Plumbing work is not possible without high-quality sealing. For this purpose, specially designed sealants are used. One such effective means is plumbing tape for sealing sewer pipes. It is also ideal for working with plastic plumbing systems. However, in order for the result to be high-quality and durable, it is important to choose the tape wisely and know the rules for its use.

Sealing joints of elements with tape

Concept and types

Tape for sealing water pipes is a thin, narrow film made of fluoroplastic. Performs a sealing function during the installation of sewers and water pipes.

Pipe Sealing Tape

There are two types of such film:

- Thick white.

- Thin (translucent).

Both species have similar characteristics. They are heat-resistant, elastic, resistant to chemicals. Their width is 10-60 mm. On one side, the film is coated with a special lubricant. To prevent sticking. There are options without lubrication.

Thin type of tape

Advantages

The unique structural structure of the asmol-polymer material makes it capable of operating in temperature conditions of different environments. Retains properties for 30 years.

Overlapping winding does not create bulges. Suitable for thermal insulation of gas, water, exhaust pipes. The film is resistant to mechanical stress, protects against corrosion, and increases reliability in the operation of highways. The use of polymer-asmol tape makes it possible to lay pipelines in soils of any moisture content.

Polymer-bitumen cast core is intended for coating, like a wrap, during the period of major repairs of gas pipelines. Suitable for corrosion protection of steel underground gas pipelines and water pipelines.

Silicone tape juncotape, geb is a universal tool for quick repairs. Flex sealant can seal the walls of any pipes and repair hoses.

The Siloplast complex is suitable for all water pipelines, steam mains, and gas pipelines. The complex is universal, suitable for repairing drinking water pipes. Has a certificate from the Federal Service for Supervision of 2005 and test reports.

How to choose a ribbon

Before purchasing, you need to find out the purpose and type of work. There are films intended for utility lines, household or industrial. Lubricant-free belts are intended for objects that interact with oxidizing agents and oxygen. There are also types that seal threaded connections during the installation of highways or household systems.

Depending on the purpose and location of installation, the tape for sewer or water supply pipes is selected taking into account its characteristics. The stability of the device to an aggressive environment, heat resistance, melting point, etc. must be assessed. It is important to take into account the “behavior” of the film at pipe joints, under pressure and under other significant conditions.

Winding tape onto threads

Tape for plastic pipes must also meet certain requirements. First of all, it is worth studying its technical characteristics. High-quality products will last at least ten years.

It is recommended to pay attention to the following indicators:

- film length and width;

- elongation at break as a percentage;

- the presence or absence of lubricant, it is also indicated in %;

- maximum stretch during tension.

All these indicators will “tell” about the quality and purpose of the tape. It can be difficult for beginners to decide. Therefore, it is recommended to consult with the experts in advance.

Sealing tape

Types of sealing tapes

The film varies in color. FUM tape for gas is yellow, for all other connections it is white. The yellow tape is intended for the low pressure gas supply system.

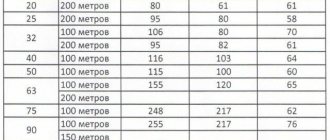

This material is produced in the form of winding on a reel up to 10 meters long. Successfully used for winding onto pipe threads in pressure systems, including water, gas and heating systems.

Its purpose in connections is a deformable filler that acts as a thread lubricant, helping to increase tightness. This seal is available in 3 types:

- Type 1 – for use in pipeline systems for transporting aggressive liquids, used using purified petroleum jelly;

- Type 2 – for pumping strong oxidizing agents, which prohibits the use of additional sealant in the form of oils;

- Type 3 – used for transporting relatively pure liquids and gases; the use of lubricants is excluded.

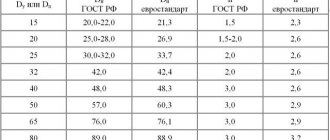

FUM tape for plumbing differs from tape for gas pipe connections. The thickness of the sanitary seal is 0.075 - 0.2 mm, for gas 0.1 - 0.25 mm with a width of 10 to 20 mm. It is wound on reels, which, when executed in the gas version, are highlighted in yellow.

For gas networks with low pressure, the use of plumbing tape is allowed.

Choosing a sealant for domestic plumbing

Tape for sealing water pipes is the most popular when working with plumbing. It is also used in home heating systems, for PVC pipes. If the material is selected or installed incorrectly, this will be noticeable after turning on the supply tap for the first time.

The most suitable options for plumbing:

- 12 mm wide. Thin film used for connections with fine threads.

- 19 mm wide. And a little thicker than the previous one. For large types of threads.

When choosing sewer or plumbing sealants, you must take into account the possibility of quickly disassembling the system if necessary. Even after several years, the tape should be easily removed from the pipe joint.

Application

A popular type of sealant based on silicone and acrylic. Plumbing sealant has high plasticity, is universal, and can be used with any material.

When choosing, it is important to understand where it will be used: water supply, gas pipeline, heating, sewerage.

Silicone is durable, thanks to special additives. You can seal joints during interior work between different materials: metal, plastic, glass, enamel, stone.

Silicone electrical tape is ideal for repairing leaks in sewer pipes, heating risers, and taps. You can seal leaks yourself without calling a plumber. Insulating tape looks little different from the usual insulating tape. But it does not have a sticky layer. The layers can simply be wrapped around the leak area. Good elasticity allows you to increase the length, thereby reducing consumption. A simple winding over a wet pipe will solve the problem in a short time. Self-vulcanizing silicone tape is heat-resistant; it is applied to hoses under pressure to eliminate leaks in the bathroom and kitchen.

A sewer pipeline made from a polyvinyl chloride pipe can be additionally sealed with bitumen tape. In the heating system, you can use all heat-resistant types of sealants: silicone, FUM tape, flax fiber.

For plastic pipes, acidic silicone is used.

Asmol-polymer is used to protect pipes. It is based on polyvinyl chloride tape. In fact, asmol is the only insulating material that has no temperature restrictions.

Selecting tape for heating systems

PTFE film is recommended. It has a low percentage of friction. During the threaded connection you do not have to apply much effort. The joining of parts occurs quickly. Fluoroplastic is an eternal material and does not react to chemical compounds.

But the use of such tape is limited, since it has some features:

- If the size of the parts to be joined exceeds 25 mm, the sealing result deteriorates.

- If the elements have rough threads, the material cannot withstand and breaks.

- Low adhesion of fluoroplastic. If parts are subject to deformation when exposed to temperature, the film cannot withstand pressure. She gets squeezed out.

This tape is not suitable for connecting parts of radiators. It is recommended to seal heating parts with special plumbing thread. Its qualities are similar to fluoroplastic tape, but it is easier to install and lasts longer.

Silicone tape for sealing leaks

Hi all. Today's review will focus on silicone tape, the main purpose of which is to eliminate leaks. I purchased it on eBay quite a long time ago, but until last weekend it was gathering dust on a shelf in the pantry, since there was no way to check its functionality. Unfortunately, the lot where I bought it is no longer active, so the link above leads to another similar one. But I don’t exclude the possibility that there are cheaper options. But the track from the parcel remains, so if anyone is interested, you can see its route from China to Belarus here. True, the track is not very complete, so information about movement only within the territory of the Middle Kingdom is available for viewing.

Be that as it may, the parcel was successfully received and sent to the shelf until a neighbor living downstairs disturbed the calm Friday evening. She came to me not for salt or sugar, but with the claim that we were flooding her toilet. A joint inspection of my restroom showed that, at first glance, everything was dry, but, as it became known, the problem was hidden behind a decorative wall. In the very compartment where all the pipes are hidden. The problem was that cold water was leaking. No one knows how long it lasted, not even the neighbor. But while dripping, the water leaked through the ceiling of the technical compartment and began to drip from the ceiling of the neighbors. Fortunately, they also had drops in the technical department.

The location of the leak was quickly identified - a tap extending from the riser to the meter. Moreover, it was dripping in front of the tap, that is, it was not possible to eliminate the leak by turning it off. When you enlarge the photo, you can see wet tow, as well as a dripping drop.

Moreover, it was dripping in front of the tap, that is, it was not possible to eliminate the leak by turning it off. When you enlarge the photo, you can see wet tow, as well as a dripping drop. The drops formed quite vigorously and I think that more than one liter “escaped” this way. Fortunately, the leak was in front of the meter

The drops formed quite vigorously and I think that more than one liter “escaped” this way. Fortunately, the leak was in front of the meter

Since it was Friday, and even in the evening, it was not possible to call a plumber from the local housing office (I would have been more surprised if I had managed to do this). I was about to look for commercial advertisements, but I remembered the very same tape that is the hero of this review.

So, the tape is a silicone strip wound into a roll. In appearance it is not much different from ordinary insulating tape, except that it is wider. The width of the strip is 2.5 centimeters.

The length of the tape is 3 meters. I didn’t measure it myself, but this is exactly the information available on the seller’s page.

Each layer of tape is separated from the other by something like a rigid film. This was done to prevent the layers from sticking together.

The thickness of the tape (including the film) is 0.3 millimeters.

The feel of this silicone tape is not at all similar to the electrical tape we are used to. First of all, it doesn't have a sticky side. That is, the layers do not stick to each other, but fit tightly due to the high friction force, so to speak. Due to this, it can be used underwater, in water and on wet surfaces. The moisture is simply squeezed out from under the tape. Secondly, it is very elastic. It stretches without any problems at all, and, if you have a certain desire, a piece 10 centimeters long can be stretched to 20 centimeters.

Due to its elasticity, the adhesive properties of the tape only increase. It has no foreign smell, which is also good news.

And here is what is written in the seller's description:

— Suitable for sealing hoses and pipes; — Ensuring waterproofness of electrical connections; — Optimal for emergency repairs; — Work even on wet, dirty or oily surfaces; — Can be used as a tourniquet or emergency wrap for bleeding; — Material: silicone; — Length: 3 meters / 10 feet; — Width: 25 mm / 1″; — Thickness: 0.5mm / 20mil (in reality 0.3 mm); — Insulation: 800 Volt; — Temperature range: from -60 to 260 degrees Celsius; — Pressure: up to 5 bar.

I wound it in several layers, covering about half of the previous layer with a new one. I used a piece of tape about 15 centimeters long. Thanks to its good elasticity, this was enough to wrap both the tap and part of the pipe. I didn’t clean or wipe anything, that is, the surface of both the pipe and the tap was in its original (dusty and wet) state.

This “repair” was hastily carried out on Friday.

He lasted 4 days - until Monday evening. And judging by what I saw, during this time not a single drop fell on the ceiling. That is, the tape coped perfectly with the task assigned to it. Here is a photo of the scene the next morning - as you can see, everything is dry :):

Not only was the repair carried out as quickly as possible, but there was also no need to shut off the riser, thereby leaving the entire entrance without water for several hours, or even the entire weekend. But on Monday the riser was closed, although it was done for about 20 minutes in order to replace the tap. As it turned out, it cracked, causing a leak. Perhaps the tape would have prevented the crane from collapsing further, but I didn’t take the risk. If the tap had burst completely, she would definitely not have been able to save her. But as a temporary remedy, tape turned out to be an ideal option. So I believe that this product belongs to the must-have category and should be in the pantry of any owner (unless you get water from a well and there are no communications in the house). It is not expensive, but it can save you from a local disaster. It’s a pity that I didn’t have it at that moment when the heating radiator leaked a few years ago... Oh, what a fun night it was...

So I have only positive impressions from using this silicone tape. It’s a pity that the damaged tap was thrown away along with the used tape - we should have left it and monitored its condition in the future. Perhaps it is self-vulcanizing and will eventually turn into a single sealing ring... But even if this does not happen, it still performs its functions perfectly.

That's probably all. Thank you for your attention and your time.

Liquid FUM or anaerobic sealant

This is a polymer resin. Slow-hardening one-component product. The gel sealant not only increases the impermeability of the connecting area, but also significantly increases its ability to withstand mechanical stress. Which is very important in pipeline systems due to constant vibration influences and water hammer.

In essence, such a connection corresponds to the “set it and forget it” principle. But you will have to remember when dismantling it, since it can only be disassembled after heating it with a blowtorch.

The sealant hardens upon contact with air or the mating surfaces of the threaded joint, acting as an adhesive and turning the assembly into a monolithic part.

Used as a sealing material for metal threaded connections. Plastic and resistant to temperature changes and vibration. Liquid FUM is a viscous liquid of blue or red color with a slight odor.

The most common way of classification is by color and there are two main positions for this division:

- blue – represents medium strength sealants. Can significantly reduce the intensity of the thread loosening process. In practice, even the slightest weakening of a joint will require prolonged exposure to serious loads of an alternating nature. But when using blue sealants, it is still possible to turn the thread, although with great difficulty;

- When using red sealants, such an operation without heating does not seem realistic. This gel simply glues the structure together. For pipelines it is used in places with strong vibrations (from pumping equipment) and when water hammer is possible.

Specifications:

- density – 1.09 g/cm³;

- operating temperature – -55° +180°;

- pressure – up to 50 bar;

- soluble in acetone and trichloroethane.

Replaces flax and FUM tape in water and gas pipelines, in systems with petroleum products and chemicals, except oxygen.

The hardening time at a temperature of +20° for pipes with a diameter of up to 1 inch is 15-35 minutes, and for larger diameters – up to 1 hour. After this, the connection cannot be untwisted manually. Intermediate hardening – 2-3 hours. The final result is in 12-24 hours. At lower temperatures, the hardening time increases and additional heating is required.

The sealant reliably seals the thread and protects it from corrosion.

Mode of application

The threaded connection must be thoroughly cleaned and degreased.

Apply a thick layer of sealant to the external threads of the parts being connected. On the inside - less, spread evenly over the entire surface of the thread. Connect the parts in the usual way. Remove excess sealant. Leave until completely sealed. If necessary, the connection can be easily disassembled and then reassembled. In this case, there is no need to remove old residues before applying the sealant.

Modern synthetic materials are easy to use. The process of sealing threaded connections occurs quickly and without any particular difficulties.

Leak at the junction: elimination methods

- LiveJournal

- Blogger

Pipes often leak due to poor insulation of joints.

Most often, the user is faced with the fact that a plastic pipe is leaking at the joint. A leak in a metal-plastic pipe can be eliminated by installing new connecting fittings (the line was installed incorrectly), or by replacing the entire wiring (the wrong material was selected - for example, polypropylene was chosen for heating for cold water supply).

Advice: “It is recommended to coat all joints with sealant (for example, a universal heat-resistant sealant for heating pipes can be used).”

A similar defect is observed in cast iron pipelines, but it will be somewhat more difficult to deal with. You can seal a leak in a heating pipe in the following ways.

Caulking joints of cast iron pipes

The joints of such highways can initially be sealed in different ways. Based on this, one or another algorithm of actions is selected.

If the pipes were caulked with lead, to eliminate a leak in the heating pipe you will have to:

- Strip down to the base metal (joint area).

- Caulk the resulting gap, for which it is recommended to use a blunt chisel. The implementation of this repair option is explained by the softness of lead, which easily fills the gap.

It will be more difficult to eliminate a leaking heating pipe that was sealed with cement mortar:

- Remove the remaining cement mixture using a hammer and a narrow chisel.

- Remove the seal and clean the resulting gap.

- Hammer a new sealant (for example, tarred fibers) into the gap, after which it remains to be covered with a cement solution (one to ten).

Advice: “When starting to hammer in new strands, you should take care to pre-treat them with a special mixture, which consists of cement (seven parts), asbestos (three parts) and water (added gradually until the mixture looks like plasticine).”

Pipe joints are sealed with cement

- LiveJournal

- Blogger

Cement is suitable for sealing metal pipes.

There are situations when there is nothing else at hand except cement. It turns out that this is quite enough to seal a leak in a heating pipe.

The sequence of actions is as follows:

- Clean the joint.

- Remove the old seal, for which it is not recommended to use heavy tools, otherwise the pipe may be damaged.

- Prepare cement, water and a wide bandage.

- Dissolve the cement in a small amount of water - a slurry should form, in which the bandage (or piece of gauze) is moistened.

- Wrap the heating pipe with a treated bandage. In this case, each joint is evenly wrapped.

- The structure is left to harden, and after 2…3 hours it is sanded and painted over with suitable paint.

Basic technical properties of sealing tape

Fluoroplastic is stable in a chemical environment and retains its properties over a wide temperature range.

Sealing gas connections

Physical properties of the gas tape:

- Reduced friction coefficient. The fluoroplastic seal, in addition to being plastic, is slippery, which simplifies the screwing of fittings.

- Thermal stability, operating temperature from -70° to +260° without destruction or loss of sealing properties. In addition, fluoroplastics are very effective dielectrics.

- Strength and ductility. Seals made of this material operate stably at pressures of up to 10 MPa and are able to withstand short-term loads of up to 42 MPa, for example, those occurring during water hammer in pipeline systems. The service life of a seal made from FUM tape (fumka) is determined to be 13 years. It degrades faster when exposed to light, but this is not for our case; we just need to take this factor into account when organizing the storage of the material.

- Chemical passivity. Without being subject to destruction under the influence of acids and alkalis, which is determined by the uniform distribution of fluorine atoms over the surface of the product. To date, no solvents capable of destroying this seal have been invented. Resistant to rotting processes.

- Density –1.2 g/cm³.

The material is non-flammable, rot-resistant, and versatile. Its inertness allows its use in pipelines and drinking water containers.

Gas tape can be used in plumbing, but plumbing tape cannot be used in a gas system.

FUM gas tape is best suited for sealing plastic and metal-plastic pipes and thin-walled fittings. Therefore, it is used in laying gas pipes in an apartment, in small sections of the pipeline. In the main pipelines - gas supply to the house, flax is used for sealing.

Household gas is very dangerous. To obtain a reliable connection of pipes, work using fum tape is best carried out by an experienced craftsman. He will show you how to wind the fumka correctly and will do the winding efficiently. A beginner should not take on such a responsible task.

Let’s look at how to properly use FUM tape for plumbing pipes or gas in more detail.

Fixing a leak in a metal pipe

It is quite difficult to choose the right repair if a leak occurs in a metal pipe of the heating system. This type of structure is contraindicated for welding, since the consequences after such a leak repair are the formation of corrosion in the sealing areas, a decrease in the wear resistance of the metal and the unsuitability of the communication for subsequent use.

It is recommended to repair small holes using a clamp or rubber gasket, which can completely block the damaged section of the pipe. If there is no banding system or gasket, you can try steel wire. It is carefully wrapped around the pipe, thereby fixing the location of the burst.

First, the area is freed from moisture, rust, and thoroughly cleaned. After this, the steel wire is securely fixed; you will need to apply force so that the leak is completely wrapped. Thus, the problem is eliminated and the risk of further rupture in this place of the pipe is minimized.