Many home craftsmen are interested in how to measure the diameter of a pipe.

After all, when troubleshooting problems in a water supply or drainage network, you often have to replace pipes with new ones or repair old ones. This is required not only for the listed systems, but also when installing a gas system or chimney. Professional craftsmen know well how to select assortment sizes for a water supply system, or any other system.

When repairing a water supply or sewer system, it is necessary to accurately determine the diameter of the line.

Metric and inch units

Before measuring the size of the assortment, you should take into account that the technological features of laying and carrying out calculations when working with steel and plastic lines are different.

For this reason, it is necessary to first gain an understanding of the standard sizes of pipe-rolling materials for pipelines, and only then measure them. Without this knowledge, it is impossible to determine the size of the assortment in millimeters or inches.

Rolled steel pipes are primarily determined by their internal volume, measured in inches. In accordance with these units, you can find the names “inch” and “half-inch” pipe materials. One inch is equal to 25.4 mm, and half of it is correspondingly defined as 12.7 mm.

Plumbing fixtures are in no hurry to measure the outer diameter. Often installation can be done without it. It is necessary to measure this value in cases where it is necessary to measure a pipeline fastened with joints on a threaded connection.

It is usually cut on the outer part of the tubular product, and its size depends on the dimensions of the wall of the tubular product. During these actions, you should remember that if you measure pipes with different internal volume indicators, the wall size will be different.

To make it easier to measure and calculate the amount of materials needed for a pipeline, you can use a special thread system to indicate the external volume of pipe products. These values differ from the usual indicator, which can be measured in mm.

To correctly determine the size of pipe products in millimeters or find out their dimensions in inches, you need to take into account the following information.

For example, if the diameter of the metric thread knurling is designated M16, then the tubular product has an outer volume of 16 mm. In the version with pipe threads, all this is different. In inches these calculations are slightly different.

The outside diameter of a half-inch product does not reach 21 millimeters, and its thread knurling is the same in size. And this product gets its name “half-inch” because of the volume inside. In inches this value is denoted - ½. To make it easier to convert inches to mm, it is recommended to use special tables.

Ways to measure external and internal volume

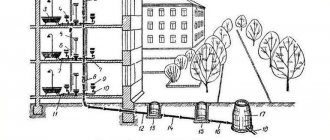

Before you start working and find out how the diameter is measured, you will have to establish exactly what volume is needed for a specific task. All pipes for any pipelines are measured and classified according to their internal diameter. It is called “conditional passage” because it is responsible for the network’s throughput capabilities.

If the internal diameter is measured, it is designated Dу, and the external diameter is designated Dн. The wall thickness is indicated as h. With these designations it is convenient to measure and perform calculations, and draw up projects of various highways for residential and industrial buildings.

As for the methods for measuring the volume size of pipe products, the first thing that is important to note is the difference in their features depending on the conditions. They must be taken into account, otherwise many mistakes can be made.

Determining the choice of one or another option depends on how accessible the object being measured is located. Now about some of the methods in more detail.

What tool do you need for each method?

Before choosing the diameter of a heating pipe, or any other system, you need to know what is used in such situations.

well-known caliper is used more often for measurement than other tools. But, it may not be among the set of home tools. Therefore, we have to solve the question of how to measure the diameter of a pipe without a caliper.

It is also not possible to find out the exact dimensions of a product with a large diameter for heating or water supply using this device. In such situations, it is possible to measure the required length of the volume of the tubular product using simpler devices:

- flexible ruler;

- tape measure;

- knowledge of the value of Pi, which is 3.14.

If access to the network is not difficult, a better option for calculating the value would be a tape measure or a metal ruler. But, with a hard ruler it is easy to calculate the size of only the end parts of the line that is being measured.

Watch the video

How to measure the diameter of the riser

Another option for measuring the circumference of a pipe inside or outside is the copying method. In such a situation, for example, a ruler is brought to the pipe. This section of the highway is then photographed. Further measurements in order to obtain the entire set of necessary information should be taken from the photograph. Figures that correspond to reality are obtained after scaling the photographs taken.

In addition, you can find the diameter using the following formula:

D = L:3.14.

In it, D indicates the diameter, and L is the circumference of the tubular product. In a simple example it looks like this. The circumference of the pipe is 62.8 cm. This number is divided by 3.14. The result is 200 mm.

It's not just home plumbers who work with this formula. It is also used in production conditions, only in this case there is a slight amendment. The formula for the work remains in the same form, only the double thickness of the tape measure and the value of 0.2 are subtracted from the final result. This number includes a correction for the adherence of the tape measure to the surface of the highway.

Circle and circumference

A circle is a set of points that are located at equal distances from the main point - the center. This distance is called the radius.

The distance between two points on a given line is called a chord. In addition, if a chord passes through the main point (center), then it is called a diameter.

Now let's look at what a circle is. The set of all points that are inside the outline is called a circle.

How to measure using a ruler or tape measure

Before you measure the diameter of the pipe with a tape measure or a flexible ruler, you should know that this option is simple, and this task will be feasible even for inexperienced craftsmen. Here you only need to take one measurement.

It is necessary to measure the circumference of the pipeline. The resulting value is divided by the value of Pi. To measure and get more accurate numbers, you should use not 3.14, but 3.1416. But, for the task of finding the outer diameter of a pipe with a large volume, a ruler will not be enough. You will need to take a tape measure to work.

To determine the volume of a pipe, they also use the method of measuring the dimension of the wall at the cut. This can be measured with the same instruments. It is also possible to use a caliper. The wall thickness indicator is subtracted from the dimensional indicator of the volume outside.

When installing highways, it is important to know that to determine the internal volume of the assortment imported to us, it is necessary to determine that it is supplied with accompanying documentation.

Watch the video

How to measure the diameter of a pipe?

It indicates the internal volume in inches. To convert internal or external dimensions to centimeters, they need to be multiplied by 2.54. For a similar conversion of the internal and external diameters back, you should multiply the indicator by 0.398.

Below is another interesting way.

How to measure with a caliper

If you ask a professional plumber how to measure with a caliper, the answer to this question will be as follows: “a caliper for such actions is the most convenient device, and you can use it to measure the required dimension very easily without making additional calculations. But only pipes with dimensions up to fifteen centimeters can be measured in this way.”

You need to press the jaws of the device firmly against the wall of the assortment, but it is not recommended to apply much force. Then you can measure and determine the dimensions in centimeters, and, if necessary, in millimeters.

Also, using a caliper, you can measure and determine the size of the end part. If this part of the highway is located in a hard-to-reach place, and the connection here is permanent, then this device will even come in handy.

But, the length of its legs should not be more than half the volume of the pipeline. To determine the measurement, the measuring device is applied to the pipe at its widest point.

Watch the video

Measurement with caliper ShTs-1

Before determining the diameter of a steel pipe using this method, you should remember that experienced craftsmen recommend using only a high-quality device for work. Only he can guarantee accurate sizing.

How to measure with a micrometer

If the diameter of a metal or any other pipe is determined, then each measurement can be made with high accuracy (up to 0.01 mm) using a micrometer.

In appearance, the device resembles a bracket. On one side there is a heel - a support, and on the other there is a stem and a high-precision thread equipped with a microscrew. The microscrew contains a metric scale. To find out how to find the volume indicator of the assortment using a micrometer on a metal or other pipe, you need to place the part between the heel and the end, then start rotating the screw.

Continue until 3 clicks are heard. Next, you need to find the readings on the stem, where there is a scale in millimeters, and the data from the second scale of the device (these are hundredths of a millimeter) are added to the obtained figures. The sum of these two indicators determines the required value. And, as you can see, finding it is not at all difficult.

Micrometers equipped with an electronic digital readout function allow you to most correctly measure the diameter of a pipe. They are the most convenient to work with and allow you to determine the result with an accuracy of 0.001mm. If the battery in such a device runs out, you can measure it with it, just like with a regular micrometer.

The only disadvantage in this case is the high cost of the devices, which is not always acceptable for a home craftsman. Therefore, in order to correctly measure at home, such devices are used extremely rarely.

Laser sensors

The diameter of a metal or any other round pipe can be measured using scanning laser sensors. How is the pipe diameter determined by these devices? Everything is simple here.

Such devices consist of a receiver and a receiver. These devices use a plane of light produced by a laser, which is deflected by a rotating prism and directed through a lens.

In the receiver, the laser is focused on the diode. It takes time for the laser to pass through a metal or other system.

What is circumference?

After we have covered all the definitions, we can calculate the diameter of a circle. The formula will be discussed a little later.

First, we will try to measure the length of the outline of the glass. To do this, we will wrap it with thread, then measure it with a ruler and find out the approximate length of the imaginary line around the glass. Because the size depends on the correct measurement of the item, and this method is not reliable. But nevertheless, it is quite possible to make accurate measurements.

To do this, let us again remember the wheel. We have repeatedly seen that if you increase the spoke in the wheel (radius), the length of the wheel rim (circumference) will also increase. And also, as the radius of the circle decreases, the length of the rim also decreases.

If we carefully follow these changes, we will see that the length of an imaginary circular line is proportional to its radius. And this number is constant. Next, let's look at how the diameter of a circle is determined: the formula for this will be used in the example below. And let's look at it step by step.