PVC sewer pipes: technical characteristics

You may be interested in information about sewer pipe fittings

Products made of polyvinyl chloride - PVC are currently extremely popular on the building materials market (as are soft PVC windows). This material is used to make many useful products, from the familiar disposable gloves to massive structures. Like any plastic, polyvinyl chloride has certain limitations associated with its physical properties. In order to correctly apply all the advantages of this material, for example, when choosing and installing PVC sewer pipes, you need to clearly know its technical characteristics.

PVC sewer pipes for internal sewerage

Physical characteristics of PVC (polyvinyl chloride)

PVC sewerage system pipelines are in very wide demand. However, despite all the visible advantages, we must not forget that the performance indicators of such pipes depend on the physical properties of polyvinyl chloride. This plastic is quite popular in the industry and has many other names: hostalite, vestalite, vinyl, corvik, winnol, jeon, sicron, sumilite, nippeon, lukovyl, norvik, helvik. Don't be confused by the big names - in fact, it's still the same good old uPVC.

PVC sewer pipeline diagram

Pure polyvinyl chloride is a colorless, transparent plastic. It may not react for a long time to exposure to a chemically aggressive alkaline environment, does not decompose under the influence of motor oil, and even resists the action of many acids and solvents.

Fittings for sewer pipes

Polyvinyl chloride and products made from it do not burn in air. This material begins to melt already at 65 degrees Celsius, so its use as hot water pipes is impractical. Also, pipes made of polyvinyl chloride are characterized by relatively low frost resistance. They begin to collapse already at minus 15 degrees. Thus, the use of PVC pipes in open areas in winter is excluded.

Factory-manufactured sewer pipes made of polyvinyl chloride

Features of the production of products from polyvinyl chloride

Polyvinyl chloride is made from thermoplastic, which continues to retain its shape as a result of heat treatment and even in the event of mechanical stress. PVC contains two main compounds - ethylene and stabilized chlorine. The additional use of additives can improve the thermal and other properties of products.

PVC sewer pipes are produced in two types:

- polyvinyl chloride PVC (PVC);

- unplasticized polyvinyl chloride PVC-U (PVC-U).

Experts prefer pipes made from PVC-U because they have the best technical parameters and are used in the construction of pressure sewer structures.

Types of PVC pipelines

The relative ease of manufacturing PVC pipes has led to the fact that there is a wide range of products of this type on the market.

Sewage polyvinyl chloride pipes for indoor use

You may be interested in information about the diameters of sewer plastic pipes

Polyvinyl chloride (PVC) pipes can be divided according to their purpose.

- Sewage PVC (polyvinyl chloride) pipes for outdoor use . Despite the low frost resistance, such products can be used to form the outer contour of the sewer system. In this case, the pipes are either lowered into the ground or additionally insulated. As a rule, products with a large cross-section are used for installation of external circuits.

- Sewage polyvinyl chloride pipes for internal use . For these purposes, pipes of different diameters and different configurations are used. The scope of their application inside the building is practically unlimited.

Sewage pipe for outdoor use

Also, PVC pipelines can be manufactured to work with different working flows.

- Gravity pipelines have a relatively low strength index and are intended for sewer collection systems where wastewater moves by gravity, without creating additional operating pressure. The flow speed in such products does not exceed 8 meters per second.

Production of PVC sewer pipes

- Pressure PVC pipes operate in complexes containing circulation pumps. Depending on the modification, such pipes can withstand a working flow pressure of up to 10 atmospheres.

- Separately allocate corrugated PVC pipes. This product has excellent flexibility, which allows them to be used in the most complex structures with hard-to-reach areas. They can direct wastewater flows along almost any trajectory.

Corrugated PVC pipes

In addition, some PVC pipes have performance properties that allow them to work in environments with increased aggressiveness. For this purpose, special additives are added to the plastic. This composition increases the cost of the pipeline and therefore products of this type are used only in specialized systems.

Prices for PVC sewer pipes

PVC sewer pipes

How to choose?

Previously, people did not have the opportunity to choose sewer pipes and used only the material that was commercially available. Today, in specialized warehouses you can find products made from different materials. Cast iron is gradually being replaced, and products made of plastic, PVC, polypropylene and others are appearing on the market. For the installation of external lines and drainage systems, it is advisable to use corrugated two-layer pipes. They are not afraid of large volumes of wastewater and soil pressure.

Cast iron structures have not lost their relevance and are quite widely used for laying external sewage systems in industrial enterprises. They have high strength and resistance to temperature changes. In addition, they are quite convenient to work with. But since cast iron quickly becomes contaminated, which reduces the permeability of wastewater, their installation is not considered a good solution.

To organize water supply in an apartment, it is best to purchase plastic structures. They are quite durable, resistant to ultraviolet rays and tolerate temperature changes well. The polyethylene system is quite flexible and rigid, which allows it to pass wastewater moderately. To create an improved throughput system in the segment, it is best to choose PVC pipes. They not only have high ring rigidity, but also have excellent resistance to axial loads. They can be safely installed not only horizontally, but also vertically.

The choice of sewer pipe diameter should correspond to the average volume of water consumed. But taking this parameter into account is only necessary if the installation is planned in an apartment; for a private house, such a calculation is not needed. When choosing sewer pipes, it is worth considering the advantages and disadvantages of each material. It is worth remembering that steel structures can easily withstand high temperatures, but are highly susceptible to corrosion. But cast iron products are not afraid of corrosion, can withstand heavy loads, but have a lot of weight and price.

To choose the right pipes for internal sewerage, you need to take into account their future location. For example, waste structures with a diameter of 50–75 mm are suitable for sanitary equipment, such as a shower stall or sink. To organize a drain from the toilet, you need to select a pipe with a diameter of at least 100 mm. To install heated floors, you need to purchase polybutylene pipes, as they have elasticity and high thermal conductivity.

To create high-quality water supply at your dacha, it is better to choose products made of polyethylene, as they are durable and flexible. For cold water supply, you need to purchase pipes with high density. If PVC pipes are chosen for installing a sewer system, then it is worth remembering that they contain a chlorine compound. You can connect them together using special glue.

We purchase PVC products for pipelines

With all the wealth of choice, when purchasing PVC products for pipelines, it is necessary to consistently pay attention to the following technical and physical characteristics of the products.

- Pipe section. Different sections of sewer systems use pipes of different sections. So, to organize a drain from a bathtub, a pipe with a cross-section of 5 centimeters is suitable, but to connect the system to the main riser, a pipe with a cross-section of at least 10 centimeters is required.

Size chart for PVC-U sewer pipes

- Section length . The industry produces pipes with different section lengths. When drawing up a sewer system project, it is necessary to measure all distances. It is better if you have entire sections of pipes installed on straight sections without additional connections.

- Working environment . There may be corrosive liquids in your sewer system. This is, for example, important for small industries. In this case, it is imperative to compare the characteristics of the pipe with the possible composition of the wastewater.

- Durability . The low density of the pipe leads to the fact that it can sag over extended sections, especially when filled. Therefore, when installing such areas, it is necessary to use additional brackets.

PVC external sewerage pipe with socket, class C (SN8)

Important! Of no small importance is the exact correspondence of the declared markings on the pipe to their actual values. When purchasing polyvinyl chloride pipes, request a quality certificate. Also pay attention to how the items were transported before being sold. Transportation of PVC products for pipelines at low negative temperatures can lead to their damage even before installation.

How to install a 110 mm pipe

The laying of sewer pipes is determined according to a certain technology. Compliance with it ensures high-quality functioning of the sewerage system. During installation, certain features should be observed and certain nuances taken into account.

Slope of the sewer system

One of the most important parameters is the slope of sewer pipes. The drainage water should flow away easily and without any obstruction. The natural process of drainage requires the construction of some slope. According to the standard, the slope is 1 cm per 1 m of pipe. To arrange the slope, markings are first made, and then fasteners are installed in accordance with the markings. The marking is done using a level, preferably a laser. First, mark a horizontal line that runs level with the drain hole on the riser. Then it rises by a number that corresponds to the distance from the riser to the original drain point.

Connection process

An important and directly main factor in the quality arrangement of a sewer system is pipe connections. The process itself is simple, but there are some nuances that ensure the reliability and tightness of the joints. Negligence in this matter can lead to the following negative factors:

- leaks;

- unpleasant smell.

In order to prevent the defects listed above when connecting 110 mm pipes, sealing gaskets are used, which are available in several types: single-feather, double-feather and double-feather with a plastic ring. The installation of these gaskets is carried out with some differences, which should also be taken into account. For example, single-feather gaskets are usually installed, but when installing others, it is necessary to use a special lubricant. So, in order to correctly connect 110 mm sewer pipes:

- Insert the gasket into the socket. We make sure that distortions do not form. Also, you should first inspect the gasket so that it does not have any defects.

- As a lubricant, you can use available products: detergent, soap, Vaseline. The main thing is that these products do not negatively affect rubber gaskets and do not change their structure. It is difficult to predict this, so experts recommend using a specialized lubricant that is made on a silicone basis. Silicone itself cannot be used, as it is aggressive to rubber.

- After the seals are installed, all that remains is to connect the products together. During the work, we make sure that the joints are tight.

Sequence of connections

- The drainage system begins with a turntable fitting, to which a flexible corrugated hose is connected on the inside, and a 110 mm pipe on the outside. Many people don't use this element. Then in this case the tightness of this connection cannot be guaranteed.

- Don’t forget, when connecting the product to the fitting, a rubber gasket must be installed. We also monitor the planting depth.

- If it is necessary to arrange a branching sewer system, tee fittings are used. To change the diametrical cross-section in the sewer system, adapter fittings should be purchased.

- The last rule in the connection. All joints must be placed along the flow of water.

Master Class. How to cut PVC pipes

When installing PVC pipes (we will talk about this in more detail a little later), they will need to be cut. As noted above, this material is easily cut with various tools, which greatly simplifies working with it. You don't need complicated tools or special equipment. How to cut such pipes? Now we will tell you about it.

Option No1. Hacksaw for metal

Step 1. First, you need to clamp the pipe with a vice so that it does not move and you do not get hurt during cutting. If there is no vice, you can use another clamping device to secure the workpiece on the workbench. Use what you have on hand. It is also recommended to clamp the product a couple of centimeters from the future cut to ensure sufficient clearance.

Cutting with a hacksaw

Step 2. The location of the future cut is marked. Using a marker, you need to mark the place where the pipe will be cut. There is no need to worry that marks will remain after finishing the work - if visual appeal is so important, the ink can be easily removed with medical alcohol.

Step 3. Place the hacksaw on the mark and, pressing with one hand on the top of the tool, begin cutting. Try to immediately start cutting in the required place so that there are no unnecessary cuts left.

Step 4. During cutting, you must closely monitor the process, trying not to move away from the mark set at the beginning. You need to cut fairly quickly, but not so quickly that the teeth jump over the cut being made.

Option No2. Pipe cutter

Step 1. Pipe cutters for plastic pipes can be locking/scissor (the latter are suitable for products with a diameter of 10-25 millimeters).

Application of pipe cutter

Step 2. Install the product into the lower part of the tool, made in the shape of a crescent. It is first necessary to indicate the location of the future segment.

Step 3. Next, you need to press the trigger handle on the tool so that the blade comes out and cut the pipe. It is recommended to hold it with your other hand for greater stability. There is no point in overexerting yourself at this time.

Option No3. Miter saw

Step 1. If you need to make small specific cuts on a PVC pipe, you can use a miter box. Use a toothed saw, taking into account the availability of miter cuts and the type of cut.

Step 2. The pipe is installed at the required cut location. The main advantage of using a miter box is that you certainly won’t miss with it.

Step 3. Now you can cut the pipe, preferably pre-fixed. If required, other cuts can be made at other angles.

Note! Do not use a circular saw or band saw to cut pipes. The same goes for a regular wood hacksaw - its teeth are too sparsely spaced and therefore you will not be able to cut PVC properly.

Cost of PVC pipe products for sewerage

The price is directly affected by the dimensions of the PVC sewer pipe, such as its diameter. Also, the cost depends on the manufacturing company, the method of manufacturing pipe products and the area of application - for arranging an internal or external sewer system.

Recently, during the construction of wastewater disposal systems, modern sewer pipes made from polyvinyl chloride have begun to actively replace outdated cast iron and other metal products, which, due to their technical characteristics, cannot provide high performance indicators.

Most property owners prefer PVC pipe products primarily because their parameters are ideal for laying a high-quality and inexpensive sewer system that will serve for a long period.

How to install PVC sewer pipes

Perhaps the most important advantage of PVC pipes is the ability to install them yourself. This process is quite simple. As a result, even the services of third-party experts in installing such products are relatively inexpensive.

Shaped parts for PVC pipes have a wide range and include units of various configurations, angles of different degrees of bend, tees with bends, crosses and revisions, as well as transitions for their compatibility with other materials

In order to work with PVC pipes, you should prepare:

- pencil;

- silicone;

- roulette;

- saw for metal.

What you need for work

Step 1. First, a highway laying diagram is drawn up. Using a tape measure, the length of pipes required for work is measured, the measured places are indicated with a pencil. If all measurements have been made correctly, you can begin cutting PVC pipes (we described this in more detail above).

Pipe cutting

Pipe preparation

Step 2. First you need to assemble short nodes connecting the elements. Do not forget: the diameter of the pipes may vary depending on the specific operating conditions. For example, a diameter of 3.2 cm is intended for draining bidets and washing machines, 5 cm for sinks and bathtubs, and 10 cm for toilets and sewerage.

Assembling connections

First, short pipe joints are assembled

Step 3. When laying the sewer pipeline, special attention should be paid to the slope of the pipe. It is important that the slope of all pipes is directed towards the riser, that is, towards the common drain.

Laying a sewer pipeline

Step 4. PVC sewer pipes are installed in the wall, after which they are sealed with cement mortar. In addition, under washbasins and sinks it is necessary to install a siphon, the design of which includes an S-shaped section, which serves to create a water plug in the pipeline. This stopper will prevent unpleasant odors from entering the room.

Important! During installation, the pipe should fit into the socket of the connecting element approximately 2/3 of the length of the mounting socket, and without much effort. Next, it should move with greater effort.

Step 5. To make the connections as tight as possible, you need to use a special glue (it is also recommended to roughen the contact surfaces in advance). Once the glue is applied, you can put on the fitting.

Preparation for gluing

Scheme of direct installation of PVC pipes

Important! After installation is complete, fill the system with water (for example, by closing the main drain) and leave it under load for an hour to check for leaks. In order to fix the slightest drops, you can put pieces of toilet paper or paper napkins under the joints.

Installation of sewer PVC pipes is completed

Drying time of the compound

Sewage pipelines and connecting products made of polyvinyl chloride or PVC are step by step replacing traditional cast iron sewer pipes. This is due to their excellent technical characteristics and great ease of installation.

Rules for installing sewerage systems made of plastic pipes

There are several rules, the application of which in practice will make it possible to create a strong and reliable sewer system. When installing sewerage from plastic pipes, you should adhere to the following recommendations:

- Make a slope in the place where the pipe leaves the plumbing fixture. The slope angle depends on the purpose of the device and is on average 30 0.

- Avoid perpendicular joints. If the system turns by 90 0, it is better to make two turns of 45 0. A perpendicular joint is a potential source of clogging;

- Place the toilet as close to the riser as possible so that sewage immediately goes into the sewer;

- At branch points, install inspection fittings designed to clean the system in case of contamination;

- Do not leave pipes open. Plastic ones are a source of noise. This especially causes a lot of inconvenience to residents of apartment buildings. Such pipes should be placed in polystyrene foam, and then special boxes with windows in the places of inspection fittings should be built over them;

- Before installing connected pipes to the system, they should be checked for leaks, paying attention to the joints.

We recommend that you read: How to independently build a columnar foundation from PVC pipes - step-by-step instructions

PVC pressure and non-pressure pipes

There are two types of materials:

- polyvinyl chloride (PVC for sewerage);

- polyvinyl chloride, its service life is much longer, and in terms of characteristics it is more preferable.

Pressure products are manufactured using unplasticized polymer material. They are designed for different pressure levels: 1.24-4.14 MPa. Pipes of this type are used to organize the outflow of sewage systems, technical and household wastewater, and the transportation of drinking water. Main characteristics:

- resistance to corrosion, including electrolytic corrosion caused by stray currents;

- light weight;

- service life - about 50 years;

- due to the smoothness of the internal walls, the likelihood of clogging is reduced, the decrease in clearance occurs much more slowly than in the case of cast iron/steel products;

- high resistance to aggressive environments;

- heat resistance is +160…+170°С.

Non-pressure communications can withstand pressure of no more than 0.16 MPa. They do not tolerate exposure to temperatures above +45°C. Such products are presented in the following types: single-layer, three-layer. Unplasticized CPVC (chlorinated polyvinyl chloride) is used in production. Both pressure and non-pressure products are available with a socket, which allows you to create a more reliable connection.

The varieties under consideration are non-flammable. The main difference between PVC communications is that the thermal conductivity value is the same as that of insulating materials. This increases the efficiency of insulation. In addition, these types of products do not contain harmful substances, which helps to expand the scope of their application. During installation, it is recommended to use fittings made of the same material. As a result, the likelihood of compromising the integrity of the pipeline during linear expansion of polyvinyl chloride is significantly reduced.

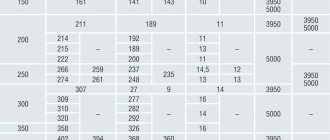

Dimensions and diameters

Communications are selected according to size, taking into account the intended purpose. Conversely, knowing the diameter, you can determine for what purpose this or that option is suitable. For example, an external PVC pipe (diameter - 200 mm) is used only for the installation of storm sewers, sewer pipelines, and culverts. Standard sizes of PVC drainage products: 160 mm, 200 mm. PVC 250 mm is often used. PVC products 50 mm are used when installing internal pipelines. PVC pipe sizes in the table:

| Diameter (D), mm | Ring stiffness (SN) | ||

| 2 | 4 | 8 | |

| Wall thickness, mm | |||

| 50 | — | 1,3 | 1,6 |

| 63 | — | 1,6 | 2,0 |

| 75 | — | 1,9 | 2,3 |

| 90 | — | 2,2 | 2,8 |

| 110 | — | 2,7 | 3,4 |

| 125 | — | 3,2 | 3,9 |

| 160 | 3,2 | 4,0 | 4,9 |

| 200 | 3,9 | 4,9 | 6,2 |

| 250 | 4,9 | 6,2 | 7,7 |

| 315 | 6,2 | 7,7 | 9,7 |

Products with a diameter of 32 mm, 63 mm, 75 mm, 90 mm, 100 mm are used less frequently than analogues 50 mm, 110 mm, 200 mm, 250 mm.

Features of installation work

If the installation of a sewer pipeline is carried out independently, which is quite realistic, then it is important to take into account some features of the work. These features include:

- Plastic products, depending on cast iron, are thinner and more fragile, so to provide additional protection it is recommended to place them in special boxes, casings or foam shells.

- When a pipe is connected to a socket, you need to chamfer the outside of the product that will be placed inside the socket. In this case, it is imperative to remove burrs in the internal cavity of the pipe to prevent the formation of blockages.

- To simplify the process of connecting two pipes, they resort to the use of lubricants: Solidol, Glycerin or Litol.

- The neck of the pipe is fixed with a clamp, since O-rings are not able to provide the necessary rigidity of the structure.

- Fixation of sewer pipelines in the room with clamps is carried out every 50 cm.

- It is recommended to install the external pipeline at a depth of at least 50-70 cm. The presence of a slope of such a pipeline will eliminate the occurrence of stagnation and clogging of the pipe.

- For increased loads, it is recommended to use corrugated sewer pipelines.

When connecting sewer pipelines, it is recommended to additionally coat the joints with waterproof sealants. This will eliminate not only the occurrence of leaks, but also an unpleasant odor in the room.

Plastic sewer products are characterized by efficiency, unlike their cast iron counterparts. If there is a need to repair the sewer system or build a new drain, then it is recommended to give preference to a new type of material for the construction - plastic.