');> //—> The volume of water in a pipe is a quantitative characteristic of the space occupied by water inside the pipe.

The mass of water in a pipe is a quantitative characteristic of the mass of water located inside the pipe.

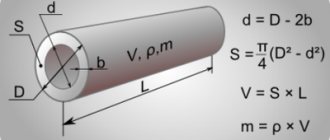

Volume calculation formula:

V = π * d 2 * l / 4

l is the length of the pipe; d is the internal diameter of the pipe.

The relationship between volume and mass is determined by a simple mathematical formula:

v—volume; m—mass; p—density.

In the calculation, the density of water is taken to be 1000 kg/m3.

You can quickly perform this mathematical operation using our online program. To do this, enter the initial value in the appropriate field and click the button.

This page presents a program for calculating the volume and mass of water in a pipe in accordance with the internal diameter of the pipe and its length.

- 02 February 2013 12:25:50

- Reviews :

- Author: Dmitry Z

- How to calculate the volume of a pipe, table, calculator.

How to calculate the volume of a pipe.

These calculations are required to determine the volume of the heating system when choosing an expansion membrane tank

.

The volume of the expansion membrane tank

is selected based on at least 10% of the total displacement of the system.

Determine the radius of the pipe R. If you need to calculate the internal volume of a pipe, then you need to find the internal radius. If it is necessary to calculate the volume occupied by a pipe, the outer radius should be calculated. By measuring, you can easily obtain the diameter (both internal and external) and circumference of the pipe section. If you know the diameter of the pipe, divide it by two. So, R=D/2, where D is the diameter. If the circumference of the pipe section is known, divide it by 2*Pi, where Pi=3.14159265. So, R=L/6.28318530, where L is the circumference.

Calculation of pipe volume

Please indicate dimensions in millimeters

D1 - internal diameter of the pipe D2 - external diameter of the pipe L - length of the pipes The program will help calculate the volume of water or other liquid in the pipes. To calculate the volume of the heating system, add to the result the volumes of the radiators and heating boiler. This data is usually indicated in the product passport.

As a result, the program will calculate the total volume of pipes, its surface area and the volume of pipes per 1 linear meter. Surface area can be useful in calculating the amount of paint needed.

For calculation, indicate the internal and external diameter of the pipe and the total length of the pipeline. All dimensions are indicated in millimeters.

The volume of pipes is calculated using the formula V=π*R1*R1*L The surface area of the pipe is calculated using the formula P=2*π*R2*L R1 - inner radius of the pipe R2 - outer radius of the pipe L - length of the pipe

Volume of water in polypropylene pipe

| diameter | 20 | 25 | 32 | 40 | 50 | 63 | 75 | 90 | 110 |

| water volume m3 | 0,14 | 0,22 | 0,35 | 0,55 | 0,87 | 1,38 | 1,96 | 2,83 | 4,20 |

How to connect PPR PN25 pipes

Pipe welding is carried out using the thermal polyfusion method. The parts to be welded must be heated and quickly connected. A special soldering iron is used for heating. Some models have two heating elements at once, the power of which is designed to heat pipes of a specific diameter, but this does not always have a positive effect on the quality of welding.

Important! The use of two elements at once can lead to overheating of the plastic and overload of the electrical network. Therefore, the second heater should be used when the first one becomes unusable. The heating time depends on:

- pipe diameter;

- welding belt width;

- ambient temperature - it should be within normal limits.

After heating, the material does not retain its plasticity for long. The connection must be fixed within a few seconds, without allowing distortions. The optimal temperature for heating is considered to be +260 ˚С. For a reliable connection, the pipe material must be very heated. But excessive heating can cause the shape to change. To avoid this, it is necessary to control the execution time of this operation. It should not exceed:

- 8...9 seconds for pipes with a cross-section of 20 millimeters;

- 9…10 seconds when welding a pipe with a diameter of 25 millimeters;

- 10...12 seconds for pipes with a diameter of 32 millimeters, etc.

Heated and already connected pipes must cool down. Fixing takes the same amount of time as heating. If the required time is not maintained, deformation of the connection will occur. Welding polypropylene pipes is a relatively difficult process. The quality is affected not only by the heating time, but also by violation of soldering rules. They are as follows:

- During operation, the welding machine must be constantly heated;

- Marks must be applied to the pipes in order to ensure the proper depth of the weld seam;

- The elements being connected must be heated simultaneously.

Classification of propylene pipes according to the composition of raw materials

- PPR pipes. This category usually includes structures that are created using a static polypropylene copolymer, which is distinguished by the presence of a crystalline molecular structure. These products perfectly withstand temperatures in the range from - 170 to + 1400 degrees Celsius. At the same time, they cope well with shock loads, which is why they are widely used when carrying out work on the construction of sewerage, plumbing and heating. These products are most often used in the construction of residential buildings. If we talk about their sizes, they are about 16–110 mm. The signs of their classification may include, first of all, a parameter such as pressure.

- PPH pipes. The material used to create these structures is raw materials, which are mixed with modifying additives. The latter can be antistatic agents, fire retardants, and nucleators. The effect of introducing the latter into the composition provides an increase in the impact strength of the polymer. Using similar structures, external cold water supply systems, as well as ventilation and drainage systems are erected. At the same time, they do not seem to be the best option for creating heating systems based on them. The reason for this is due to the low melting point. The diameter of structures in this category is usually quite large, since most of them are used in the construction of industrial sewerage and drainage systems.

- PPB pipes. If we consider the structure of this material, then its basis is formed by homopolymer micromolecules having different structures, compositions and locations. It is the special molecular structure that is responsible for the property of this product, which is its high resistance to impact. For this reason, they are most often used in the installation of underfloor heating systems and cold water supply.

- PPs pipes. This category is represented by polymers of the highest class, the main feature of which is a unique molecular composition. The advantages include high resistance to loads and heat. They also have high wear resistance and strength characteristics. The diameter of structures created on the basis of such polypropylene is about 20–1200 mm. Most of them are used in the installation of ventilation systems, hot and cold water supply, and heating.

Classes and their use in heating systems

Polypropylene pipes are divided into several main classes depending on their design features:

- PN10 – pipeline for cold liquids up to +45оС and nominal operating pressure up to 1 MPa

- PN16 – transitional type for water supply of cold and warm liquids with temperatures up to +60°C, pressure up to 1.6 MPa

- PN20 – pipeline for hot liquids with temperatures up to +95°C inclusive, pressure 2 MPa

- PN25 – pipeline with reinforcement for liquids with a temperature of +95°C and a nominal pressure of up to 2.5 MPa

The withstand nominal pressure most often implies a liquid temperature of +25°C. As the temperature rises, the permissible pressure decreases, but it is still sufficient for organizing water supply systems for domestic and industrial needs.

Regardless of the type of product, polypropylene has the following properties:

- Density – 0.9 g/cm3

- Elongation at break – 200-800%

- Flexural modulus of elasticity – 6700-12000 kgf

- Tensile yield strength – 250-350 kgf/cm2

- Brinell hardness – 6.0-6.5 kgf/mm2

- Thermal conductivity of the material at an ambient temperature of +20°C 0.24 W/mC

- Specific heat capacity at a temperature of +20°C – 2 kJ/kgC

Polypropylene pipe PN10, PN16

For heating systems, all types of PPRC polypropylene pipes are used, depending on the temperature of the coolant. PN10 is suitable for organizing heated floors. It is flexible enough for installation in coils, supplied in coils, this is the key point that allows you to create completely seamless heated floors of almost any configuration and for any area. In addition, polypropylene is strong enough to withstand further pouring with screed without deformation or reciprocal destruction of concrete floors under load.

PN16 is a transitional type and is rarely found on sale. However, it can be used for laying heated floors or low-temperature heating systems in private houses, and provides heating for greenhouses and industrial facilities where a coolant with a temperature of up to +60°C is used.

Polypropylene pipe PN10 110 x 10mm Tebo

Polypropylene pipe PN20, PN25

For most heating systems using coolant temperatures up to +95°C, classes PN20 and PN25 are used. At the same time, PN20 is excellent for organizing autonomous heating, in which high pressure is not created, and the system must have an expansion tank or a compensation valve with air release. The problem with polypropylene heating pipes PN20 can only be called the very significant permeability of the material to oxygen, which leads to the formation of excessive oxygen concentration in the coolant.

For central heating systems, the appearance of gases in the coolant is critical, because this can lead to the formation of air pockets, which negatively affects the condition of main lines and boiler room equipment. Therefore, for apartments connected to central heating, it is better to choose polypropylene materials, whose technical characteristics are more practical - PN25. They are reinforced with a thin sheet of aluminum. The metal layer, with a constant wall thickness, is located in the middle, between the layers of polypropylene. All layers of the composite material are connected using glue, which prevents their displacement relative to each other due to thermal expansion and mechanical influences within permissible values.

Connection methods, fittings

The enormous practical advantage of polypropylene pipes for heating over metal products is in the method of their installation. For this purpose, a wide range of special fittings are used, designed for each diameter and type. Among the connectors, there are almost all possible options that allow you to design wiring of any format. Available:

- couplings;

- tees, crosses;

- knee;

- adapters;

- shut-off and control valves;

- staples and compensators;

- stubs.

A wide range of connectors and adapters, on one side, have a hole for soldering PPRC pipe, and on the other, a metal insert with internal or external threads is securely seated to ensure a strong, reliable connection with the transition from plastic to metal.

For heating systems, such adapters are extremely necessary, because most often the terminals of heating boilers or central heating risers are made of metal; you should carefully and reliably switch from it to plastic. In addition, such adapters are used to connect additional measuring or control equipment to the water supply line.

Due to minor differences between pipes from different manufacturers, fittings should also be selected and purchased from him. It can be accurately determined as a defect if the pipe is inserted into the fitting even in a cold state.

An irreplaceable property of polypropylene, like many other plastics, is the possibility of their strong soldering at relatively low temperatures. At the joint, a monolithic diffusion homogeneous seam of considerable width is formed, providing a connection that is often much stronger and more durable than steel welding. The connection of polypropylene heating pipes with high-quality installation does not differ from the strength of the product itself, which is almost impossible to achieve using metal.

Separately, it is worth noting the need to use special expansion joints for polypropylene pipes, especially non-reinforced ones. When operating heating systems, the material is deformed under the influence of heat and cold; the coefficient of linear expansion for reinforced pipes, although significantly less, is still present.

Special compensators can cope with this using an unreinforced polypropylene pipe for heating. A loop is prepared around a circle of 10-15 radii, which is welded into an area with a sufficiently long duration, for example, in risers between floors. In the case of frequent turns and the use of fittings such as elbows or tees, the pipes are fixed not at the connection points, but at a distance of approximately 10-15 cm from them, leaving a power reserve. All fastenings are made without rigid binding, sliding.

Soldering of polypropylene pipes

For this, a special soldering iron is used, on which nozzles are installed that can heat pipes of different diameters. One side of the nozzle heats the pipe from the outside and from the end; it is shaped like a small glass, and the second heats the connecting element (tee, angle or coupling).

The task is to simultaneously melt the outer part of the pipe and the internal cavity of the transition. It is at this moment that many novice plumbers make one significant mistake - they must not overheat the pipe and connector. This is fraught with the fact that the small internal hole intended for the flow of water is, at best, almost halved, which reduces the throughput of the pipe, and at worst, it seals it tightly. And then look for where it happened, it’s good if you haven’t had time to wall it up yet.

We insert the pipe and the “connector” into the nozzles, forcefully press them into it until it stops, count two or three seconds, remove the pipe from the soldering iron and connect the two elements together. Here you need to understand that the larger the diameter of the pipes being connected, the more time it takes to warm them up. Let's just say that 2-3 seconds of warming up is an axiom for a pipe ø20 (in the old days it is ½ inch), and for the subsequent diameter (ø25 or ¾ inch) the warming up time increases to 5-6 seconds. And so on with each diameter.

READ ALSO: Why Frost is Dangerous for HDPE Pipes

Then another nuance arises. Firstly, the elements to be joined must be held with force until the polypropylene hardens - as a rule, this is 15-20 seconds. Secondly, at the moment the polypropylene hardens, you need to hold it firmly and securely so as not to turn or move the pipe in the connector. If you disturb the joint at this moment, you're guaranteed to leak.

Droplets of water that may remain in the plumbing system during its repair or the addition of any elements have the same detrimental effect on the joint. The steam generated at high temperatures simply will not allow the polypropylene to combine into a single whole. In this case, ordinary bread crumb is used. It is packed into the pipe and gives several additional tens of seconds, during which you need to have time to solder everything. Subsequently, the crumb is completely dissolved by water, and there can be no talk of any plugs.

If you are soldering polypropylene pipes for the first time, it would be good to invite a person who has already done similar work as an assistant. Experience is of great importance, and in some moments, competent advice on how to properly solder polypropylene pipes can be very helpful.

At first, when mastering this type of work, soldering propylene pipes will not be done quickly at all. But you shouldn’t rush, because if you rush, the quality will suffer. Do you need leaks?

By gaining experience, you will learn to work more efficiently, and the time spent on soldering polypropylene pipes will be reduced.

Who knows, over time, having learned how to solder propylene pipes, you may want to improve not only the plumbing in your home, but also the sewerage and heating systems, and you will be able to help your friends in repairing communications.