If your installation work has reached such objects as pipes, then the question of their fastening both to each other and to the surface inadvertently arises. The solution to this issue lies in ordinary products that are specifically designed for these purposes - clamps. With their help, you can not only connect pipes to each other, but also mount them in the ceiling, on the floor and even to the wall. In our article you can see photos of pipe fasteners.

Factors for choosing mounts

The most important criterion determining the choice of the owner or master is the type of pipeline itself.

How to choose pipe fasteners:

- The material from which the main parts are made. Plastic pipes will require better fasteners to prevent damage to the outer coating. But metal, cast iron (especially in old houses), and asbestos-cement pipes can also be used to furnish a home and private yard.

- Pipeline location (on the surface of the earth, underground, under water).

- For street structures, it is important to know the features of the terrain and climate. For example, metal clamps can quickly be damaged by exposure to groundwater that comes close to the soil surface.

- It is very important to know what will move through the pipes (gas, water, sewage waste). Of no small importance is the pressure inside the pipeline created when the substance moves.

When choosing to attach pipes to walls, craftsmen should always take into account the properties of the underlying material (its qualitative composition, strength, presence of construction defects).

Definition and types of pipelines

GOST 32569-2016 is considered the basic standard for laying pipelines. The document has been in force since the beginning of 2015 and contains requirements for steel technological pipeline networks. In relation to similar structures of industrial enterprises, GOST 14202-69, adopted in the USSR and in force since 1971, is still relevant.

In accordance with the regulatory framework, a pipeline is understood as an engineering structure of a linear type, which is designed to move liquids or gases, or, less often, bulk solids. Transportation occurs due to pressure or height difference.

Main structural elements of a linear structure:

- pipes directly;

- nodes for connecting pipes into a single system;

- fittings that are used to control the movement of gas or liquid;

- a fastener whose function is to secure it to a load-bearing surface or structure.

The choice of fasteners is facilitated by determining the type of pipeline. To classify structures, different criteria are used:

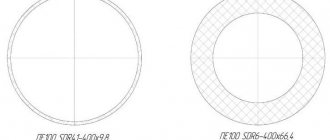

- production materials – metal (steel, cast iron), plastic (polyethylene, PVC and other materials with similar characteristics), reinforced concrete and asbestos-cement;

- laying method - ground, underground, underwater and floating;

- type of transported substance – water (heating, water supply, sewerage and drainage), gas (gas supply), oil and oil products, steam;

- scale – highway (over long distances), technological (inside a building or complex of buildings), utility (from utility providers to consumers), machine and ship (inside a vehicle);

- temperature of the working substance (cold, medium and high temperature);

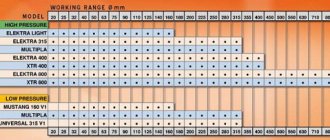

- the pressure that is created in the pipe (low, medium and high);

- purpose – gas and water supply, sewerage, heating;

- type and scale of the object - apartment or private building, industrial enterprise, municipal systems of the settlement.

In most situations - for any pipeline systems of industrial enterprises, utilities and apartment buildings - the requirements for fasteners are regulated by the above GOSTs. The contractor is required to select a supplier or manufacturer of products. Typically, a financial criterion is used for this.

When laying utility networks for a private house, the issue of completing the pipeline is decided by the contractor or customer of the work independently, taking into account a large number of different parameters.

Advantages of metal fasteners

Today, the most famous are two types of fasteners used to organize pipelines: those made of metal and plastic.

The advantages of metal devices include:

- Particular strength. The most popular fasteners are made of steel, which are resistant to moisture, abrasive compounds and chemically aggressive solutions.

- Wide range of applications. Metal fasteners are used for all types of pipelines, regardless of their purpose.

- Wide selection of fastening types. These can be clamps, staples of various shapes, brackets, anchors, studs, bolts.

- Possibility of part repair.

By giving preference to metal structures, the owner of a house or cottage chooses high quality and durability of use. However, heavy weight and lack of ductility are significant disadvantages of iron parts.

In addition, a low-quality manufacturer may violate the fastener manufacturing technology, which will lead to corrosion and rapid destruction of the part.

Advantages of plastic fastening

A modern alternative to metal parts are fasteners made of plastic. The production uses universal PVC, polystyrene and polypropylene.

The advantages of these devices include:

- Strength, which is slightly inferior to metal parts.

- Light weight of the structure, which significantly reduces the load on the pipes and the underlying wall.

- Long service life, which is in no way inferior to metal parts.

- A huge selection of available forms of fastenings (anchors, brackets, brackets).

In addition, such products are very convenient to transport, for example, when delivering parts to a dacha. All stages of construction and installation work can be easily carried out using plastic fasteners.

Advantages of pipe clamps

The shape of the fastener, which is correlated with the type and size of the pipeline, is important for repair work. One of the most popular types of pipe fasteners today are clamps.

Features of clamps include:

- This part can be made of plastic or have a metal base. According to their purpose, they are divided into support, crimp and guide types of construction. Clamps in the installation industry are universal types of fastenings, since they are used for a wide variety of pipes of various diameters, pressures, and purposes. In addition, clamps can be additionally equipped with studs, tapes, clips and many other construction devices.

- Installing the clamp does not require any special knowledge or experience.

- As a rule, the clamp is located in hidden niches, in pipelines under walls and flooring. The reason for this choice lies in the unpresentable appearance of the part.

- The classic clamp has two rings, a pin with fasteners, and a dowel for mounting to the wall.

For self-assembly, you need to make markings, mark the dowel location points, and drill the designated points. The dowel is installed first, then the clamp is installed. Lastly, install the pipes and secure them with two rings.

How to connect

In addition to the main fasteners, you also need auxiliary ones that will serve to connect the entire structure into a single whole:

- You can drive nails into a wooden surface. Spacers or washers are also used to reinforce everything;

- Bolts, screw products - suitable for fastening if there is a screw thread. Any type of fastener can be fixed with them. They are easy to use and versatile;

- Self-tapping screws or self-tapping screws - the first option is universal, the second is more often screwed into wood;

- Dowels - used to secure a screw or self-tapping screw;

- Nuts or washers - Sometimes the design of the piping system is provided, so they must be used. Strengthens the reliability of the fastener and its tightness.

Benefits of using clips

Clips are widely used for fastening plastic pipes in the house, bathroom or toilet. Such plumbing pipe fasteners can be single or double, and have a certain amount of elasticity.

This fact makes it possible to use parts to hold cold and hot pipes.

The installation process is no different from installing a clamp, but you will need to make some effort to secure the pipe. A successful installation is indicated by a characteristic click.

Tips for choosing

The holders are selected so that the inner diameter of the clip matches the outer section of the outlet, and the fasteners fit tightly to its surface.

When choosing a joined tape of clips, pay attention to ensure that it does not fall apart at the slightest touch.

Often you come across products with latches that cannot withstand even two or three opening and closing operations.

approximate price

The cost of holders for plastic pipes starts from one and a half rubles and depends on the presence of such attributes on the clip or in its set as a latch and dowel, single or paired knot. In any case, your family budget will not suffer from their purchase.

Bracket for fixing pipes

The bracket is made of various metal alloys and is one of the most reliable pipe mounts.

This part is a console with a fastening screw that allows you to fix the pipe at a certain distance from the underlying wall.

The use of a bracket is permissible for hot water supply pipes, where the ability to expand the holding structure is necessary. Due to their shape and reliability of fixation, brackets are widely used to hold pipelines on the wall, on the floor, on walls.

How to fasten with clips

Fastening work with clips is simple. They can also be carried out by a person inexperienced in repair matters.

The work process begins by marking the wiring and placement points of the holders. To do this, use a level, a large ruler and a construction pencil.

At the marked points, holes are drilled with a hammer drill, using a drill with a diameter sized for the dowels used.

Next, the holders are attached with self-tapping screws through dowels inserted into the holes.

The pipes are snapped into plastic clips with little effort and a securely fastened structure is obtained.

Recommended mounting pitch

The distances between the fastening points, called the fastening pitch, should be approximately 100 cm when laying heating pipes, 110 cm when laying a plumbing system.

If plastic pipes have a diameter of 110 cm or more, the pitch will be 160 cm and 190 cm, respectively.

Anchor shackle

The new product, which allows fixing two adjacent pipes, has greatly simplified the task for craftsmen and owners of new houses.

The bracket consists of a dowel and two plastic brackets, shaped like an anchor. This part is designed to hold only pipes under a warm water floor.

Design

Most fasteners are made from both metal and plastic. The area of use, characteristics and selection criteria are determined by the design of the products.

Clamp

The most common type of fastener. Available in metal or plastic. It is produced in three types - support, crimp, guide. The popularity of clamps as fasteners is explained by a number of factors:

- versatility. Used for laying pipelines of any diameter and purpose;

- diversity. From a design point of view, there are several types of clamps - U-shaped, with a fixing pin, clips, tapes and others;

- ease of installation combined with good performance properties, including reliability, durability, practicality;

- low production price.

The only noticeable drawback of the clamps is their unpresentable appearance. This minimizes installation in residential areas and in public view.

The standard clamp design includes three elements:

- two semicircular rings. Complete with rubber gaskets and connecting bolts. Designed for fixing pipes;

- pin with fastening. Welded to one half ring. The basic function is to fix the clamp to a load-bearing surface or structure;

- plastic dowel. Used when the pipeline is attached to a brick or concrete wall.

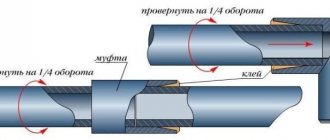

The installation technology includes the following steps:

- Marking placement points on the supporting structure.

- Drilling holes for dowels or other connecting fasteners.

- Dowel installation.

- Installation of the clamp.

- Pipe installation.

- Work on fastening and fixing the pipe with two half rings using connecting bolts.

It is made of polystyrene, less often - other plastics with similar technical and operational properties. Typically used when laying water supply networks. Fixation occurs by snapping, that is, inserting the pipeline inside the clip. In this case, force is applied, so the diameter of the pipe is slightly less than the inlet distance.

There are two types of clips - single and double. The second option is intended for water supply, when two pipes are laid side by side - hot and cold water supply. Using special connecting elements, the clips are folded into a structure for any number of parallel pipes.

By design, clips are divided into:

- collapsible. They have the form of a bracket that is attached to the load-bearing surface with a self-tapping screw or dowel;

- whole. The dowel acts as part of the structure. This option is somewhat more expensive, but more convenient to use.

The order of laying pipes with fixation with clips looks like this:

- Marking the position of the fastener.

- Drilling holes for the connecting element (dowel).

- Installation of dowel and clip.

- Fixing the pipeline by snapping the clip.

bracket

A variety of wall, floor and ceiling mounting. It is used in hot water supply and heating networks, the operation of which allows linear expansion of the pipeline when heated. Provides free fixation of the pipe.

The bracket is a support element in the form of a console, which allows you to secure the pipeline at a certain distance from the surface of the supporting structure. Made from metal or plastic. Often used in conjunction with other fasteners - supports, pendants, clamps.

Clamp

The clamping device resembles a clip. The difference is the closed design. The pipe is held in place not by snapping, but by secure fixation using a special clamp with a threaded connection.

There are two types of clamps. In the first, the pipe and dowel are fixed in the wall using one self-tapping screw, in the second, two connecting elements are intended for this.

The main area of practical use of such clamps is metal-plastic pipelines. The only difference between the installation technology and that described for clips is the need to first open the latch and then close it at the final stage of installation.

Dowel hook/anchor shackle

A dowel hook is a dowel with one or two hooks on the outer end that are designed to hold pipes. The difference between the anchor bracket is the use of a certain shape for fastening the shank, reminiscent of an anchor and held in the supporting structure due to notches.

The anchor dowel is a universal type of fastener. The anchor bracket is designed to fix the pipe to the heat-insulating material and has a narrow area of practical application - installation of warm water floors. It is made of impact-resistant polystyrene, which is explained by the peculiarities of installation and operating conditions.

Bracket

Available in several versions, usually made of galvanized steel. The most popular types of brackets are single-legged (for minimal loads), two-legged (standard design) and P-shaped (used for flexible pipelines in the form of hoses or corrugations).

If necessary, the bracket is equipped with a rubber gasket. The presence of an additional element minimizes vibrations that occur during operation of the pipeline and more reliably fixes it to the load-bearing surface.

Connection fastener

Fasteners that are designed to connect individual elements into a single system and hold them in the supporting structure deserve special consideration. Typically used for this purpose:

- nails. Exotic option. Used for fastening to wooden surfaces. Rubber washers and gaskets are used as additional elements;

- screws, bolts. Classic type of threaded connection. Actively used for all types of fasteners. Pros: accessibility, versatility, extreme simplicity of design, reliability. In the form of additional elements they are equipped with washers, gaskets, and groovers;

- screws, self-tapping screws. The first option is used for wooden surfaces, the second is universal and has a wider range of practical applications. Often equipped with gaskets, washers and other elements to increase the tightness and reliability of the assembly;

- anchors, dowels. They use a similar fixation principle. An element is installed inside the supporting structure (in the form of a conical sleeve for a dowel, a free-form for an anchor), to which a screw, self-tapping screw or other connecting elements are attached;

- threaded rods. It is made in the form of a straight metal pin, on the surface of which a thread is cut - completely or partially. Installation occurs using nuts. One of the most popular types of connecting fasteners. The production of high-quality products requires competent organization of production and the use of high-precision equipment. Before ordering threaded rods, you need to verify the qualifications of the manufacturer or supplier;

- rivets. They are rarely used for laying pipelines. They use the shockless principle of fixation using a special tool and one-sided installation;

- nuts, washers, gaskets, groovers. Special fixing elements: main (nuts) and additional (rest). It is used to increase the reliability of the fastening unit, as well as to increase the tightness of the joints of individual elements. Often, the installation of additional elements is a mandatory requirement of GOSTs and technical regulations for the laying of pipelines.

Today in Russia a wide variety of fasteners for laying pipelines are sold. Understanding the types and sizes of products on your own is far from easy. The easiest way to purchase suitable fasteners is to contact professionals who have been producing and supplying products for a long time and have been productive.