When starting to install decorative fabric or PVC cladding on the ceiling, you need to be prepared to deal with the most unusual situations. For example, you will need to make a transition around a decorative column, or bypass a pipe with a suspended ceiling. And although such tasks are usually not new to an experienced craftsman, for most amateurs and novice specialists the problem may seem too complicated to try to do the work with their own hands.

The main thing is to accurately transfer the markings onto the panel

How to bypass a pipe with a suspended ceiling: possible methods

Almost all rooms of the apartment, with the possible exception of the hallway, have vertical pipes crossing the space from ceiling to floor. This could be a heating system riser, sewer or water pipe. This is not the point; any pipe is located at some distance from the wall, which means it interferes with securing the edge of the tension fabric to the frame.

It is impossible to cut the canvas or film in order to insert the material behind the pipe; firstly, this may result in the fabric breaking, and secondly, cracks will appear around the riser, significantly spoiling the appearance of the finish.

There are three ways to solve the problem:

- Use a ceiling box, that is, add a suspended box-shaped structure made of plasterboard to a conventional suspended ceiling, with the help of which it is easy to build a pipe passage unit through a rigid plasterboard sheet;

- Use a pipe bypass kit, which is usually offered by the manager as part of the fittings for suspended ceilings;

- Make your own plastic cover or ring, with which you can close the cut in the stretch ceiling or mask the cracks.

Homemade part for wrapping the film

The latter option is usually used for bypassing on non-standard stretch fabrics made of PVC film.

Important! The presence of a pattern on the surface of the stretch ceiling and unusual colors of the panel make the use of a standard set of white color pointless. A white spot attracts attention and spoils the appearance of the decorative ceiling.

Therefore, for colored ceilings, they use bypass elements made of transparent polyvinyl chloride, or make decorative overlays themselves. To disguise the bypass unit, just stick a piece of ceiling film onto the front part of the plastic trim.

A piece of white plastic covered with PVC film

Pipe bypass fittings

The standard element of the passage through a suspended ceiling of any risers is a part consisting of two rings connected by a split lintel. One element can be used to bypass a package of two pipes, if, of course, the distance from the wall to the cut point of the film allows.

PVC cover with split “leg”

A ring with a double split “leg” is glued to the canvas, and thereby fixes the location of the cut, compensates for the forces and prevents the cut line from spreading further along the surface of the stretch ceiling.

If the distance from the baguette to the pipe is just a few millimeters, then you can use a split decorative overlay to bypass it, as in the photo. In this case, the cut on the tension fabric and the harpoon is sealed with a piece of film, and the line itself is masked with an overlay element.

The nozzle closes the cut in the film

The most desperate craftsmen use a heat shrink ring to bypass the pipe. They are used to bypass heating pipes, the temperature of which can reach 60-70o. In this case, the joint line is welded or glued with a piece of fabric laid on the back side of the tension ceiling cladding.

Equipment and materials

You can mark the location of the cut with a marker or pencil - the accuracy of the work does not depend on this. The main thing is that the lines are drawn as accurately and evenly as possible. The most convenient way to measure distances is with a tape measure. In addition, you need to prepare the following:

- High quality glue. It should be such that contact with it does not damage the film and fabric.

- Sharp scissors or utility knife. The sharper the object, the better: the accuracy of the cut depends on this.

- Thermal insulation strips made of plastic. They come in different diameters and are inexpensive. If you don’t want to or can’t buy them, you can make them yourself. The planks make it easier to create an opening.

- Plastic bypasses for pipe products or mounting for a lamp. What exactly depends on the purpose for which the hole is cut.

When you can do without lining a pipe with a suspended ceiling

The use of a plasterboard box significantly complicates the design of the ceiling finish, but, on the other hand, the absence of cuts and bypass elements is a guarantee of the durability of the canvas or film on the ceiling.

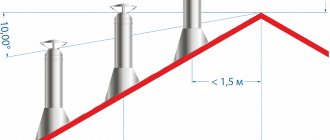

It is not necessary to build a box 10-20 cm in size; usually the heating pipes passing through the ceilings in the apartment are 5-6 cm away from the walls. In order not to use a bypass unit, it is enough to lay the supporting profile on a wooden beam or supporting U-profile , sewn around the perimeter of the walls of the room.

Passage through ceiling curb

In this case, the pipe will be behind the baguette; you will only need to hem the lower part of the beam with strips of plasterboard or cover it with polyurethane ceiling borders.

Important! Sometimes you need to install an exhaust duct or a pipe from a gas water heater. In this case, there is no need to cut the film or fabric from the point of passage to the edge. It is enough to glue a heat-shrinkable ring with a diameter slightly larger than the outer size of the casing and install the pipe in the hole. Moreover, this can be done after installing suspended ceilings.

Preparatory work

Installation of equipment requires a level base. Therefore, first of all you will need to level the floor. There are many ways, the choice depends on the design and material of the building, as well as on the desired speed of work:

- A traditional wet screed allows you to get a perfectly flat base, but it dries within 28 days. If the screed has already been poured, it can be leveled with construction self-leveling compounds.

To level the walls, use plaster, plasterboard or CSP boards.

How to bypass the pipe when installing a stretch ceiling

The simplest and most affordable way to solve a pipe problem is to use a standard kit, materials and bypass technology. Any home-made options not only do not provide a guarantee, but also an additional risk:

- The quality of seam connection using a non-standard method is unknown and can often lead to irreparable damage to the tension fabric;

- The longevity of the pipe bypass assembly is unknown.

Therefore, first of all, it is important to buy only proven materials, and the assembly principle, which allows you to bypass the pipe with a suspended ceiling, is outlined in the video.

For your information! If there were simple and universal methods for constructing a bypass, then manufacturers of suspended ceilings would have used them in practice long ago.

Required tools and materials

In order to assemble the unit, in addition to the standard set used for assembling suspended ceilings, it is necessary to purchase additional tools, fittings and consumables:

- Construction tape;

- Marker;

- Overlays for constructing a pipe bypass;

- An adhesive specially designed for repairing and gluing PVC sheets or films;

- Stretch ceiling trims;

- Stationery knife.

Installation of the unit is carried out while attaching the canvas or film to the frame, so an assistant is needed who would use a heat gun to heat part of the film in close proximity to the pipes while the second worker installs the bypass.

Technique for wrapping a stretch ceiling around a pipe

The technique to bypass the obstacle on the ceiling is as follows. Initially, you need to measure the distance from the nearest landmark with a tape measure, for example, from the side profile to the pipes.

This is necessary in order to transfer the markings to the prepared tension panel and glue the contour strip on the back side. The glue dries quickly, so after 10-15 minutes you can begin installing the decor on the ceiling. The length of the leg of the lining is selected such that the edge does not reach the harpoon by 2-3 mm.

After gluing the ring, the harpoon is cut to the center of the hole

Next comes the most difficult part: you need to place the tension fabric so that the marking line is located exactly opposite the riser. The film is fixed, heated, stretched on the frame with the harpoon embedded in the profile locks. An area 20-25 cm wide, located opposite the pipe, remains unsecured on the baguette.

All that remains is to make a direct bypass of the pipe:

- Warm up the stretch fabric;

- Cut the film along the inner line on the leg of the bypass element;

- Insert the pipe into the cut, tighten the edges and secure them to the baguette.

To prevent the cut line from coming apart, the film along the harpoon is additionally glued on the back side with a piece of PVC fabric.

The cut must be sealed

This way you can bypass any pipes. If the diameter of the riser is slightly smaller than the internal size of the lining, a gap will appear. To close them, a split ring made of PVC plastic is glued over the bypass assembly.

What you need

Before work you need to prepare:

- stepladder;

- sharp knife;

- glue "Cosmofen";

- roulette;

- calipers;

- pencil;

- ready-made outline or plastic for homemade (sheet 1-3 mm thick);

- sandpaper;

- an additional piece of fabric to strengthen the film.

Difficulties of pipe bypass on suspended ceilings

The main problems arise with marking the place and sticking the contour strip. The easiest way to do this is before installing the tension fabric on the ceiling. It is very difficult to position the material on the frame so that the glued overlay exactly matches the line on the wall. If you manage to combine two points, you are guaranteed to get a good result. But this technique is only available to experienced craftsmen, or if there is only one riser in the room.

Sometimes you have to cut the film and glue the lining after installing the ceiling

Therefore, they often do it in the opposite way. First, the fabric or film is heated and stretched onto the frame, leaving the area near the pipe unsecured.

Next, stretching the material, determine the cut point, glue the edge strip on the front side, cut the film and insert the pipe into the cut. All other operations are performed as in the previous case. The probability of success is 60%, but only if a partner heated the PVC to the required temperature while the strip was being glued and the riser was inserted into the resulting hole. In this case, it is very difficult to guess how and how much to heat; everything is decided by the experience and professional skills of the workers.

To simplify the tracing process, the strip has to be glued from the front part of the canvas. Experienced tilers can glue a bypass element on the back and front sides in a couple of minutes. This is not a whim; you have to resort to a similar solution if a fold forms on the cut line, or the cut itself spreads to the sides.

Holes for ceiling lights

When installing a stretch ceiling, you need to take care of creating holes for lamps. It is better to calculate how many there will be in advance, because after installing the canvas it will be more difficult to cut holes. The work is not as difficult and tedious as it might seem, the main thing is to do everything according to the instructions, following the sequence.

If the hole for the chandelier was not made in advance , it can be cut out on a stretched fabric, but this will be less convenient. There are two ways. The first is used when you need to remove an additional lighting fixture. The canvas must be completely dismantled, and embedded elements must be installed in those places where lighting devices will be located.

The places that coincide with the lamps are marked on the PVC film. Glue rings cut out of plastic, wait until the glue dries, then make holes. Straighten the fabric and stretch it. Lighting fixtures are fixed to the mortgages.

There are chandeliers that are attached to special hooks. To install them, the ceiling does not need to be removed. The work is done like this: a plastic circle is glued to the place where the chandelier is fixed. Wait until the glue dries well. Make a round hole. Using a hammer drill or dowel, make a hole for the hook and secure it.

Errors when circling pipes on suspended ceilings: photos

The most common mistake is related to incorrect marking of the space for the holes for the pipe. Most often, when determining the center of the future hole, the canvas is stretched too much. After cooling, the PVC shrinkage increases and a hole appears between the wall and the pipe.

Film rupture due to material overstretching

The second problem is related to the insufficiently strong adhesive connection. You have to quickly attach the contour strip to the stretch ceiling; the glue does not apply evenly, so the strip may even fall off the panel.

A sign of such a defect is the formation of folds and ruffles. We have to heat the stretch ceiling in a new way, remove the edge with the harpoon from the baguette, and glue the bypass from the front side. If this does not help, then you can close the damaged area using a plastic insert and a ceiling plinth.

In what cases can the canvas not be cut?

Sometimes you don’t need to do a tension contour; cutting the blade in this case is not necessary. Pipes that are located at window openings can be easily hidden by making a hidden baguette. In this case, the canvas will not need to be brought to the external wall, and cutting of the material will be avoided.

If a bypass of ventilation pipes or hoods is required, you can install a protective ring of suitable size. Large fixed pipes can be bypassed by joining the sheets. Another option is to use extra baguettes.

Installation Features

To ensure thermal insulation of suspended ceilings from a heated surface, plastic rings are used. They can be both hidden and external. The first option has a more attractive appearance, but if it is located close to the wall, installing it will be problematic. Therefore, in such cases, decorative overlays are used, which press the canvas and can partially hide small defects. In both cases, the fastening can be done either with a harpoon or without a harpoon.

Small embeds for piping

Installing a hidden mount

As with external installation, the canvas is first stretched around the perimeter. Then a marker is made at the location where the pipe passes. After this, a cut is made crosswise, the edges are coated with glue, a ring is put on the back side and they are glued. A harpoon is glued along the cut line along the edges. The canvas is mounted around the perimeter, a ring is put on the pipe, then the seam is tightly fastened, the final stretching and fixation of the canvas is carried out. This option is good because with complex decorative colors there is no need to select suitable external fastening elements and the joint location will not be very noticeable.

Installation of embeds