Vinyl plastic material is a modified polyvinyl chloride. It is made by mixing polymer resins, dyes, stabilizers and lubricants.

Vinyl plastic products

Its increased resistance to environmental aggressiveness makes it possible to use vinyl plastic products in various fields of activity. Manufacturers have learned to make high-quality, reliable and durable vinyl plastic pipes.

Vinyl plastic pipes

Advantages and disadvantages of vinyl plastic

The main advantages of the material include the following:

- very plastic, does not collapse in case of small deformations;

- resistant to acid, alkali and other aggressive chemical compounds;

- no hazardous chemicals are released when heated;

- does not allow electricity to pass through;

- durable and fire resistant;

- technologically advanced and easy to process, therefore widely used in industry;

The possibility of connecting products in several ways is attractive: gluing, welding, drilling holes. Easily welded with electrodes designed for working with metal.

Pipe installation

Like any material, vinyl plastic also has disadvantages. But they rather relate to its features and operating conditions:

- Unresistant to aromatic hydrocarbons, highly concentrated nitric acid, solvents and essential substances.

- Impossibility of storing products in open spaces. And also, at temperatures exceeding 35 degrees and near heating devices.

- If vinyl plastic was transported at high temperatures, it is important to keep it for a day at 20 degrees.

Application area

Viniplast is especially widely used in the construction of process pipelines, which is explained by its resistance to such chemicals as:

- Acids;

- Alkalis;

- Solvents;

- Salt.

However, in addition to process pipelines, it is also often used for the following purposes:

| When laying electrical networks | As cable channels |

| When installing ventilation systems | As exhaust shafts and ducts |

| When installing sewers | Both in gravity and pressure systems |

| When installing cold water supply | As an internal water supply |

Pipes for external sewerage

Types of vinyl plastic pipes

The variety of their types allows you to choose the right products for specific jobs. There are these types:

- single-layer;

- two-layer;

- smooth;

- corrugated;

Corrugated double-layer pipes

- hard;

- flexible.

Depending on where the pipes need to be used, they are selected. GOST 28117-89 provides for two types of pipes: with a socket and without a socket. The sockets are made with the addition of O-rings or joined with glue.

Bells with elastic band

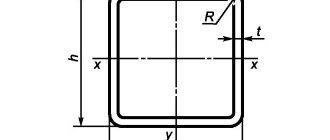

Pno fp , (1)

where Pnom—nominal pressure, MPa; d— outer diameter of pipes, mm; sgdop - permissible stress calculated for transporting water at a temperature of 20°C, MPa.

Calculated pipe wall thickness values are rounded up to 0.1 mm; values less than 0.005 mm are not taken into account when rounding.

5. Permissible deviations of the average diameter (Ad) and wall thickness (AS) in millimeters are calculated using the formulas:

The calculated values of Ad and AS are rounded up to the nearest 0.1 mm.

6. Indicated in table. 1 and 2, the masses of the pipes are calculated based on the average density of uPVC equal to 1.4 g/cm 3 at a temperature of 20 ° C, taking into account half the tolerance for wall thickness.

Weight values are for reference only.

7. Working pressures for pipes of types 100 and 125 individual rows are selected according to table. 3.

Allowable operating pressure, MPa, no more, for pipes

8. An example of a symbol for a pipe made of uPVC type 100, row 4, with an outer diameter d=160 mm and a wall thickness S=7.7 mm:

PVC-U pipe 100—160×7.7 GOST 28117—89

1. INTRODUCED by the USSR Ministry of Chemical Industry

Yu. B. Zimin, I. V. Gvozdev, V. S. Thay, L. I. Tugova, N. B. Galiullina

3. By Decree of the USSR State Committee on Standards dated April 24, 1989 No. 1072, standard of the Council for Mutual Economic Assistance ST CMEA 6220-88 “Pipes made of unplasticized polyvinyl chloride. Types and assortment" was put into effect directly as a state standard of the USSR on July 1, 1990.

4. Inspection frequency - 6 years.

b. The standard includes international standards ISO 161/1-78, AND SO 3606-76.

Editor N. P. Shchukina Technical editor M. I. Maksimova Proofreader M. S. Kabashova

Order "Badge of Honor" Publishing house of standards, 123557, Moscow, GSP, Novopresnensky lane, 3 Type. "Moscow Printer". Moscow, Lyalin Lev.. 6. Zak. 678

Source

Technical characteristics of vinyl plastic pipes

There are different types of vinyl plastic pipes, which vary in size. The diameter is 16, 25, 32, 40, 50 mm. All products are manufactured in accordance with the relevant GOST standards, for example, GOST 28117.

Depending on the parameters, pipes have different purposes and characteristics.

Vinyl plastic pipe is used for electrical wiring, pipelines, ventilation ducts and exhaust shafts. They also construct water supply pipelines for houses and other buildings.

To make wiring for ventilation, work with elements of 16, 25, 32 mm. Or use a 50 mm vinyl plastic pipe. Ventilation products must have the following qualities: resistance to fire and lack of electrical conductivity. Vinyl plastic has these qualities without a doubt.

Corrugated parts are used to lay cables in the ground. And for work with premises, more aesthetic types of insulation are chosen. To mount the gasket, a 25 mm vinyl plastic pipe is used. or 50 mm. According to their technical characteristics, these materials are quite effective for such purposes.

Cable tension

Connection diagram of the cable on the drum to the traction rope:

Note that this device has a dynamometer that monitors the pulling force. The maximum permissible forces for XLPE cables can be taken from the tables:

Technical characteristics for cross-linked polyethylene cables for 6-10kv, 20kv, 35kv, 110kv, 220kv.

In modern installation organizations, traction winches equipped with a minicomputer are used for installation, which automatically controls the tension and draws up a cable pulling protocol.

This protocol indicates the tensile force, speed and other installation data. The protocol is included in the passport of any PPE cable line.

On complex routes, with long lengths, a pull-up device is widely used. The cable passes through it.

Such a device must operate synchronously with the traction winch. This is achieved by connecting their control circuits to each other.

Manufacturing of sewers

For work with sewers, vinyl plastic P 51613-2000 is used. Since sewer wiring must have the following qualities:

- elongation of the material when heated is more than five percent;

- avoiding softening at 78 degrees;

- smooth both internal and external surfaces of the elements.

The requirements for gravity sewerage are different. To build a sewer system in a private house, they work with corrugated products. Despite the fact that according to the State Standard it is prohibited to use materials with a corrugated surface for such work. To build a gravity system, you need a pipe size that matches the amount of water consumed.

Sewer wiring is resistant to rust, chemical deposits inside, lime, etc. It will not be damaged by mechanical stress or high humidity. Connections with sockets are also used for installing sewer systems.

Cable grip

To grip the end of the cable when pulling, you can use two devices:

stocking made of steel wires

wedge grip

The wedge grip clings to the exposed current-carrying conductor. Laying cables in pipes using it is prohibited. The fact is that there are often residual water in the pipes.

They appear there as a result of leaching, after punctures underground.

In addition, in rainy weather, it is also prohibited to pull the XLPE cable using a wedge grip.

Therefore, in 90% of cases a stocking is used. First, a mouthguard is installed on the end of the contact line, and only then the stocking itself is put on it.

Several turns of bandages are applied over the stocking. Bandages are made with either copper or steel (not magnetic) wire. Number of bandages – minimum 5 pcs.

When pulled, several of them may break. The rest must keep the stocking taut. Put less, they will all break and your cable may get stuck in the middle of the pipe when laying it.

You'll have to pull it back, drag the cable and start all over again.

There are special stockings designed to be attached simultaneously to three single-phase cables. True, you should be able to pull three phases of the XPE at the same time.

The rule limiting such installation is no more than two turns along the route, with an angle of a maximum of 30 degrees.

Intermediate stockings are also available. They are a detachable mesh that is superimposed on the cable. Next, all this is fastened with a cable woven into this mesh.

This fastening grip can be placed anywhere on the cable without the risk of damaging it. This is used to install an auxiliary winch in the middle of the cable line, in order to comply with the permissible traction forces.

Installation of water pipelines

To supply buildings with water, vinyl plastic is also used. It is strictly permissible to use it when installing cold water pipes. The diameter of the conductor is selected taking into account the number of consumers and the amount of water consumed on the site.

To make a plumbing liner, use a diameter of 16 mm. The piping system must be sealed. It is built in by “cold welding” or a low-temperature soldering iron.

POLYVINYL CHLORIDE

GOST 28117-89 (ST SEV 6220 - 88)

USSR STATE COMMITTEE ON STANDARDS

UDC 678.5-462:006.354 Group L27

STATE STANDARD OF THE USSR UNION

PIPES MADE FROM UNPLASTIFIED POLYVINYL CHLORIDE

Unplasticized polyviny Icfi ioride pipes. Types ana assortment

Validity period e 01.07.90 to 01.07.97

Failure to comply with the standard is punishable by law

This standard applies to round pipes manufactured by screw extrusion from unplasticized polyvinyl chloride (UPVC).

1. PVC-U pipes are made of two types:

type 100 - with permissible stress used to calculate the wall thickness of pipes Odop^10.0 MPa;

type 125 - with the permissible stress used to calculate the pipe wall thickness oД0П=12.5 MPa.

2. PVC-U pipes are manufactured in the following series:

row 1 - pipes, 0.16 MPa (Yanom 1.6);

row 2 - pipes, 0.4 MPa (Yanom 4);

row 3 - pipes, 0.6 MPa (Yanom 6);

row 4 - pipes, 1.0 MPa (Rnom 10);

row 5 - pipes, 1.6 MPa (Moat 16);

1.6 MPa (Rnom 16) with a wall thickness increased by 1.5 times compared to the wall thickness of row 5 pipes.

3. The range of pipes type 100 is given in table. 1, assortment of pipes type 125 - in table. 2.

Reproduction prohibited (g) Standards Publishing House, 19&>

Allowed ogg-KVBone&tte A 5, mm

* The wall thickness is taken to be greater than the thickness calculated using formula I.

** Permissible deviation of the average outer diameter, determined by measuring the perimeter or as the arithmetic mean of the results of two measurements of outer diameters perpendicular to each other.

GOST 28117-89 (ST SEV 6220-88) P. 4

Permissible deviation* Ad, mm

Permissible deviation A 5, mm

Permissible deviation AS, mm

Permissible deviation AS, mm

* Permissible deviation of the average outer diameter, determined by measuring the perimeter or as the arithmetic mean of the results of two measurements of outer diameters perpendicular to each other.

5 GOST 28117-89 (ST SEV 6220-88)

4. The pipe wall thickness (S) in millimeters is calculated using the formula

Recommendations for choosing material

The material is transported packed in bags weighing no more than two tons. And they sell products in lengths from 4 to 12 meters.

If you decide to install a water supply or sewer system on the site yourself, you will have to purchase the material for the work. The first step is to study the purpose of each diameter and the scope of application of the corresponding types of pipes. Please consult with a knowledgeable person or the seller first.

Upon inspection, the products must be free of damage and creases. Pipes, except corrugated ones, must be smooth, without roughness or abrasions. Minor waves or streaks are allowed.

Be sure to ask for a certificate of conformity for vinyl parts. You can also inquire about the sanitary and epidemiological certificate for the product. The information contained in these documents confirms the quality of the products and their compliance with GOST.

Peculiarities

In terms of its properties, such a material is very rigid and opaque, made from a polymer mass, without the use of plasticizers.

It is based on vinyl resins and polyvinyl chloride. At the same time, to impart the necessary physical properties, antioxidants, heat stabilizers, as well as various coloring pigments and light stabilizers are added to the composition.

Thus, thanks to stabilizers, it was possible to achieve resistance of the material to various influences during its operation. And the addition of coloring pigments makes it possible to give finished products any desired color.

This material is considered to be non-plasticized polyvinyl chloride, but it contains a small amount of plasticizers. The maximum amount of this substance for the entire volume is no more than 10%. Also, this material adheres perfectly to various surfaces, from wood to concrete or even metal.

Due to the specific composition of the material used, the finished vinyl plastic pipe has excellent resistance not only to high temperatures, but also to various acids and alkalis.

In addition, the product is non-flammable, and its welding requires a temperature of over 250˚C. Such parts also adhere perfectly to each other, and as a result, a joint is formed whose strength is only slightly inferior to the overall strength of the product.

It is very common to use vinyl plastic pipes for:

- laying electrical wiring;

- creating ventilation;

- arrangement of water supply or sewerage.