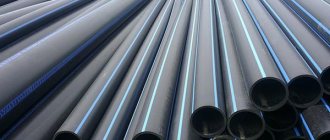

In recent years, polyethylene pipes (PE) have become widely used, especially in the construction industry.

PE pipes are used in the construction of gas pipelines and water pipelines, they are used to equip swimming pools, automate irrigation, and are widely used in other industries. Polyethylene itself is a thermoplastic material; it is obtained by polymerization of an oil refinery product. In this article we will look at the characteristics of various types of products and understand what the marking “PE SDR pipe” means. All data on the characteristics of a particular pipe are displayed in the markings

The equipment used for the production of such pipes is not bulky or particularly complex. Polyethylene pipes for gas and water pipelines are made of various diameters in accordance with GOST, and they are marked accordingly. Depending on the purpose, they differ in characteristics; each type of PE pipe has a corresponding brand.

Polyethylene grades

Grade PE 80, PE 63, PE 100 corresponds to the strength index MRS 8; 6.3 and 10, i.e., means the minimum long-term strength of the polyethylene from which these pipes are made. Pipe polyethylene of these grades is obtained from a rigid polymer with a linear structure and a high degree of crystallinity. These products have good resistance to most inorganic and organic acids, petroleum carbons, alkalis, salts, etc.

Polyethylene grades PE 100, PE 80 and PE 63 are widely used nowadays; its main distinguishing feature is density, strength and, of course, cost.

PE 32 SDR pipe is also produced, its quality is regulated by GOST 18599-2001, its scope of use is water supply (at a nominal pressure of 2.5 atm.) and sewerage.

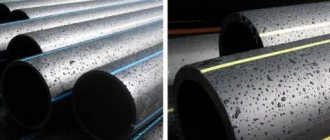

In addition, such pipes have a visual difference depending on their purpose. For example, pipes with a blue stripe are used to install a drinking water supply system, and products with a yellow stripe are used to lay a gas pipeline.

PE 100 pipe

It is characterized by high working pressure, maximum tensile strength and resistance to mechanical stress. Certified raw materials are used for its production. Qualitative characteristics made it possible to reduce the wall thickness of this product and reduce its weight. Pipes of this brand are most often used for the following purposes:

- installation of water and gas pipelines;

- installation of pipelines for supplying food products in liquid form (juices, milk, wine, beer, etc.).

PE 80 pipe

These products are wear-resistant, quite lightweight, and medium-pressure plastic is used for their manufacture. Pipes of this brand belong to low-pressure pipes, the main purpose of which is the installation of low-pressure and free-pressure sewerage systems in multi-apartment residential buildings. In addition, they can be used to install small-diameter pressure water supply in a small area.

The products are certified and can be used for their intended purpose.

PE 63 pipe

This grade of polyethylene contains mainly ethylene molecules; it is characterized by short-term strength, but at the same time it is prone to cracking and destruction. Due to these characteristics, it is less often used in civil and industrial construction for the construction of drainage systems of road communications, basements of buildings, foundations and sites.

These pipes are used in the laying of electrical cables and fiber optic lines, where they are used as a casing for utility lines. Sometimes these pipes are used in agriculture; with their help, moisture is drained from waterlogged areas and swamps.

Examples

Polyethylene pipes of the same brand with different SDRs can have significant differences. So, for the most popular brand of polyethylene PE-80 it is:

- PE 80 SDR 13.6 – very durable, can be used for the construction of long-term water supply systems;

- PE 80 SDR 17 are considered products with average performance and are recommended for installation in water supply systems of low-rise buildings, where their strength is sufficient, and their low weight and low cost will save on installation work;

- PE 80 SDR 21 are not recommended for pressure systems, burial in the ground and gas pipeline construction, as they have low compressive strength and internal pressure.

IMPORTANT! When choosing an SDR pipe, be sure to consider the grade of polyethylene from which it is made. Even for the same dimensional coefficients, a pipe of a higher grade will be stronger and more resistant to mechanical stress. For example, PE 100 SDR 17, unlike PE 80 with the same index, can be used for pressure water and gas pipelines.

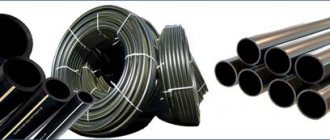

Polyethylene pipe (HDPE) and its SDR

What is SDR

One of the main indicators characterizing a PE pipe is SDR. It displays the ratio of the outer diameter of a polyethylene pipe and the thickness of its wall; it is calculated using a table or formula:

SDR = D/s, where

- D = outer diameter of PE pipe (mm);

- s = pipe wall thickness (mm).

This indicator characterizes the strength of the pipe: the higher it is, the weaker the pipe and vice versa.

Accordingly, a product with a small SDR can withstand greater pressure compared to the same product, but having a higher value. Thus, polyethylene pipes whose wall thickness is more capable of withstanding quite noticeable pressure.

The ability of polyethylene to be stable and neutral to gaseous and liquid substances determined the scope of its application. In addition to gas and water mains, PE (HDPE) pipes are used for transporting gaseous and liquid materials and other purposes.

Determining SDR

Polyethylene pipes (HDPE) with different SDR

Each type of pipe has its own characteristics, let’s consider them:

- Polyethylene grade 100:

- The PE 100 SDR 17 pipe is indispensable in gas pipelines and pressure water supply systems, especially in pipelines with a large cross-section. Its technical characteristics allow the use of such pipes for the installation of long-distance pipelines. This polyethylene pipe SDR 17 belongs to a new generation of products, which was obtained by using modern technologies used in the manufacture of PE 100. Excellent performance characteristics of pipes made from this material are achieved due to the high strength properties of polyethylene.

- Polyethylene pipe SDR 11 is made from polyethylene obtained at low pressure. Moreover, its high density makes it possible to use these products on high-pressure water pipelines. In addition, this type can be used for the installation of sewer collectors due to its resistance to aggressive environments. Laying can be done in almost any soil.

- Products made from PE 100 polyethylene, such as the PE SDR 26 pipe, can withstand pressures of up to 6.3 atm, and are used mainly in non-critical water supply systems, in gravity sewers and for protecting communications.

- PE pipe SDR 21 grade 100 - its main purpose is to install water pipes; according to experts, the water in this product does not have any foreign taste and retains its taste well.

- Polyethylene grade 80:

- A product such as the PE 80 SDR 11 pipe belongs to a new generation of products, the characteristics are much higher than those of PE 63. Its main purpose is to supply cold water; in addition, if necessary, it can be used for sewerage and gasification.

- The PE 80 SDR 13.6 pipe is used for installation and repair of water pipes and pipes for liquid chemicals, to which polyethylene is neutral.

- PE 80 SDR 17 pipes are the optimal choice for low-rise construction, as they have sufficient strength for it and at the same time an affordable cost.

- The PE 63 SDR 11 pipe is made from various types of polymers. Can be used for supply lines in water supply systems, like sewer pipes, and also as a protective case for communications and power supplies.

HDPE pipes for home heating systems

One of the most basic stages in the construction of houses and cottages is the design and installation of water supply and heating systems. After all, the comfort and convenience of living in the finished housing ultimately depend on the efficiency of the functioning of these systems.

HDPE pipes are considered the most popular material for equipping such systems today.

This type of building materials has earned similar demand due to the combination of good performance characteristics and the fact that the installation of polyethylene pipes is considered a fairly simple and understandable operation.

Characteristics of HDPE pipes

The name “HDPE pipes” stands for pipes made of low pressure polyethylene. They are made using continuous screw extrusion technologies.

Polymer ethylenes obtained in a similar way have a number of parameters that make them suitable for transporting water of different temperatures and other liquid and gaseous substances. Among these parameters, we can highlight inertness to the effects of aggressive chemical and radioactive substances, environmental friendliness, frost resistance, resistance to corrosion and the absence of prospects for “overgrowth” of the pipe lumen.

Also, the list of advantages of HDPE pipes includes a long service life (up to fifty years) and a low price. The listed characteristics make them an excellent material for equipping heating systems and organizing water supply for residential buildings.

Water or a heat carrier for heating systems can be used as a circulating fluid in a system of HDPE pipes. The optimal option for using HDPE pipes would be low-temperature heating systems that do not require heating the energy carrier to extremely high temperatures.

Such systems include surface heating systems (heated floors, walls, ceilings). In the case of using liquid energy carriers heated above 90 degrees for heating, instead of HDPE pipes, it is better to use plastic pipes that can withstand higher temperatures.

For example, reinforced propylene pipes.

Advantages of using Polyethylene PE (HDPE) pipes

The wide range of applications of these products is explained by many advantages over their analogues made of metal, such as:

- products made of polyethylene have a warranty period of about 50 years;

- they are not exposed to moisture, aggressive environments, corrosion, stray currents, and do not require cathodic protection;

- are light in weight;

- installation is simple, while maximum tightness is achieved, and there is no need for professional equipment;

- the pipes are frost-resistant and do not burst even when the water in them freezes;

- due to the ideal inner surface of the pipe, no deposits form on the walls;

- prices for the purchase and installation of pipes are reasonable.

Synonyms: HDPE pipe, PE pipe, plastic pipe, polyethylene pipe, HDPE technical pipe, HDPE pipe for water supply, PE 100 pipe, PE sdr pipe, polyethylene pipe, polyethylene pipes.

You can buy HDPE pipes, as well as HDPE fittings and ask any questions you have from our managers by making a request by email or by calling the office at +7 (351) 777-94-98

Labeling Details

Now more specifically about labeling. In the first place is the brand of polyethylene. That is, it is low or high pressure. The designation is: HDPE (HDPE) or LDPE (LDPE).

Next comes an indication of the density, for example, PE100. The following markings are three English letters and a number. For example: SDR11.

SDR is an abbreviation of three English words: standard dimension ratio. It denotes the ratio of the outer diameter of a polyethylene pipe to the thickness of its wall.

The number after the letters indicates this ratio. It usually ranges from 11 to 17. The lower the number, the stronger the pipe material, but the heavier it is. SDR is valid when comparing polyethylene pipes of the same density. For example, you can compare PE80 SDR 11 or 17. You cannot compare PE80 SDR11 and PE100 SDR17.

The next indicator in the marking is the outer diameter and wall thickness. They are written either through “x” or through “*”. For example, 20x2.0. The outer diameter in this case is 20 mm, the wall thickness is 2 mm.

Next in the marking is the designation of the purpose - the pipe line is intended for drinking water supply or technical. That’s what it says on the surface – “drinkable”. This means that such a pipe can be installed on a water supply system in a suburban area.

Latest designations in the markings:

- GOST, according to which polyethylene products were manufactured;

- date of manufacture;

- roll length in meters.

In marking, the sequence is not always maintained exactly this way. Some positions may be reinstalled, which does not change the information content of what is written.

On the building materials market there are polyethylene pipes without markings. It is not recommended to use them anywhere.

Another point concerns the color of the strip that runs along the pipe. If it is blue, then the product is suitable for transportation for water. If it's yellow, it's for gas. The marking of polyethylene gas pipes must contain the word “gas”. This is clearly visible in the photo below.