Crimp flange is a connecting structure used in the installation and repair of pipelines and connecting various flange fittings. The use of a crimp flange allows you to avoid welding work. The versatility of this extremely reliable fitting is expressed in the ability to connect pipes made of different materials - cast iron and steel, asbestos cement and polymers.

Crimping flanges are used to connect pipes or install fittings with a flange connection

Crimping flanges for PE and PVC pipes

The crimp flange for PE/PVC is used for tensile load-resistant connections of various flange fittings (gate valves, valves, faucets, valves, filters, etc.) with PE (HDPE) and PVC pipes. The installation of a crimp flange on a pipeline is carried out in the following way: a flange is placed on the smooth end of the pipe (with the socket part) and the bolts are tightened crosswise, with the help of which the process of crimping the pipe and reliable fixation of the fitting occurs.

Technical characteristics of crimp flanges for HDPE pipes

- Name: crimp flange for PE pipes, fixing flange for PE and PVC, coupling with flange for PE pipes, flange adapter for PE, crimp flange for PE and PVC pipes, PFRK.

- Body: Ductile iron with epoxy coating.

- Appearance: blue or black fitting with a brass ring and a rubber seal inside.

- Seal: EPDM/NBR.

- Operating temperature: from -20°С to +70°С (short-term up to +80°С).

- Application: water supply systems, sewerage, air, slightly aggressive environments, viscous liquids.

- Dimensions: from DN 050 to DN 600 mm.

- Pressure: PN 10/16.

- Connection type: flange (according to GOST 12815-80, EN 1092-2).

- Manufacturers: Dendor, HAWLE (Hawle), AVK (AVK), Jafar, Feros, Viking Johnson.

Advantages of crimp fixing flanges for PE/PVC pipes:

- corrosion protection;

- flanging of plastic pipes without welding (electrofusion or butt welding);

- convenience and ease of installation;

- possibility of installation in any conditions (dirt, narrow trench, groundwater);

- long service life;

- do not require additional equipment;

- Possibility of dismantling at any time after installation;

- the use of a lip seal allows pipe installation with minimal effort;

- The brass ring provides a reliable connection that is resistant to tensile loads.

Fixing crimp flange UR-13

Universal crimp flange ur 13 (flange coupling or flange coupling) is used for connecting the free ends of pipes with a diameter of 50 to 1400 mm, installing valves or other flanged fittings. The pressure parameters correspond to PN 10/16.

This universal fixing flange can be used in systems made of steel, cast iron, plastic, asbestos-cement pipes.

That’s why it has the corresponding word “universal” in its name, since it is suitable for connecting almost all types of pipes made of a variety of materials.

Crimping flanges allow you to quickly and reliably fix shut-off valves on the pipeline

Features of the ur 13 fixing crimp flange:

- suitable for pipes made of different materials and having unequal outer diameters;

- installation is carried out without the use of special tools or equipment;

- easy to install (no specialist is needed to work with it);

- quick connection (installation);

- instant start-up of water supply and sewer systems is possible (without preliminary testing);

- impossibility of installation due to an error or defect in the connection.

The mechanical fixing adapter ur 13 has an additional function - protecting the pipeline from deformation during soil subsidence or thermal expansion (compression).

During installation, it does not require preparatory work on systems that have already been put into operation (residual water in the pipes does not in any way affect the quality of the connection).

Can be installed in any weather conditions.

Overview of the UR-13 fixing crimp flange (video)

Positive properties

In water supply and sewer systems made of metal pipes, the installation of crimp flanges is very effective during urgent work, for example, in case of an accident.

They resort to using this type of reinforcement in the following cases:

- if necessary, create a connection that is subject to subsequent dismantling or changing the configuration of individual system elements;

- multiple temporary installations of the same device in different areas - this allows you to save considerable money;

- to increase the elasticity of the connection, which significantly reduces the risk of accidents during the operational period;

- when a quick connection is needed, without the use of special tools (equipment) and the involvement of qualified specialists - an obvious saving of time and money;

- to guarantee the absence of leaks, which often occur due to poor quality welding work;

- when an additional fixing element is needed on a certain section of the pipeline;

- in case of adverse weather conditions.

Compression flanges are indispensable when reconstructing a pipeline or replacing it with a plastic one.

Based on this, compression flanges are a universal tool when there is a need to make a high-quality connection or install additional equipment. Even in cramped circumstances, the quality of the connection will be guaranteed with the least time and material costs.

Flange adapter for PE and PVC pipes

The flange adapter is used to connect polyethylene PE and PVC pipes with flanged shut-off and control valves. Flange adapters are used in cold water supply when transporting non-aggressive liquid media.

Specifications

- Material: Ductile iron, brass retaining ring.

- Operating temperature: -25°C to +80°C.

- Application: water supply.

- Connection type: flange according to GOST 12815-80.

- Universal flange drilling PN 10, PN16.

- Seal: EPDM.

- Pressure: PN 10, PN 16.

- Standard: tightness class A according to GOST R 54808-2011.

Crimping flange for cast iron pipes, fixing 7602

In stock

Flange

crimp for cast iron pipes, fixing 7602 is used in pipeline systems transporting liquid substances. This type of fitting is made from malleable cast iron. All modifications of this product have additional epoxy powder coating, which significantly increases the reliability and durability of the flange connection.

Those. flange data sheet for cast iron pipes (PDF, 499.91 KB)

print version

Main characteristics of the product

- Brand

Standard sizes

| Name | Nominal size DN | Pressure | Price, rub. |

| Crimping flange for cast iron pipes, fixing 7602 | 50-300 | 16 | 0 |

Detailed Specifications

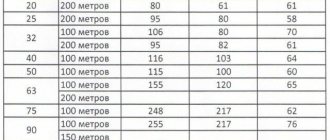

| Conditional pass | Pressure | Flange type | Length, mm | Weight, kg |

| DN 50/66 | 16 | 10/16 | 73 | 2,93 |

| DN 60/77 | 16 | 10/16 | 79 | 3,23 |

| DN 65/82 | 16 | 10/16 | 76 | 3,70 |

| DN 80/98 | 16 | 10/16 | 78 | 3,94 |

| DN 100/118 | 16 | 10/16 | 78 | 4,57 |

| DN 125/144 | 16 | 10/16 | 85 | 6,07 |

| DN 150/170 | 16 | 10/16 | 98 | 9,32 |

| DN 200/222 | 10 | 10 | 105 | 13,88 |

| DN 200/222 | 16 | 16 | 105 | |

| DN 250/273-274 | 10 | 10 | 105 | 17,56 |

| DN 250/274 | 16 | 16 | 105 | |

| DN 300/326 | 10 | 10 | 105 | 21,68 |

| DN 300/326 | 16 | 16 | 105 |

Flange

crimp for cast iron pipes, fixing 7602 is used in pipeline systems transporting liquid substances. This type of fitting is made from malleable cast iron. All modifications of this product have additional epoxy powder coating, which significantly increases the reliability and durability of the flange connection.

Flange for cast iron pipes 7602

differs from welded analogs by a crimp ring made of hardened steel. It is thanks to this design feature that the fittings presented in our online store provide reliable fixation and sealing of the pipeline, which avoids the need to use supporting devices, the presence of which significantly reduces the reliability and resistance of the main system to mechanical stress.

Compression flanges 7602

easy to operate and install. The fully assembled fitting, together with a gray cast iron clamping ring and sealing sleeve, is easily inserted onto the pipe section to be joined. Then the resulting structure is brought to the “counter” flange, observing the allowance of the edge of the pressure ring within 10 mm. After this, the bolts are tightened in a cross pattern.

Compression flanges

7602 allow easy dismantling of the connection without compromising the integrity of the pipes. In addition, fittings of this model can be installed on pipeline systems with no strict perpendicularity along the cut end protruding from the mating flange by 12-15 mm.

The online store valve-shop.ru offers to purchase crimp flanges with a diameter of 50-300 mm. As the dimensions of the product increase, the weight of the fittings correspondingly increases. All products sold, due to the high environmental friendliness of the sealing materials, are suitable for main systems transporting clean drinking water.

Flange

crimp for cast iron pipes, fixing 7602 is used for pipelines, the pressure of the working medium does not exceed the range of 10-16 bar. For installation of fittings of this type, standard M16-M20 bolts are suitable. The fixing crimp flange for cast iron pipes 7602 boasts an impressive warranty period (according to the manufacturer - 10 years). The actual service life of such fittings often exceeds the declared value several times.

PFRK crimp flanges for cast iron and steel pipes

A universal crimp flange is used in construction to connect different types of pipes (cast iron, steel, PVC, asbestos-cement) to each other, as well as to connect flanged fittings (gates, valves, faucets, valves, filters) to the pipeline without welding. Using a crimp flange, repair work is carried out to replace steel and cast iron pipes with polyethylene ones, and additional water branches are diverted from the main pipeline.

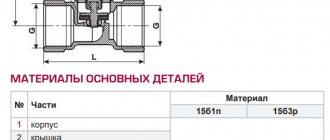

Compression flange design

The compression flange consists of two parts: a body with a flange and a ring, connected by fasteners (bolts, washers and nuts). A sealing rubber is installed between the body and the ring, which allows you to compensate for linear expansion when the coupling crimps the permissible pipe diameters for each type of crimp flange size, creating a tight connection. The compression flange is made of cast iron or steel with a heat-treated coating. The connecting dimensions of the flanges correspond to GOST 12815-80. The design of the crimp flange allows it to be installed on a pipe with an uneven edge, as a result of which it is possible to carry out repair work in a short time, without trimming the pipes.

Installation of universal crimp flanges

Installation of a crimp flange on a pipeline is carried out in the following way: a flange is placed on the smooth end of the pipe (socket part with a sealing gasket) and the bolts are cross-tightened, with the help of which the crimping process occurs and the fitting is securely fixed to the pipe. The compression flange works on the principle of a coupling, which makes the connection detachable and allows it to be reused.

Dimensions and characteristics of the fixing flange for PE pipes

- Name: crimp flange, PFRK, fixing flange, universal flange, flange adapter, crimp flange for all types of pipes, crimp flange for cast iron and steel pipes, flange-socket pipe with smooth end.

- Body: Ductile iron with epoxy coating.

- Type: blue or black fitting with a rubber seal inside.

- Seal: EPDM/NBR.

- Operating temperature: from -25°С to +70°С (short-term up to +80°С).

- Application: water supply systems, sewerage, air, slightly aggressive environments, viscous liquids.

- Dimensions: from DN 050 to DN 1000 mm.

- Pressure: PN 10/16.

- Connection type: flange (according to GOST 12815-80, EN 1092-2).

- Manufacturers: Dendor, HAWLE (Hawle), AVK (AVK), Jafar, Feros, Viking Johnson.

Advantages of universal crimp flanges

- corrosion protection;

- a large crimp range allows you to connect almost all types of pipes within a given nominal size;

- pipe flanging without welding;

- convenience and ease of installation;

- excellent performance under various operating conditions;

- long service life - at least 10 years;

- do not require additional equipment;

- Possibility of dismantling at any time after installation;

- The use of a lip seal allows pipe installation with minimal effort.

Application area

Flanges allow you to connect pipes or install additional equipment without welding.

In this case, the connection will be absolutely sealed and will receive an additional fixing element that will not allow a long section of the system to deform under the influence of external forces.

Crimping flanges are installed on pipes made of various materials - cast iron, steel, asbestos cement, PVC, which make up water supply and sewerage systems.

Quite often their use is due to the installation of such system elements as valves, shutters, taps, etc.

Installation on HDPE pipes is possible, but only if additional support is provided, which will prevent the occurrence of tensile forces that could lead to a violation of the tightness of the connection.

Design and installation

The main part of such a connecting element is a flat ring made of metal (cast iron, steel).

Compression flange allows for quick and reliable installation

The tightness of the connection is ensured by a rubber seal. The production of this type of fittings is regulated by GOST 12815-80, which describes all the operating parameters under which the equipment can be used.

It is impossible to do without a crimp flange when creating complex systems of cast iron pipes supplying or discharging water.

What is noteworthy is that its installation does not require the use of special equipment or the participation of highly qualified specialists.

It just takes a few steps:

- put on the ends of the connected pipes;

- align the mounting holes;

- insert and tighten the bolts in a cross pattern.

Connecting pipes using a crimp flange is possible even when their ends are not cut exactly perpendicular.

Using a crimp flange, you can make the transition from a metal pipe to a plastic one

In this case, deviation from a straight line is allowed up to 15 mm.

Installation of the crimp flange

The use of compression fittings simplifies repair work. The tightness of the connections does not suffer at all, while they acquire elasticity, which helps reduce the accident rate.

The crimp flange is mounted in the following order:

- The pipe is cut at a right angle. Note that the design of the fitting allows it to be successfully used even with an uneven cut. The chamfer is not removed after trimming.

- The flange is placed on the end of the pipe with the side where the diameter is smaller.

- An O-ring is installed that protrudes beyond the edge of the pipe to a distance of one centimeter.

- The rubber seal is coated with a layer of lubricant.

- The fitting is pushed onto the rubber seal until it stops.

- The bolts are tightened with a wrench using a criss-cross pattern.

Before installation, you need to loosen the bolts located at the corners of the flange

Carrying out work on installing a crimp flange, regulated by GOST 12815-80, can significantly reduce the time and cost, avoiding damage to materials that is inevitable when using welding equipment.

When joining pipes with wafer ends or connecting a fitting to a shut-off valve or other device, resort to installing flange adapters. The design includes:

- coupling;

- flange and a pipe welded to it.

The use of a flange adapter is associated with:

- ease of installation;

- possibility of application in above-ground and underground conditions;

- free access for maintenance;

- resistance to high temperatures and corrosion;

- duration of operation.

Crimping flanges connect different types of pipes, including polymer ones