Plastic pipes, due to their low cost and other advantages, have almost completely replaced their cast iron counterparts in sewer systems. However, thanks to certain technical characteristics, cast iron pipes still remain in demand for sewerage installations. They can be found not only in old systems, but also in new ones.

Of course, cast iron pipes cannot be called an ideal material for arranging pipelines, but they are still quite reliable products that have a number of advantages. Although cast iron is a fragile material, it can crack under mechanical stress: a blow or a fall, but with careful installation it will last for decades.

Pre-installation preparation of cast iron pipes

As mentioned above, due to the large weight of cast iron products, their delivery to the job site and assembly are significantly difficult.

Therefore, and also for the purpose of safe and long-term operation of the equipped pipeline, before starting work with the products, it is necessary to check them for all kinds of defects. In addition, the material is highly fragile, so even dropping the product from a small height can damage it irreparably.

To eliminate such factors, before starting work you need to:

- inspect the ends and sockets of the products, noting the presence or absence of irregularities;

- check that there are no significant variations in diameter along the length of the pipe;

- evaluate how good the bitumen coating is - it should be smooth, uniform, and not become sticky even at elevated temperatures;

- tap the products along the entire length, making sure that the sound is uniform and thick;

- make sure that all auxiliary materials (cement, tow, etc.) are prepared before starting work.

Positive and negative qualities

Today, cast iron pipes are installed in most sewer systems. The properties of these products allow them to be installed in any type of soil. The main advantages are:

- very high strength;

- not afraid of temperature changes;

- long service life;

- does not burn;

- meets modern environmental requirements, does not emit toxic substances;

- has excellent soundproofing properties;

- does not react with aggressive substances;

- not afraid of corrosion.

Unfortunately, in addition to such a large number of positive properties, cast iron products also have a number of characteristic disadvantages. Some factors greatly influence the labor intensity when installing a sewer system:

- large mass;

- increased fragility;

- installation requires special equipment and additional materials;

- very high cost;

- repair work requires large financial investments.

Features of cast iron pipes

New plastic drainage system pipelines. They are cheaper, light weight and easier to assemble. All alternative options are used only in systems that operate in difficult conditions.

If the pipeline is cast iron, the sewer joints will have to be processed separately. Each connection requires caulking (this is what experts call the compaction procedure during assembly). This applies to socket parts equipped with special connecting elements. There are also products that are assembled using couplings. They are not equipped with connecting units, which simplifies production, but additional parts are required for installation. They are expensive, which increases costs and the overall cost of the network. The coupling method is used to install pressure-type cast iron sewers. It is widely used in industrial wastewater systems.

The system includes two groups of parts:

- pipes. These are straight elements that form straight extended sections of the network;

- fitting. These are parts designed for branching or turning channels. In addition, fittings are used for cleaning and other types of system maintenance.

Since the rules for laying networks were developed a long time ago, on metal pipelines, the basic requirements for installation work differ little from modern standards. Required to provide:

- line slope, which depends on the diameter of the pipes;

- tightness, no leaks;

- When laying, the sockets should be directed towards the starting (highest) point of the line.

Installation of sewerage from cast iron pipes is carried out at the stage of primary construction of buildings or structures. Later assembly of systems requires destruction of the finishing of the premises. Before assembly, it is necessary to calculate the network, draw up a diagram and a working drawing of the line. This is an important stage in the construction of the system, since working with metal elements is complex and requires effort and time.

Advantages and disadvantages

The advantages of cast iron drainage networks include:

- strength;

- ability to withstand high pressure and large external loads;

- low coefficient of thermal expansion;

- long service life;

- cast iron pipes are less susceptible to corrosion;

- low noise level.

Flaws:

heavy weight When working with large diameter pipes, lifting equipment is required; connecting cast iron sewer pipes is complex and time consuming; cast iron is fragile

Assembly must be done carefully so as not to split the connecting elements; the surface of the material is rough, which promotes the growth of fatty deposits on the walls; the finished line is difficult to repair or replace individual elements.

The disadvantages of metal elements led to a transition to more convenient plastic lines. However, systems operating in difficult conditions and withstanding significant loads are still assembled from cast iron parts. If the assembly is done with high quality, the line can operate for up to 100 years or more, which makes the material relevant in the present day.

Conclusions and useful video on the topic

Some useful tips on choosing pipes will be useful for creating sewage systems with your own hands:

Meanwhile, polymer products are inferior in technical and operational indicators to products made from cast iron. They have significantly more disadvantages compared to cast iron sewer pipes.

Polymers are convenient and rational to use in internal sewage systems, but for serious external communications it is reasonable from any point of view to use cast iron.

Do you have useful information on the issue of installing external sewerage systems made of cast iron pipes? Would you like to tell us about how you built the system on your site? Please write comments in the block below, post photos related to the topic of the article, and ask questions.

Cast Iron Pipe Standards

The weight, diameter and other dimensions of cast iron sewer pipes, as well as other requirements are specified in the GOST standards “Cast iron sewer pipes and fittings for them” - 6942-98 and 9583-75.

The first article prescribes the requirements for pipes for domestic use - 50, 100 and 150 mm in diameter, and the second the requirements for pressure products with a diameter of up to 2000 mm.

Household products:

- are produced with bells; socketless products can be manufactured only by agreement with the customer;

- GOST regulates all diameters: internal, external, socket diameter;

- length, according to the rules, can be equal to 750, 1000, 1250, 2000, 2100 and 2200 millimeters;

- the diameter cannot fluctuate by more than 0.2 mm, and the length by more than 0.9%;

- the presence of any external defects is not allowed;

- the edges of any of the ends can be smoothed or rounded;

- cast iron pipes are supplied to the consumer only after applying an anti-corrosion coating to the internal and external surfaces;

- in production, diameters of 50, 100 and 150 mm are observed.

Pressure pipes

Features according to GOST:

- the measured length of pipes can range from 2 to 10 meters in increments of one meter;

- according to GOST standards, pressure products undergo mandatory hydraulic testing under a pressure of 20 kgf/cm2;

- the anti-corrosion coating of such pipes must be approved by the Ministry of Health;

- The diameter of the products can be from 65 to 2000 mm.

Installation of cast iron pipes

The general rules for installing sewerage on the street (usually pipes with a diameter of 100-150 mm are used) and in the house (a 50 mm pipe is suitable for wiring), repair and dismantling are the same for all pipes.

It is necessary to pay attention to the depth of soil freezing, maintain slopes, avoid a large number of bends and turns, and, if necessary, insulate. Tapping into cast iron is done using a grinder

Let's move straight to the features of installing cast iron products.

Joining using a socket:

the tail part of the pipe is inserted into the bell (extension) of the previous link; the resulting gap must be sealed with special tow, using a wooden or rubber hammer for compaction; the remaining space is filled with solution or sulfur; Considering the weight of the product, it is better to place stands under the pipeline until the joints completely harden; to organize turns or branches, angles and tees made of the same brand of cast iron are used; inserting a cast iron pipe into a wall or foundation should be done with the utmost care, taking into account the fragility of the metal;

Socketless connection:

Under the influence of progress, cast iron products have a new modification, from which socketless cast iron sewerage is installed. Pipes of all diameters (50, 100, 150 mm) are securely connected using stainless steel clamps.

- the pipeline is installed end-to-end using clamps that attract a rubber cuff that is resistant to aggressive environments;

- the cuff is tightened with bolts;

- to transport wastewater under pressure, the joint must additionally be sealed with a special crimp collar;

- Considering the weight of cast iron, sagging of the pipeline is not allowed.

It is worth noting that you are unlikely to need repairs and dismantling of cast iron sewers, because cast iron lasts a very long time. But, if you still need to carry out such manipulations, follow the following rules:

- Repair and dismantling is carried out using only rubber or wooden tools so as not to split the pipe.

- Repair of cast iron products is carried out using the same materials as their joining: mortar, sulfur, cuffs, clamps.

trubypro.ru

Marking

When choosing cast iron pipe products, you should pay attention to their markings, which indicate all the parameters of the pipe, starting with its type, namely:

- type of product;

- production standard;

- length;

- conditional capacity.

For example, the marking ТЧК-150-2000 GOST 6942-98 designates a bell-shaped non-pressure product with a diameter of 150 mm and a segment length of 2 meters.

Range of cast iron pipe products

There are only three units of the range, which differ in cross-sectional size. There are two main types: SMU - with smooth ends and SME - one end is smooth, the other with a socket. Pipe products made of cast iron are marked according to their nominal cross-section.

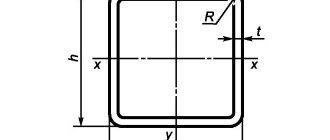

The first part of the inscription is the grade of material, the second part is the nominal cross-section (for example, if the marking indicates DN 100, then the internal diameter of the cast iron sewer pipe is 100 mm, the outer diameter is Ø110 mm). Products with a socket are divided into 3 classes - A, B, LA (depending on the wall thickness).

| Table of sewer pipe diameters | ||||

| Outer dia. (mm) | Nominal diameter (mm) | Wall thickness | ||

| Class A | Class B | Aircraft class | ||

| 81 | 65 | 7.4 | 8.0 | 6.7 |

| 98 | 80 | 7.9 | 8.6 | 7.2 |

| 118 | 100 | 8.3 | 9.0 | 7.5 |

| 144 | 125 | 8.7 | 9.5 | 7.9 |

| 170 | 150 | 9.2 | 10.0 | 8.3 |

| 222 | 200 | 10.1 | 11.0 | 9.2 |

| 274 | 250 | 11.0 | 12.0 | 10.0 |

| 326 | 300 | 11.9 | 13.0 | 10.8 |

| 378 | 350 | 12.8 | 14.0 | 11.7 |

| 429 | 400 | 13.8 | 15.0 | 12.5 |

Standard sizes of sewer pipes and their purpose

Modern industry produces sewerage pipes in accordance with the required technical standards. Indicators vary for each type of room (kitchen, bathroom, toilet), and also depend on the expected load on the system. The last point is determined by the number of family members living in the apartment or house.

The main parameters that it is recommended to pay attention to when choosing sewer materials are the following:

- internal diameter - the main parameter, which is fundamental for the entire sewer network, is designated as “D”;

- nominal diameter – designated “DN”, determines the nominal value of the internal diameter of the pipe;

- nominal diameter - designated “DN”, indicates the total diameter of the entire structure.

In addition, professionals pay attention to the thickness of the pipe wall and its material of manufacture. In addition to technical data, it is worth paying attention to the components - when choosing adapters, you must adhere to exact compliance with the dimensions and purpose of the products

PVC

The tables show values for internal and external plastic sewage systems.

Table No. 1 - internal system:

| DN (mm) | D (mm) | Wall thickness (mm) (minimum value) | Wall thickness (mm) (maximum value) |

| 32 | 30 | 1 | 1.8 |

| 40 | 38 | 1 | 1.8 |

| 50 | 47.4 | 1.3 | 1.8 |

| 75 | 71.2 | 1.9 | 2.3 |

| 90 | 85.6 | 2.2 | 2.8 |

| 110 | 104.6 | 2.7 | 3.4 |

Table No. 2 – external system:

| DN (mm) | D (mm) | Wall thickness (mm) (minimum value) | Wall thickness (mm) (maximum value) |

| 125 | 118.6 | 3.2 | 3.9 |

| 160 | 153.6 | 3.2 | 4.9 |

| 200 | 192.2 | 3.9 | 6.2 |

| 250 | 240.2 | 4.9 | 7.7 |

| 315 | 302.6 | 6.2 | 9.7 |

| 400 | 384.6 | 7.7 | 12.3 |

| 500 | 480.4 | 9.8 | 15.3 |

| 630 | 605.4 | 12.3 | 19.3 |

| 800 | 769.2 | 15.4 | 24.5 |

| 1000 | 960.8 | 19.6 | 30.6 |

| 1200 | 1151 | 24.5 | 36.6 |

The optimal pipe sizes for internal sewerage are considered to be 32-110 mm. For outdoor – 160-500.

Based on the fact that manufacturers produce almost all possible sizes of sewer components, choosing the optimal one for individual housing is not a problem. The most common values, which also comply with the approved SNiP requirements, are considered (data in mm):

- washing machine and dishwasher – 25;

- sink – 30-45;

- bath, kitchen sink – 40-50;

- combined drain (bathroom, bathtub) – 50;

- riser outlet – 70-85;

- central drain - 110-120.

The indicators are typical for internal sewerage. When laying sewerage outside the house, it is recommended to use plastic components of the following diameter (data in mm):

- output to the cleaning system – 160-200;

- removal of water from the bath – 200;

- swimming pool – 230;

- city sewer network - from 300 to 1100.

How to determine pipe sizes

Foreign-made polypropylene, polyvinyl chloride and other plastic communications are most often designated by inches. It may also be that you need to install fasteners on the pipeline, but its dimensions are also given in inches, while the pipe is indicated in mm.

Pipe inch thread

To do this, you need to convert the known inch dimensions into millimeter ones. According to the data, 1 inch is 25.4 mm. It turns out that a pipe with a diameter of 2 inches = 50.8 mm, etc. Fractional values are very often used, this is how clamps, fittings, couplings and communications are marked.

Let's look at their meaning in the table:

| In inches | In millimeters | In inches | In millimeters |

| 1/8 | 3,2 | 1 1/8 | 28,6 |

| 1/4 | 6,4 | 1 1/4 | 31,8 |

| 3/8 | 9,5 | 1 3/8 | 34,9 |

| 1/2 | 12,7 | 1 1/2 | 38,1 |

| 5/8 | 15,9 | 1 5/8 | 41,3 |

| 3/4 | 19 | 1 3/4 | 44,4 |

| 7/8 | 22,2 | 1 7/8 | 47,6 |

| 2 1/8 | 54 | 3 1/8 | 79,4 |

| 2 1/4 | 57,2 | 3 1/4 | 82,6 |

| 2 3/8 | 60,3 | 3 3/8 | 85,7 |

| 2 1/2 | 63,5 | 3 1/2 | 88,9 |

| 2 5/8 | 66,7 | 3 5/8 | 92,1 |

| 2 3/4 | 69,8 | 3 3/4 | 95,2 |

| 2 7/8 | 73 | 3 7/8 | 98,4 |

PVC pipes of different diameters

But, when measuring a socket manually, for example, with a ruler, the nearest minimum size is always taken. For example, the diameter in millimeters of a sewer pipe for a sink is 34. It turns out that the outer diameter is 1 ¼ inches. Be careful when selecting sizes, otherwise you will have to buy additional spacers or adapters. But the coupling is selected based on the nearest larger indicator, i.e., 34 mm will be considered 1 3/8 inches.

Video: Joining pipes of different diameters in the sewer system.

Steel two-way communications may have different indicators on different sides; you need to double-check the data. This can be done by experimental measurements with a caliper or plug gauge.

Table: Diameters of ceramic pipes

Pre-insulated products

The cast iron products of the TML classifier group are complemented by products that are pre-insulated cast iron pipes. Such modifications are successfully used in environmental conditions with low temperature values.

Essentially, these are the same high-strength socketless or socketed pipes (1), additionally coated with technological layers (2, 3, 4) of thermal insulation.

A variant of a socketless cast iron pipe, supplemented with a thermal insulation element. Products in this design are called “pre-insulated pipes”. They are intended for use in low ambient temperatures

Thermosetting foam (3) or a similar material with a dense structure and non-flammable properties of class A2 is used as an effective heat insulator. The heat insulator is covered with a casing made of galvanized steel sheet (4). The thickness of the casing sheet is at least 1 mm. The casing is fixed with clamps (2), also made of galvanized steel.

Pre-insulated cast iron pipes are designed to withstand humidity conditions up to 75%. Insulation eliminates the formation of condensation at low and critically low temperatures. There are modifications with the introduction of a heating cable directly into the structure of the heat insulator.

How to choose?

To select the required diameter of sewer system pipes in an apartment or private house, you should calculate all expected drains. Most often, the main pipe leading to the riser is installed with a diameter of 110 mm in order to easily drain both plain water and sewage. And the sizes of the remaining drainage channels depend on the type of plumbing to which they are connected.

Sink

The shaped parts of any washbasin, as a rule, are designed to combine them with pipes with a diameter of 40 to 50 mm. It makes no sense to install larger elements, as this will entail unnecessary expenses and clutter up the free space.

Toilet

The largest pipe used to drain sewage and water from plumbing elements is a pipe with a diameter of 100 mm connected to the toilet. With such a width of the product, its length should be minimal, and its location in space should not allow bends and turns. The earthenware or ceramic product itself is connected to the outlet using a corrugated element, the lower end of which is inserted into the pipe. The corrugation should also not be twisted or have a large length.

Bath

Although the volume of water leaving a filled bathtub is several times greater than the same volume of a toilet bowl, it is enough to use a drain pipe with a diameter of 50 mm. This is due to the fact that a small drain hole at the bottom of the bath will not allow a larger flow to exit from it. In addition, a small grille is additionally installed at the hole itself, which reduces the rate of water loss several times.

The shower cabin can be connected to a pipe of even smaller diameter, since such a large volume of water does not drain from it at one time. The diameters of the pipes for it can vary from 32 to 50 mm. Most often, a 50 mm pipe is installed, since it is more universal and you can connect the drain to it from both the sink and the washing machine.

Washing machine

The diameter of the drain hoses of almost all models of washing machines is 32 mm, which means the minimum size of the outlet pipe. However, installing a separate outlet pipe to connect a washing machine is a rare case. Therefore, the hose is connected through a special rubber collar to a conventional 50 mm pipe of the internal drainage system.

Kitchen

In the kitchen, both one sink and a washing machine and dishwasher can be connected to one pipe. The diameters of their bends differ significantly from each other, so it makes sense to lay one pipe with a 50 mm diameter, and connect all smaller bends to it with special cuffs or other fittings.

Features of installation and docking

During installation, special attention is paid to the joining of products. In order to achieve an ideal result, you should prepare the putty without wood waste and impurities. Before filling the socket with an asbestos-cement mixture, it is necessary to fill it with tarred hemp strands. Then it is rolled up into a rope and caulked into the slit of the bell. You must act carefully.

The thickness of the strand should be greater than the width of the slit, the length should be such that the strand fits into the socket 30 mm from the edge. To obtain a mixture of cement and asbestos, mix 400 grade Portland cement and asbestos fiber. These ingredients are mixed in a ratio of 70 to 30.

Before use, the mixture is moistened by adding water in a volume of 12% by weight. The joining of shaped parts to cast iron pipes is carried out by sealing the gaps that appear between the inner surface of the socket and the shaped part or the end of the pipe. When installing a pipe, the direction of the socket must be ensured in the opposite direction from the movement of the liquid.

Metal-plastic

Metal-plastic pipes do not have many of the disadvantages that are typical for products made of pure metal or plastic. The structure of such a pipe is quite simple: the aluminum layer is covered from the inside and on top with layers of polymer origin.

The service life of metal-plastic collectors is significantly affected by:

- ultraviolet radiation;

- working pressure value;

- installation method;

- temperature constancy. This means that you cannot first run hot water through the same pipe and then immediately run cold water. Such a procedure, if it becomes regular, can lead to delamination of the pipe, since aluminum and plastic have different thermal expansion coefficients.

If you adhere to these conditions, then metal-plastic collectors can last up to 40-50 years.

Features of choosing the diameter of waste pipes

The question of what diameter of sewer pipes should be selected is one of the first when designing. Typically, pipes with a diameter of more than 100 millimeters are suitable for toilet drains, and up to 50 mm in the kitchen and bathroom.

The diameters of sewer pipes have a wide range of values due to two factors:

- The toilet is a plumbing fixture, the features of which include the passage of a very large volume of water in a short period of time at the time of flushing. It may contain solid fractions, with which a pipe with a smaller diameter is more likely to clog.

- Despite the fact that when the bath is emptied a lot of water is also drained, the drainage pipes are made of a much smaller diameter. This is due to the fact that, according to hydraulic conditions, the permeability of the pipe is equal to the permeability provided by its narrowest point. And in the bathroom the outlet has a disproportionately smaller diameter, in addition, it is blocked by a grill. This makes it impractical to install a large diameter pipe in relation to the bathtub.

Pipe diameter for series-connected plumbing fixtures

What to do if in the toilet room there is a bidet in addition to the toilet? In this case, the diameter of the sewer pipe should not be increased to 150 or 200 mm. This is explained by the following formula: the permeability of a pipe depends on the square of its diameter.

That is, if we take a two-hundred-millimeter pipe, we find that its permeability is four times greater than a pipe with a diameter of one hundred millimeters. In addition, it is almost impossible for the toilet and bidet tank to be filled to the maximum.

Diagram of the correct selection of pipe diameters in the direction of movement of the drains to the riser

In other words, the diameters of sewer pipes - toilet pipes are taken larger not because a smaller diameter will not allow the required volume of water to pass through.

It should be noted that in order to pass the required volume of wastewater, including solid fractions, the pipe must have an air gap

This is important because when the water front moves through the drain pipe, air is displaced and is under high pressure

The vacuum formed in the absence of an air gap in the pipe can squeeze out the water seals in all outlets, thereby causing a lot of troubles, from the appearance of an unpleasant odor in the room to the need to wash plumbing fixtures.

https://youtube.com/watch?v=x7LSxcXYiMw

https://youtube.com/watch?v=rBSOMS8P62o

Metal sewer pipes - how to connect cast iron and steel

Metal sewer pipes can be connected in only two ways:

- Installation in socket

- Welding installation.

Moreover, welded installation is practiced only in the process of assembling a sewer system from steel pipes. But socket installation is typical only for cast iron pipes. Next we will look at both processes.

Connection of cast iron communications (into a socket)

Before connecting sewer pipes - cast iron to plastic or cast iron to cast iron - you need to take into account that the assembly process looks identical to the operation that is practiced when installing plastic pipelines. That is, to install cast iron pipelines you just need to insert the smooth end into the socket of the previous pipe. Differences in the assembly process of cast iron and plastic pipes will only be noticeable during the process of sealing the joint

The process of pressing the rope—chasing the joint—is performed as follows:

- The pipe is centered in the socket using wooden or metal gauges driven into the slot.

- After centering the pipe, the first turn of tarred rope is wrapped around it, which is driven into the joint at ¾ of the depth of the socket.

- Next, a second turn is wrapped around the pipe, which is minted after the first. And so on.

- At the very end of the embossing, we apply a cement patch to the seam (on top of the rope).

The result is a very strong and tight connection.

Welded connection of steel communications

This installation method does not involve the use of fittings (couplings or tees). Communications are connected by a weld seam applied to the joint of the mounted elements. To implement this process, either gas (oxyacetylene) or arc (electric) welding is used. Large-diameter pipes are joined using a special welding machine. Well, small-sized pipelines with a diameter of 50-150 millimeters are welded manually.

This installation method is the most reliable and cost-effective: the homeowner only pays for the pipes. However, to implement it you need

Reasons for replacing cast iron with polymers

What is the reason for the growing popularity of polymer products that are being sought to replace cast iron?

As it turns out, the main reasons are:

- risks of cast iron corrosion from damage by stray currents of electromagnetic fields;

- lack of additional protection of the internal walls of pipes from aggressive environments;

- rigidity of products, which has a positive effect on an individual pipe, but provokes a displacement of the total soil loads at the joint points on a pipeline assembled from a dozen or more pipes;

- technical difficulties that inevitably arise during the repair process or in the event of creating new communication connections.

Polymer pipes are much more often used than cast iron pipes to create autonomous sewage systems in private homes.

You will learn about which pipes are best used in the construction of the external part of the sewer system in a suburban area from the following article devoted to this difficult issue.