Since 2006, we have been providing services for inspecting pipeline networks, searching for water and heat (coolant) leaks. Hidden underground water leaks are a serious problem for any business. Deterioration of networks, lack of funds for their timely repair, a significant amount of hidden water losses - all this leads to the relevance of such activities as technical diagnostics of pipelines and search for leaks in pipes, examination and inspection of pipeline communications.

When there is a water leak, there is an increased flow rate on the metering devices, knockouts and flooding may occur, and the pressure in the system decreases. To accurately determine the location of the leak, pipe examination and instrumental diagnostics of water supply, heating, and heating pipeline systems are required. This allows you to minimize the cost of excavation and further improvement of the territory when eliminating water supply leaks or leaking heating pipes.

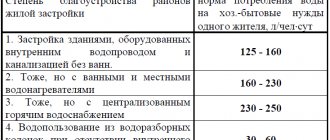

Signature. Example of an inspection area to detect hidden leaks.

Our advantages

Experience and reliability

has been providing engineering services for inspection, diagnostics and examination of pipeline networks for 15 years. We employ only highly qualified water supply and water supply engineers. During this time, hundreds of successfully completed works in different regions of the country, grateful reviews from clients were received, and strong partnerships were built with many design and survey institutions, construction companies, and equipment suppliers.

Powerful instrument base

The company has dozens of pieces of equipment owned by the enterprise. We have the opportunity to perform work using several technologies and different types of instruments at once, and, by comparing the results, achieve the most reliable data, minimizing the likelihood of error. Often people come to us after bad experiences with other companies, and we find a solution to the problem.

Flexibility and mobility, following the client

In urgent and emergency cases, we are ready to go to the customer immediately and without prepayment. We take on complex and non-standard cases. Taking into account the requirements and wishes of clients, we are always focused on long-term cooperation.

Quality of services and responsibility

The company is accredited as a forensic institution; our reports and expert opinions are accepted by government and judicial authorities. Survey results and conclusions are always as substantiated as possible, and the equipment is certified and properly verified. We value our reputation.

Independence and confidentiality

We are professionals and respect our work and our clients. We carry out all work conscientiously and on time. The independence of the enterprise guarantees the objectivity of expert examinations and the maintenance of complete confidentiality. We have an individual approach to each client, since each case in our work is unique in its own way.

Problems[edit | edit code]

The problem of the emergency condition of water supply networks faces all major cities of the world. This situation is caused by the impossibility of replacing all network elements in a short time due to the end of their design life, for a number of reasons:

- Interruptions in water supply. The result is a drop in production and a deterioration in the epidemiological situation.

- Increased fire danger is the inability to quickly obtain water for extinguishing needs.

- Practical paralysis of road traffic due to excavation work on the streets.

- Huge cost and labor intensive work.

Correlative leak detection method

Leak detection using the correlation method is based on digital analysis of the vibroacoustic signal (the noise of a pipe leak) propagating from the place where the pipe is leaking. Sensors are installed in underground water wells that sense this noise and transmit information to a correlation leak detector. Based on the known values of the speed of sound propagation in the pipeline, the location of the leak from the pipeline is calculated. This method is most effective for metal pipes when you need to find a leak in a pipe: examination of heating, plumbing and heating networks, leak diagnostics.

Classification of leak detectors

All available models differ in operating principle. The following categories are distinguished:

- Acoustic.

- Correlation.

- Network.

Each group has certain design features, a special operating principle, scope and capabilities. Let's take a closer look at them.

Acoustic devices

When an underground water pipe breaks, the flowing water creates ground vibrations. An acoustic leak detector uses a microphone to record these vibrations and convert them into electrical signals to determine the location of the breakdown .

Such devices may use electronic filtering of the incoming signal. The main task of such filters is to determine among the general noise exactly that created by the flowing water.

The main characteristic of these leak detectors is the degree of filtration; the higher it is, the more thoroughly interference is suppressed. For various soils - concrete, turf, clay, ice (if the pipes were laid inside) - special sensors are used.

There are also acoustic leak detectors without the use of filters. They are very difficult to diagnose within the city, since excess noise makes it difficult to accurately detect the necessary one. Therefore, only very experienced operators can handle such devices.

There is another type of acoustic leak detector that uses a pseudo-correlator option. They determine the distance to failure, taking into account the difference in vibration magnitude.

Correlation devices

These devices use a correlation method. Two sensors are used, which are installed on the pipe. They measure the vibroacoustic signal caused by a leak and record the difference in the time it takes for the signal to travel from the breakdown to the first and second sensors.

Knowing the speed of sound through the pipe and the distance between the sensors, you can accurately determine the location of the accident and eliminate the breakdown.

The sensitivity of the device is not affected by temperature, soil type or line pressure. Therefore, they are more versatile and can be used not only in water supply systems, but also in oil pipelines.

Information from the sensor is transmitted via radio channels to the operator’s computer monitor. The person in charge can then listen to the magnified signal through headphones or determine its strength in a graphical display.

Using a correlation leak detector (video)

Network devices

The operating principle of network leak detectors is the same as that of correlation detectors, only there are many more sensors. They are located throughout the entire pipeline and constantly monitor the condition of the pipes.

The devices analyze the noise, and if a leak is detected, the information is instantly transmitted to the working PC or server. Thanks to built-in batteries and low power consumption, sensors can be in the system for up to 5 years.

In order to save battery power, the sensors are programmed to check at a certain interval. In the device settings, you can set certain parameters related to the characteristics of the environment and location.

With these leak detectors, the operator no longer wastes time troubleshooting. If the patrol engineer is within the range of the sensors, he receives all the necessary information automatically.

The message accurately indicates the sensor number and the location of the suspected problem. If necessary, he can listen to the noise coming from the sensor right in the car.

Thanks to a wide range of settings, the network leak detector can be programmed so that information about the condition of pipes and the presence of leaks (or lack thereof) will be transmitted directly to the central office using GSM or GPRS, or via SMS messages to a mobile phone.

Using modern advances, searching for water pipe leaks will not take much time and effort. Thanks to leak detectors, a breakdown can not only be quickly corrected, but also eliminated in a timely manner.

Source: trubypro.ru

Acoustic leak detection method, acoustic inspection of pipelines

An acoustic method for detecting leaks is to “listen” to the noise from the pipeline from the surface. The operator, using a geophone (acoustic leak detector), listens to noise from the surface while moving along the pipeline route. In the area of pipe leakage, this noise takes on a special character and greatest intensity. Modern geophones have an indication that allows you to quantitatively characterize the noise level at various points, as well as filters that separate interference and extraneous sounds. The acoustic inspection method is most in demand for detecting and reducing hidden leaks, leaks on non-metallic pipes, as well as for clarifying the results of the correlation method.

How to find a hidden humidification area of building structures

Finding a leak is difficult. Even an experienced engineer cannot determine its source. As a result, after several openings of building structures and going through possible options for independently detecting leaks, people give up.

We recommend contacting the sanitary and epidemiological station and using the service to find defects using a modern device - a thermal imager. The tool finds problem areas and makes them visible. The accuracy of the pipe break location is 0.5 - 2 meters. It depends on the thickness of the screed, laying features, and the use of materials (heat insulating). You will not need to destroy the building structure. It is enough to cut out a small piece of the wall to make the problem area accessible.

This examination method is the most accurate.

Thermal imaging inspection and diagnostics of pipes (search for leaks)

Searching for leaks in pipelines based on thermal imaging involves identifying the most heated area of the surface above the damaged section of the pipe. This method is especially effective when the task is to find a hot water pipe leak or a heating system leak.

Our diagnostic laboratory has all the necessary equipment and qualified specialists, which will allow us to combine methods and equipment used, depending on specific conditions. Even in the most difficult situations we can find the leak!

Read reviews

Cost of services

1. Tele-inspection, video diagnostics, tele-diagnostics of pipes, sewerage and storm water pipelines, video camera inspection - from 120 rubles/m

2. Search for water and heat leaks in pipelines, underground - from 100 rubles/m

3. Expertise, diagnostics and inspection of the technical condition of heating systems, heating networks, water supply and sewerage systems, assessment of the level of wear and the possibility of further operation - from 150 rubles/m

4. Search for lost (buried, paved) sewerage and water supply wells - from 150 rubles/m

5. Search for engineering systems, communications, cables and pipelines underground, tracing of water supply pipes, heating networks, sewerage - from 120 rubles/m

6. Inspection of water supply, engineering and plumbing knowledge systems (heating, water supply, sewerage, drainage) - from 150 rub./m

7. Measuring water and wastewater flow in pressure and gravity pipelines, canals, wells - from 20,000 rubles.

Equipment for detecting water leaks and hidden pipe leaks

The greatest efficiency, reliability and accuracy of searching for water and coolant leaks in pipelines is achieved by us by combining the use of the best diagnostic equipment from different manufacturers:

- Leak noise recorder with correlation processing SoundSens (Radcom Technologies Ltd., UK), 2 sets. The use of the SoundSens system allows you to save up to 200% of the time usually required to determine the location of a fault. Six correlator sensors used together can locate leaks in complex pipe network systems. The SoundSens system can be used with a variety of pipe materials, including cast iron and plastic, even over relatively long distances.

- Correlator MicroCorr Digital + (Palmer, UK). A reliable, well-proven correlation leak detector from a well-known European manufacturer.

- Correlator “Korshun-10” (MP “DISIT” NASU, Ukraine), equipped with an automatic digital filtering system, is the most sensitive and one of the most accurate on the market, which has been demonstrated in numerous comparative tests.

- Acoustic leak detector HL5000 (Hydrolux, Germany). Designed to “listen” to pipelines from the surface of the earth to detect leaks. The device has a reliable system for filtering extraneous noise, which allows you to determine the location of leaks up to 6 m deep. There are prefabricated rods for “listening” to pipes in wells. There is a digital indication of the noise level on the display.