Before cutting off a gas pipe, it is important to familiarize yourself with the regulations and rules for working with gas equipment. Have you noticed how few users do exactly this? The majority decides to look into SNiPs, already holding an angle grinder in their hands. Some even completely ignore the rules established by law. Meanwhile, each stage of this event is regulated and has a certain sequence of implementation.

Improperly shortening a gas pipeline is fraught with serious consequences, the most dangerous of which is the leakage of explosives. The work requires precise professional tools, experience and knowledge of safety precautions. Without such a set, you should not take responsibility for unauthorized modification of the pipe. It's better to entrust this to a master. But how can you check if it is working correctly?

In this article, we have presented all the rules regarding cutting gas pipes in houses and apartments, compiled an algorithm of actions, and a list of tools and materials. After reading it, you will save time searching for information, you will be able to correctly plan your actions, prepare all the necessary documents on time and monitor the work of the specialist.

Reasons for cutting a gas pipe

The most common motive is carrying out repairs, during which a decision is made to change the position of the slab or install new equipment.

All this can encourage owners to shorten the gas pipe. In addition, the initiator can be a representative of the gas company, who legally demands that the meter be moved out of sight.

It may also require shortening due to the inconsistency of outdated communications with modern rules. Standards are regularly updated, and residential property owners rarely independently monitor the changes made.

Following the rules

It is necessary to cut a gas pipe on the top floor or on another only legally. According to the laws, only a professional with the required level of clearance should repair, install and dismantle any gas equipment and networks.

Therefore, the first step is to find a reliable organization that cuts gas pipes. The requirements for it were outlined above. It should have reasonable price tags. The master arriving at the site must have the required permission and experience.

The second most important point is agreeing on the time of work. The key link here is the distribution point. It is he who stops supplying gas for the period of this event. Without permission and agreed time, no specialist will work.

Cutting a gas pipe without turning off the gas is madness and a crime.

And if the period of the operation has not been agreed upon with the necessary authority, you should not begin the work with your own efforts and offer bribes to the foremen. No normal person would dare commit this crime. And therefore, in the event of a refusal by the specified authority, there is no need to ask questions such as how to cut a gas pipe under pressure, how to quickly implement these tasks yourself, and other nonsense. Try to coordinate the issues at the distribution point again. Although there are usually no refusals.

4 Presentation of work results

Who to contact to replace the meter

It may also be necessary to cut a gas pipe if there is a need for planned or actual installation or replacement of gas consumption meters. Only representatives of the housing and communal services or gas service are authorized to carry out such manipulations.

Previously, when gas supply pipes were installed in private homes, they could be given the most unimaginable shapes - for example, “snakes” to go around furnace equipment, a column or boiler. That is, if modern homeowners want to get rid of such “beauty” and make the gas pipeline and heating pipes as inconspicuous as possible, they can resort to one or another method of cutting pipes.

Pipe replacement

Replacement of gas pipes is done quite rarely, since the fuel itself does not have serious destructive effects on them.

This is usually due to external factors - metal corrosion from high environmental humidity or physical damage to gas pipelines. But, if the owner of the premises wishes, qualified specialists will replace all the required communications with more modern and impact-resistant ones. It is also beneficial to replace pipes during a major renovation of a building to prevent their moral and physical obsolescence and the possibility of future breakthroughs.

Railing systems

Often in kitchens you can see a situation where a gas pipe runs along the kitchen apron, that is, between the countertop and the upper cupboards. In this case, the decor of the gas pipe can be made with an imitation of the railing system.

In this case, we mean a way to place various kitchen items directly on the kitchen wall on all kinds of shelves, hooks and brackets. So the gas pipe will look like a part of this design.

To fit the pipe organically in this case, only a few manipulations will be required:

- The pipe is thoroughly cleaned from paint to metal.

- Then it is coated with chrome paint in several layers to obtain an even color.

- After drying, various shelves and hooks for towels, oven mitts or napkins are hung on the wall directly above the pipe, so that it seems as if the accessories are hanging not on the wall, but directly on the gas pipe.

Following the rules

It is necessary to cut a gas pipe on the top floor or on another only legally. According to the laws, only a professional with the required level of clearance should repair, install and dismantle any gas equipment and networks.

Therefore, the first step is to find a reliable organization that cuts gas pipes. The requirements for it were outlined above. It should have reasonable price tags. The master arriving at the site must have the required permission and experience.

The second most important point is agreeing on the time of work. The key link here is the distribution point. It is he who stops supplying gas for the period of this event. Without permission and agreed time, no specialist will work.

Cutting a gas pipe without turning off the gas is madness and a crime.

And if the period of the operation has not been agreed upon with the necessary authority, you should not begin the work with your own efforts and offer bribes to the foremen. No normal person would dare commit this crime. And therefore, in the event of a refusal by the specified authority, there is no need to ask questions such as how to cut a gas pipe under pressure, how to quickly implement these tasks yourself, and other nonsense. Try to coordinate the issues at the distribution point again. Although there are usually no refusals.

Options for masking a gas pipe in the interior

It is impossible to tightly sew up decorative panels and hide a gas pipe in the wall (as well as pipes for heating and water supply), since this will complicate repair work in the event of an emergency.

Installation of a camouflage pencil case

Special canisters for gas pipes are commercially available

One of the options for hiding a gas pipe in the interior is to decorate it with an elegant grille, or laminated or plastic panels:

- A frame made of UD metal profile, usually used in plasterboard systems, is mounted along the pipe. When installing it, to obtain a level structure, you should use a level.

- Two UD profiles are connected to each other so that the grooves are directed in different directions, forming a fragment of an angle.

- The resulting fragment is connected using metal screws to the guides located on the wall.

- A plastic starting profile is attached to the resulting frame.

- The length of the panel is measured, cut with a hacksaw and installed in the grooves of the starting profile.

- After decorating the gas pipe with panels is completed, it is necessary to make several holes on each panel using a special cutter.

Other ways to decorate a pipe

Wrapping a gas pipe with hemp rope

The gas pipe can be made less noticeable if:

- Paint the pipe to match the color of the wallpaper.

- Wrap a hemp rope around the entire length of the pipe and tie several ribbons of strong fabric on it.

Pipe decor to match the colors of the wallpaper in the room

- You can use dark paint to make a stadiometer for a child on a gas pipe by simply drawing a vertical scale measured in centimeters.

- Tie a very bright small toy at the very top of the pipe.

- You can stick several multi-colored butterflies purchased in a store or made with your own hands on a gas pipe. You can make your own butterflies from small colored scraps.

- Decorate the pipe when this style is combined with the style of the kitchen or room, purchased from the construction market with halves of bamboo trunks.

Bamboo gas pipe decor

- Glue artificial flower heads of different shades and sizes onto the pipe in a scattered pattern, not along a line.

- Another option on how to disguise a gas pipe that is located vertically in a niche is to build a cabinet, which is also always useful in everyday life for storing various small items. To do this, you need to strengthen a special frame in the niche and then hang the cabinet itself on its hinges. Since over time such a structure can become deformed from gravity, it is advisable to attach small valves from the inside. The finished product is varnished and decorated, for example, by sticking small shells on it.

- Thick pipes can be decorated by using interior mosaics for this purpose, which will create an unusual and interesting element of decor that will look stylish and fresh.

- If you have artistic creativity, how to hide gas pipes will not be difficult for you. You can paint a gas pipe. For example, the pipe will be the trunk of a birch tree, and the leaves will be depicted on the wall. The pipe can be painted with various patterns. You can do the painting yourself, but if you have doubts about your capabilities and strengths, then it is better to entrust this task to a professional designer or artist.

An original method of masking a gas pipe

An interesting design option for a gas pipe is also the use of decoupage technique. To perform this decoration, you will need multi-layer napkins with a pattern, varnish and PVA glue. First you need to thoroughly clean the pipe and paint it. Then, after moistening a napkin with PVA glue, separate the top layer of paper with the pattern. This layer is glued to the gas pipe, while simultaneously smoothing the picture. The result should be a unique ornament on the pipe. The napkins must be completely dry, then the pipe is varnished to give the surface a shine.

There are many ways to decorate a gas pipe in the interior - you just need to use your imagination. But it is always necessary to remember about safety, therefore, when covering the pipe with decorative cabinets, they must, of course, be done without a back wall and with full access if necessary.

How to saw off a pipe evenly with a grinder: at 45 degrees, large diameter and around the circumference

Pipes are the most common type of rolled metal and plastic. These products are used in various fields.

Depending on the purpose, the products are cut to the required length, evenly or with a bevel at a certain degree. Several methods are used for cutting, including using a grinder.

You can understand how to cut a pipe smoothly with a grinder by learning all the intricacies of cutting.

Cutting metal with a grinder

How to cut a pipe evenly with a grinder

To ensure an even cut from the grinder, it is recommended to use special devices for fixing the metal workpiece. Prepared templates, miter boxes or vices are suitable for this.

It is necessary to mark the place for cutting very evenly so that the cut does not go to the side. For large volumes of work, for industrial purposes, special equipment in the form of lathes or tape machines is used to cut pipes.

You can make vertical and horizontal cuts on a metal profile, and cut it at any angle.

Cutting pipes at right angles

The technology for cutting at right angles is quite simple. You just need to fix the metal part, mark the cut line, and directly cut the workpiece. The end of the cut part of the pipe should be above the support.

To mark the cut, use wide or narrow tape, a marker or a simple pencil. You just need to wrap the product, mark the cut location, and make an even cut. When winding, both ends of the tape must fit together accurately

Methods for cutting metal products at an angle

Conventional perpendicular cutting at 90°, using a grinder, is carried out quickly and efficiently, if you do not neglect the advice of specialists.

Many people believe that if a large tool with a large powerful disk is used for sawing, then there is no need to apply markings. Experts do not recommend sawing without marking, because after cutting the parts may not align.

Note! Before you understand how to cut a pipe evenly with a large grinder, it is better to make markings several times to make sure the calculations are accurate. After cutting a profile or gas pipe incorrectly, you will have to start working all over again.

Features of cutting a cylindrical pipe at 45

Most often, making a cut at an angle of 45 degrees is required when installing heating or plumbing systems. The main difficulty in carrying out the work is that after combining the cut parts of the pipe, a right angle of 90 degrees should be obtained. A simple way to prepare a homemade pattern will help you achieve the quality of the cutting process:

- Prepare a plain white sheet of paper.

- Fold it diagonally.

- The protruding part of the sheet must be cut off with scissors so that when unfolded you get a square.

- The resulting triangle must be wrapped around the pipe so that the long side runs parallel to the section.

A paper template is great for cutting metal products in the middle.

Paper template

The resulting triangle, folded in half, must be divided into two parts. Then the templates need to be wrapped around the pipe and secured with tape or tape. The templates should be positioned so that one edge of the base coincides with the second.

Reasons for moving gas pipes in the kitchen

All work on moving and replacing metal pipes, especially those requiring welding, is carried out by representatives of Gorgaz or another authorized organization. Having received an application from residents, they are always interested in the reasons for the planned transformations.

Most often, it is necessary to change the piping in the kitchen without changing the layout or moving equipment to other rooms.

The reasons may be different:

- replacing old equipment - purchasing a gas water heater, stove or boiler - which requires a little more space;

- major renovation in the kitchen;

- moving the gas stove from the window 0.5-2 m towards the sink;

- changing the installation location of the gas meter;

- moving a horizontal pipe from a great height under a table top, etc.

Often, the relocation of pipes is required in new buildings, where the original location of significant kitchen objects defies logic and explanation: suppose, if in a 15-meter kitchen the gas stove is located near the window, the sink is in the opposite corner, and the hood is on the other side, above the entrance to the kitchen.

We have to correct the design mistakes and move the stove closer to the sink so that food can be cooked in comfortable conditions.

The most common reason is the purchase of a new kitchen set with built-in equipment (oven and hob). In this case, the pipes need to be either shortened or lengthened, depending on the planned installation location of the devices.

If you want to find out how best to move a gas pipe in an apartment with redevelopment, we recommend contacting a design organization to draw up a transfer plan.

The fact is that in typical city apartments it is prohibited to reinstall risers, pipes, as well as any gas equipment in living rooms, and even to combine a kitchen and a room, permission is also required.

Recommendations from experienced professionals

It is much more convenient to install and connect a gas stove to a cut pipe when an even and vertical cut is made during processing. When choosing a tool, preference is given to a pipe cutter.

Depending on the method of forming a cut, these products can be telescopic, roller or clamp type. Each model is selected based on ease of use in the kitchen. Very often the most suitable option is a mini pipe cutter.

Mini pipe cutter

Unusual disguise options - use your imagination

In many homes, there are gas taps installed at a height of 70-75 cm from the floor - they are easily hidden under the countertop of the set, but there is a problem with access to them. Craftsmen did not stand aside here either, making removable countertops in their kitchens.

This gas pipe will hide perfectly under the countertop.

In some cases, you don’t have to make removable tabletops: as an option, you can simply extend the gas handle, making it higher than the level of the tabletop, while making a special hole for it in the tabletop itself.

It turns out that only a handle will be visible on the surface of the countertop, by turning which you will close and open the gas damper (gas workers will have no complaints against you - such designs fully comply with all standards).

Hole for gas pipe

When renovating, another pressing problem may arise - hiding the gas riser in the kitchen. Having visited various authorities, you will not receive an intelligible answer - it is allowed to hide it or not, but something can really be done.

For example, burying it in a box equipped with a removable panel (at the level of the gas tap) - such a design is, in principle, permitted and will not cause any complaints from gas workers.

Railings

Nice railing where a gas pipe fits perfectly

In many apartments you can see a picture - gas pipes run along the entire kitchen wall, and exactly in the place where the apron should be. How to hide it and give your kitchen expressiveness? For such cases, roof rails were invented! What it is?

The railing system includes an innumerable number of shelves, hooks and hangers for placing all kinds of kitchen utensils. In this situation, the gas pipe can serve as an excellent structural element for the roof railing system.

Railing along the entire length of the apron

Equipping your kitchen with such a system is quite simple; you just need to perform the following manipulations:

- Clean gas pipes until shiny;

- Cover them with chrome paint;

- Use your imagination in this matter and place heated towel rails, hooks for mittens and aprons above the pipe, and attach shelves for plates and other kitchen utensils.

Your kitchen will be transformed before your eyes - the convenient arrangement of kitchen equipment will turn this room into a real treasury for the housewife, in which she will enjoy working.

Price aspects

How much does it cost to shorten a gas pipe? The cost of this operation is determined by its complexity, applicable technological methods and materials. Typically, companies try to create the most favorable conditions for their clients.

The following is a summary table of the average price. This does not take into account the price tag of blocking the pipe. The pipes are cut, threaded, and the valve is installed.

| Pipe diameter (cm) | Price list |

| 1,5 | 2700 |

| 2 | 3200 |

| 2,5 | 3700 |

| 3 | 4200 |

What do the regulations say about masking gas pipelines?

Many, no doubt, have seen all sorts of tricks that neighbors, relatives and friends go to during repairs in order to hide gas pipes. The Internet offers even more ways. However, few methods may suit your design. At the same time, certain methods of decoration are generally prohibited from being used inside residential premises.

For example, it is prohibited to shorten, cut, reposition or transport gas kitchen equipment yourself. To carry out such actions, permission from the gas service is required, and work on dismantling and moving systems must be carried out by professionals.

Failure to comply with this rule threatens kitchen owners with considerable trouble if a violation is discovered. At best, they will be required to pay a fine for arbitrariness, after which they will be forced to eliminate the violations; at worst, due to poor quality work, there is a possibility of a gas leak, which could lead to an explosion and death of residents.

So is it possible to hide a gas pipe in the kitchen yourself? Of course it is possible, but many owners refuse drastic options, preferring to hide the pipeline in various ways.

Among the various solutions for closing unwanted protrusions, do not forget about building codes and regulations that contain a number of prohibitions. For example, it is strictly prohibited:

- hide gas pipes in any mines;

- cover with a non-removable box;

- mount into the wall, reducing accessibility.

You can formulate basic requirements to guarantee safety and at the same time transform the space.

- First, the space should not become completely enclosed to prevent critical concentrations of natural gas from leaking.

- Secondly, if an object is closed, then free access to it is always necessary when a specific smell appears and to check the condition of the system.

- Thirdly, it is dangerous to use damaging materials when hiding.

Self-activity or specialist services

Can I cut the gas pipe myself? This operation may seem simple at first glance. But it must be carried out in coordination with gas and utility services. It must proceed without violating SNiP. And besides, the final result of independent intervention can be an explosion. After all, there are many nuances in this matter. Only experienced professionals can handle them. Therefore, any amateur activity is prohibited here.

For these tasks, it is better to contact special licensed companies. They must have legal permission to carry out work on gas infrastructure in a given region. Their service is not free. The cost of shortening a pipe is determined by the following factors:

- The level of complexity of the work.

- The materials and technologies involved.

The master analyzes each case individually. A specialist visits the site at any time convenient for the customer. Most often, the visit takes place on the same day. An analysis of the facility and the scope of upcoming work is underway. An estimate is being formed. Approved.

Other requirements for the company carrying out this work:

- The use of equipment characterized by high precision.

- Providing a guarantee for these works.

- Availability of a complete set of necessary documents.

- Consulting at all stages of work.

DIY box manufacturing technology

How to make a plasterboard box for pipes in the kitchen yourself? Despite the fact that drywall is easy to process, all operations must be carried out carefully and carefully, since the material, along with many positive qualities, has fragility. The entire installation process occurs in several stages.

Required tools and materials

To install the box you will need:

- Drywall is moisture resistant.

- The profile is rack and guide.

- Crab mounts.

- Screwdriver.

- Self-tapping screws for metal.

- Drywall screws.

- Grinder with cutting discs for metal and drywall.

- Dowels 6x60.

Preparing the premises

The essence of the preparation is to ensure that the box continues to perform its functions effectively and for a long time, as well as to facilitate the work.

To do this you need:

clear the space near the riser, remove all objects that interfere with work;

- clean old putty from the walls;

- check pipes for damage;

- treat the walls with a solution that prevents the appearance of mold and mildew on them.

After this, it is necessary to apply markings to the floor, walls and ceiling in accordance with the previously drawn up project. In this case, be sure to use a level to avoid curvature of the product.

Frame assembly

The manufacture of the box begins with the assembly of a metal frame, which serves as the basis for further fastening drywall to it. To do this, the metal profile is cut into pieces according to the width of the future box and mounted to the wall in increments of 30 cm. In this case, the first fragment is attached to the countertop of the floor cabinet or table, and the last one is attached to the bottom plane of the wall cabinet.

Step-by-step instructions for installing the frame:

- a guide profile is attached in accordance with the marking line;

- using a perforator, a hole is made in the wall and in the profile into which the dowel is inserted;

- the profile is screwed to the wall. Vertical racks must be secured to the walls and floor;

- all elements are checked using a building level;

- The profile is attached on the other side using the same principle.

The next step is to connect the fixed profiles with jumpers, which are installed in increments of 50 cm, which will result in rigidity to the structure. In this case, gas pipes should be hidden using elements that prevent them from dangling or not fitting tightly.

Sheathing with plasterboard

After completing the installation of the metal frame, you can move on to the next, no less important and responsible step - covering it with plasterboard. To do this you should:

To do this you should:

- apply markings to the sheets in accordance with previously selected dimensions;

- cut out the required elements using a construction knife;

- Screw the resulting parts to the profiles with self-tapping screws. In this case, you must try to ensure that they do not protrude above the surface of the material, but are slightly recessed.

In addition, the box should be sewn up with plasterboard in such a way that the gap between the parts is as small as possible. The design requires final finishing, which will facilitate further design in accordance with the style of the kitchen.

This requires the following operations:

- serpyanka (special self-adhesive tape) is laid on the joints;

- putty is applied on top of it, and it is also necessary to seal all the places where the screws are screwed in;

- after it dries, all remaining roughness is rubbed down with sandpaper;

- The surface of the box is coated with a primer, and it is best to use a deep penetration material. After drying, the structure is treated with an antiseptic that prevents the appearance of fungus and mold;

- a thin layer of finishing putty is applied.

Carefully following these steps will result in a perfectly flat surface of the box.

Finishing the structure

In conclusion, all that remains is to design the closing box in accordance with the kitchen interior. The characteristics of drywall make it possible to finish it with almost any type of material:

- tile . An excellent option for the kitchen, especially if the riser is close to the sink or stove. Such a solution will look best in the kitchen;

- painting with waterproof paint. Also quite a popular option, since skillful painting allows you to effectively highlight the box or ensure its inconspicuousness;

- water-repellent wallpaper. Less common, but also used to hide structures;

- imitation stone. A stylish and attractive solution, but it is not suitable for every interior.

Choosing a Trimming Tool

Hacksaws and pipe cutters are often used to cut gas pipes. The grinder is used less often. Quite often, gas service workers use electric or gas welding. According to experts, each tool has its own advantages and disadvantages.

Let's take a closer look at them:

- hacksaw for metal . Makes it possible to make a neat cut without soot and other traces of processing. A significant disadvantage is the labor intensity and duration of work;

- pipe cutter Its use ensures the perpendicularity of the cut, a smooth end and the absence of metal filings. The downside is the volume of the tool, which often exceeds the distance between the wall and the pipe;

- Bulgarian _ The advantage is high cutting speed. The disadvantage is the formation of sparks, which require additional protection of surfaces in the work area;

- gas welding and electric welding . With proper preparation, including thorough cleaning of the metal from paint, dirt and rust, the tool provides a high-quality cut. But it is worth remembering that the method is fire hazardous.

An experienced specialist will determine the advisability of using this or that equipment during the first inspection. The choice of tool depends on the skills of the master, the availability of equipment, the location of the pipes relative to the wall, as well as the material of the walls and ceilings.

Even the most compact pipe cutter may be useless if the pipe is laid almost close to the wall. The only way out in this case is to try to bend it a short distance or use another tool

In wooden houses, special protection of walls and ceilings is required when using an angle grinder or gas welder. Flying sparks and high metal temperatures can cause a fire.

Therefore, before work, it is necessary to cover all wooden surfaces with metal sheets.

Fine for moving a gas pipe in an apartment

A situation often occurs when it becomes necessary to move a gas appliance to another location. As a result, it is necessary to relocate the gas pipe in the apartment. Such work should be approached with full responsibility and should be carried out by professionals with the appropriate skills and knowledge.

Such a service from specialists is not cheap, but incorrect actions can lead to very sad consequences.

It should immediately be noted that moving gas pipes in an apartment consists of two large and important stages:

- coordination of the movement of gas equipment in special services;

- carrying out work to move the gas supply line.

Instructions for moving a gas pipeline

For professionals, moving gas equipment is not a very difficult task; it is carried out in the following sequence:

- Using the gas tap, turn off the gas supply to the room.

- The gas pipeline is then purged to remove any remaining gases from it.

- In the place where there is a connection to the gas pipeline, an unnecessary section of pipe is cut off and the resulting hole is welded (read: “How to cut a gas pipe - rules and recommendations”).

- A hole is drilled in a certain place and an outlet, which is a metal tube and tap, is welded to the gas pipeline.

- Then they install the branch to the gas appliance by applying threaded connections.

- Before using the equipment, the installed gas tap and pipe with welded joints must be checked for leaks.

To connect household gas units, use a flexible bellows hose no more than two meters long. Before moving the gas pipe in the apartment, it is advisable to think about the fact that perhaps this length of the hose will be sufficient and this movement will not be required.

To work with gas pipelines, specialists must have a permit; they undergo recertification at least once a year in order to confirm their qualifications.

Preparing to move pipes

Before moving a gas pipe, the property owner should contact the gas supply organization at his place of residence with a statement regarding his desire to make changes to the gas supply system of the apartment. A technical specialist will come to the specified address to inspect whether there are conditions for moving gas equipment.

If possible, a representative of the organization will make the necessary calculations and draw up a cost estimate. It is possible that there will be a need to draw up a new technical plan for the room where the gas pipe passes, in which the transfer will be taken into account. After making an advance payment for services, the gas workers will set a day for the work.

The owner of the premises needs to make sure that the gas company is certified and ask its employees for the appropriate documentation, which should be provided to customers upon their request.

When specialists arrive to move the gas pipe, you should check that they have certificates that will confirm their qualifications. Only then can craftsmen be allowed into the apartment. After completing the transfer process, gas workers must draw up a report on the work done and make a corresponding entry in the gas passport.

SNiP provisions on the arrangement of gas pipelines in an apartment

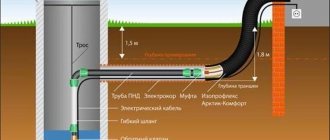

According to the provisions prescribed in SNiP, the distance between a gas pipeline laid openly in a room or in the floor and utilities for other purposes (sewage, heating, water supply systems) should allow for inspection and repair of gas equipment and related fittings.

At the same time, gas pipelines must not be allowed to cross ventilation grilles, window and door openings.

Between the gas pipe laid in the wall and the means of wired communication and broadcasting, the minimum gap is determined taking into account safety precautions, which are provided for by the rules regarding work with cable lines.

The minimum distance and permissibility of intersection between the gas pipeline and electrical wiring located indoors are determined on the basis of the PUE.

The gas pipeline is laid in residential buildings at a height of at least 2.2 meters from the level of the floor covering to the bottom of the pipe, and if there is insulation on it, to the bottom of the insulating material.

How to perform a transfer or replacement

It is not recommended to change anything yourself, even flexible eyeliner. All the more so, cutting, extending or moving pipes should be carried out by a representative of the gas service. However, knowing the sequence and some nuances of actions when working with pipes will not hurt the homeowner.

#1: Preparing to work with pipes

Usually a team of workers (most often 2 people) arrives within the next week after approval. By this point, it is already known which sections will be dismantled or extended, and whether additional equipment will be installed, for example, a geyser. Let's look at what else is worth considering.

All equipment used in the kitchen belongs to the owner of the apartment and is purchased at his expense, therefore, it is better to immediately ask what else needs to be purchased for moving appliances and working with pipes.

If we are talking about connecting a stove or oven, you will have to buy a bellows hose of a certain length. Installers bring metal pipes with them, their cost is included in the total payment for services.

To avoid any hiccups and for the work to proceed quickly, you need to free up space from excess furniture or other items. Anything that cannot be removed must be covered with thick, non-flammable material.

#2: Dismantling the old structure

Most likely, when moving the pipe, you will need to cut off a piece of the old one and build a new one, but in a different direction. To do this, the master, using a special tool, removes unnecessary sections of pipes.

When dismantling the branch leading from the riser to the consumer, it is necessary to leave a small area on which the gas valve is attached. This horizontal piece of pipe cannot be removed or changed. The only exception is if the pipeline is damaged and requires complete replacement.

Sometimes residents of the top floors require the removal of a large piece of pipe that rises 1.8 m from the floor to the ceiling and then bends down 180°. It is strictly prohibited to cut the pipe and install a tap on the remaining section. The only way out is to weld the pipe so that the tap can be installed under the countertop, at a height of 0.75 m.

#3: Options for changing gas wiring

The transfer of pipes always follows the same pattern: they are moved parallel to the ceiling or walls, since diagonal and any crooked placement is prohibited. Consequently, most often the branch from the riser is lowered down, under the tabletop (rarely raised), or the vertical fragment is moved to the right/left.

When changing the direction of pipes, remember the following rules:

- internal gas distribution is an open system, all covering elements are camouflage in nature and should not be firmly fixed;

- It is prohibited to lay pipelines through ventilation ducts, as well as doors and windows;

- metal structures are predominantly used; flexible connections are allowed in equipment connection areas, but their length should not exceed 3 m;

- a rigid method of connecting pipes and hoses to pipes is used;

- Pipe transitions through walls/partitions are equipped with special adapters - sleeves.

Any work related to the transfer of pipes must begin with shutting off the gas. The organization providing the services is responsible for this.

#4: Welding metal pipes

According to SNiP standards, any changes in the position of pipes must occur by welding. Detachable connections between two sections are prohibited.

Threaded connections are used only when installing gas meters, household equipment and shut-off valves.

Places burned by welding have an unpresentable appearance and also require protection against corrosion. After finishing the work, they must be treated with waterproof metal paint, matched to the color of the walls.

#5: Using Bellows Hoses

Before extending or moving a gas pipe, it is necessary to consider the option of installing a flexible transition. This is done using a bellows hose.

Previously, rubber and rubber-fabric products were used, but the bellows turned out to be stronger than outdated materials. At its core, it is a metal or composite corrugation, but it has unique qualities.

For a long period of time, it maintains tightness and elasticity even under active mechanical stress. The structure of the shell is preserved even under high pressure of the transported medium or under constant mechanical stress.

The installation of bellows connectors is also carried out by a gas service worker. He connects boilers, columns, stoves and ovens in accordance with all the rules of the PUE and, if necessary, uses adapters and seals, for example, FUM tape.

They try to hide gas pipes in the kitchen behind decorative panels or furniture. Options for masking a pipeline are described in this article.

Reasons for moving gas pipes in the kitchen

All work on moving and replacing metal pipes, especially those requiring welding, is carried out by representatives of Gorgaz or another authorized organization. Having received an application from residents, they are always interested in the reasons for the planned transformations.

Most often, it is necessary to change the piping in the kitchen without changing the layout or moving equipment to other rooms.

The reasons may be different:

- replacing old equipment - purchasing a gas water heater, stove or boiler - which requires a little more space;

- major renovation in the kitchen;

- moving the gas stove from the window 0.5-2 m towards the sink;

- changing the installation location of the gas meter;

- moving a horizontal pipe from a great height under a table top, etc.

Often, the relocation of pipes is required in new buildings, where the original location of significant kitchen objects defies logic and explanation: suppose, if in a 15-meter kitchen the gas stove is located near the window, the sink is in the opposite corner, and the hood is on the other side, above the entrance to the kitchen.

We have to correct the design mistakes and move the stove closer to the sink so that food can be cooked in comfortable conditions.

It is strictly forbidden to carry out work to move the gas riser. The only change allowed is to disguise the pipes with easily dismantled structures, for example, wall-mounted kitchen cabinets

The most common reason is the purchase of a new kitchen set with built-in equipment (oven and hob). In this case, the pipes need to be either shortened or lengthened, depending on the planned installation location of the devices.

If you want to find out how best to move a gas pipe in an apartment with redevelopment, we recommend contacting a design organization to draw up a transfer plan.

The fact is that in typical city apartments it is prohibited to reinstall risers, pipes, as well as any gas equipment in living rooms, and even to combine a kitchen and a room, permission is also required.

Duration of work

The duration of work is determined by the following factors:

- Structural specifics of the pipe.

- The skill and experience of the worker.

Tools used in work. The pipe can be cut with a grinder, welding method, hacksaw or pipe cutter.

The richer the employee’s theoretical and practical experience and his skill, the more diverse the range of tools, the higher the dynamics of work.

It is better to contact a company with a proven reputation. Its masters will master tasks of any complexity. The work is completed quickly and with very high quality. This is a guarantee of safety, reliable operation of gas appliances, and comfort in the apartment.

5 Special requirements

Painting

The most affordable and easiest way to disguise is to paint the pipe to match the kitchen backsplash. Gas service employees will be satisfied and will not find fault with this decision.

Of course, the problem will not disappear completely from view. But the pipes will definitely not be an eyesore with their design.

Now you can achieve any shade of paint. Don't be afraid to experiment. After all, you can always paint over it with a new layer.

Or, on the contrary, you can use painting to emphasize the design on the pipes. For example, if you turn gas communications into birch branches. It's easy to do.

Mark black strokes on a white surface with strokes. If there is no open fire nearby, then wrap the pipe with an artificial vine with leaves. This option is not suitable for modern style kitchens, but will look great in kitchens made of natural wood.

Main stages of work

Since cutting a gas pipe in an apartment is possible only when the entire riser is disconnected, it is necessary to agree with the utility service not only the date, but also the exact time of the work.

Housing and communal services employees will notify residents in advance, and upon completion they will personally notify them that the gas supply will be restored. The master, who arrives at the appointed hour, will once again check the owner’s documents, turn off the gas, ensure effective ventilation and begin work.

Further work is performed in the following sequence:

- According to the scheme approved by a specialized service, the master will cut off the excess pipe segment.

- Install the plug into the resulting hole.

- If necessary, perform welding by attaching rotating elements.

- Install shut-off valves, sealing the FUM joint with tape with a thickness of 0.1 to 0.25 mm.

- Check the integrity of the gas pipeline.

- Will draw up a certificate of completion of work, which must be signed by the owner of the property.

The integrity of the connections is checked by applying a soap solution. When bubbles appear, the technician must re-examine the questionable connection and check again.

After confirming integrity, a representative of the gas service must issue a certificate of service provision and give recommendations for treating pipes with a coloring compound.

Since the main purpose of painting is to protect the metal from moisture and rust, gas workers usually recommend vapor-proof compounds. The owner can choose the shade in accordance with the main interior palette.

Possible mistakes

When organizing work, errors are taken into account, which must be eliminated in the future. These include violations of the requirements of current standards, such as:

- Lack of coordination with local utilities.

- The neighbors were not warned about the gas riser being turned off.

- Incorrect pipe cutting tool selected.

- Safety regulations regarding fire protection were violated.

After shortening the pipe and connecting it to the gas stove, there is no need to immediately open the gas supply valve. From this point on, enhanced monitoring of the condition of the pipe system is necessary. To do this you will need to perform the following operations:

- Organize its purging to remove excess air from the pipe lines.

- Using soap foam, check the tightness of all existing connections (both threaded and welded).

Leak test

- Matches are not allowed to be used at all.

Upon completion of the verification operations, you can begin to operate the upgraded wiring (open the valve).

Legal requirements for the customer and contractor

Since a faulty gas pipeline is a source of danger to people’s lives, legislators identified the customer - the initiator of cutting or moving the gas pipe and the contractor. The law places special requirements on the latter.

Therefore, it is worth paying special attention to them

Who should apply?

Until 2005, in the Russian Federation, municipal gas services were responsible for the condition of gas pipes and equipment connected to them. Later, the law shifted it to homeowners: management companies began to monitor intra-building networks in apartment buildings, and owners or tenants began to monitor intra-apartment networks.

In private households this has also become the responsibility of the owners. Therefore, before shortening the gas pipe in the kitchen, it is necessary to determine the owner.

The figure visualizes the division of responsibilities between the management company and residents. At the same time, payments for servicing in-house equipment are included in monthly receipts. But for manipulations with intra-apartment networks, including cutting pipes, residents pay separately

Confirmation of this rule can be found in Resolution No. 410 dated May 14, 2013, edited by the Government of the Russian Federation on October 6, 2020.

According to the general provisions of this resolution, when cutting a pipe in an apartment or private household, the customer can be the owner of the square meters or the tenant. In this case, the lease must be officially formalized.

Who has the right to do the work?

The executor is also clearly defined in the government document. This is a specialized organization that carries out maintenance and repair of gas equipment under an agreement with the owners or management company. In addition, the supplier company can also take care of cutting the pipes.

The law imposes the following requirements on the performer:

- the presence of certified employees with specialized education on the staff;

- availability of production instructions for carrying out gas hazardous work;

- mandatory use of control and measuring equipment.

All tools and devices used by gas service technicians must undergo regular calibration according to a schedule approved by the organization.

As can be seen from the list above, the requirements for the performer are quite high. Therefore, it is not worth shortening gas pipes yourself or with the help of unauthorized persons.

Preparatory stage - obtaining permission

First of all, it is necessary to determine whether, from a technical point of view, it is possible to shorten the gas pipe and how to do this. To do this, you need to apply to a specialized organization.

The application is written in free form, indicating the exact address and passport details of the owner.

Since the applicant, by law, can only be the owner of the premises, a gas service employee may ask to see title documents already on the first visit

After receiving a signal from the owner of the premises, the gas service sends its representative to the place. The foreman will listen to the applicant’s wishes, inspect the gas pipeline and equipment connected to it, and issue a verdict. If the customer’s wishes turn out to be contrary to safety standards, he will offer other options.

After finding the optimal solution, the specialist will draw up a diagram showing the condition of the pipe after cutting. Based on this scheme, the gas company will issue a permit and provide an estimate. It will take into account the cost of upcoming work and consumables.

Reasons for moving gas pipes

The reason for moving pipes may be their emergency condition

The official program of government agencies allows major repairs and replacement of gas main risers in old apartment buildings free of charge.

Reasons for work:

- gas emission was detected when the tap was closed (repairs are being done in the apartment);

- damage to pipes and welds is visually distinguishable;

- The service life has expired (for houses built more than 50 years ago).

Utility workers report a planned replacement of the supply pipeline, and the organization is developing a work schedule. Residents are given access to equipment within designated periods.

Redevelopment

Replacing pipes may be associated with the purchase of new furniture for the kitchen

A common reason for altering the gas distribution in an apartment is the purchase of a kitchen unit that has a built-in heated panel or oven. For installation, it is necessary to shorten or lengthen sections of pipes in order to supply gas to the installation site.

It is recommended to contact a licensed design firm to draw up a plan for redevelopment, movement of equipment and laying a gas pipeline from the common input. In apartments, it is prohibited to move risers, slabs, and pipelines into rooms. Coordination is also necessary to combine the living room and kitchen.

Major renovation

Before starting repairs, housing and communal services inform residents about the inspection and the start of repairs. Carrying out dismantling and installation work causes discomfort for residents of the apartment. Residents are concerned that experts may damage furniture or finishes and are trying to negotiate additional agreements with contractors.

The organization invited to redo the gas pipeline is not required to draw up an agreement with the owners of each apartment. Owners provide access to the replacement site as part of the utility equipment replacement program. Residents do not have the right to refuse, so as not to provoke further emergency situations. In the absence of cooperation, the gas workers turn off the common tap on the riser.

Alteration of gas wiring

Flexible gas pipes cannot be carried by yourself

Sometimes there is a gas pipe where kitchen cabinets are hung. The owners cut the back walls, make holes in the furniture, and move the cabinet away from the wall using spacer bars. Such actions entail a reduction in kitchen space. Specialists can weld the line at a different height from the floor so that furniture installation takes place without obstacles.

Duration of work

The duration of work is determined by the following factors:

- Structural specifics of the pipe.

- Tools used in work. The pipe can be cut with a grinder, welding method, hacksaw or pipe cutter.

- The skill and experience of the worker.

The richer the employee’s theoretical and practical experience and his skill, the more diverse the range of tools, the higher the dynamics of work.

It is better to contact a company with a proven reputation. Its masters will master tasks of any complexity. The work is completed quickly and with very high quality. This is a guarantee of safety, reliable operation of gas appliances, and comfort in the apartment.

Conclusions and useful video on the topic

The initiator of shortening the pipe can be the owner of the premises, and the contractor can be a specialized organization with a staff of certified specialists with specialized education.

Trimming should be carried out taking into account the restrictions prescribed in SNiP 2.04.08-87, after turning off the fuel supply throughout the riser. Independent manipulation of the gas pipeline is prohibited.

Please note that in the video the master uses both an angle grinder and an electric welder. The company focuses on checking the quality of work and issuing accompanying documentation:. If you have ever cut gas pipes in an apartment or participated in this process, we invite you to share your observations

Below is a form in the fields of which you can leave, ask questions to relevant specialists or other site visitors

If you have ever cut gas pipes in an apartment or participated in this process, we invite you to share your observations. Below is a form in the fields of which you can leave, ask questions to relevant specialists or other site visitors.

Existing restrictions

The main condition that must be unquestioningly observed before starting work is compliance with the requirements of SNiP 2.04.08-87, which boil down to the following restrictions:

- gas distribution in residential buildings is carried out exclusively by welding metal pipes;

- threaded connections are allowed only at the points of connection with the metering device (meter) and at the points of connection with the fittings of consumers available in the kitchen;

- after cutting (shortening) the section of the gas pipeline must be provided with free access necessary for servicing the gas main;

- according to SNiP 2.04.08-87, valves that block the flow of gas to kitchen consumers must also remain open (hiding them in furniture niches is not allowed);

- the distance from the kitchen pipe to various types of chimney must be at least 2 meters horizontally and 80 centimeters vertically;

- The distances specified in the standards must also be maintained in relation to the heating pipe lines.

Note! In accordance with the requirements of SNiP 2.04.08-87, a ventilation system is required in the room to ensure effective air outflow from it.

Upon completion of the work, all detachable connections are checked for leaks using a special monitoring device called a gas analyzer.