Dear readers, today we will talk about the construction of a copper pipeline. During the installation process, reliable connection of the elements that make up the structure is important. Capillary soldering is considered one of the simplest and most reliable methods of connecting pipes. This installation method requires the appropriate tools - a special soldering iron or torch for soldering copper pipes.

Rules, features and methods of soldering copper pipes

Pipe soldering is the joining of pipeline elements by adding molten solder. After the solder hardens, the connection becomes inseparable; the cooled solder firmly fixes the soldered elements.

It is important to remember that the melting temperature of the solder must be lower than the melting temperature of the parts being joined. This soldering method ensures uniform distribution of solder throughout the joint.

Copper pipes are soldered in two ways:

- The low-temperature method is used when installing household pipelines. In this case, both hard solder, which is heated to a temperature of at least 450 degrees, and soft solder, heated to 400 degrees, can be used.

- The high-temperature method is used for the installation of more serious pipelines that are subject to heavy loads. When connecting using this method, the solder is heated to a temperature of 600-900C.

Bottom line

Gas soldering torches are an effective tool that will help with various installation work, roofing, soldering copper pipes and aluminum structures.

The advantages of soldering with a gas torch are high safety, no melting, and low heating. This allows this method to be used for working with aluminum, since its structure can change at high temperatures.

This technology provides reliable, high quality connections.

What is needed for soldering

To make a capillary connection of copper pipes, you will need the following tools and materials:

- tools for pre-processing of joined elements;

- flux and solder;

- special fum tape;

- threading tools and ferrules;

Types of solders

There are two types of solders - hard and soft. Soft solder is a wire made of metals and alloys with a low melting point (tin, lead, silver, etc.). The diameter of such solder is no more than 3 mm.

Brazing alloys are made from refractory metals and have a larger diameter.

A connection made using hard solder can withstand heavy loads.

Flux and soldering paste

To ensure reliable connection, flux or paste is used. This substance prevents foreign elements from entering the joint, and the seam is reliable and without pores. Flux is based on boric or hydrochloric acid, zinc chloride. In order to create a protective film at the joint, resins, rosin, and wax are used.

Soldering fluxes are divided into liquid, solid and special pastes. The ready-made mixture is more expensive than other materials, but it is also much more convenient to work with.

Fitting

Fittings are special parts that are installed at the junction of workpieces of different diameters, connecting several pipes at one point, or when switching to another pipeline material.

During installation, fittings made of the same material as the pipes are used.

If you have to use fittings made of a different material, it is important that the coefficient of thermal expansion and other technical parameters of the material of the pipes and fittings match.

Tools

To solder a copper pipeline you will need:

- pipe cutter;

- chamfer;

- pipe expander;

- brushes, pipe cleaners, sponges.

Tips for choosing the best burner

Choosing a torch is a complex issue, given the number of tools available on the commercial market and modern gas torch manufacturing technologies.

Therefore, the term “best”, in this case, should, perhaps, be attributed not so much directly to the tool - a torch for home soldering of copper pipes, but rather to the conditions of work that are expected.

However, if you select a specific device for each individual condition, it won’t take long to go broke, literally. Therefore, it is logical to consider a universal design to be the best burner. A striking example of versatility is, for example, a device from Castolin - model CT27 .

The soldering machine from Bernzomatic, popular among craftsmen of various levels, is one of the good choices that ensures the production of work of varying complexity.

Among the popular companies supplying high-quality gas equipment for copper soldering, in addition to Bernzomatic and Castolin , mention should be made of SLEDOPYT , DAYREX , Flame Gun , Energy , REXANT , Rothenberger . By the way, the products of the last mentioned brand have a rather high price tag.

In addition to the manufacturer, when choosing the optimal device for soldering, it is advisable for beginners to look at the characteristics. If the burner can be used in almost any type of work, including connecting copper pipes and other actions, then a similar model can be taken.

Another criterion is the type of power supply and flame adjustment. It’s good if the portable design you like for copper soldering is designed to be powered by “SAS/Pro” or “MAPP/Pro” cylinders and can provide fine adjustment and fixation of the flame.

An equally important role is played by the weight of the device - for example, a good option is a torch weighing about 400 grams, which, moreover, is specially adapted for soldering in any position

As for the configuration, a torch for a beginner in copper soldering should be equipped with at least three different tips:

- standard;

- cyclone;

- super cyclonic.

This set of tips will allow you to process solder joint points of a wide variety of configurations and form beautiful, inconspicuous seams.

Actually, approximately according to this principle you should select a device for soldering. The modern market opens up extensive opportunities for choosing a suitable burner.

Types of burners

The equipment presented on the construction market is divided into several types.

Burners with stationary and disposable cylinders

Such devices are equipped with disposable gas cylinders with propane, acetylene, etc. The advantages of using this type of equipment include mobility, ease of operation, and safety.

The only drawback of burners with disposable cylinders is that the cylinder must be changed every time after use.

You can use such a tool both when installing plumbing and heating systems.

Hand torches

The advantages of such equipment include, first of all, compactness. Using a hand soldering iron, it is convenient to assemble a pipeline in a small room and solder pipes in the most inaccessible places.

The hand torch operates on a disposable flammable gas cylinder. The tool is equipped with a flame length regulator; the kit usually includes nozzles of different diameters. The tool does not require connection to an electrical outlet. If you follow all operating rules, the connection is reliable and durable. Hand tools can easily cope with the installation of air conditioning systems and other household communications.

Professional burners

Equipment classified as professional is capable of working with particularly refractory solder. It is used when installing structures at industrial facilities where the pipeline is subjected to significant loads.

The advantage of industrial burners is the high flame temperature.

The large weight and dimensions will not allow you to work in a cramped apartment. It is not advisable to purchase such devices for domestic and personal use - household communications do not require such a quality connection, and the cost of the device is higher than that of other types.

Homemade burners

Sometimes craftsmen use devices assembled with their own hands. They differ in their characteristics and belong to both manual and stationary types. Homemade burners consist of the same basic elements as purchased ones. However, it is not recommended to use such devices, as there is no guarantee of operational safety. And in terms of performance characteristics, they are usually inferior to factory equipment.

Types of gas appliances

There is a fairly wide range of gas soldering devices, which are logically divided into types depending on the operating temperature.

According to this criterion, devices can be household, where the heating rate reaches a maximum of 1500°C, and professional - with an operating temperature of over 1500°C.

According to the design, burners can have an elongated nozzle or a shorter one. Some models are also equipped with a flexible hose for connecting to the cylinder

The type of connection also varies.

Cylinders are distinguished:

- threaded;

- collet;

- pierced.

The fuel container can be refillable or disposable.

As for fuel, depending on the power source, the burners use propane, MAPP gas, oxygen gas, multifuel. The latter option is not used for soldering copper pipes, but is very convenient in everyday life, especially when hiking. Although experts consider such burners less reliable.

Below we will consider in more detail each of the mentioned types of gas equipment using different types of fuel.

Type #1 – propane burners

Propane tools ensure efficient performance of work aimed at heating, melting, and soldering metals of relatively small mass. The thickness of the working metal is usually 2-9 mm.

Typically, the base of a propane torch is made of brass. The nozzle structure is made of high temperature metal, usually stainless steel.

Propane burners are equipment for soldering, as well as other work related to high-temperature heating. This type of soldering equipment, quite popular, is actively used in practice.

For the most part, these are devices with manual flame adjustment through a control “reducer” - a regulator located on the pipe, which goes to the nozzle. Propane burners produce a flame temperature of 1300°C.

Type #2 – devices for MAPP gas

Gas burners, designed to power the MAPP with gas, are successfully used for various purposes related to the processing of metals, in particular copper.

Possible operations with metal:

- heating;

- annealing;

- fuse;

- soldering.

The gas mixture used “Methylacetylene-Propadiene-Propane” contains several ingredients, which provides increased thermal power.

Tool for soldering copper and other metals. The design, in this case, is based on the formation of a high-temperature flame through the supply and combustion of a MAPP mixture

This type of burner is characterized by a good flame shape and high heat flow intensity.

Maximum flame temperature is 2400°C, demonstrating improved temperature efficiency compared to propane units.

Type #3 – oxygen gas devices

Another type of apparatus for soldering, melting, welding, heating, where the working source of energy is a mixture of gas and oxygen.

The design feature is the supply of individual components of the mixture with the same pressure (0.5-1 ATI). Therefore, such burners are equipped with a special gearbox.

The gas-oxygen version of the burner is a design with which you can achieve very high heating temperatures, which means soldering in cases where other devices are not suitable

Oxygen gas devices support the use of various oxygen gas mixtures.

This factor allows you to obtain a wide range of flame temperatures:

- acetylene – 3260°C,

- hydrogen – 2680°C,

- propane – 2640°C,

- butane – 2760°C.

The design of the gas-air burner ensures a stable, evenly directed flame, which has a positive effect on the quality of soldering.

Type #4 – multi-fuel gas burners

Multi-fuel designs are compact, small-sized, and equipped with additional devices, for example, a heat reflector or wind protection.

The designs of gas burners, which use so-called multifuel, technologically exclude the production of copper soldering. However, it is a convenient tool for household needs.

A type of gas burners that differ structurally in that they are designed for the use of different types of fuel:

- petrol;

- diesel fuel;

- kerosene;,

- alcohol, etc.

The devices are mostly represented by household tools, convenient for tourism purposes, as well as for performing various household works related to heating.

A fairly high thermal power of up to 3000 W ensures heating of 1 liter of water in literally 3 minutes, the parameter in the specifications is 3.0-4.5 minutes.

How to choose a burner

When choosing equipment, the main attention should be paid to the class and performance characteristics.

If you buy a torch only for soldering household pipelines, you can get by with a manual or semi-professional device. Such a device is cheaper than a professional burner and will cope with the tasks. To install communications subject to high loads, you will need to use hard solders, so you will have to purchase professional equipment.

The most popular models and manufacturers

The construction market today offers a large number of devices from various manufacturers. Domestic gas burners are popular: Profi-Tools; Allgas; Donmet. Foreign manufacturers also enjoy a good reputation: Rothenberger; Kemper; Virax; Rems; Uniweld.

Most companies offer burners of different classes - from hand-held mobile devices to professional powerful devices. A semi-professional propane burner costs from 1.5 to 10 thousand rubles. Professional units will cost more – the minimum cost is 20 thousand rubles.

Soldering process

Before proceeding directly to joining the cut pieces, they must be pre-processed. First, the joint is cleaned, minor defects and burrs are eliminated. After this, the surfaces of the connected pipes are treated with brushes and cleaners from the outside and inside. Do not use abrasive tools, otherwise scratches will occur.

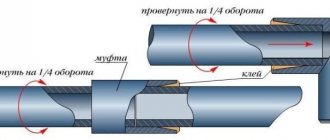

If required, one tube is expanded. The diameter of the copper pipes must be such that one piece fits freely into the other. Before this, it must be heated, otherwise mechanical damage will occur, which will subsequently affect the tightness of the connection.

To protect against air getting into the seam and for better adhesion, flux or paste is applied to the surface.

Only after completing the preparatory work should you start heating the solder and pipes using a torch. Heating must be done evenly to prevent overheating.

After the pipes have heated up, solder wire is introduced into the gap between them. It melts and fills the gap at the junction of the pipes, forming a seam. After cooling, the flux is removed.

Safety precautions

To avoid injuries and other unpleasant consequences, it is important to comply with safety requirements: install and repair pipelines only with protective gloves and goggles, in work overalls, do not allow the burner flame to come into contact with unprotected skin, do not allow the heated metal to touch unprotected skin, do not work with open fire near flammable materials.

After soldering is completed, the gas supply must stop.

Basic mistakes

The process of soldering copper pipes is not particularly complicated, however, beginners often make mistakes that subsequently affect the quality of the connection. Common mistakes made by beginners:

- insufficient pre-treatment of the soldering site;

- pressing - failure to maintain a sufficient gap between the pipes, resulting in an uneven seam;

- using the wrong solder;

- overheating of pipes, which leads to deterioration in performance;

- insufficiently thorough cleaning of flux after soldering, which causes corrosion.

In addition, it is required to follow a pre-prepared design diagram.

Design of a modern gas burner

Let's start with an analysis of the design aspects characteristic of modern models of gas burners.

Equipment in a modern design, designed for economic use, is primarily distinguished by its mini design factor. This equipment is easy to use, lightweight and, as a rule, can be disassembled into individual components.

Portable, disassembled into individual parts - such equipment for soldering copper pipes is really convenient and preferable for work

Such devices are easy to transport, placing them, for example, in a standard plumbing box or in a plumbing bag.

The devices are traditionally equipped with removable mini-cylinders filled with a special gas mixture, which ensures a high operating temperature and an even (stable) flame output.

Most designs are equipped with an ignition element, which ensures ignition of the device with one movement of the hand.

To adjust the flame, a design for smoothly changing gas pressure (reducer) is used, thanks to which you can set the optimal soldering mode.

There is a version of the burners with a direct connection of the cylinder to the nozzle, and there is a version where a hose transition is provided.

The piezo ignition system and smooth adjustment gear allow you to set the required flame shape to perform soldering work, taking into account obtaining a high-quality result

It should be noted the versatility of household burners with gas cartridges. In other words, such devices can be used not only specifically for soldering pipes, but also for performing other tasks. For example, it is quite acceptable to use a burner as a tourist accessory.