Drilling wells for water supply to a private home is the most common method of extracting water. Moreover, their depth can reach 150 meters when water is drawn from an artesian aquifer (300 meters in industrial wells). It is not always possible to discover an aquifer during the drilling process, and the exploitation of the well source itself may become impossible for a number of reasons—in these cases, well abandonment will be required.

When carrying out work, it is useful to know the correct technology for carrying out this procedure - this will prevent harm to the environment and human health. In addition, compliance with the technological rules of liquidation or conservation is also necessary for the owner of the site if he drills another well - a contaminated aquifer as a result of incorrect liquidation measures or their absence will make the water unsuitable for further use.

Rice. 1 Abandoned well sources

When is it necessary to abandon wells?

Liquidation of a water well may be caused by the following reasons:

1. During drilling, an aquifer was not discovered (absence or too deep), an insurmountable obstacle or the geological structure of the soil makes the construction of a well unprofitable (fine pulverized sand).

2. Wells that have expired. A well source on sand can operate from 5 to 15 years, after which its flow rate decreases and operation becomes unprofitable.

The main factor influencing the service life of the well is the composition of the sand - with a fine-grained structure, sanding will occur quite quickly, if the fractions are large, the well will last much longer (the service life on pulverized sand is several days).

3. Impossibility of further exploitation due to severe pollution (silting) of the aquifer. This problem only occurs in sand wells under the following circumstances:

- Incorrect installation of the well during drilling. As a result, the lower pipe with the filter in the casing will not be located in the aquifer, but will go too deep into the sandy-silty bottom. As a result, water will enter the source only through the upper part of the filter (the lower part will be in the rock), and over time, sandy sediment will block the inlet holes.

- Mistakes when selecting a well filter. A filter casing pipe with holes that are too large will lead to a large amount of sand fractions entering the channel and causing it to silt.

- Low water consumption. Low water flow will lead to the fact that small sand or clay particles that are not pumped from the source to the surface will gradually settle to the bottom, reducing the well flow rate. If pumping is not carried out in a timely manner, the thickness of the bottom sediments will increase over time, they will become too dense in the lower part and further exploitation of the source will become impossible.

- Use of surface electric pumps. If the source has a depth significantly exceeding the maximum lifting height of self-priming surface pumps of 9 meters, then as a result of water intake from its surface, and not in the near-bottom area, siltation of the bottom will occur over time, leading to a decrease in the static level and well flow rate.

- Application of a vibration electric pump. As a result of vibrations, bottom sediments are gradually compacted and the well source quickly silts up. If the vibrating electric pump has an upper water intake or is located too high, the process is further accelerated.

4. Technical problems. In individual wells, damage to plastic casing pipes may occur (cracks during installation and during operation, surface destruction when using defective materials). Common reasons for well abandonment are the fall of the electric pump or its parts into the well channel as a result of improper installation. If it cannot be removed to the surface, it will block the filter inlets or contaminate the water through corrosion of internal parts or oil that may leak into the water source.

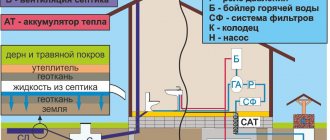

Rice. 2 Liquidation plugging of a well - diagram

Removal of wells from mothballing and restoration of abandoned wells

I have never encountered this, but life forced me to look in this direction. If anyone has any information or experience, please share, everything is interesting: technology, equipment, personal impressions and memories. Thanks a lot!

About 2 years ago, we at Tatneft reactivated the well for injection, a natural storage facility for natural gas. was mothballed on December 31, 1969. The documents were not found, how or what, the statute of limitations. The essence is this: 8″ conductor at 340 m, at 650 m - anomalous pressure, nitrogen layer, R.pl. 800 approximately, then at 1700 they have complete withdrawal, they say there was absorption and then the GNVP arose. They somehow liquidated the well. Where are the bridges, where is it, we don’t know, everything is by touch, so to speak. Then they found some kind of plan for eliminating this well ., but the bridges didn’t come together, they apparently didn’t touch the bridges, they were probably celebrating the New Year too!!! they just burst out with their tongue and dragged it along the entire well. There was still a bollard on top. They barely reached the bottom, it was a hassle with the solution, with constant processing, but they reached the bottom and the well was delivered with a 5″ column. The most difficult thing was to drill out the head of the column, they hammered it with 5″ and 6″ bolts for the 2nd day, 2.5 m was filled in, and in the middle there was a tube with a flag. The main thing is so as not to drop it it was. If only the old people had wrapped the plug!!!!

I have never encountered this, but life forced me to look in this direction. If anyone has any information or experience, please share, everything is interesting: technology, equipment, personal impressions and memories. Thanks a lot!

1. Each exploration or prospecting well is a “pig in a poke,” so always expect surprises or something that is not in the well’s case. 2. pay great attention to the preparatory stage, i.e. PDK protocol - project - work plan, everything according to RD 153-39-023-97, RD 07-291-99, RD 08-492-02, step left, step right - execution :4wink: , but it’s not simpler RTN or PFI they will sign your plan + you need a project for the development and land 3. never wait for the flow rate that was obtained during the initial test, immediately lay down retesting, hydrodynamic testing and technical condition with the ACC, but in general this is a creative and interesting process + almost free additional production, good luck in your endeavors...

I have never encountered this, but life forced me to look in this direction. If anyone has any information or experience, please share, everything is interesting: technology, equipment, personal impressions and memories. Thanks a lot!

What's the problem?

You take and reactivate the well, according to the plan or project for reactivating the well, drawn up according to the above-mentioned RD. The problem with reactivating an old well is the unpredictability of its actual condition. Therefore, the first thing to do is to examine her, based on this, and make a plan.

The problem with reactivating an old well is the unpredictability of its actual condition. Therefore, the first thing to do is to examine her, based on this, and make a plan.

Inspection of the technical condition of the well is one of the mandatory points of the plan.

You can find primary information in the regional department of RGTI, the geological department of the customer, or ask around with old-timers in the field. During the first run, it is advisable to include cutters in the line-up and proceed with the development of the column from the mouth with washing, this way you will protect yourself from surprises. The rest has already been listed.

Inspection of the technical condition of the well is one of the mandatory points of the plan.

Yeah. But not the main one. You must first draw up a plan FOR INSPECTION OF THE WELL.

You can find primary information in the regional department of RGTI, the geological department of the customer, or ask around with old-timers in the field. During the first run, it is advisable to include cutters in the line-up and proceed with the development of the column from the mouth with washing, this way you will protect yourself from surprises. The rest has already been listed.

Even all of the above does not give the real picture. It is difficult to find “old-timers” if the well has been mothballed since the 60s. You need to act carefully and carefully so as not to aggravate...

those wells , which in the 70s were considered unprofitable, but are now a tasty morsel for small oil producing companies, so the restoration of wells continues and production from small companies competes even with large companies.

those wells , which in the 70s were considered unprofitable, but are now a tasty morsel for small oil producing companies, so the restoration of wells continues and production from small companies competes even with large companies.

That's not the point. Involving old wells in work is, of course, a good thing, but the point is different: in those days, smart people also worked, and if a well ended up in such a fund, then there were serious reasons for it. And not always set out on paper.

1. Each exploration or prospecting well is a “pig in a poke,” so always expect surprises or something that is not in the well’s case. 2. pay great attention to the preparatory stage, i.e. PDK protocol - project - work plan, everything according to RD 153-39-023-97, RD 07-291-99, RD 08-492-02, step left, step right - execution :4wink: , but it’s not simpler RTN or PFI they will sign your plan + you need a project for the development and land 3. never wait for the flow rate that was obtained during the initial test, immediately lay down retesting, hydrodynamic testing and technical condition with the ACC, but in general this is a creative and interesting process + almost free additional production, good luck in your endeavors...

I remember that the Orekhovskoye field had not been drilled for almost 30 years; there were 3 wells there, oil production rates were 3, 8 and 21 tons/day.

Finally, “Magma” was gored by the licensing commission, they wanted to hand over the license, but then they reactivated the best well and received 105 tons per day….. The mood immediately changed, and we were ordered a project…. thank you very much, both for the advice and for the kind word, there are candidate wells, some with a flow rate of 10-15 tons, drilled from the late 70s to the mid-80s, then they were low-yield, and we’re wondering what will come out of there , maybe for a hundred or maybe not a damn thing, the work plan is of course interesting, but it’s important for us not only to work but also to get the result, examination of EC, PFA, is already included in the plan, now we are working on coiled tubing, we’ll try this way and that, boosters our own, most likely we will also have a PKO, suddenly the PZP is clogged up, there is an option to release the cyclones, there are a lot of possibilities, but who will pay for it????

thank you very much, both for the advice and for the kind word, there are candidate wells, some with a flow rate of 10-15 tons, drilled from the late 70s to the mid-80s, then they were low-yield, and we’re wondering what will come out of there , maybe for a hundred or maybe not a damn thing, the work plan is of course interesting, but it’s important for us not only to work but also to get the result, examination of EC, PFA, is already included in the plan, now we are working on coiled tubing, we’ll try this way and that, boosters our own, most likely we will also have a PKO, suddenly the PZP is clogged, there is an option to release the cyclones, there are a lot of possibilities, but who will pay for it????

Colleague, of course, you can make plans, but first get to the bottom...

especially if it is not lined up and the documentation is God knows where!!! when the wells are being mothballed, apparently they didn’t stand on ceremony with them. In my practice, there were a lot of surprises with the old stock. According to the plan, there were 4 categories, but in reality it was a fountain, etc.

Yes, of course you can find a lot of surprises in a mothballed well. Although there may be much more of them in an abandoned well. And it is not a fact that you will receive the indicated flow rates (both with the + and - signs). Everything is verified empirically.

Yes, reactivation and liquidation is a very interesting topic. 1. Find out the economic issue: who owns the well, the enterprise (yours or not), the administration of the subject of the federation. (I just encountered such problems that the well is not owned by either the state or the enterprise - then there will be problems with the tax authorities) 2. Write a letter to the RGTI (technical supervision) that you are going to carry out the work and will soon send a plan for approval (so that you would immediately find out if they have fundamental objections) 3. Raise all sorts of documents to find out what happened to the well (this information is available in funds or in territorial bodies for subsoil use, right down to copies of files) 4. Make a plan - there is, of course, a lot of room for imagination Immediately prepare a column head+FA kit. also a couple of sets of SBT, blocks and chisels with end mills and possibly a left-hand tool (or find where you can quickly get it). It just happens that during conservation (liquidation) so much iron is thrown into wells (pipes, geophysical cables, and so on - all kinds of iron). 5. complex of geophysics - SGDT and AKTs, technical condition of the column (preferably also MIDK) 6. All plans must be coordinated with the RGTI authorities and the business entity BEFORE the start of work! The acts must also be coordinated with everyone - then there will be fewer problems.

PS, liquidation with re-preservation is akin to archeology, a very interesting activity

Categories of abandoned wells

The instruction from RD 08-347-00 establishes the following categories of wells that are abandoned after closure:

- Exhausted. A well that has reached the end of its service life must be abandoned; this category includes sources after long-term operation with a low flow rate, in which preventive pumping work does not give a positive result.

- Geologically ineffective. The group includes drilled mines that have not reached the aquifer, ineffective in further exploitation due to low flow rate (with a dusty geological sand structure) or sources that are silted for various reasons. Sometimes wells become unusable due to contamination of the aquifer with waste from nearby enterprises, landfills, storage facilities for harmful chemicals or other industrial facilities.

- Failure due to technical reasons. This group includes wells where there has been corrosive or physical wear, damage to the casing as a result of natural disasters (earthquakes, landslides). One of the reasons for the closure is the fall of a submersible electric pump into the canal, as a result of which further operation of the source is ineffective or hazardous to health.

- Harmful to the environment, installed in violation of technology. This group includes sources with low-quality casings, expired conservation periods, located in restricted zones (sanitary protection, water protection) without approval from environmental authorities. Borehole sources operating in zones where there has been a change in the environmental situation, which has caused a discrepancy between environmental and sanitary requirements for the new status of the zone.

How quickly is a conservation order executed?

Having decided on the need for conservation, the owner must collect documents, fill out a sample application and submit the papers to the appropriate authority.

What happens next is:

- The application is subject to consideration and the reasons are assessed;

- The order is printed;

- The owner is notified of the decision.

Almost everyone probably wants to have access to artesian water, but not everyone manages to protect nature. Unnecessary or unprofitable sources must be liquidated, and in accordance with the procedure established by law. After a thorough examination, the optimal conservation technology is selected. It is not possible to do this without special equipment, so it is advisable to entrust such a responsible task to professionals.

Organization of events

To make the right decision, you should contact specialists who will give an opinion on the feasibility of the work. Gostekhnadzor establishes the following requirements for liquidation measures of well sources:

- The liquidation and conservation of wells must be carried out in compliance with the work technology in ways that are safe for human health and life, ensuring the safety of the water source, the protection of nature and objects in the zone of influence of the actions being carried out.

- The initiative to carry out work must come from the owner of the source, he must carry out all procedures and is responsible for the protection of water resources.

- The abandonment and conservation of wells must be carried out according to a project approved and agreed upon with the territorial bodies of Gostekhnadzor.

- All costs of liquidation work are borne by the owner, who pays for the work of professional services or can carry out the liquidation on his own.

Rice. 4 Magnets and devices for extracting electric pumps from water wells

Removing Objects from the Wellbore

A lot of objects can get into the wellbore during installation or during operation - construction tools, water pipes, cables, most often an electric pump breaks and falls to the bottom. When it falls, various fishing tools are used - crampons, hooks on a thick fishing line or cable, various homemade devices.

Before or during work, it is useful to examine the bottom area in the area of the fallen electric pump - for this, borehole acoustic television (SAT) systems are used, which are a video camera on a long cable that is lowered into the shaft.

Removal of metal parts (electric pump) is carried out as follows:

- Often, the fall of an electric pump occurs as a result of a broken cable or its weak fastening, while the HDPE water pipe, fixed to the outlet pipe of the electric pump with a threaded connection, remains in the borehole channel, coming off at the point of attachment to the head. Its upper end is located at a distance of several meters from the mouth - the electric pump can be removed by pulling up the HDPE pipe. Craftsmen have developed various technologies with long pieces of reinforcement or pipes with spacer or thread screwing into a HDPE pipe, but the simplest and most effective method for removing it is the following option. A ring with sharp inner edges of a slightly larger diameter is lowered onto the HDPE pipeline and pulled upward with a cable. As a result of the distortion, it is tightly fixed on the surface of the HDPE pipe, which is easily removed from the well source along with the electric pump.

- If an electric pump falls into a well (plastic casing pipes) without a HDPE pipe, the easiest way to extract it is using a special Neodymium-Iron-Boron search magnet with an eye bolt to which a cable is tied. Its clamping force (tearing force) reaches 600 kg, the cost varies widely depending on the magnetic properties and manufacturer (the average price of powerful magnets is about 50 USD). It is clear that purchasing it to lift an electric pump is not commensurate with the costs of drilling a new well. One option to save money would be to hire professional drillers to lift the pump.

Rice. 5 Cementing wells - methods using special equipment

Well abandonment by plugging

Well plugging is a set of engineering works to isolate its segments from the earthen rock in order to prevent landslides and erosion of the soil, separate aquifers (prevents the penetration of groundwater and contaminated formation waters into water intake strata with fresh water), cover voids, cracks, caverns (cavities) behind the casing string.

The main grouting materials during the work are cement (mortars based on Portland cement), clay mortar, bitumen and clay-cement mixtures, resins, quick-setting (FSS) materials.

Clogging is one of the main methods of abandoning wells; its purpose is to isolate all aquifers along the path of the well and the water intake horizon from the ingress of surface water through the wellbore, to eliminate the circulation of water between the layers along the well channel after removing the casing pipes.

Current instructions

In order to avoid all kinds of precedents, Gosgortekhnadzor has developed instructions according to which it is necessary to act when abandoning a well.

If you decide to preserve the well yourself, then it is better to first familiarize yourself with the adopted instructions of Gosgortekhnadzor

The main provisions are:

- The purpose of the instructions is to ensure the order of work;

- The subsoil user must ensure the abandonment of wells that are not subject to further use;

- Liquidation at the initiative of the owner is carried out in the manner prescribed by law;

- Conservation is carried out within the time limits regulated by the territorial bodies of Gosgortekhnadzor.

In general, the instructions consist of dozens of points, each of which is mandatory. However, there are exceptions to every rule, so the technology may also vary.

Preservation for the winter

To preserve industrial well sources, they are washed and the barrel is filled with a neutral and non-freezing liquid in the upper part. A mothballed well is opened after the expiration of technological terms for further operation according to the documentation.

For domestic use, there is often a need to preserve a well source for the winter; all operations are carried out inside a caisson or structure from a well, without affecting the well water intake trunk. The main conservation procedure is insulation, which is carried out in the following sequence:

- The electric pump is removed from the borehole channel and all automatic equipment is dismantled, if it is located in the caisson - pressure and idle switch (automation unit), pressure gauge.

- A pipe with a diameter 200 mm larger than the head is made from a tin strip or other material and placed on it; insulation material (foam rubber, mineral wool) is placed in the free space.

- The walls, the bottom of the caisson and the hatch are also insulated with foam plastic, mineral wool, pipes and shut-off plumbing fittings are wrapped in unnecessary rags, which are removed after winter.

Rice. 8 Preservation of a water well in a caisson pit

The liquidation of artesian wells, which are strategic state water reserves, according to the law, must be carried out by authorized organizations in compliance with technology and documentation. More common sand wells, where gravel-filled filters are installed, can be plugged with your own hands after disinfection with bleach. To do this, crushed stone and sand are poured inside a casing column cut to 2 meters (it is not removed to prevent mixing of aquifers) and the materials are poured on top with cement mortar.

Self-liquidation

It all starts with removing the equipment.

If you have a sand well on your site, then its plugging is not regulated by law, since it does not pose a danger to strategic deposits and horizons.

But if you don’t want perched water and corrosion products to pollute your aquifer, it’s better to plug it:

- We remove pumping equipment, water pipes and other equipment from the shaft of the structure;

We remove the equipment.

- We install a tripod with a winch above the well;

We install the lifting device.

- We lift the casing using a winch and gradually dismantle it, fixing the pipes with a clamp;

We disassemble the casing, fixing it with a special clamp.

- We fill the aquifer zone with a mixture of sand and gravel;

We fill the water intake area with gravel and sand.

- We fill the remaining trunk with cement clay, which we carefully compact;

We fill in and compact the clay.

- We dig a small pit at the mouth and fill it with concrete.