What is an American?

This is a quick release connection with a union nut. It is convenient to use such a connection in hard-to-reach areas where it is impossible to completely connect two threads. For example, there are two threads, but the pipes are only connected end-to-end. How to connect them? There are two options.

- To connect pipes (polypropylene or any other), you can use a pusher, which drives the coupling and nut. All this sits on a sealant, for example, flax. That is, it is wound onto the pipe on one side and tightened with a nut, and the seal is also wound on the other side and also tightened with a nut. Thus, a tight connection is obtained, but less convenient than when used with an American coupling sealing ring.

- Using an American quick release coupling is much more convenient and simpler. It is necessary to screw one part of the coupling onto the first branch of the pipe; we also use a sealant. And the other part on the second branch of the pipe, also with winding the seal. In the middle there is a union nut with an elastic band. That is, this connection is tightened with a union nut and a strong, sealed connection is obtained.

The second American connection option is very convenient and is often used today when carrying out various repair and construction work or any fastenings.

Characteristics

Differences between TPL tape and regular adhesive tape:

- The basis of the adhesive tape is polyethylene tape, which is reinforced with fiberglass, which provides increased strength.

- Provides excellent adhesion quality as well as easy peeling without leaving marks thanks to rubber-based adhesive.

- The adhesive tape has high tensile strength. This tape can stretch up to 6 percent of its length;

- High temperature resistance. Up to 80 degrees Celsius, the tape retains its normal shape, as well as adhesive properties;

- Increased resistance to chemicals and moisture;

- Good adaptability to uneven surfaces;

- Adhesiveness parameters. The adhesive applied to the inside of the tape consists of rubber (natural or synthetic). Thanks to this, this tape is characterized by increased quality of adhesiveness, as well as the ability to be dismantled without leaving any traces;

- Strength parameters. The base of the tape is made of a compound of natural fabric fibers and synthetic threads. This ensures high tensile strength of the adhesive tape during longitudinal tension. Reinforced adhesive tape , due to its well-designed fabric, is distinguished by easy transverse tearing, which allows it to be torn without the use of additional devices.

Types of American women

It is important to know that there are several types of American women and for certain repair work it is convenient to use one or another type.

- A regular American coupling with an o-ring . This coupling is screwed on with special wrenches for quick-release connections (wrench for American couplings). A coupling with a ring is a fairly reliable fastening and is mainly used when connecting various pipes.

- disassembled cone coupling The joint is connected end to end and tightened with a union nut from above. This type of American is more reliable, but takes up a little more space. The coupling is sealed on both sides and tightly tightened with a nut in the middle. The seal is achieved by a precisely made coupling cone.

- American angle coupling . Very convenient to use if you need an angle. In order not to add or screw in additional corners, the coupling is already angular. This is one connection less expensive and much cheaper if several such angles are required. American corner couplings have many options for degrees of bending and diameters. It is easy to purchase couplings with 1350, 900, 600 and 450 bend angles.

- Couplings with taps . American ones come with ball valves or thermostats. Couplings with taps have a stainless steel body and brass inserts, resistant to corrosion and reliable. They are used, for example, for a radiator, or when watering a garden if the tap is outside. Here the quick release connection is very convenient.

Flax fiber: characteristics

High-quality tow should be without shreds or tears, and have the appearance of a braid.

No one will remove tow from store shelves, because this type of fabric is not capricious, but it is not entirely easy to work with. After all, a situation often arises in which it is not easy to unwind a thread with flax fiber wound on it, and sometimes such ideas remain unrealized. And in the Soviet era, such connections were additionally treated with enamel (red lead), then tightly twisted. Once the paint dried, the joint bonded perfectly. This method was distinguished by its strength and reliability.

As soon as silicone-based sealants appeared on Russian markets, flax compounds were forgotten. Although many experts consider the latter type of material to be a thing of the past, it does not leave its position even today.

Despite the certain complexity of working with tow, its installation is carried out through the following steps. First, the tow is distributed among the fibers, then they are placed in the grooves between the threads. There should be no kinks through the turns. Then you need to apply the sealant. When screwing in flax fiber, remember that there should not be an excess of this fabric. After all, with further operation of the connection, excessive stress appears, as a result of which parts can break.

Recommendations for use

When using this or that type of coupling, I would like to give some advice on where and how best to use them. For example, an American one with a rubber sealing ring is especially often used when repairing or installing a riser. For example, a polypropylene magpie pipe and the height from ceiling to floor is 2.5 meters, it is difficult to make a bend on the magpie pipe so that it is convenient to solder. To avoid such difficulties, an American one with a rubber sealing ring is used. The result is an even, neatly made and sealed connection, which can be disassembled if necessary.

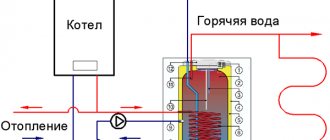

Such a connection is quite reliable, but if after a certain period, after about one year, it needs to be disassembled, then the O-ring must be replaced before reassembling it. Otherwise, perhaps the American will leak. Therefore, it is recommended to replace the rubber seal. When installing a riser using polypropylene pipes, we take an American coupling made of the same polypropylene material. This connection can be used almost anywhere. Including when mounting a boiler water heater, American ones with a rubber sealing ring are mainly used. It is compact, convenient and inexpensive.

If it is necessary to secure the heated towel rail coil, then an American cone is used, since in these cases such couplings are much more reliable. In view of the fact that water supply in multi-storey buildings is supplied under a pressure of about 7 kg, in order to avoid such difficulties with rubber sealing elements, it is better to use an American cone coupling. Despite the fact that this quick release connection with a union nut is quite effective, it is recommended to wrap fum tape around the connection during installation. Why is this necessary? Sometimes it is difficult to tighten the American coupling so that it completely does not allow water to pass through. Rarely, but sometimes this happens. Basically everything is simple: install, tighten and everything works great. But sometimes you come across a coupling with a not very accurate cone.

A way out of this situation can be sealing fum tape. Then everything is simple: connect the cone into a cone, dock and tighten. Here, the fum tape compensates for slight misalignment, if it is present in the American coupling. Therefore, when installing the connection, it is advisable to immediately wind the fum tape. It happens that they are very crooked, and this method cannot be eliminated. In this case, the best option is to replace the coupling in a store under warranty with a high-quality one.

Specifications

FUM tape, the technical characteristics of which meet the requirements for the quality of work at a particular site, will serve flawlessly for at least 10 years. In order to accurately select the most suitable product, it is recommended to familiarize yourself with the characteristics of the 1st and 2nd grade films.

| Characteristics | FUM-1 | FUM-2 |

| Film thickness (mm) | 0,1-0,14 | 0,035-0,2 |

| Film Width (mm) | 10-60 | 5-60 |

| Elongation at break (%) | 100-200 | 100 |

| Availability of lubrication (%) | 20 | 0,3 |

| Maximum tensile stress (kg/cm2) | 40 | 60 |

It is difficult for a beginner in plumbing work to understand all the intricacies of choosing sealing films the first time. Therefore, you can rely on the recommendations of experienced craftsmen and use the same materials in your work.

Questions often arise about which films to use when installing household water pipes. These are the most popular plumbing jobs, during which mistakes made will be noticeable immediately after water is supplied or will be discovered in the near future.

The most suitable fulente for water is as follows:

- for small threaded connections - width 12 mm, thin (0.075-0.1 mm);

- for large threads - width 19 mm, thickness 0.12-0.2 mm.

What is FUM tape?

FUM tape (fluoroplastic sealing material) is used for high-quality sealing of threads in various couplings. This sealing tape has a thin synthetic structure, translucent, white color and has fairly high mechanical and thermal stability due to its fluorine content. Long service life, does not break when stretched, does not lose properties under the influence of high temperatures or aggressive chemical environments. The main advantages of such a seal: non-toxicity, ductility, good strength and high resistance to metal corrosion.

Pros and cons of using

The main advantage of choosing tape is its availability. FUM is sold at a low price, cheaper than flax tow and most other sealants used in plumbing.

The material is characterized by ease of installation. With proper skill, winding the tape occurs in a matter of seconds, but for this you should practice winding it on connections of different diameters for some time.

An important advantage of using tape is that the parts fastened with it can be easily disassembled. The connections do not freeze tightly; they can be disassembled even years after installation.

The main disadvantage of the material is that it is not the most reliable of seals, therefore, as a rule, it is not used for industrial installation. However, for household repairs the hermetic properties of FUM are quite sufficient.

Another disadvantage is that the tape often protrudes outward from the joints, so the pipes may look sloppy because of this.

Threaded tapeSource sdelairukami.ru

How to use correctly

Wrap a folded or twisted ribbon around the edge of the American one, approximately two turns. Then make two more turns on top across the entire width of the tape. There's not a lot of winding required here. Two turns is quite enough since the tape very quickly takes the shape of the product.

Today, the American coupling is the most universal, widely in demand and indispensable device, which is used in the construction of industrial and domestic pipelines of various configurations. The market offers a huge selection of American women made of various materials and different models: copper, plastic, brass, galvanized, steel (stainless steel), with internal thread, with threaded fitting. We talked about the simplest, most affordable and widely popular types of couplings for American women.

Basic properties

Fluoroplast-4 is the basis for FUM tape. Strips of this material are rolled out under a press and then wound to form rolls. Roll width is from 1 cm to 1.6 cm.

There are 3 main types of FUM tape:

- FUM 1 – using Vaseline lubricant (20%). For industrial pipelines, as well as in aggressive environments;

- FUM 2 – without lubrication. Where there are strong oxidizing agents in the system;

- FUM 3 – for systems with a non-aggressive environment.

Main properties of FUM tape:

- Non-toxic;

- Durable;

- Plastic;

- Chemically resistant;

- Thermally stable;

- Corrosion resistant.

Application temperature – up to 200°С, minimum temperature – from 60°С.

The following characteristics are used for the FUM-1 tape:

- Thickness – 0.1-0.14 mm

- Width 10 mm, 15 mm, 20 mm, 60 mm.

- Breaking stress 40 kgf/cm2

- Elongation at break 100%

- The percentage of Vaseline lubricant is 17-20%

FUM-2 is characterized by:

- Large range of thickness – 0.035 – 0.2 mm

- High tensile stress – 60 kgf/cm2

- Lubrication rate less than 0.3%.

FUM-3 represents average indicators, because These are the cut edges from the first two brands.