Esbe valves are one of the most reliable and functional components used in various water supply systems, including domestic and main ones. It has a very wide model range, which includes: rotary vrg131, dn25, as well as other popular varieties.

Esbe three way valves

Currently, a three-way rotary sample of such equipment can be installed in every home. In order to do this correctly, let's understand the intricacies of working with such equipment and the features of its use.

Need for use

This design, on the one hand, is quite simple, but on the other, it is designed to perform an extremely important task, being part of engineering networks. Everyone knows the rule that demand creates supply, which is why on the market today you can find many models that are represented by all kinds of manufacturers. However, valves produced by Esbe have excellent performance characteristics. A three-way valve of this type can be purchased at an affordable cost. This is confirmed by user reviews.

Design features

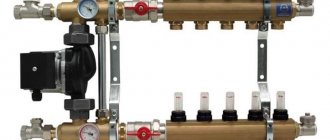

Today you can find a wide range of Esbe products. The three-way valve is no exception. This element has a regulating component, which is a ball or rod. The latter moves vertically, but as for the ball, its movement occurs around its axis. Due to the fact that the movements of the control element do not allow the flow of liquid to be blocked, distribution and mixing occurs. The most common and simple models are cranes.

Carrying out installation work

Almost all of the described valves that are on the market are connected based on the same circuit. Mixing taps are most often used in water supply systems. Their main goal is to reduce the risk of backflow. There will inevitably be a pressure difference between the cold and hot water flows. It may cause backflow. If you install a valve, you will not encounter such a problem. If we are talking about a heating system, then such devices are used exclusively in three directions, namely to stabilize the temperature regime of the coolant flow in the incoming pipeline of boiler equipment, to reduce the supply of high-temperature water from the heating device to the pipeline, as well as in the conditions of mixing units of systems like a warm floor.

How to choose

When choosing a three-way valve, you need to consider several parameters. It is good to enlist the help of an experienced plumbing engineer during the selection process.

First of all, you need to evaluate the purpose of the device - separation or mixing. The next step is to determine the installation location on the system diagram, as well as how to control the device. If you are planning automated heating control, you need to decide how this faucet will be controlled - by electric drive, thermostat or manually.

The following technical characteristics are subject to further analysis:

- Highway capacity. This is the volume of liquid passing per unit of time. The capacity of the crane must be no less. Too little clearance will create unwanted flow resistance and impede the operation of the entire system.

- Maximum and working pressure. It must also correspond to the calculated values for the heating system.

- Connecting dimensions. If an exact match of diameters cannot be achieved, then adapter fittings are used.

- Operating temperature adjustment range.

Guided by the listed parameters, you need to select from dozens of market offers several models that meet the specified requirements.

At this stage, it is time to compare price, warranty period, service availability and, of course, the reputation of the manufacturer. Guaranteed quality is provided by such market leaders as:

- Honeywell. The American company has been manufacturing, supplying, installing and servicing a wide range of components and entire heating, ventilation, and security control systems for the second century.

- Esbe. The Swedish company has also been supplying precise and highly reliable valves, fittings and system components for over 100 years, specializing in heating technology. The Scandinavian tradition of meticulous, high-quality workmanship is combined with innovative approaches to design.

- Valtec is a Russian-Italian enterprise that successfully combines high Italian quality with a seven-year warranty and affordable prices. Completely localized production with a European quality control system appeared on the market not long ago, but has already gained popularity.

There are also many suppliers on the market who have not managed to achieve such an impeccable reputation. Saving on the cost of the valve can later lead to its unstable operation, increased costs, or even failure of the entire system.

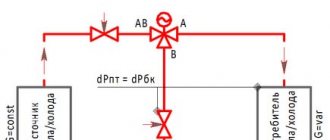

Connection in the mixing unit

If you are interested in Esbe products, you can purchase a three-way valve at any relevant store. One has only to first consider how the faucet is used in a heated floor system. The use of a mixing unit allows you to create an additional circuit in the system. It is connected to the distribution manifold at two points, this allows for constant circulation of water at the outlet. As for the input, the flow is provided only if there is a need to obtain additional heat. A valve with a thermostat is connected to the mixing unit. Due to the fact that all the valves are located at the point, they are narrowed, which can cause insufficient flow of the pumping equipment. To increase it, it is necessary to create an additional line, with which you can reduce the electricity consumption of the pump. During the installation process, it is worth remembering that a second line is not always required. A number of valve models have a fairly large bore. The Esbe three-way valve, the connection diagram of which can be developed based on the instructions presented in the article, may suggest insufficient flow power in the first line. In this case, the thermostat is not able to open the passage of the required size. This issue can be easily resolved in two ways: the first involves narrowing the second line, while the other option is to install a balancing valve on it. The latter option is considered more productive, as it allows you to customize the flow.

Kinds

There are several types of such devices:

- With hydraulic drive.

- With pneumatic drive.

- Electrically driven.

A motorized three-way valve, such as the ESBE model, will have a slightly different operating principle. The electric drive performs the function of a conventional thermostat, which allows you not only to mix flows, but to maintain a given temperature. When the temperature decreases/increases, the drive automatically changes the position of the shut-off valves, increasing or decreasing the cross-section of the hot water flow. At the same time, the cross section at the point of inlet of the cold flow also changes. The result is water with a constant temperature. The ESBE crane does not require any human intervention. Its operation is regulated automatically.

Valve operating principle

Equipped with electric actuators and thermostats, ESBE valves are equally suitable for use in heating and hot water systems. In principle, the valve can be installed in any pipeline where it is necessary to mix two liquid streams with constant temperature maintenance. No matter how high-quality and reliable a three-way valve with a thermostat is, it will have one drawback that is characteristic of absolutely all devices of this type.

This disadvantage is the strong narrowing of the entrance points. The narrowed cross-section of the inlet point, in turn, increases hydraulic resistance.

Such a faucet will work well in water supply systems. ESBE valves are suitable for installation in underfloor heating systems, but require a special connection diagram. In addition to the designs described above, three-way thermostatic valves are available on the market. These devices are often confused with each other, but they are still completely different. Thermostatic models have a thermostat with a remote sensor, but they differ not only in this element, but also in the principle of operation. Unlike conventional models, in thermostatic taps the flow is regulated at only one point, the remaining two are open and their cross-section does not change. When choosing such a design, you need to check whether there is any narrowing at point 2, otherwise hydraulic resistance will lead to difficulties in the operation of the device. It may be necessary to install a mixing valve in an alternative ring to minimize the problem.

Installation of a valve for a heating boiler

This issue, according to professionals, must be considered separately. The main task of installation is to prevent the flow of cold water from entering the incoming pipeline, which is connected to the heating equipment. If this requirement is not taken into account, condensation will form on the pipes, and temperature changes will lead to deformation at the joint points. If we talk about the consequences of deformation, then in the best case you will encounter a small leak, while in the worst case the system will need to be completely changed. In order to avoid the need for repair of the Esbe three-way valve, it is important to connect the shut-off valves to the boiler, which is characterized by temperature changes during operation. If you install a mixing valve, you can ensure that water with a temperature below 50 degrees does not enter the equipment inlet. Temperature differences are significantly reduced, and the negative effects of cold are reduced. Experts advise supplementing systems that use plastic pipelines with mixing valves. In this case, the task is to prevent high-temperature water from entering the pipeline. Despite the fact that polymers have many advantages, they do not cope well with frequent temperature changes that may be higher than operating temperatures.

When exposed to such conditions, the pipeline system soon fails. Experts advise choosing Esbe products. The three-way valve, installation instructions for which are presented in the article, has been manufactured by this company for a long time. If you use this element, you will be able to provide temperature readings ranging from 75 to 85 degrees, which are recommended by experts. Installing a valve can solve many problems, but the model must be selected in accordance with the characteristics of the network, and also have a sufficiently large passage.

Some useful knowledge

Three-way rotary valve ESBE

The three-way valve is a control device in piping systems with liquid working media. In simple terms, built into the design of the heating network, it will act like a well-known faucet that switches or mixes flows. Installing the valve allows you to solve a number of practical problems:

- Redirection of flows coming from different pipelines.

- Achieving the required temperature of the working fluid by mixing hot and cold flow.

- Achieving a jet with a constant temperature through dynamic redirection.

Difficult? Only at first glance. In order to understand the principle of operation of the device, let's consider its design features.

Adjustment features

When purchasing Esbe products - a three-way valve, installation and adjustment instructions for which are presented in the article - you must remember that with the help of this device it is possible to mix cooled water from the return to the supply. For high-quality regulation, not only a three-way valve, but also a four-way valve, which must be present in the heating system, is installed in the system independently. It is placed directly in front of the heated floor circuit. The handle allows you to open the bypass, while circulation pumps and equipment draw cooled coolant from the return line, where it mixes with hot water. In order for the adjustment to be made as efficiently as possible, you need to understand what happens at certain positions of the handle. The latter can be set to the bypass shut-off position, in which case the hot coolant will flow into the pipe of the underfloor heating system. As for the mode in which the supply is shut off, water enters the tank and circulates in a small circle. The third position allows you to recharge the supply from the return system without blocking the full cycle of water passage throughout the entire circuit.