The outer and inner diameter of metal pipes.

In the manufacturing process of metal pipes, their outer diameter is taken as a basis. Also, based on the general division of pipes into 3 types, the following applications are possible:

- Small pipes are used to install water supply in apartments.

- Medium-diameter pipes are suitable for installing urban water supply systems. In addition, crude oil is extracted using medium pipes.

- Large diameter pipes are almost always used in the construction of main oil and gas pipelines.

The internal diameter of metal pipes is not standardized according to GOST and is available in different sizes.

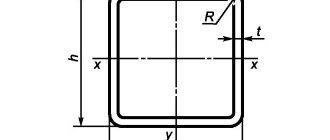

To organize the difference in the internal diameter of metal products, a special parameter is used - “conditional bore (Dу)” . This parameter is the minimum internal diameter of the pipe, rounded to the nearest whole number. The value of Dу is designated according to GOST 355-52. To calculate the internal diameter, subtract twice the wall thickness from the external diameter of the pipe.

Steel pipe diameter table

The amplitude of the internal diameters of steel pipes ranges from 0.6 cm to 20 cm.

In addition, the diameter of finished products can be indicated in inches. (1 inch = 2.54 cm)

Straight-seam electric welded pipes

The main area of application for longitudinal welded pipes is process pipelines designed for medium internal pressure, but if necessary they are quite suitable for the installation of metal structures.

The standard for steel pipes produced by this method is determined as follows:

- Technological features of the production of longitudinally welded pipes are regulated by GOST 10704-91;

- According to the standard, the outer diameter of this type of pipe can vary from 10 to 1420 mm, and the wall thickness - from 1 to 32 mm;

- Products with a diameter of up to 426 mm can be produced in both measured and unmeasured formats, and the length of a steel pipe with a larger diameter can only be unmeasured;

- In addition to ordinary pipes, production can also create products that have a reinforced weld, but in this case, GOST 10706 will regulate the production process and the dimensions of the pipes.

There is another important point regarding steel pipes - a straight seam can be created using argon arc welding or induction welding. In the first case, a more reliable connection is obtained, but the second method is much cheaper and faster.

Diameters of plastic pipes.

In the modern world, various plastic pipes are most popular: polypropylene, polyethylene, metal-plastic. Most companies that manufacture plastic pipes use their own sizing chart. As a result, when arranging a water supply system, it is better to use components from one manufacturer.

Table of diameters of plastic pipes

Water Pipe Size Chart

| Conditional pass | Outside diameter | Pipe wall thickness | Weight of 1 meter of pipes, kg | ||||

| lungs | ordinary | reinforced | lungs | ordinary | reinforced | ||

| 6 | 10,2 | 1,8 | 2,0 | 2,5 | 0,37 | 0,40 | 0,47 |

| 8 | 13,5 | 2,0 | 2,2 | 2,8 | 0,57 | 0,61 | 0,74 |

| 10 | 17,0 | 2,0 | 2,2 | 2,8 | 0,74 | 0,80 | 0,98 |

| 15 | 21,3 | 2,35 | — | — | 1,10 | — | — |

| 15 | 21,3 | 2,5 | 2,8 | 3,2 | 1,16 | 1,28 | — |

| 20 | 26,8 | 2,35 | — | — | 1,42 | — | 1,43 |

| 20 | 26,8 | 2,5 | 2,8 | 3,2 | 1,5 | 1,66 | 1,86 |

| 25 | 33,5 | 2,8 | 3,2 | 4,0 | 2,12 | 2,39 | 2,91 |

| 32 | 42,3 | 2,8 | 3,2 | 4,0 | 2,73 | 3,09 | 3,78 |

| 40 | 48,0 | 3,0 | 3,5 | 4,0 | 3,33 | 3,84 | 4,34 |

| 50 | 60,0 | 3,0 | 3,5 | 4,5 | 4,22 | 4,88 | 6,16 |

| 65 | 75,5 | 3,2 | 4,0 | 4,5 | 5,71 | 7,05 | 7,88 |

| 80 | 88,5 | 3,5 | 4,0 | 4,5 | 7,34 | 8,34 | 9,32 |

| 90 | 101,3 | 3,5 | 4,0 | 4,5 | 8,44 | 9,60 | 10,74 |

| 100 | 114,0 | 4,0 | 4,5 | 5,0 | 10,85 | 12,15 | 13,44 |

| 125 | 140,0 | 4,0 | 4,5 | 5,5 | 13,42 | 15,04 | 18,24 |

| 150 | 165,0 | 4,0 | 4,5 | 5,5 | 15,88 | 17,81 | 21,63 |

Diameter and weight of cast iron pipes.

Nowadays, water supply systems made of cast iron pipes are practically not applicable in apartments. The main reasons: great fragility and very heavy weight. At the same time, due to the durability of the material, cast iron water pipes are laid in external conditions.

From this table you can find out how much a cast iron pipe weighs:

Table of diameters of cast iron water supply pipes

How to measure pipe diameter

When laying pipelines, installers are faced with various options for their location, which often determines how the pipe is measured. To find the necessary parameters at home, they usually use any measuring instrument that is at hand, and, if necessary, a simple calculation formula.

In production, measurements are mainly carried out for control by more complex, high-precision instruments (for example, a laser meter or a ruler, a circummeter, is used).

Rice. 12 Methods of installing fittings on PEX pipes: compression, tension couplings, press fittings, push fittings

How to measure the diameter of a pipe with a ruler and tape measure

A tape measure or ruler can almost always be found in households; they can be used to find out the parameters of a pipe cut across. To determine the dimensions, apply the tools to the pipe end and look at their scale, visually comparing its readings with the cross-section of the product. The accuracy of this method is low - it is difficult to take measurements accurately diagonally.

If communications are located in hard-to-reach places and are not cut, it becomes too difficult to accurately determine the diameter of the pipe with a tape measure or using a ruler. You will have to attach rectangular parts to the wall around the pipe shell on both sides and measure the distance between them as close to the shell as possible to reduce the error.

Rice. 13 How to measure the diameter of a pipe with a tape measure and ruler

Using a caliper

A caliper is a fairly convenient measuring tool for determining internal and external dimensions in a circle up to 150 mm with an accuracy of 0.1 mm. Modern devices, in addition to a mechanical scale, may have an electronic or dial indication.

It is convenient to use a caliper to measure the pipeline in hard-to-reach places, touching or even partially located in the wall, less than half of the screed. An accuracy of 0.1 mm is quite acceptable for any business purpose.

Even more accurate readings can be obtained by using a micrometer, however, if calipers are occasionally found in the household, then a micrometer is an expensive industrial control and measuring device, the high accuracy of whose readings is not needed in everyday life.

Rice. 14 How to measure the diameter of a pipe with a caliper

How to measure the diameter of a pipe using string and the formula

Sometimes solving the problem of how to measure the diameter of a pipe is difficult due to the inconvenience of taking measurements and the large overall dimensions of the pipeline - in these cases, a combined method can be used.

To do this, tie the pipe with thread or rope (several turns can be made), and mark them with a marker or pen. Then lay the thread on the table and measure the distance between the marks. The resulting value is divided by pi, equal to 3.142, and the desired size is obtained. This method of calculating the diameter allows you to find out the parameters of the pipeline with higher accuracy thanks to the thousandth values of the number pi and the greater extent of the circumference than the directly measured parameter.

Sometimes it is difficult to determine the internal pipe size for a number of reasons; in this case, the problem of how to determine the pipe diameter is solved using a complex method. First, measure its external size in a circle, then the thickness of the wall, after which, using the formula, divide the first indicator by the number pi and subtract double the thickness of the shell from it.

Rice. 15 How to measure the diameter of a pipe using measuring tapes and the appearance of the circometer

Measuring tapes

One of the fastest ways to measure the diameter of a pipe is to use tapes with dimensional scales. Sometimes, for these purposes, a construction tape is used, which has a flexible tape with marked divisions and length values.

In everyday life, a measuring tape is often used, which is used to determine the size of clothes in sewing; it can also be used similarly to a tape measure. After measuring the length along the outer circle, a simple calculation is carried out: the result is divided by 3.142 and the outer diameter is found in this way.

An analogue of household tape meters is an industrial circummeter - a special device with a graduated flexible steel strip for measuring circumference lengths.

Photo copy method

The photographic method allows you to find out the parameters of the pipeline in extreme and emergency conditions in the absence of lighting, poor access to communications, and a limited time interval. When measuring pipe diameters using photography, place a tape measure with divisions or any object that can be taken with you next to the pipe, and take a photograph with a camera or cell phone. Then, under calm conditions, the photograph is analyzed, comparing the dimensions of the digital tape measure or the dimensions of the object with the parameters of the pipe.

Rice. 16 Comparative table of diameters of water pipes made of various materials

Thanks to the standard range of standard sizes of steel, copper, and polymer pipelines, the problem of how to find out the diameter of a pipe is, in most cases, successfully solved by studying the relevant state standards. If for some reason there is a need for measurements, for household purposes it is quite possible to get by with a ruler, tape measure, use measuring tapes or a piece of string, obtaining the desired result using a simple formula.

How to correctly convert inches to mm.

Inch is an English unit of measurement equal to 2.54 cm. When marking products, inches are indicated by numbers with quotation marks (1″, 2″, etc.)

For example, in order to calculate the outer diameter of a pipe = 1″, you need to add the wall thickness multiplied by 2 to 2.54 cm.

When carrying out work on installing a water supply system, it is necessary to observe the dimensions as accurately as possible. Otherwise, the water supply joints will not have a sufficient degree of tightness. And the service life of such a system will be significantly reduced as a result of leaks.

Seamless hot-formed pipes

The specifications for the lengths of steel pipes of this type are as follows:

- The production technology and standard sizes of hot-deformed pipes are regulated by GOST 8732-78;

- The outer diameter varies from 20 to 550 mm, and the wall thickness can range from 2.5 to 75 mm;

- Pipes can have measured and unmeasured lengths, which vary from 4 to 12.5 meters.

The dimensions of seamless steel pipe produced by this method may differ from standard ones. In extreme cases, a calibrated blank is taken, a through hole is drilled inside of it, and the result is a pipe with especially thick walls.

Duration of operation

The list of important technical characteristics includes the service life of the finished structure. This indicator largely depends on the conditions in which the pipeline is located.

Non-galvanized structures that are constantly in contact with cold water fail over several decades, as the walls under the threads gradually become thinner and the clearance decreases.

Galvanized products, even in contact with humidity, can last 50-80 years without repair.

The absence of humidity (gas pipeline) allows the facility to be operated for more than 80 years.