Pipe repair tape is an excellent sealant, used in water supply, sewer, and gas systems. Sealing tape is indispensable in systems with high temperatures and in aggressive environments. Easy to use, it's essentially insulating tape. Application does not require preparation. Plumbing tape is necessary in emergency situations; leaks can be easily dealt with even if you have no experience.

Purpose and use of PVC adhesive tape for pipeline insulation

Adhesive tape is intended to protect the external surfaces of gas and oil pipelines from damage; it is used for insulation and protection. It is also suitable for waterproofing heating mains.

Important! The adhesive tape must be of high quality, without holes, missing adhesive layers, damage or tears. The adhesive layer should not peel off and transfer to the other side of the product. The rolls are perfectly smooth, without wrinkles or other defects.

Typically the product is produced in black or blue. It is wound onto plastic sleeves in the form of a roll, and then it is packed into polyethylene bags.

What is fum tape

FUM tape is a sealant, which is a narrow thin unsintered film made of fluoroplastic. The abbreviation “FUM” stands for: fluoroplastic sealing material.

All manufacturers of this sanitary film offer two types: white (thick) and translucent (thin). Both of these materials have a similar list of characteristics. Namely:

- are characterized by heat resistance;

- elastic;

- resistant to chemicals;

- average tensile strength 1.5 MPa;

- elongation at break not less than 200%;

- thickness 0.075-0.2 mm.

The film is made by rolling a fluoroplastic rope and wound onto polypropylene reels equipped with a lid. The width of the tape can be different: from 10 to 60 mm. To prevent the thin elastic film from sticking together during winding, one side of the tape is coated with lubricant. Most often this is medical Vaseline oil. There are also sealing films without lubricant.

Advantages and disadvantages

PVC insulating tape for pipes has many advantages, among which are:

- withstand high voltage, which ensures safe operation of equipment and devices;

- excellent adhesive properties, able to adhere perfectly to metal, glass, cardboard surfaces, tiles and plastic;

- It is heat-resistant and can withstand temperature changes from minus 30 to plus 70 degrees;

- safe for health, odorless and not capable of releasing harmful substances and allergic reactions;

- has elasticity, allows easy work even on thin wires and surfaces with pronounced relief;

- can stretch more than 100%;

- safety in case of fire and strong heating of wires in case of insulation breakdown, prevents fire, ignites only in open fire, but goes out quickly;

- resistance to moisture, provides wires with reliable protection from moisture, prevents the formation of fungi and corrosion on the surfaces used.

In addition to these positive aspects, it is worth highlighting the affordable price for consumers.

Specifications

FUM tape, the technical characteristics of which meet the requirements for the quality of work at a particular site, will serve flawlessly for at least 10 years. In order to accurately select the most suitable product, it is recommended to familiarize yourself with the characteristics of the 1st and 2nd grade films.

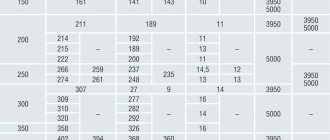

| Characteristics | FUM-1 | FUM-2 |

| Film thickness (mm) | 0,1-0,14 | 0,035-0,2 |

| Film Width (mm) | 10-60 | 5-60 |

| Elongation at break (%) | 100-200 | 100 |

| Availability of lubrication (%) | 20 | 0,3 |

| Maximum tensile stress (kg/cm2) | 40 | 60 |

It is difficult for a beginner in plumbing work to understand all the intricacies of choosing sealing films the first time. Therefore, you can rely on the recommendations of experienced craftsmen and use the same materials in your work.

Questions often arise about which films to use when installing household water pipes. These are the most popular plumbing jobs, during which mistakes made will be noticeable immediately after water is supplied or will be discovered in the near future.

The most suitable fulente for water is as follows:

- for small threaded connections - width 12 mm, thin (0.075-0.1 mm);

- for large threads - width 19 mm, thickness 0.12-0.2 mm.

Varieties

PVC adhesive tape meets all safety standards and regulations, it can be classified as first or highest grade. The product must be free from bubbles, punctures, tears and other possible defects.

Main product differences:

- First grade tape may have bulges and gaps between layers, which can be seen with the naked eye. The highest grade has a perfectly smooth surface without gaps or omissions.

- The first grade tape withstands less stretching than the highest grade during loading. Such products, which belong to the highest grade, have great elasticity and stability.

- Stickiness is also important. Materials of different grades may be the same in thickness, but their adhesive properties are different. This value can only be measured during the experiment. The stickiness of the first grade tape is less than that of the highest grade, which is determined by the peeling time in seconds during the process of hanging a load from it.

The cost of the product may vary depending on a number of conditions:

- insulation thickness;

- material width;

- roll size.

When purchasing a product, you can check all the details with the seller and inquire about the properties of the adhesive tape for pipes.

Which is better linen or fum tape for water?

A professional plumber always has different types of seals on hand:

- fum tape;

- flax and sanitary paste;

- threads (type “Tangit”);

- anaerobic sealant.

The craftsmen know that all seals, when installed correctly, perform their task 100%. But to do this you need to know how to use it, what to use and under what circumstances. The abundance of modern sealing materials has displaced flax from its leading position. But not all masters agree with this.

The fact is that in past decades flax was used together with red lead or oil paint. Today – with Unipak plumbing sealing paste. Its main task is to prevent the flax from drying out and rotting. Connections made using these materials can be adjusted (axially shifted) by 45° without loss of tightness.

Benefits of flax:

- inexpensive price;

- suitable for sealing threads of any diameter;

- the connection will be good regardless of whether the base surface is wet or dirty.

The disadvantage is that any connection made with flax subsequently requires additional twisting and tightening. Another “minus” of flax is that it is not very convenient to work with: the fibers delaminate and cling to clothing and the tools and materials used.

Life time

The service life of the insulating material may depend on the conditions under which the product is used. For wiring, the most optimal winding level to achieve electrical insulation is considered to be 3-4 layers.

Important! It should be remembered that when gluing to a surface, it must be thoroughly cleaned. It will not be able to reliably hold a wet, dirty or greasy surface. To achieve the longest possible service life, it is advisable to clean and degrease the surface with an alcohol solution. It is also possible to prime the required surfaces and process them with sandpaper to securely secure the adhesive layer.

There are other nuances of use:

- may become unusable due to the interaction of organic solvents, aggressive and flammable substances, chemicals on it; for example, it is highly undesirable to apply PVC tape to polymer and silicone surfaces containing fluorine;

- the average shelf life can be about 3 years after release, but with proper storage it can reliably serve for 10 years, it is advisable to store it at an air humidity of no more than 70% and a temperature range from 0 to 40 degrees Celsius, it is recommended to keep it away from heating devices and batteries.

If you regularly use PVC adhesive products, it is advisable to purchase several rolls at the same time. They can have different colors, widths and lengths. Every home owner should definitely keep this product in stock.

How to use

As mentioned above, in order to properly seal the connection of two pipes, you do not need to undergo special training. However, there are some nuances here, without which all efforts can be wasted; they will be discussed further.

To better ensure high-quality sealing, you first need to prepare the connection: remove all dirt and, if any, rust.

Next, wipe the joint with gasoline or any solvent and let it dry. After the pipes are prepared, the tape is wound onto the external thread, as we twist it, clockwise.

You don’t need to pull the tape hard, it just might break, just make sure that it doesn’t dangle, the tighter you screw it, the better the sealing will be. Then pull out the end of the tape so that it does not interfere with screwing another element onto the thread.

Please note: if it becomes necessary to unwind the connection after you have wound the FUM tape, then you will have to wind it again from the beginning, because in this case, the tightness is lost

So, if you are dealing with a metal-plastic or plastic pipe, feel free to use FUM tape. When sealing metal pipes, you need to use tow, taking into account the nuances of its winding.

The cost of the tape depends on the manufacturer and width, for example, 15 m of tape with a width of 19 mm will cost 65 rubles. It is widely represented in all construction stores and is affordable for everyone. Choose a tape according to our recommendations, use it correctly and then not a single extra drop of water will spoil the operation of your plumbing.

Sealing cast iron sewer pipes

To connect cast iron riser pipes, another is inserted into the socket of one pipe, and the joint is sealed with the selected material. Experienced craftsmen usually carry out everything using the following technology:

- Linen tow is inserted into the gap between the riser pipes without impregnation to a depth of approximately 2/3 and caulked (compacted).

For your information! Flax tow can be replaced with hemp treated with resin.

- On top of the tow, in the free space of the joint, a mixture of water and Portland cement is placed in a combination of 1:9, respectively.

For your information! To create a mixture, if necessary, you can use cement in combination with asbestos fiber, in a 2:1 combination, respectively. And before pouring it into the pipe, add a little water to the mixture.

All of the above materials can be replaced with silicone sealant, which is simply poured into the free space between the riser pipes. And to protect this type of sealant from drying out too quickly, the application area is covered with polyethylene or a damp cloth.

Types of fum tape

There are three types of sanitary fum tape. Each brand is intended for use at sites with different work requirements. The numbers indicate the grade of the product. 1 – first grade, 2 – second grade, etc.

- Brand "FUM-1". Designed to perform plumbing work on utility lines for domestic and industrial purposes. Resistant to aggressive environments, heat-resistant (begins to melt at temperatures from 520°C). Contains lubricant: petroleum jelly.

- Brand "FUM-2". Sealing films of this type are intended for use on objects that interact with oxygen and oxidizing agents. Does not contain lubricant.

- Brand "FUM-3" are narrow strips, which are sections of the edge parts of films of the first two types. It is often used to seal threaded connections when installing domestic lines.

Rules for working with fum tape

The first rule of working with fluoroplastic seals is the correct choice of material. For high-quality connections, only those films that stretch well are suitable. All the rest will eventually begin to crack and turn into crumbs.

In order to avoid installation errors, you need to know how to wind fum tape onto a thread. Masters advise you to remember a few simple rules and adhere to them in your work.

There are no recommendations for the number of turns to be wound. You need to look at the parameters of the tape: its thickness and width

You also need to pay attention to what kind of thread it is. When winding the film, it is slightly stretched. The tape should fit into the grooves of the thread and fit tightly around them. If the film breaks during winding and stretching, place the free end on the thread and continue working. Winding is carried out until all the threads are hidden under the tape.

Its ribbing should look smoothed, but visible through the seal.

Masters claim that the skill of using fum tape comes quickly. It is enough to practice several times and understand the principle of working with this material.

How else can you seal sewer pipes?

Sealing a plastic pipe using sealing tape.

Sealing of sewer pipes can be done using other sealing compounds that can seal seams and joints. Suitable materials for these purposes include industrial sulfur, epoxy resin, hemp rope, resin strand, Portland cement, asphalt mastic and petroleum bitumen.

The most common sealing compound is epoxy resin. It is mixed with cold curing hardeners such as polyethylene polyamine (PEPA) and hot curing agents such as maleic anhydride (DEET). You need to add very little of them. The resin to hardener ratio is 10:1 or 5:1. Epoxy resin is often used at home.

Technical sulfur is crushed before embedding, then heated to a melting state and poured into the cracks of the joints of the sockets of cast iron sewer pipes. A solution is prepared from Portland cement for caulking the socket joint of the same cast iron pipes.

Hemp rope impregnated with resin is used to seal the sockets of cast iron or ceramic sewer pipes. A filler is prepared from asphalt mastic and petroleum bitumen, which will ensure the tightness of joints, as well as fill the sockets of ceramic pipes.

How to seal sewer pipes?

Sealing of sewerage systems in modern construction conditions is also carried out by other types of materials. Craftsmen often use epoxy resin, asphalt mastic, resin strands, hemp ropes and technical sulfur.

Most often, when working at home, epoxy resin is used. To harden this material, polyethylene polyamine is used for cold hardening, and maleic anhydride is used for hot hardening. But others can also be used. The combination proportion can vary and on average varies from 10:1 to 5:1.

Technical sulfur is used to seal sewer outlets. To do this, it is crushed, heated to a suitable plastic state and poured directly onto the inner surface of the joints of the exhaust pipes. This compound is made from Portland cement, in this case you need to prepare a solution.

Tarred hemp rope is excellent for working with ceramics and cast iron. And the filling of petroleum bitumen and asphalt mastic well seals the joints of ceramic pipes.

Silicone pipe sealants

Self-adhesive tape is well suited for processing pipe joints, but this material is not always applicable in construction. There are other materials and substances that can ensure the tightness of the sewer system.

Silicone sealants are substances that harden upon contact with air and have excellent sealing properties. Apply directly to the area requiring treatment.

Sealants can be made from a combination of different starting materials. One of the most popular is silicone (or siloxane), consisting of silicone rubber and additives that increase the strength and adhesion of the material. To accelerate the polymerization of the substance, various vulcanizing impurities are used. The result is a rubber-like elastic material with excellent sealing properties and a wide range of applications.

How to wind FUM tape correctly

To make a threaded connection airtight, you do not need to have any special skills. However, this matter still has its own nuances that you definitely need to know about.

So, to begin with, the fum tape is wound onto the external thread clockwise, that is, in the direction of its twisting. While winding, you need to slightly stretch the tape so that the resulting winding is tight enough and does not dangle. The more the tape is stretched, the better the connection will be, but do not forget that if the tension is strong, the fum tape may break. In addition, the end of the tape must be brought out in such a way as not to interfere with the process of winding the connecting element.

When working with fum tape, you should also take into account a number of its physical features. Firstly, it is quite slippery, so it can cause some inconvenience during installation. Secondly, after packing the tape and tightening the thread to the end, it can no longer be turned back without losing the tightness. Therefore, if it becomes necessary to loosen a connection assembled using fum tape, it can no longer be tightened back - such a connection will need to be disassembled and repacked again.

Silicone sealants for sewer pipes

Silicone sealants are mastic coatings that harden when exposed to air. Among the advantages of this material is ease of use. The surface of the pipes does not need to be treated with primers in advance.

Such sealants are made from silicone rubber with plasticizers. They increase the degree of adhesion, and at the same time the strength of the protective coating increases.

Sealing pipes with silicone sealant requires a minimum of time. Anyone can complete the task. The composition is applied using a mounting gun. If there is no tool, but sealing the pipe is urgently required, then the work can be done with a regular hammer. Its handle will act as a piston for feeding the composition. When the mastic dries, it will reliably protect the joints from leaking. Silicone waterproofing for sewer pipes is easy and quick to apply.

What to choose FUM or LEN

Linen, or tow as it is called, is an outdated material for sealing.

The process of its application is quite labor-intensive and takes place in several stages. At the first stage of winding the connection of tow, you need to divide it into fibers and lay it in furrows, making sure that there are no overlaps.

In the second stage, apply the sealant using a brush.

Experts do not recommend using tow without experience working with this material, and here’s why. The use of this material requires some features:

- If there is not enough tow, the connection will depressurize

- And if there is an excess amount, during twisting it is cut off by pipes, and excess stress is created - hence various deformations of parts during operation.

The only case where it is better to use tow is when working with metal pipes, which are often found in old houses.

Application of silicone sealants

Connection of sewer pipes for internal and autonomous sewer systems, where 1 – cutting the pipe to the required size with a cutter; 2 – installation of a sealing collar on the pipe; 3 and 4 – additional sealing of the bell and cuff with silicone sealant; 5 – making a socket connection.

Self-adhesive tape is very suitable for sealing joints, but besides it there are other sealing materials. We are talking about sealants - mastics that have the ability to harden under the influence of chemical agents and air. Sealants are characterized by good adhesion, resistance to various temperature changes, excellent water resistance, high mechanical strength and long service life.

There are several types of sealants, but the most common and versatile of them is silicone, or siloxane. This material is created on the basis of silicone rubber using special additives that enhance adhesion and strength. Thanks to vulcanizing impurities, polymerization is accelerated, and an elastic mass is formed, reminiscent of rubber in its characteristics.

Sealing pipe sockets using the traditional method.

According to the type of hardener, silicone sealants used for sealing sewer joints are neutral and acidic. Acid sealants are less expensive, but may not be used on some surfaces. Neutral can be used to seal seams and joints of any surface. Silicone sealants work well for plastic and metal pipes.

In order to squeeze the sealant out of the tube, use a mounting gun. If you don’t have one at hand, you can replace it with a regular hammer. The hammer handle is inserted into the tube and pressed on it like a piston.