One of the important tasks of modern monolithic construction is the reliable joining of load-bearing metal reinforcement. If previously welding assembly and overlapping strapping were used for connections, now mechanical coupling fastening is being introduced everywhere. Construction technology using reinforcing couplings is in demand for the construction of buildings with increased load-bearing loads: multi-storey buildings, hydroelectric power plants, bridges, as well as in seismically unstable areas.

What are couplings?

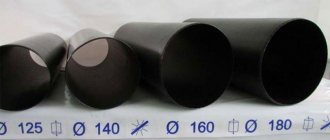

In the production of parts, small diameter pipes are used - smooth or with microthreads. The material for production is high-quality steel of different grades, depending on the type of fittings. The finished hollow parts have a cylindrical shape. The length of the cylinder ranges from 7-20 cm, and the diameter depends on the thickness of the rod. The walls of the part have a thickness of 2-5 mm. Reinforcement couplings are similar in shape to similar elements used when laying pipelines.

To ensure a strong connection, the shape and source material of the coupling and rod reinforcement must comply with GOST 10922-2012. Regarding the connection of reinforced concrete monolithic structures, they are guided by GOST 34278-2017.

Couplings for connecting fittings with standard threads - description, characteristics

Xfix-L couplings (X-fix-L) are designed for connecting building reinforcement and any other metal structures with cut standard metric threads.

This is essentially a variant of a particularly tall DIN nut, the height of which is equal to 3 diameters of the part being connected. This coupling is made only from certified steel (St. 3, St. 45, St. 40x) according to the customer’s needs. The price for this coupling is minimal. Read

Purpose and features

With the development of monolithic frame construction technology, couplings have become more in demand. They facilitate reliable fastening of reinforcement directly in the work area.

Installation of the coupling unit takes up to 10 minutes. Does not require specialized equipment or training. The ends of the reinforcement are fixed inside the coupling and then screwed onto the thread or the following fasteners are used:

- valves;

- valves;

- limiters.

If you need to connect reinforcement of different thicknesses, positional couplings are used. They are also suitable for cross and straight fastening of curved rods. The cost of assembling the structure is calculated when planning the overall estimate.

Crimp couplings for fittings - description, characteristics

Xfix-H couplings (X-fix-H) are designed for connecting reinforcement without additional preparation.

A coupling, which is a sleeve, is placed on the reinforcement, which is then pressed with a special hydraulic press either across the ribs or along. The resulting connection is strong. Unfortunately, more time is spent on crimping a connection than on cutting threads and assembling a threaded connection: 1 minute per transverse compression + the number of compressions is at least 6 per coupling. Read

Connecting reinforcement with couplings: pros and cons

The socket connection technology has 5 main advantages over welding and lap joints:

- Speeds up construction speed. Provides up to 500 joints per 1 construction team per shift.

- Allows you to reduce the number of workers due to high productivity.

- Eliminates the need for highly qualified welders, as a mechanical joining method is used.

- Guarantees material savings. The joining of reinforcement and the absence of overlaps eliminates overexpenditure.

- Allows you to increase the height due to the strength and lower weight of the reinforcement in the frame.

Using a mechanical connection, it becomes possible to carry out knurling and installation simultaneously. No additional hardware is required for vertical installation. This significantly reduces the operating time of the cranes.

The disadvantages of mechanical fastening include:

- reduction in metal thickness as a result of cutting, and, as a result, decrease in strength;

- the need for physical effort when tightening the coupling;

- the use of expensive hydraulic presses for crimping;

- high cost of cylinders.

It is worth noting that the costs in this case quickly pay off.

Couplings for fittings with conical threads - description, characteristics

Xfix-C couplings (X-fix-C) are designed for connecting reinforcement with a tapered thread.

Due to the technology of cutting with special equipment, the conical thread partially extends onto the body of the reinforcement ribs. The coupling, in turn, also twists not only onto the main body, but also onto the body of the ribs (see figure). The result is a strong connection that has the effect of threaded fixation and is resistant to cyclic loads. Read

Types of fastenings

To fix the rods and prevent loosening of the structure, threads are made inside the couplings or crimp rings are installed. According to the type of fastening on the rod, couplings are divided into 2 types:

- threaded, with a thread applied inside;

- crimp, implying the additional use of tightening elements (rings or nuts).

For each method, appropriate preparation and processing of materials is provided.

Threaded couplings

If threaded installation technology is used, couplings with applied threads are used. At the end of the reinforcement there is a thread with an appropriate pitch. Thus, correct fixation is ensured, and the connected rods are no worse in strength than solid ones.

Threaded technology is optimal for reinforcement with a thickness of over 16 mm.

The thread type can be conical or straight. With straight threads, the cylinder size is minimal. The type is determined during the preliminary preparation of the reinforcement. The rod ends are threaded, which must match the thread of the coupling.

During professional threaded installation, rods up to 20-30 meters in length are assembled without segmentation. In this case, no additional elements or wire are used. To fix it, you just need to prepare the joints of the reinforcement and screw it into the coupling. Threaded fastening is a low-cost and easy-to-use method.

Bolted reinforcement couplings

For equal-strength installation of reinforcement without preliminary preparation of the ends, bolted couplings are used. The design includes the following elements:

- cylindrical metal tube with holes for bolts;

- shear bolts;

- screwing tool.

The bolt system is universal. It is applicable to reinforcement of any thickness and shape, smooth and profile. This type of fastening is used for the reconstruction of monolithic buildings.

Crimp fittings

Hydraulic equipment is required for operation. The coupling rods may have an internal partition. They thicken the joints somewhat, but at the same time, ensure quick installation.

Couplings for fittings with cylindrical threads - description, characteristics

Xfix-P couplings (X-fix-P) are designed for connecting reinforcement with rolled cylindrical threads.

The size of the thread in the coupling corresponds to the maximum thread size that can be rolled on the reinforcement with minimal removal of ribs. Due to the fact that in the process of thread rolling, additional strengthening of the surface layer of the reinforcement occurs, the reinforcement retains high strength properties during connection with the coupling. Read

Types of connection equipment

The equipment for joining depends on the type of coupling used and the location of work. There are 2 types of machines available: for crimping and threaded fastening.

For crimping under construction conditions, mobile hydraulic presses are used, consisting of: a press, an oil station and high-pressure hoses. The press operates in semi-automatic mode. Control is carried out from a remote control built into the handle or manually.

Using a portable press, mechanical crimp fasteners form a reinforcement joint with high tensile strength. At the same time, the actual force to the temporary resistance of the compressed rolled product increases significantly and unlimited endurance is guaranteed.

Machine for thread cutting on fittings

The machines are designed to prepare joints for subsequent coupling fastening. They are applicable to rods with a diameter of 16 to 40 mm. Provide a maximum thread length at the outlet of up to 80 mm.

Depending on the cutting, there are 2 types of machines:

- For conical cutting. Mechanism of action: removing excess body from the reinforcement with cutters, followed by giving it a cone shape and cutting. Productivity - up to 1000 notches per shift.

- For cylindrical knurling. The reinforcement ribs are cut with cutters, and the notches are rolled with rollers. Can be used directly on a construction site with a productivity of 400 threads per shift.

Crimping machine

The machines provide a complete set of crimping technology. The system connects reinforcement in the range of 16-55 mm. The kit includes replacement dies for different rod diameters. The standard machine consists of the following components:

- Reinforcement press (stationary or portable).

- Pumping station.

- Winch for moving the press relative to the coupling.

- High pressure hose.

The machine creates a fastening that is identical in strength to a reinforcing bar. Managed by one operator. Can be used in any position in space.

What fitting couplings do you use?

Threaded

Crimping

Threaded couplings for fittings

| In addition to general construction products, our metal products plant produces threaded couplings for connecting reinforcement under the brand name ARCON-A. Our products have all the necessary certificates and test reports. Each batch undergoes mandatory production control. Threaded couplings are designed for connecting reinforcing bars, on which threads are pre-rolled at the ends of the joined bars. The coupling itself is a pipe made of high-strength steel with threads similar to those applied to the ends of reinforcing bars. Rolling is done on thread rolling machines. ARCON-A couplings have been tested for compliance with the main regulatory documents for mechanical connections:

|

View photo gallery >>>>

Go to product catalog >>>

| Sectional view of a threaded coupling | Sectional view of a threaded coupling |

| We will calculate the cost on the day you contact us! Send your application to the email address The email address is being protected from spambots. Javascript must be enabled in your browser to view the address. |

Threaded couplings for connecting reinforcement bars with a diameter of 16 mm to 40 mm - both standard and transitional, connecting rods of different diameters, are made from seamless steel pipes and are used for joining non-tensioned rod reinforcement of classes A400 and A500 in accordance with state standards for rolled reinforcing bars. They are used for mounting reinforcing bars with rolled cylindrical threads. Rolling is carried out at the construction site - in the reinforcement shop, or on the territory of the plant, when finished threaded rods cut to size are delivered to the site. As a result of thread rolling, the rod is further strengthened, providing high strength characteristics of the threaded connection.

1. Standard straight thread couplings

2. Adapter threaded couplings with cylindrical threads

3. Advantages of connections with threaded couplings

4. Types of couplings

5. Disadvantages of other types of connections

6. Installation steps

7. Thread rolling machine

8. Delivery geography

Standard threaded couplings are used to connect rods of the same diameter, with the obligatory condition that one of the connected rods is able to rotate freely.

Parameters of standard threaded couplings

| Name | Outer diameter of the coupling, mm | Coupling length, mm | Weight, kg | Order |

| Threaded coupling standard d16 | 26 | 40 | 0.090 |

Write to us!

Send a request for a quote or ask a question

Threaded coupling standard d1829440.125 Threaded coupling standard d2032480.165 Threaded coupling standard d2236520.220 Threaded coupling standard d2540600.310 Threaded coupling standard d2845660.415 Threaded coupling standard d3250720.625 Threaded coupling standard d3656801.100 Threaded coupling standard d4062901.120Transition couplings are used when it is necessary to connect rods of different diameters. At least one of them must have a free axis of rotation in order to be able to secure the couplings.

Parameters of adapter threaded couplings

| Name | Outer diameter of the coupling, mm | Coupling length, mm | Weight, kg |

| Transition coupling with parallel thread d18/16 | 28 | 47 | |

| Transition coupling with parallel thread d20/16 | 31 | 52 | |

| Transition coupling with parallel thread d20/18 | 31 | 52 | |

| Transition coupling with parallel thread d22/16 | 33 | 57 | |

| Transition coupling with parallel thread d22/18 | 33 | 57 | |

| Adapter coupling with parallel thread d22/20 | 33 | 57 | |

| Transition coupling with parallel thread d25/16 | 37 | 63 | |

| Transition coupling with parallel thread d25/18 | 37 | 63 | |

| Transition coupling with parallel thread d25/20 | 37 | 63 | |

| Adapter coupling with parallel thread d25/55 | 37 | 63 | |

| Transition coupling with parallel thread d28/16 | 41 | 68 | |

| Transition coupling with parallel thread d28/18 | 41 | 68 | |

| Transition coupling with parallel thread d28/20 | 41 | 68 | |

| Transition coupling with parallel thread d28/22 | 41 | 68 | |

| Adapter coupling with parallel thread d32/16 | 47 | 76 | |

| Adapter coupling with parallel thread d32/28 | 47 | 76 | |

| Transition coupling with parallel thread d32/22 | 47 | 76 | |

| Adapter coupling with parallel thread d32/25 | 47 | 76 | |

| Adapter coupling with parallel thread d32/28 | 47 | 76 | |

| Adapter coupling with parallel thread d36/16 | 54 | 84 | |

| Transition coupling with parallel thread d36/18 | 54 | 84 | |

| Transition coupling with parallel thread d36/20 | 54 | 84 | |

| Adapter coupling with parallel thread d36/22 | 54 | 84 | |

| Adapter coupling with parallel thread d36/25 | 54 | 84 | |

| Transition coupling with parallel thread d36/28 | 54 | 84 | |

| Transition coupling with parallel thread d36/32 | 54 | 84 | |

| Transition coupling with parallel thread d40/16 | 59 | 90 | |

| Transition coupling with parallel thread d40/18 | 59 | 90 | |

| Transition coupling with parallel thread d40/22 | 59 | 90 | |

| Transition coupling with parallel thread d40/25 | 59 | 90 | |

| Transition coupling with parallel thread d40/28 | 59 | 90 | |

| Transition coupling with parallel thread d40/32 | 59 | 90 | |

| Transition coupling with parallel thread d40/36 | 59 | 90 |

Each batch of couplings undergoes the testing required by the technical specifications. For this purpose, several random samples are selected from the batch and undergo visual inspection and tensile testing. According to GOST 10922-2012 “Reinforcing and embedded products, their welded, knitted and mechanical connections for reinforced concrete structures”, the connection section must withstand the same breaking load as the rod itself of a given diameter in accordance with GOST R 52544-2006 As a result of tests for each batch of couplings a passport is issued, and, if necessary, test reports.

| Site mounted couplings | Reinforcement bars ready for installation |

Advantages of connections with threaded couplings

- ease and speed of installation of monolithic structures with a large percentage of reinforcement;

- ease of thread rolling onto reinforcement bars using a thread rolling machine;

- the ability to perform installation work in any weather conditions;

- guaranteed strength characteristics of the coupling connection;

- high reinforcement speed; — ability to work in cramped conditions or at heights;

- equal strength of the joint;

- reducing the percentage of reinforcement.

Types of threaded couplings

Depending on the type of thread on reinforcing bars, connections are:

- with conical thread;

- cylindrical thread.

According to the type of reinforcement being connected, couplings are divided into:

- standard – designed for connecting rods of the same diameter;

- transitional - connect rods of different diameters;

- welded - designed for joining the rod to the platinum;

- bolted - connect load-bearing metal structures with reinforced concrete foundations and other structures;

- positional – does not allow free rotation of the joined rods;

- end – used as anchorage for reinforcement in concrete structures.

In the process of connecting reinforcement cages, couplings are used to join reinforcement with rolled or cut threads. This type of fastening provides good fixation of the reinforcement bars; the customer receives a reliable method of joining at low material and labor costs. Materials used in the manufacture of threaded couplings All couplings intended for connecting reinforcement bars mechanically are made from low-alloy rolled steel grade 35GS, 25G2S in accordance with GOST 5781-82. After special processing of the pipe blanks, threads are applied from the inside.

Disadvantages of other types of connections

Lap joint | Bath welding |

|

|

Installation stages

Stages of connecting reinforcing bars using a threaded coupling:

- Installation of thread rolling machines, purchase of couplings according to specifications.

- Preparation of reinforcing bars for installation - rolling threads on machines.

- Installation of rods in the design position.

- Fastening the coupling to one of the rods.

- Installation of the second reinforcement bar;

- Tighten the connection using a torque wrench.

- Visual meter connection control.

The coupling reinforcement connection is tightened using a torque wrench. It should be remembered that when rolling threads for connection with standard couplings with cylindrical threads, the thread at the end of the rod must be one turn longer than the second length of the coupling with which it is planned to connect the rods.

The coupling must be installed in the following order:

The coupling is screwed onto the first rod to the edge of the thread. If after this operation it is necessary to carry out monolithic work, then a protective sleeve or cap is put on the coupling.

Before screwing in the second rod to be connected, all protective devices are removed, the second rod is screwed into the coupling until it touches the first, and the threaded coupling is tightened using a special wrench.

The tightening force must be fully directed to only one of the rods, the second must be securely fastened to prevent rotation by fixing it inside the concrete structure, or using a pipe wrench.

Thread rolling machine

| To connect reinforcing bars with a coupling, it is necessary to roll threads onto the ends of the rods. For this purpose it is used thread rolling machines different power. Our company produces this equipment in the Krasnodar region. You can buy we have a thread rolling machine, or take for rent for the duration of the work. The machine is connected to the electrical network (three-phase current, 380 V). The delivery set includes an electric motor, drive mechanism, and thread rolling heads. The equipment is mounted on a frame or chassis with wheels for easy transportation around the site. Characteristics: Diameter of processed rods: from 16 mm to 40 mm Processing time for one reinforcement rod - from 30 seconds to 2 minutes Operating voltage: 380V, 50Hz | |

Delivery geography

Our production is located in Krasnodar. We supply couplings mainly in the South of Russia (Krasnodar Territory, Crimea - Simferopol, Sevastopol, regions of the North Caucasus: Karachay-Cherkessia - Cherkessk, Chechnya - Grozny, Dagestan - Makhachkala, Kabardino-Balkaria - Nalchik, Ingushetia - Magas, North Ossetia - Vladikavkaz, Stavropol Territory - Stavropol, Pyatigorsk.

PRESKO system with crimp couplings

The MSA “PRESKO” system forms reinforcement joints with a diameter of 18 to 40 mm using standard and transition couplings that connect the ends of rods of the same or different diameters by crimping them without preliminary preparation of the ends. During compression, the metal of the connecting element fills the differences in the periodic profile, thereby forming an equal-strength joint. Such a joint is more economical compared to connections with bypasses, and compared to welding, it is less labor-intensive, and also does not require a highly qualified specialist to perform.

The connection device using coupling compression consists of two operations:

- installation of the PRESCO connecting element at the joint in the design position;

- crimping the joint using a mobile hydraulic unit.

PRESKO crimp couplings were used in the construction of the capital's Hanoi-Moscow business center, the Rostov Arena football stadiums, the VTB Arena complex, facilities in the satellite city of Kazan "Innopolis", the Akhmat Tower, the Grozny Mall shopping center in capital of Chechnya.

Classification of Mechanical Connections of Fittings

The current regulations classify ISAs according to the method and purpose of the connection. So the connections could be:

- threaded , due to a connecting cylinder with an internal conical or cylindrical thread connecting the ends, where a thread of the same profile is already made;

- pressed , when the ends of the profiles are connected by a steel cylinder, compressed by a hydraulic press, as a result of which the metal from which it is made is pressed between the ribs of the periodic profile;

- screw , in which the connection is made by a coupling, where a screw periodic profile, similar to a reinforcing one, is cut inside, as well as locknuts screwed onto steel rods;

- bolted , where the fixation of the connected reinforcement occurs due to bolts screwed through the coupling wall into the profile body, and their number depends on the amount of force perceived by the connection.

According to the purpose, according to the design solution of the connecting element, MSA can be:

- standard , connecting fittings of the same diameter, when at least one of them can rotate;

- transitional , similar to standard ones, but connecting fittings of different diameters;

- positional , connecting the fixed ends of steel profiles;

- welded : for joining reinforcement frames and metal structures.

These types of MSA are manufactured by domestic and foreign manufacturers; they are already used in practical construction.

Which reinforcement connections are best for ASG?

Much work on the introduction of innovative ISAs into mass construction in Russia and the countries of the Customs Union is carried out by the NIIZhB named after. Gvozdeva and group (GK PSK). They jointly developed design and technological documentation for the use of a number of MSA systems in the production of reinforcement works, incl. at particularly dangerous, technically complex, unique objects. Each of them already has experience of practical use on residential, warehouse, industrial buildings, bridges, overpasses, built in Russia and abroad.

The variety of objects already built using MSA shows the applicability of these technologies for use in mass construction when reinforcing structures for various purposes that can withstand almost any effort, and most importantly, the PSK Group guarantees an increase in the speed of the entire complex of reinforcement work when implementing any of the selected technological systems. PSK's trained fitting engineers will not only help with the implementation of the selected technological system, but are also ready to perform all the work on cutting or rolling threads on fittings using their own equipment.