Tapping into a pipeline under pressure is a technically complex operation, the need for which arises, as a rule, during the construction of new networks or on highways where shutting off the flow of the transported product (gas, oil, water, etc.) is impossible or entails economic losses.

PROMTECHNOLOGIES LLC carries out work on tapping into an existing pipeline under pressure without disconnecting consumers and without reducing the pressure in the network. This technology for connecting to a functioning pipeline can significantly save both financial resources and time.

Tapping under pressure can be made into pipelines made of various materials: steel pipeline, cast iron, polyethylene, etc.

Possible insertion directions:

- Horizontal;

- Vertical;

- At an angle;

- Down up.

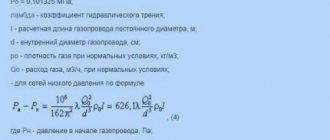

Gas pipeline capacity

Before cutting into a gas pipeline, you need to calculate the throughput of the pipeline and the pressure in it.

When cutting into a city gas pipeline, preliminary work is performed - calculating the throughput. In this case, the purpose of the gas pipeline is of fundamental importance. For domestic needs, a simple low-pressure system is installed. In such conditions, calculations are performed using the simplest formulas, taking into account only the diameter of the pipe and the average pressure in the network.

Qmax = 0.67 DN² * p, where

- Qmax – throughput;

- DN – nominal diameter of the pipe – internal diameter indicated in the documents;

- p – the sum of the working pressure in the gas pipeline and 0.1 MPa.

When calculating, average values are used - pressure surges; the magnitude of the friction force that occurs during movement is not taken into account.

If the connection is made to lines with higher pressure, other parameters must be taken into account. The formula is used: Qmax = 196.386×D²×P/Z×T, where:

- Qmax – maximum throughput;

- D – internal diameter of the gas pipeline;

- P – sum of working pressure and 0.1 MPa;

- Z – gas compressibility coefficient;

- T – temperature of the supplied gas in Kelvin.

From here the dependence of throughput on temperature is clearly visible. To increase this parameter, it is necessary to maintain a stable temperature of the supplied fuel and insulate the gas pipeline.

To calculate network capacity for industrial needs, much more complex calculations using gas flow equations and continuity equations are used.

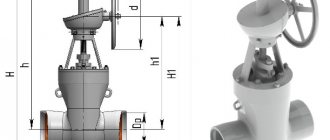

Installation of a manhole at the insertion point

When tapping into a pipeline, a manhole can be installed. This action is desirable, but it can be eliminated. Steel products are in no way inferior to cast iron reinforcement in terms of ring rigidity, but they are more ductile compared to cast iron. This explains the possibility of using original technology when cutting into a steel pipe. The technique is similar to that where polymer products are used.

The installation of a tie-in into a steel pipeline is carried out using a certain technology. The pipe must be cleaned, freed from rust and prepared for work. A flange threaded pipe is welded onto the product, which is made from the main fittings. For the pipe, it is permissible to use any type of rolled pipe, the main thing is that it is based on structural steel.

The initial stage of tapping under pressure into a gas pipeline

The preparatory stage includes not so much work as collecting documents and obtaining permits. Typically, tapping into an existing main gas pipeline is required when constructing a new private house.

The owner submits the following documents to Gorgaz:

- gas supply system design – approved;

- application - the document is certified by the head of the territorial office personally;

- passport and identification code of the owner of the building;

- permission to connect - issued by the architectural planning department;

- registration certificate for your home - you can submit a copy certified by a notary;

- photography - a photograph is taken during a topographical survey of the site, the photo captures the entire infrastructure: water supply, heating networks, sewerage; The photo is certified by gas service workers.

If the construction has not yet been completed, the package is accompanied by an architectural design of the building and a permit for its construction. If the total area of the house exceeds 300 m², a thermal calculation of the building, a situational plan of the plot on a scale of 1:5000 and the consent of the neighbors on the site to connect to the gas pipeline will be required. The latter is necessary if part of the network has to be laid across their territory.

In addition to documents for permission to tap under pressure into a main or city gas pipeline, information about the gas appliances being installed is required: boiler, gas stove, gas meter, boiler. You need to have on hand technical passports of all products, certificates, permission for their use (they are obtained from the city gas department), contracts for maintenance and repair of devices.

For fuel combustion, a sufficient air supply and a system that allows you to get rid of combustion products are required: hoods, chimneys, ventilation ducts. If the building is ready, the owner needs to obtain an inspection report for the ventilation and chimney systems. If the task is under construction - a ventilation project.

A connection made without completing the necessary documents and permits will result in administrative penalties. If the gas connection leads to damage to the main line, criminal liability may apply.

Peculiarities

All work related to the additional use of the city or village water supply system is coordinated with the local water utility. Unauthorized connection to a main pipeline or even an individual one to a plot, house, or apartment before the meter is an administrative violation, for which large fines may be imposed on the guilty person. If permits are obtained, work on the main lines to insert additional branches with shut-off valves using a common meter must be carried out by water utility specialists. The applicant carries out the wiring of the water supply system inside the house or site independently, but according to the floor plan and profile drawing of the water supply pipelines, which were documented when obtaining the permit.

Employees of water supply organizations carry out raids every week to identify violators, especially in cases of large differences in consumption indicators by devices and actual water consumption. The violator can use the water for only two days, and the fine is calculated using a calculation formula for at least six months. The risk of being discovered more than 20 times in these six months is too great. Is the game worth the candle? Of course not.

Security

The next stage is carried out by an invited team. Before connecting to the gas pipeline, you need to:

- draw up a diagram of connection angles;

- choose the insertion method, calculate the order and method of reducing pressure, determine ways to maintain the indicator at the desired level;

- calculate and select the required amount of materials, tools, rescue and protective equipment;

- close the taps, valves, plugs on the connected pipe;

- stock up on the required amount of water to prevent fire or fire.

Before insertion, control testing of pipes, connected system and air outlets is carried out.

[edit] Fight against oil thieves

For security, oil pipelines are patrolled by private security companies, police and employees of oil companies; alarm systems are also installed in oil pipelines that can respond to vibrations in the soil, loss of pressure; police raids are carried out in villages located near oil pipelines to identify tanks, pumps and other devices suitable for stealing oil. , fuel tankers are checked to see if the contents correspond to the bill of lading, and test purchases of fuel of dubious origin are made.

Rules for tapping work

When connecting to a gas pipeline under any pressure, strictly follow the following safety rules:

- Tapping into a gas pipe under high or low pressure is carried out only by employees of the relevant organization and only with a certificate confirming their qualifications. This is very dangerous work.

- Connection to a low-pressure network is carried out at values no higher than 20–80 mmHg. To do the same at high or medium pressure, you must first reduce the value to an acceptable one. Switching devices are used, and a bypass is installed in dead-end gas pipelines.

- If the pressure cannot be reduced, specialized equipment is used. Such work is much more difficult and expensive.

- When welding or gas cutting, it is necessary to maintain the pressure in the work area in the range from 40 to 150 kg/cm.

With strict compliance with safety regulations, the likelihood of accidents and emergency situations is reduced to a minimum.

Expert recommendations

When inserting into a pipeline using the technology described above, an inspection well can be placed at the installation site. To do this, the bottom of the pit is deepened, sand and gravel are poured onto it, and then rings are installed, the first of which will have a hole for pipes. The pillow, if desired, is strengthened by pouring concrete, the thickness of which should be 10 cm. To do this, you need to use grade M-150 or M-200. It is important to bring the head of the well with the hatch to zero ground level. This design makes it easier to repair the water supply system. The consumer will have the opportunity to shut off the system using a central valve.

Pressure tapping technologies

Equipment for tapping into an existing gas pipeline

Connection to the gas main is made with a complete shutdown of the gas supply or at reduced pressure. The second method is used more often, as it reduces work time and does not create problems with the supply of fuel to already connected consumers.

Cold tap

The essence of the method is the installation of control valves before the actual connection. The technology is quite simple.

- Clean the gas pipe from rust and dirt, install a clamp that exactly matches the diameter of the pipe and secure it with bolts.

- The valve is fixed to the clamp flange. The valve is tightly closed before drilling.

- A drill with a lid is attached to the valve. The fastening is practically airtight due to seals. The drill bit must be long enough to pass through the valve and the pipe wall.

- Drill the main pipe and connect the outlet. In this case, gas leakage is eliminated, and the pressure drop becomes insignificant.

Cold tapping is one of the safest installation methods.

Welding

A more reliable method, as it provides a high connection density. However, it is more dangerous and can only be carried out by specially trained people.

Insertion into a low-pressure gas pipeline without shutting off is carried out through a pipe. Bends are connected to the main gas pipeline using an end connection, a T-bar, or a telescopic one.

T-connection diagram:

- A pipe is made - a connecting element of appropriate dimensions. One end of it must be connected to the main line, the second - to the new gas pipeline. A window is made in the pipe for manipulation, but this fragment - the visor - is retained.

- The future hole is marked on the main pipe. A steel rod is welded to the marked fragment so that it can be pulled out later. Then the disc is cut out. In this case, a 5 mm jumper is left. During cutting, the gas ignites. It is extinguished by coating the cut site with clay.

- The pipe is mounted and welded to the main line and to the gas pipeline being installed.

- A wooden disk coated with clay is fixed in the pipe to prevent the possibility of an explosion.

- Using a rod, remove the wooden plug and the cut pipe wall on the steel rod. Immediately fix the visor on the asbestos sheet.

- The connected pipe is purged to get rid of the gas-air mixture. Then the visor is welded. A steel plate is mounted on top.

This method is considered obsolete today.

Tapping into a low pressure gas pipeline

The gas pipeline serving private homes is supplied with fuel at a pressure of no more than 0.15 MPa. With such indicators, you can not turn off the gas supply, and make the connection even without a transition element.

The technology is similar.

- The pipes are cleaned of insulation, heated, and the junction point is marked. The connected pipe is cut and the edge is processed.

- The branch is placed on the main gas pipeline and welded.

- Then a technological hole is cut in the connected pipe - a visor. And through it they make a hole in the main pipe - a nickel. The fragment is not removed, but is held in place by a thin bridge. Extinguish the flame, if it appears, by coating the cut site with clay.

- The prepared canopy is laid with moistened asbestos with a thickness of at least 3 mm.

- The next stage is carried out very quickly: the welder knocks out the nickel, and the second worker immediately covers the window with a visor. The cracks are immediately filled with asbestos. The nickel is taken out. To do this faster, you can weld a rod to it.

- The visor is welded, the seams are cleaned. The connection is isolated.

If, according to the diagram, the pipes are welded at an angle relative to each other, use an insert with a steeply curved or bent outlet into the gas riser.

Modern tools make it possible to obtain extremely thin seams and cutting points. In this case, practically no gas comes out, and fire is excluded.

Insertion into a high pressure gas pipeline

Pressure tapping into the gas pipeline is made using a reel or T-joint. If necessary, connect a new gas pipeline not to the end of the existing one, install an additional transition piece: a branch pipe, a tee, a coupling with a valve.

All manipulations are performed after a preliminary reduction in pressure in the work area. This is done using disconnecting devices. If the system is looped, gas distribution points are used - with a safety relief valve and bypass. In order not to provoke an increase in pressure in the previous section, a “candle” gas pipeline is installed. Excess gas is burned.

Welding will be performed according to the technological map. They are developed for each connection process.

Tapping without shutdown

Gas injection under high pressure can be carried out without shutting down. This will require other devices: a design with a valve or a PGVM.

In the first case, a coupling and a pipe fitting with a flange made to fit the pipe diameter are welded to the main line. A valve with a chamber is attached to the flange. A hole is cut through the coupling in the main pipe, a fragment of the wall and the cutter itself are removed through the chamber. The valve is immediately closed, after which a new gas pipeline is welded to the flange.

The second method is more complicated, but provides more reliable operation. A pipe is welded to the main line, inside which a sleeve is fixed to the wall with the base of the pipe. A pin and a rod with a cutter are screwed through the bushing, then machine oil is poured in.

The PGVM is mounted on the flange, and then a hole for the outlet is drilled using a milling cutter. The cut disk is removed along with the cutter and rod, and the hole is blocked with a rubber stopper. When the gas is opened, the plug is wrapped in the pipe and the PGVM is removed. The cork is scalded around the perimeter.

After completing the work, check the seams for tightness using soap emulsion and only then insulate them.

[edit] Consequences of the activities of oil thieves

[edit] For the environment:

Accidents on oil pipelines caused by such activities create oil pollution of water resources and soil.

[edit] Economic

For an oil company, these are primarily losses in income caused by the theft of oil itself, as well as often compensation for environmental damage; for the state, these are most often lost taxes.

[edit] For consumers

For cars and other fuel consumers, this most often means engine failure due to poor quality fuel. During artisanal oil refining, diesel fuel is usually not dewaxed, the necessary additives are not added, and tetraethyl lead, which has long been banned for production, and many other metal-containing additives are often added to gasoline, which spoil and have extremely toxic emissions.

Features of tapping under pressure into a gas pipeline

In private houses and apartments, plastic pipes are increasingly used when installing gas pipelines. High quality material is used for larger sections of the gas pipeline system. In this case, there is a need to connect products from different materials.

Plastic gas pipeline

Welding plastic pipes takes less time and is cheaper. The products are connected using polyethylene and steel inserts. Length varies from 80 to 100 cm.

The technology is simple: the steel insert is heated to 60 C, and a plastic structure is placed on it. The latter must be joined very tightly, with force, and a low temperature only increases the contact density.

Connection via ball valve is possible. Before assembly, fittings and heaters are installed into the network, then an overhead valve is welded. A drill rod is fixed to its branch pipe, and a hole is drilled with it after crimping the resulting unit. Then the gas is released through the gas outlet hose, the equipment is removed from the pipe and the drill rod is removed. Together with the cutter, you need to remove both the cut disk and the chips.

At the last stage, the branch is welded using a coupling to the free end of the pipe.

Insertion of plastic pipes is allowed when the pressure in the line is no more than 10 bar.

Gas pipeline made of metal pipes

Connection to steel pipes is carried out in different ways. All methods have 2 points in common.

- Welding and cutting metal requires a much higher temperature than cutting plastic. However, for gas to ignite, it requires not only temperature, but also oxygen. There is none in the main pipe, but when blue fuel leaks out during cutting, it mixes with oxygen and ignites. The gas concentration is low. To extinguish it, the area is covered with clay before cutting, and the procedure is periodically repeated during the process.

- After installation, be sure to check the tightness by coating the new seams with soapy water. If there is a leak, soap bubbles appear.

After connecting the new gas pipeline to the main line, a work completion report is drawn up. The document is certified by signatures. In the future, it is possible to conclude an agreement with a gas supply organization only if there is a connection certificate.

Insertion using polymer reinforcement

The insertion into the pipeline made of polymers will be carried out using a certain technology. At the first stage, it is necessary to reach the highway by digging a square pit. Its dimensions should be 1.5 × 1.5 m. Excavation work at the initial stage is carried out using special equipment. But as soon as you reach the metal strip pipeline system, which is located at the top of the pipeline, you should use a shovel to overcome the remaining 40 cm.

Once you see the pipe, you can proceed to digging a trench to the building. Having finished with this, you should begin to arrange the outlet. For this purpose, special clamps are used, which are also called saddles. These elements are dismountable and are used for insertion into the water supply system. They can be compared to tees, the direct-flow pipes of which have two parts. Single clamps and clips can be installed on plastic products. However, the most suitable option would be saddles, because the electric welded clamp is collapsible.

When inserting into a pipeline using this technology, the clamp must be installed above the insertion point and connected using an electric welding machine. As soon as this work is completed, the saddle should be inserted into the body of the pipe, which will ensure reliable connection and high tightness.

Insertion on a secondary section of the water pipeline

So-called secondary pipelines branch off from any central highway, supplying water to neighboring streets. The pipes of such distributions are predominantly polyethylene; they have a smaller diameter - on average 50 mm. Typically, taps are installed at branch points of secondary pipelines, closing which simplifies the work of inserting pipes, which is available in two ways.

First:

- A 2 meter long trench is dug along the pipeline. This implementation of the problem is used mainly in relation to small diameter pipes (up to 50 mm).

- The pipe is being cut.

- A tee is mounted on the pipe, which can be welded if the pipe is metal, or simply fastened with union nuts if it is polyethylene, for example.

Second:

- An overhead clamp is installed, factory samples of which are equipped with the threads necessary for installing the taps.

- The tap is screwed on.

- A hole is drilled, which is done directly through the tap. This can be done without shutting off the water supply, since secondary pipelines are characterized by low pressure pressure.

If possible, it is necessary to install a well in the place where the insertion is made. For this, a concrete ring or a used brick as a base is suitable, followed by closing the structure with a lid with a built-in hatch.

How to tap into a gas pipe

Nowadays, it is difficult to imagine a residential building - private or multi-apartment - that would not be connected to gas. Thanks to this wonderful substance, we can cook food and definitely won’t freeze. However, gas cannot enter the house by itself, and thank God, it requires a special path - a gas pipeline. And in order for it to exist, it is necessary to crash into a gas pipe.

In our country, the unauthorized process of tapping into a gas pipe is strictly prohibited, but the number of people who want to do everything with their own hands and against the law is not decreasing. Meanwhile, this is a dangerous business and often ends in death, precisely for this reason, and not because the state is greedy, unauthorized insertion is prohibited. For home craftsmen and nonconformists who go against the system, we offer a little theory.

A gas pipeline is a means of transporting and storing gas. Depending on the mission of the gas pipeline, the designs may be different: for example, to transport gas over long distances, powerful networks are installed, and gas flows into them under high pressure. It’s definitely not worth experimenting with it - a very large hole could end up in the place of not only a home-grown craftsman, but also the home itself. Here it is better to contact special services that know how to work with such systems.

From any powerful network, smaller distribution pipes branch off, the pressure in which is lower than in the main ones. However, it can still vary - from low to high. You can crash into such a pipe on your own, but it’s still better to turn to special services if you don’t have an understanding of what needs to be done and no knowledge of safety precautions.

More information about the insertion mechanism

In professional language, a tie-in is the connection of a new pipe to an operating gas-transporting pipe. Such a connection can take place even without turning off the gas, but there are a lot of nuances in this process that must be taken into account so that, no matter how pretentious it may sound, you do not give your life to connect your house to the gas main.

There are two types of insert:

- cold: it is in this case that the main pipeline operates without any changes - the volume and supply pressure remain at the same operating level;

- the traditional method is welding: this method is time-tested and highly reliable, but the work requires certain qualifications and special access from the performer.

Traditionally, gas pipeline pipes are metal, which is why welding is used - because only it can provide the most airtight and durable connection. However, nowadays, pipes made of low-density polyethylene are often used to connect houses to the gas pipeline and install utility networks. To insert into such pipes, factory fittings that comply with GOST are required - connecting elements. Of course, when installing branches you cannot do without heating, so this process in any case remains highly dangerous.

There are general rules for carrying out work on tapping into a gas pipe under pressure.

Firstly, insertion into a network with low pressure should occur at values no higher than 80 mm water column, but not lower than 20.

Secondly, when working with networks with high or medium pressure, the pressure must first be reduced to an acceptable level. If this is not possible, then it is necessary to find special equipment that allows you to work under unusual circumstances.

Thirdly, work without reducing pressure according to the law can only be carried out by organizations that have permission to conduct this type of activity (often there must even be a special category).

Fourthly, welding and gas cutting must be carried out in areas with pressure from 40 to 150 kg/cm - and this corridor must be observed during the entire working process.

Well, and most importantly, it will be better if you entrust all the work to professional organizations that have the necessary experience, qualifications and, if necessary, rank. Yes, you will have to pay some money, but it is not more expensive than your life. And even if you manage to crash yourself and survive, the very first check will reveal an illegal connection. What's next? Payment for stolen gas, a fine, testimony, imposition of criminal liability up to a term - depending on how much harm you caused by illegal tapping. And the pipe will be cut, so all the work will go down the drain.

Permission to perform work

Work on tapping into water mains, either through welding or without it, cannot be carried out without obtaining the appropriate permits.

Illegal tapping traditionally ends with the owner being brought to financial and administrative liability.

The site plan can be obtained from the Federal Center for Registration of Land Ownership, and technical specifications from the central department of the water utility.

The technical conditions for connection will indicate:

- connection location;

- diameter of the main pipeline;

- data required for insertion.

In addition to the local structure of Vodokanal, the development of design and estimate documentation is carried out by specialized design organizations that have the appropriate license.

Then the documentation for the insert should be registered at the local SES office. Simultaneously with submitting the collected package of documents to the SES branch for registration, you are required to leave an application for the issuance of a conclusion on the need to connect to the water supply.

According to generally accepted standards, the insertion of pipes under pressure and the installation of metering devices must be carried out by qualified specialists with the appropriate approval. It is prohibited to arbitrarily perform such work on your own.

You can save money by making your own efforts to connect only on excavation work during the development and backfilling of the trench.

Conditions under which insertion cannot be carried out:

- if the main network pipeline has a large diameter;

- if the land ownership is not connected to the central sewer system;

- if the tie-in is intended to bypass metering devices.

Even if all permits are available, pipe insertion into an existing network should only be carried out by qualified specialists.

You can only save money by doing some of the work yourself, the execution of which does not require a license.

These include: excavation work (digging and backfilling of trenches), delivery of material and other types of auxiliary work that are not directly related to the insertion procedure.

Of course, no one can prevent the owner from doing the tie-in himself. Therefore, the article describes in detail the sequence of actions.