More recently, choosing a sewer pipe was a simple task because it was limited by materials.

They produced only steel and cast iron. In addition, they all came in only 2 colors: gray and black. However, with the development of technology, there are much more of them. What they are made from, the most popular are:

- polypropylene;

- polyvinyl chloride;

- polyethylene.

This variety is very beneficial, but making your choice has become much more difficult. In addition, pipes began to be produced in different colors, which also complicates the choice in some way.

For example, a person who was faced with the need to replace a pipeline for the first time came to the store. Previously, he would have seen an ordinary gray pipe, but now he has a huge selection in front of him, and in different colors. What is the purpose of the extended color gamut?

Criterias of choice

The color division of pipes is used to simplify the choice of variety for certain operating conditions. So, when choosing, you should consider the following criteria:

- The place where the pipes will be laid is an apartment or a private house. Accordingly, the presence or absence of soil pressure is taken into account, which depends not only on its volume, but also on the future location on the surface of the road, vehicle parking, etc.

- Weather conditions in the current region, in terms of soil freezing depth.

- Operating temperature range.

Now let's look at the characteristics and purpose of pipes of different colors in order to easily cope with their choice.

Socket connection of sewer network

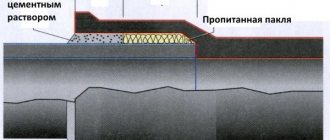

When laying a sewerage system, various methods of connecting pipes are used, one of which is a socket connection. The socket connection is a permanent type. The socket connection can be made in the following ways:

- By gluing;

- Welding.

The socket connection process must be carried out as follows:

- Clean the smooth end of one pipe and the socket of the other from dirt;

- Place a rubber ring on the connection point;

- Lubricate the connected parts with grease;

- Insert the smooth end of the pipe into the socket no further than the mounting mark.

In order to weld products, you will need special equipment. By welding, products can be joined end-to-end or in a socket.

Socket method for connecting sewer pipes

If necessary, it is possible to connect polymer products with parts of other materials using fittings. The following connection options are possible:

- With cast iron pipeline socket;

- With steel pipe socket;

- With ceramic pipe socket.

Today, manufacturers produce a wide range of sewage products. Pipes and fittings for them differ in color, material, method of application and installation method. And in order to make the right choice and decide which products are better, you need to carefully study all the nuances.

Gray pipes

They are used indoors, where there is no strong mechanical and temperature influence. The manufacturing material is polypropylene. Gray pipes are designed for the temperature of the liquid passed through them within 60-75 degrees. However, they can withstand a short-term increase in the indicator to 90-95 degrees. The external temperature should not fall below 0°.

They are characterized by chemical inertness: there are no corrosive processes and no release of harmful substances.

Since deformation occurs with a relatively small force - 50-75 kgf/m2, it is not recommended to install such pipes in places where external pressure will be exerted on them. Use for external sewerage is justified only by financial savings, which, however, may result in the need to dig a trench and replace the entire drain.

White pipes

Also used for indoor installation. Their properties do not differ from the previous variety. They have a more attractive appearance, so they can be laid in places where it is impossible to finish walls or floors to hide communications.

Distinctive features of white pipes are good thermal and noise insulation. Withstands liquid temperatures up to 95 degrees. The diameter ranges from 32 mm to 150 mm. The length of a single piece can range from 15 cm to 5 meters.

For ease of installation, manufacturers place a centimeter scale on the surface of the pipes, which simplifies the process of measuring the required dimensions.

Red pipes

Used to create sewerage outside the house. Manufacturing material – polyvinyl chloride. Such pipes are more durable, which varies depending on the class of the product:

- L – withstands loads up to 200 kgf/m2;

- N – up to 400 kgf/m2;

- S – up to 800 kgf/m2.

Another classification involves differences in wall thickness: pipes marked SN4 have a thickness of 3 mm, SN8 - 3.3 mm.

Orange pipes are not able to withstand the high temperature of the liquid passing through them. The operating range is 40-60 degrees. External exposure to negative temperatures does not affect the properties of the material.

Red pipes can withstand the weight of the soil if the laying depth does not exceed 2 meters. Placement under roads is not recommended, since there is a high probability of deformation, which will ultimately lead to the settling of solid components of wastewater and the formation of a blockage.

Significant disadvantages of polyvinyl chloride pipes include:

- They are destroyed under the influence of aggressive waste – acids or oil. If you plan to discharge such materials, you should pay attention to a separate class of uPVC product, distinguished by special properties.

- Elongation of material when exposed to high temperature.

They can be manufactured in the form of a smooth cylindrical pipe or corrugated pipe, which is characterized by higher strength.

How to make a sewer system silent

At the moment, the issue of noise insulation of sewer networks is very relevant. The sound of flowing water is transmitted through the material of the products. Despite all their advantages, modern types of materials have a significant drawback - they are very loud. This is explained by the fact that their wall thickness is much thinner than that of cast iron. Therefore, it can be determined that the occurrence of noise depends on:

- Type of material;

- Wall thickness;

- Distances between the wall and the pipe;

- Sound insulation qualities.

In order to reduce noise levels, the following measures must be taken:

- Install silent pipes;

- Make soundproofing;

- Secure the products with special clamps.

White sewer pipes

Silent products are distinguished by the following:

- The structure of the material;

- Wall thickness;

- Density.

Silent products for the sewer system are produced in white.

Today, silent products are the most modern way to absorb noise. They are made from high density mineralized polypropylene.

The only disadvantage of such products is their high price. To reduce noise, soundproofing materials and fastenings using rubber gaskets on clamps are also used.

Black pipes

They are made of polyethylene and are often used in the organization of urban sewerage, which must withstand significant volumes of passing liquid. A characteristic feature of black pipes is their diameter - this figure usually varies between 250-850 mm. However, there may also be wider pipes with increased cross-country ability.

Among the advantages are:

- resistance to possible water hammer;

- absence of corrosion processes upon contact with active substances;

- extended service life – from 50 years.

They are installed mainly at great depths - up to 15 meters. Strength is achieved due to corrugated walls, smooth on the inside. The temperature of the passing liquid should not exceed 60 degrees.

The second purpose of such pipes is protection for cables that are laid underground. There are also varieties used for drainage.

The cost of black pipes is relatively low, but the positive side is durability. Polyethylene is resistant to temperature changes and does not corrode. No special tools are required for installation, just a compression fitting.

What products are used for cable ducting

Cable sewerage is a network of underground channels that contain all types of wired communications (electrical and telephone cables). A flexible double-wall pipe for cable ducting is a modern way of installing wired communications. A flexible double-wall pipe for cable ducting is used to protect cables from atmospheric agents and mechanical damage. Flexible double-wall pipe for cable ducting has the following advantages:

- Smooth outer and inner walls;

- Elasticity;

- Chemical resistance;

- Light weight;

- Long service life;

- Easy installation.

Flexible double-wall pipe for cable ducting

The flexible double-wall pipe for cable ducting is manufactured in accordance with the requirements of regulatory documents from high-density and low-density polyethylene. Nowadays, a flexible double-wall pipe for cable ducting is one of the most popular products for laying communications. After all, repairs of networks using this pipeline can be carried out without destroying the road and digging trenches, but with the help of inspection devices.

Green pipes

Pipes used for drainage are painted green (sometimes blue). A distinctive feature is the ability to bend and withstand strong pressure from the soil settling on top.

Since the product is used in the external environment, the material can easily withstand temperature fluctuations, as well as its decrease to negative values. There may be perforations on the walls, which allows water to penetrate inside. Some manufacturers equip their products with a geotextile filter.

Let's summarize. Gray pipes are suitable for home use; if the sewage system goes into the ground, then in this place it is advisable to switch to orange pipes. Whites have the same properties as grays, but are more attractive in appearance. Black ones are larger in size and are used for laying city sewerage. Green ones are used for drainage.

When choosing pipes, the main attention should be paid to the material of manufacture and its properties. They must be suitable for future operating conditions, otherwise the service life of the products will be significantly reduced.

What role does the color of the parts play?

Sewerage components are made not only from different materials, but also in different colors. The color of the parts indicates their purpose. This distinction is necessary so that the consumer can better understand the wide range of manufactured products. The following pipes exist:

- Gray;

- Black;

- White;

- Orange;

- Green.

Gray pipe is the most common indoor use. The gray pipe is less durable, so it cannot be used for external sewerage. During installation, the gray pipe is attached to the wall. Orange is more rigid and therefore can withstand greater loads. It is used for laying networks underground. White is used where gray would not look aesthetically pleasing, and also as sound insulation.

Black products are also used for sewerage installations. They are made of LDPE and are designed for protection when laying cables, as well as for drainage.

Sewer pipes of various colors

Therefore, when laying sewers, in order to decide which products are better, it is necessary to take into account their purpose. With the correct selection of products and their intended use, the sewer system will last a long time.