When organizing a home, you have to solve a variety of issues, including choosing plumbing. It’s great if the bathtub and toilet are made in the same style. But if choosing a bathtub is quite simple, then when choosing a toilet the question often arises: which toilet is better with an oblique outlet or with a straight one. Release is an important factor in the separation of plumbing fixtures. Depending on the location of the connecting hole, it can be horizontal, vertical or oblique. In this article we will try to talk about the various nuances of choosing plumbing fixtures for a toilet room, and will dwell on the advantages and disadvantages of each type of product.

Toilet with vertical outlet to the floor

This option is used almost everywhere in America. This is due to the fact that all communications there pass inside the ceilings and the system is connected to the sewer directly to the pipe. Products of this type are becoming increasingly popular due to the fact that installation is much simpler and faster.

Main advantages with vertical floor outlet

Speaking about the advantages, one cannot fail to mention the following factors:

- The design of the flush tank ensures its high reliability and also guarantees excellent flushing quality. Such tanks usually use high-quality fittings. During operation, flushing occurs without splashing or splashing; moreover, the quality of flushing from the walls is, as a rule, much better than that of traditional options.

- The presence of a siphon in the body of the product provides a high tightening force, due to which water is consumed much more economically.

- The high water level in the bowl provides excellent protection against foreign odors and guarantees the best possible hygiene.

- If you need a compact toilet, a vertical outlet is exactly what you need. It can be placed anywhere in the room at any angle to the walls. Moreover, unlike other options, this type can be placed close to the wall, which saves every centimeter of space.

In new houses, the sewer pipe is now made higher than the floor, which makes it possible to use any design. A toilet with a vertical outlet is most often purchased by owners of private houses.

The following reasons push them to do this:

They practically make the sewer pipe invisible, and this looks much more aesthetically pleasing. Since a private house usually has a basement under the house, there is an excellent opportunity to carry out sewerage repairs.

Thanks to the complete set of the toilet, it can be installed anywhere in the bathroom.

The devices do not take up extra space, so they can be successfully installed even in very small toilets of small apartments.

It is only necessary that the sewer pipe be located in the floor slab.

When you can't do without a vertical outlet

The advantage of toilets with this outlet is obvious; it can be easily installed anywhere in the toilet. In order for it to serve you long and reliably, you need to choose:

- Porcelain model.

- A circular drain that washes the entire surface of the bowl.

- The water mirror should be located at the back along with the anti-splash, in this case there will be no splashes and the quality of rinsing will be high.

- A drain tank with reliable components must be attached to it.

Porcelain

To make porcelain sanitary ware, white clays are used, to which quartz and feldspar are added during the production process and subjected to a certain temperature. The result is products that are less porous and have higher strength characteristics. Porcelain toilets are coated with a special enamel glaze, which is more resistant to abrasion.

It is worth noting that even with a small layer of protective coating, porcelain toilets are characterized by reliability, since the manufacturing material has high strength and low hygroscopicity. When deciding which toilet is better to choose, you need to know that porcelain toilets have been used flawlessly for 20-25 years.

Types and features

Modern industry pleases with a large selection of sanitary products, including toilets. You can choose a device based on style, convenience, color, shape, even location: the toilet can rest against the floor, occupy a corner, or hang on the wall, mounted on an installation.

The types of drain outlets do not differ much. Their choice depends on the direction of the sewer pipes. In “Stalin” buildings, plumbing with a vertical outlet predominates, and in apartments of the Khrushchev era, an oblique version is installed. In the arrangement of modern homes, horizontal drains are more often used.

You can use adapters to “adapt” the outlet to the characteristics of the sewer pipes, but the use of additional connections increases the risk of leakage.

To achieve the goal, they also use a fan structure, corrugated pipes, and a plastic outlet.

Let's take a closer look at the types of releases and their features.

Horizontal release (straight)

The downstream model has a drain flush with the pipeline. This type of product is typical for luxury imported toilets. They are often used in new buildings and private homes. During installation, the plumbing fixtures should be pressed as tightly as possible against the wall, this will improve its external appearance.

The advantages of this type of release include ease of installation and maintenance of the model.

Toilets with a horizontal outlet have an aesthetic appearance, so they are purchased even for toilet rooms with a communications supply with an oblique pipe. In such cases, the connection is made using a corrugated adapter.

The disadvantages of horizontal outlets include a high percentage of blockages and fragility due to unstable joints connecting the product to the sewer.

The industry offers consumers a wide range of toilets with horizontal outlet.

- The most common are floor-mounted types that are attached to the floor. They are known to us from the Soviet past.

- Suspended models are mounted on the installation, which also hides the supply lines for communications and barrels. Everything is hidden behind a false panel and looks as if the toilet is hanging on the wall. Despite the apparent unreliability, the design can withstand up to 150 kg of load. It is easy to clean under a product that hangs in the air.

- Wall-mounted or wall-mounted toilets with horizontal outlet are increasingly gaining popularity. They are installed on the floor close to the wall, behind which communications are hidden. Only the toilet bowl is visible to the outside. This aesthetic appeal attracts many buyers.

Cast iron

In plumbing stores, cast iron toilets can be found much less often than plumbing products made from other materials. This is due to the low demand for such plumbing fixtures. Cast iron toilets have significant dimensions and heavy weight, but the service life of such products is quite short. Despite the high protection of cast iron products from corrosion and rust, the material itself is characterized by fragility. For this reason, cast iron toilets are installed in low-traffic public areas.

Installation

If we talk about connecting a toilet with an oblique outlet to the sewer system, then in principle it is almost no different from installing (replacing) another toilet with any outlet. Almost the same assembly, during which the installation of the toilet takes place, as well as securing it to the floor and connecting it to the water supply system. But when it comes to connecting it to the sewer system, you will have three ways in which you can carry out the installation. They differ from each other depending on the use of one or another connection option:

- Direct connection to the sewer branch socket. It will suit you only if the outlets from the plumbing and sewer line perfectly match, that is, you do not need to move the product to the left or right. This happens if you clearly measured the location of the socket or if you replace the old toilet with a new one, but absolutely identical. With such a connection, you will have to use a special cuff, which differs depending on the material from which the sewer pipes are made - cast iron or plastic. Its installation is very easy: lubricate the toilet outlet with soap (shampoo) and push it into the socket on which the cuff is already installed. All you have to do is mark the places for fastening and securely secure the plumbing fixtures to the floor.

- Connecting an oblique toilet using an eccentric. It is a socket with a center shifted by 50 mm, with a sealing gasket already built into it. By turning the eccentric inside the sewer outlet, you can move the toilet to the right or left relative to the center of the hole by 50 mm in any direction. In addition, it is possible to shift the center of the sewer outlet up or down. A very convenient device that allows you to connect the latrine to the sewer if there are minor discrepancies between the outlet and the socket.

- Connecting a toilet with an oblique outlet using a corrugated outlet. The eccentric helps to adjust the plumbing fixtures to the sewer outlet with small deviations, but the corrugation does this with significant deviations. Additionally, using the corrugation, you can rotate the toilet at an angle of 90 degrees relative to the sewer outlet. But at the same time, you will have one serious drawback of the corrugated outlet - your latrine will move very far away from the wall, from about 50 mm and further, depending on the circumstances. However, you can use a flexible outlet as a drastic remedy, which is used in extreme situations.

You can connect the toilet yourself

It only remains to mention that you can install a toilet with an oblique outlet even instead of the same product, but with a vertical connection. Of course, it will move forward, so experts recommend using it only as a temporary measure. You can make such a connection by simply turning the pipe at 45 degrees.

Earthenware

Faience is considered the cheapest material; it is white ceramics with a finely porous structure. The low cost of earthenware toilets makes them the most popular. Coating with special enamel significantly reduces the hygroscopicity of the porous material. The enamel coating may have a white, beige or yellowish tint, but the operational and technical characteristics do not change in any way.

A disadvantage of earthenware toilets is the reduction of the protective enamel layer during operation. A layer of enamel that is too thin cannot prevent the absorption of moisture into the porous structure of the product; as a result, the strength and reliability of the toilet bowl is significantly reduced. The average service life of earthenware toilets is about 15 years, which is very important when choosing which toilet is best.

Toilets with vertical outlet

Toilets of this design are connected to a sewer pipe located in the floor. Such models can often be seen in old houses and are preferred to be used in private buildings. This type of toilet has many advantages over other types and, having studied them, you will no longer have the question of which version to choose a toilet with.

So, what are the advantages of these models:

- An excellent model for country mansions and old apartments.

- Such structures operate almost silently.

- Such toilets most often have a funnel-shaped bowl, which effectively prevents splashing and splashing of water.

- Aesthetic appearance. The pipes are all in the floor and not exposed.

- There is more free space left.

- It is possible to choose models taking into account the design of the toilet room and your preferences.

- It is possible to use decorative elements.

Progress does not stand still and manufacturers are constantly supplying the market with new varieties. They can be divided into several groups depending on the criterion. According to the place of attachment, such toilets are:

- Floor-standing.

- Hanging.

Firms even take into account the age of their customers and produce:

- Adult toilets.

- Toilets for children.

Comfortable toilet bowl

The bowl in the equipment can have different shapes:

- Funnel-shaped.

- Rounded.

- Designer form, when custom production is possible.

The drainage system can also be different, and manufacturers have gone far in this matter. The following options exist:

- Single-mode. When you press the button, the tank is completely emptied.

- Dual mode system. There is a bifurcated push button with which you can pour out all the water from the tank or only part of it.

- Contactless. The latest invention is not yet very widespread due to its high cost.

You may often come across the question, are there toilets with side discharge? This question is reasonable in the case when we have very small dimensions of the sanitary room. People's ingenuity has no limits; if you place the toilet on its side, you can make room for a washing machine.

Such varieties are not yet available, but if you wish, you can do everything. For this you can use adapters. On horizontal sections, you need to make a 90-degree turn out of two 45, although some do 90 at once, just so that there is a slope.

Steel

In the manufacture of steel plumbing fixtures, stainless steel is used in most cases. The main characteristic of this material is its very high strength, which allows the installation of such plumbing fixtures in public places. It is also worth noting that the material does not absorb moisture, and impurities practically do not linger on its smooth surface. Steel toilets are characterized by an almost unlimited service life and a fairly high cost compared to porcelain products. This option may be one of the answer to the question of how to choose a good toilet.

Features of choosing a toilet

Progress does not stand still, and manufacturers are constantly offering consumers new types of plumbing fixtures. In order to make a responsible choice and purchase a high-quality model, you need to take into account several criteria at once.

Toilet model

This criterion depends on the area of the toilet room and your preferences. If the bathroom is small, then you can purchase a hanging option. In this case, the entire floor surface will be freed up, and the room will be easy to keep clean.

Important! In addition to hanging options, the market offers floor-standing and wall-mounted models.

Bowl shape

The following bowl shapes are distinguished: round, funnel-shaped, with a shelf (plate-shaped), with a slope. In the model with a funnel-shaped bowl, the drain hole is located in the center. In a design with a slope, the drain hole is shifted to one side.

Important! The option with a shelf is currently used quite rarely, due to numerous disadvantages.

Drain system

The market offers models with continuous drainage of water (single-mode) and models in which drainage occurs in a certain dosage (dual-mode). The latest model allows you to regulate and control water flow as needed.

Type of tank

Based on this feature, the following types of latrines can be distinguished:

- compacts (with detachable tank and cast product);

- toilets with a flush cistern of a hidden installation type;

- hanging tanks.

Models with hanging tanks are used less and less due to their unpopularity. Plumbing fixtures with a concealed-mounted cistern are becoming increasingly popular due to their advantages: compactness (the cistern is mounted in a wall or niche), stronger drainage, and quietness.

Material of manufacture

One of the distinctive features of the equipment is the material of manufacture. Models made from earthenware, porcelain, acrylic, and metal are available for sale:

- Earthenware absorbs moisture quite strongly, which leads to the appearance of small cracks on the surface and a change in the original color.

- Porcelain practically does not retain dirt, however, the cost of porcelain models is much higher. In addition, porcelain does not withstand shock and mechanical damage.

- Acrylic products can be cared for using cleaning products without abrasive particles.

Important! You can also opt for more fashionable and exotic models made of glass and stone.

Anti-splash system

Good toilets with anti-splash.

This system is designed to eliminate splashes from the toilet. The operating principle of this system lies in the special geometry of the drain hole. Often the drain is shifted to one side so that the water column is minimal and splashes are eliminated.

Toilet lid

Models with built-in microlift have appeared on the modern market. This model of lid will not wake up household members with its rattling lowering onto the latrine.

Manufacturer

Pay attention to the models of traditional market “players” - European and American manufacturers. Their products are distinguished by high quality, durability, and reliability. All these characteristics are confirmed by a long-term guarantee.

Anti-splash system

Some models of modern toilets are equipped with a system that compensates for splashes while using the toilet. The presence of such a system can be found out from the product labeling, but it should be remembered that unscrupulous manufacturers can indicate the presence of anti-splash even in models without such a system. To understand the question of how to choose a splash-free toilet, you need to understand the principle of its operation and the main components.

You should not trust a sales consultant who describes an anti-splash system in the form of an inclined wall inside the toilet bowl, through which water flows without splashing. This description is not true and should raise doubts in the client. In this case, we can conclude: the seller does not understand such issues or is trying to pass off a simple toilet as a more expensive model.

The splash compensation system in the toilet is a drain hole that has a special geometric shape with maximum narrowing and recessing at the bottom of the toilet. The hole is located with a slight offset from the center to one side and is characterized by a reduced level of the water column. To additionally compensate for splashes, a circular rim is located along the contour of the drain hole. When comparing a conventional toilet and a product with an anti-splash system, you can see that the second option has a narrower opening and a fairly low water level.

Connection to sewerage

The connection option is determined by the type of release.

Connecting a toilet with an oblique or horizontal flush

An oblique or straight outlet is located at the back of the product. To connect, you need the following tools:

- A sealing collar designed to connect the toilet to the sewer, or corrugation. If the outlet is at the same level directly with the sewer inlet and does not move in any direction, then a rubber cuff will be enough to connect the outlet and the sewer pipe. If the toilet deviates even at a minimum distance from the entrance to the sewer, then the connection is made only through a corrugation;

- You also need a corrugated hose designed to connect the toilet to the sewer system.

- Sealant.

In order to connect plumbing equipment, you must do the following:

- Place the toilet in the designated place and check that the outlet coincides with the sewer outlet. Based on the test performed, it is necessary to select a device that allows for a successful connection. In order to prevent mistakes in further work on connecting the toilet to the sewer, the area for installing plumbing equipment is marked on the floor;

- The cuff or corrugation is treated with a special sealant;

- The toilet is connected to the sewer outlet;

- The toilet is sent to its place. Straight or oblique release is connected to the fixation element. In other words, the corrugation is connected to the outlet;

- The device is secured. The corrugation is installed in the hole of the drainage system.

- The tightness of the connections is carefully checked.

The corrugation used for connection can be replaced with ordinary plastic pipes, which are intended for sewerage. Selection of pipe sizes and bends is carried out on an individual basis.

Connecting a toilet with a vertical outlet to the sewerage system

To connect a toilet with a floor outlet to the sewerage system, you will need:

- Special flange for connection, complemented by a clamp;

- An element used to install a device with a vertical outlet;

- Sealing agent.

The connection of equipment and sewerage is carried out in the following way:

- A place to place the toilet is selected. The main rule is the absolute coincidence of the toilet outlet pipe with the entrance to the sewer. After establishing the installation location, it makes sense to mark the area where the plumbing fixtures will be fixed in order to prevent deviations;

- The bolts intended to secure the toilet are placed on top of the flange;

- The flange is mounted in the sewer outlet. For reliability, the junction of the flange and the sewer pipe is resealed;

- The toilet is attached to the connecting element on top. The outlet fits as accurately as possible with the flange connector. To seal this connection, it is possible to use a rubber gasket. An alternative option is sealant;

- The toilet outlet is secured with a special element mounted on the flange;

- The toilet is fixed to the floor and the tightness of the connections obtained is checked.

There are installers who prefer to use a regular rubber seal instead of a flange. Professionals do not recommend fixing a toilet with a floor outlet in this way, because fixing the rubber gasket does not make it possible to achieve the proper level of fixation of the equipment.

Following the rules for connecting the toilet outlet to the sewer pipe, installing sanitary equipment will not be difficult without involving professionals - you can easily do it yourself.

Plastic

In most cases, acrylic is used to make plastic toilets. However, some models have a multilayer structure with fiberglass reinforcement elements. The products are distinguished by their fairly light weight and affordable price; in addition, installation of such toilets is not particularly difficult.

The disadvantage of plastic toilets is their poor resistance to mechanical loads and temperature changes, which is very important to consider when deciding which toilet to choose. The service life of such plumbing fixtures is quite short, so most often they are purchased for use in a summer cottage.

Water supply

The tank is also not as simple as it seems. Modern toilet cisterns have bottom, side and rear water supplies. What is the difference and which is better?

With a bottom water supply, the hoses are connected directly to the “bottom” of the tank. This not only looks neater, but also provides a quieter water supply. The bottom supply is considered almost the standard for a good toilet.

The rear and side inlets are located at the top of the tank and differ only in ease of installation and location of the entrance, as the name suggests. The rear connection can be completely hidden in the wall; with the side connection, the trick is unlikely to be possible. And any of these types will be noisier than the lower one. It's not a big deal and the noise of the waterfall is still a long way off, but just be aware.

By the way, the same toilet models can be produced with different types of outlet, and some immediately have universal solutions.

Flush type

There are two types of flushing

- straight

- circular

Straight is sometimes called cascading or horizontal. The water simply “runs” in a straight line from the tank, and most of the bowl is not washed. The circular type solves this drawback and is found in most modern models.

General information

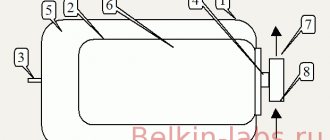

It is known that a toilet is a plumbing device that includes two components:

- - a bowl that serves to collect and dispose of the products of our vital activity;

- - a drain barrel that accumulates and stores water for flushing.

What is a toilet flush? Let's take a closer look at this. An outlet is a special drain hole that connects to a sewer pipe. Toilets come with three types of outlet: vertical, horizontal and oblique. Now we will look at each of them in more detail.

Dismantling works

Previously, in old houses, sewerage was made of cast iron pipes. If necessary, they can be replaced with plastic products. Before you get started, you need to know that modern pipes have a slightly smaller diameter than cast iron products. Therefore, you will need a special rubber cuff for connection. Before installing it, you need to thoroughly clean the sewer pipe from rust and other contaminants.

Dismantling begins with removing the mortar at the junction of the socket and pipe. To complete the work you will need a screwdriver (chisel) and a hammer. The screwdriver is placed on the cement and he begins to tap it with a hammer. When all the cement has been removed, place a stick in the pipe and begin to move it up and down. This will allow you to loosen the connection and remove the pipe from the socket.

After this, the bell is cleaned of rust and plaque. To do this, use an electric drill with a special attachment. Large pieces can be removed with a chisel or screwdriver. After this, the walls of the socket are treated with a special substance that corrodes contaminants. This will make cleaning the pipe much easier. At the final stage, the bell is wiped with a clean cloth.

Partial replacement of sewer pipes makes it easier to install plumbing fixtures, as well as extend the life of the system. Preparatory work also includes cleaning the site from various debris and contaminants that remain at the installation site of the old device. The area must be thoroughly cleaned, especially when it comes to devices with a vertical outlet.

When drilling holes for mounting dowels, it is worth taking into account the installation features of the plumbing fixture. This especially applies to the requirements for the place of their installation. The design project is also taken into account here. If necessary, the device can be moved to the side. This is possible thanks to the use of corrugated pipes.

Step-by-step installation instructions

The advantages of models with vertical flush include ease of installation. Even a non-specialist can handle the installation.

It is important to adhere to the established work order and perform all operations as carefully as possible. Negligence is unacceptable, because later, leaks and an unpleasant smell in the bathroom may appear.

Stage 1: dismantling the old structure

First, turn off the water supply, after which the remaining liquid is drained from the tank and the supply hose is disconnected. Now you can dismantle the old toilet.

If it is fixed to cement mortar, it is unlikely to be removed without damage. However, it is important to maintain the integrity of the pipe, so the solution is knocked down carefully, without touching the elements of the sewer system.

It's a dirty job. It is best to perform it with gloves and overalls. During the dismantling process, it is important to promptly remove water and clean off contaminants, so that later it will be easier to prepare surfaces for installing a new structure

You need to remove water from the bowl. To do this, the toilet is tilted slightly, then loosened and raised. Sometimes you can’t get by with a little bloodshed. Then, in order to quickly separate the product from the sewer pipe, you need to hit the drain neck with force. It will crack, and the remaining parts of the structure will become loose from vibration. They will be easier to remove.

The following article will introduce you to the details of dismantling old plumbing, which we highly recommend reading.

Stage 2: marking and preparation

It is better to install a new toilet in place of the old one, because... moving communications and replacing pipes in a toilet is not an easy and time-consuming job. To complete it, you need skills and experience. Before installing the product, the surfaces should be thoroughly cleaned and leveled.

The installation site is measured and the location of the plumbing and sewer pipes is outlined. According to the finished marking, a screw flange with a lock is inserted.

Installation of models with vertical flush is considered the easiest due to the presence of a screw flange with a lock. Its counterpart is located at the bottom of the toilet. Simply connect the elements

A standard screw flange has a round hole into which the end of the sewer pipe is secured. After fixing it, all that remains is to make sure that everything is done correctly and that the surfaces are clean and prepared for installation of the plumbing fixture.

Stage 3: toilet installation

If everything is perfectly prepared, the vertical flush device is installed with a “light movement of the hand.” The product is simply placed on the flange so that the mating part is located strictly above the opening of the sewer pipe. Then the toilet is turned slightly so that the latch works.

This is a simple operation that does not require any special effort. Once the flange automatically attaches the toilet to the pipe, the installation can be considered complete

At the moment of rotation, the flange presses the outlet pipe of the device against the sealing ring. The connection is completely sealed. If everything is done carefully, leaks are excluded, because The seal reliably compresses the toilet outlet, eliminating possible gaps.

Stage 4: connecting to the water supply

All that remains is to assemble the tank, install the drainage fittings into it and finish connecting it. This is done using the so-called. water outlets, which are provided in all bathrooms. Taps are put on them and sealed with fum tape.

Elements designed to collect water and drain it from the tank are called fittings. Sometimes when installing a toilet, it has to be adjusted so that water is normally drawn into the container and does not drain into the bowl spontaneously

One end of the supply hose is connected to the outlet of the faucet, and the other to the outlet of the drain tank. All joints are carefully sealed. When the work is finished, all that remains is to check the functionality of the toilet.

The easiest way to install a compact toilet cistern. The elements are initially designed to be installed together, so there is no need to look for separate parts. The kit also includes a seal, fasteners

Open the water supply tap, wait until the tank is full, and then press the drain button. At this time, feel the joints and rub them with a dry white cloth. If there are no traces of moisture, everything is in order: the toilet is completely ready for its intended use.

How to properly care for a new device?

Plumbers recommend installing coarse filters along with the new toilet. Tap water contains solid particles and pieces of scale from metal pipes. Getting into the tank along with debris, it provokes abrasion and premature wear of parts.

If the filter is not installed, you should take care to timely clean the drain tank so that you do not have to repair or replace damaged elements ahead of time. The structure is disassembled, limescale is removed, and the parts are washed with clean water.

You can remove limescale deposits by throwing a special tablet into the storage container. It will dissolve water stone, clean and disinfect the tank, and flavor the water. Citric acid is suitable as a folk remedy.

To avoid leaks at the junction with the sewer, preventive maintenance must be carried out. A pipe cleaning chemical (“Mr. Muscle”, Tiret, “Chister” or any other) is poured into the toilet and left for the time indicated on the package. Aggressive substances corrode plaque on the walls, which prevents blockages.

It is not necessary to spend large sums on store-bought household chemicals. Baking soda and vinegar can give the same result: flush pipes, disinfect, eliminate odors

You need to clean the toilet at least a couple of times a year. It is important to choose the right cleaning products, taking into account the characteristics of the materials from which the pipes and the device itself are made.

Let's consider three more important parameters that will protect you from splashes:

Height:

This photo shows that the height of the fall is as small as possible - waste products do not have time to accelerate to a critical speed under the influence of gravitational forces. The Anti-splash system completely eliminates the possibility of splashes.

Trajectory of falling excrement:

Before purchasing the toilet you like, you must carry out measurement manipulations and find out the optimal distance to the “Black Hole”. This picture shows that the smaller it is, the less opportunity there is for splashing. Take the tape measure with you to the store.

Anti-splash system:

You can take a pack of cigarettes with you, not necessarily Parliament. The photo shows that the pack does not reach the water surface by about 3 centimeters. Toilet bowls with a real system have a small hole

,

no more than 10 cm

.

My experiments on measuring safe height:

- By measuring the optimal fall height in a wall-hung toilet, we found that the average number is 17 cm.

- Measuring the distances, we realized that the safe distance from the edge of the toilet ends at 14 cm, but here we should immediately notify that the parameters of the edge of the toilet vary, just like our fifth point. It is better to measure in advance the optimal and “Safe amount” and, armed with specific data, head to the store.

We’ll start with a trip to the plumbing

store “Neptune ”

and inspection of the presented range of toilets. The sellers greeted us warmly and gave their consent to photograph the presented toilets.

model "Caesar Lux" No. 1:

- No visual curvature or irregularities were detected, it looks decent.

- The fastenings of the toilet lid to the toilet are of good quality - made of metal

, the lid is made of high-quality plastic.

- The distance from the edge of the toilet when measuring is 15 cm - which will protect you from unpleasant moments. The photo shows that the bowl has an “Anti-sand” system.

- The height of the fall is 18 cm - which is not bad, plus the trajectory of the fall falls on the porcelain visor.

- The system is the same as toilet No. 2

- it is trustworthy and suitable for use in Russian conditions. The only thing is that in a couple of years it will be necessary to clean and adjust the fill valve, and maybe earlier.

PS We analyzed reviews for this model:

Yes, the toilet does not flop and has a good flushing device. But there are also disadvantages that become apparent after the purchase:

- Porcelain is fragile, the lid breaks easily, when installing you need to be extremely careful to avoid chipping.

- The installation diagram in the instructions is unclear - call a plumber

.

model "Boreal" toilet No. 2:

- A visual inspection revealed no problems - everything was smooth and white.

- The seat is made of duroplast, with metal fastenings.

- The distance from the edge was 16 centimeters. The photo shows that the toilet is equipped with an Anti-splash system.

- The measurements show that the fall height is 17 cm

on the porcelain visor.

- The “Oli” fittings - we talked about it in the first toilet. Reliable.