylene pipes?”

Parameters affecting product quality

When selecting PE pipes for use in certain conditions, you should focus on some parameters:

- The source material from which the product is made. It is designed to operate at a certain pressure of the transported medium. PE 63, which has a microporous structure, has the unpleasant property of sucking air into the system. This leads to vibration of the product and the appearance of quite strong and unpleasant noises in the plumbing system. To avoid these effects, it is necessary to equip the pipeline structure with cut-off valves, air traps and other similar devices;

- Standard sizes and SDR ratio. The outer diameter of PE pipes varies from ten to one thousand two hundred millimeters. The wall thickness is set by the manufacturer in accordance with the SDR coefficients, which determine the permissible ratio with the outer diameter. That is, a larger diameter value does not necessarily mean greater wall thickness of the product. The higher the SDR value, the correspondingly lower the wall thickness and operating pressure to which the product can be exposed. An increase in wall thickness affects the throughput, as it occurs due to a decrease in the internal cross-section;

- Pipeline laying method. It plays a certain role if a closed gasket is used and safety boxes are not used. In this case, the indicator of the ring strength of the pipe becomes important, because it will experience not only the pressure of the working environment from the inside, but also additional soil pressure from the outside. When laying closed, it is necessary to select products with thicker walls so that they can withstand additional soil pressure, and a larger diameter in order to achieve high throughput.

PE pipes are laid in a hidden way, since ultraviolet radiation has a detrimental effect on them

Application of HDPE pipes PE 100

HDPE pipes PE-100 of various markings are used in various spheres of life - both for industrial needs and in the food industry.

- PE 100 SDR 41

- the lightest pipes that can withstand liquid pressure up to 2.5 kg*s/cm2, used for transporting cold water; - PE 100 SDR 26

– medium-light type with a permissible load of up to 4 kg*s/cm2 is used for pumping drinking, utility water, food liquids - milk, wine, juice; - PE 100 SDR 17 - products of increased strength with medium weight, withstanding pressure of 6 kg*s/cm2, used for installation of large-diameter pressure pipelines for transporting water or gas;

- PE 100 SDR 11

- the heaviest pipes, durable, super strong, with a permissible internal load of 10 kg*s/cm2, used for installation of communications with strong liquid pressure - water pipes, sewer collectors.

Methods for installing HDPE pipes

Communication networks using HDPE PE-100 pipes are created in the following ways:

- Compression-fitting, which is used for installation of low-pressure systems (sprinklers, water pipelines) using compression fittings and clamping nuts. Performed with a wrench using little force, it can be easily dismantled.

- Electric welded fitting. It is performed using a welding machine using special fittings; the connection is permanent. The most durable type of connection, used to create pressure water and gas pipeline systems.

- Bell-shaped. The main area of application of this method is non-pressure systems - for example, sewage.

Important!

To carry out socket installation of PE-100 pipes, it is necessary to have sockets on the products and sealing rings.

Advantages of PE pipes over other pipes

HDPE pipes have many advantages and are superior to communication systems made from other materials.

- They do not require cathodic protection, which means no labor-intensive maintenance.

- Under the same operating conditions, the shelf life of PE pipes is twice as long as metal pipes.

- The high stretch coefficient prevents the product from bursting when water freezes.

- The low weight of PE pipes makes transportation and installation of communications easier and cheaper.

- High resistance to chemical, aggressive environments and lack of corrosion.

- Low thermal conductivity reduces heat loss and the formation of external condensation.

- Simple repeated installation and dismantling of the system at low costs.

- The physico-chemical properties of HDPE polyethylene make it possible to use pipes for transporting any, even aggressive substances.

- PE is beneficial for installing water pipes: it does not interact with water, which means it does not give it a metallic taste.

- Repair and maintenance of polyethylene pipelines require minimal effort and investment.

Interestingly, the installation and reconstruction of PE communications is 40% cheaper than working with transport routes made of other materials.

What is the reason for choosing HDPE as a material?

The production of classic polyethylene is based on the method of polymerization of ethylene, which is classified as an organic gas. Polymerization is the process of combining ethylene molecules into special chains, occurring in a special pressure chamber at a temperature of one hundred and fifty degrees and under a pressure of twenty atmospheres. As a result, a new material is formed that has characteristics that have made polyethylene pipes widely used:

- withstands pressure of three to five MPa;

- a cubic meter of HDPE weighs only 900 kg;

- exhibits slight expansion when heated. Thermal expansion will not exceed three percent of the overall parameters even when the HDPE structure is heated to the maximum permissible temperature of seventy degrees;

- can be operated in a rather limited temperature range. If the temperature drops below zero, the HDPE begins to glaze. When the temperature reaches 40º C, the HDPE pipe loses its ring rigidity.

The considered properties inherent in HDPE outline the boundaries of the possible use of polyethylene pipes. It is usually used for installation indoors or in trenches, where it is laid below the freezing level of the soil.