These products are not affected by chlorinated water, and this becomes an important factor when choosing them for work.

They are the best option for laying a city water main. After all, copper areas are not affected by corrosion and serve for a long time.

Laying a main line from such pipes is carried out using various connection options. These are: soldering and welding, as well as using fittings for copper pipes for crimping.

Pros and cons of these parts

Connecting pipelines with crimp fittings is very easy. With this method, you do not need to use high temperature or use special equipment.

This is how pipes are laid even in places of difficult access. This work requires the following tools:

- Wrench;

- Calibrator;

- Cutter.

If you compare the time and labor costs for this work, they are small. And the laid pipeline comes out sealed and lasts for a long time.

But, no matter how good such a system is, it still has drawbacks. The crimp fitting must be constantly checked and tightened. For this reason, they are not recommended to be laid under concrete.

And these parts are also designed to operate the system with low pressure. If we compare their reliability with soldering, then these fittings have less reliability.

The connection, mounted with compression fittings, becomes a structure that is used repeatedly.

It can be assembled and disassembled. But, each subsequent installation and dismantling will affect its strength.

Compression fittings

Compression fittings for steel pipes are universal connecting parts. They can be used repeatedly. They make it possible to bend the pipeline in any direction.

It is possible to join steel pipes using these parts without the use of welding or threading. The tightness of the connection is at a high level.

They are made from materials that are durable and wear-resistant. At the same time, there is a large possibility of choosing different design configurations.

Such mechanisms are equipped with one or two rings. The operating principle is based on the use of a polymer seal. Under the influence of external pressure, this material is compressed. At the same time, it tightly grips the outer part of the pipe that is inserted into it. The result is a highly tight connection.

Compression fittings for steel pipes do not need to be installed using special tools. Installing them is simple and quick.

Video

Proform – stainless steel fittings

But these mechanisms have a significant drawback. They have low resistance to mechanical influence. This design may leak due to shock and vibration.

IMPORTANT! Before using crimp (compression) fittings again without losing tightness and strength, it is recommended to change the O-ring and rubber gasket.

How a crimp fitting works and works

This device includes:

- Frame;

- Compression nut;

- Crimping ring. Often one or two rings are placed. They increase the tightness of the joint and provide resistance to high pressures. This also extends the life of the structure.

IMPORTANT! It is recommended to purchase parts in which the seal is not simple rubber, but EPD M. Such products will last longer.

To produce these elements the following is used:

- Brass;

- Copper;

- Plastic;

- Metal.

For copper pipe products, brass fittings are most often used. They are easy to process and have a low cost when compared to copper products.

And the strength of brass is equal to stainless steel, and it fits much easier. To increase the stability of brass fittings, they are plated with nickel.

When purchasing such parts, you need to take into account their weight (do not take light items). Experts also recommend purchasing them from a reputable manufacturer.

This way, finances will not be wasted, and the highway will operate smoothly and reliably.

Types of crimp fittings

Video

Copper fittings

These devices come in the following types:

- Tee. For installation of branches in one direction;

- Cross. For a branch device in two directions;

- Clutch. Used to connect pipe blanks that have the same diameters;

- Retraction. Apply to create a turn;

- Stub. Placed on the end of the cut piece.

For the joint of pipes that have the same diameters, straight parts are used, and for different diameters a transitional option is used.

By type they are divided into:

- Threaded;

- Compression;

- Capillary;

- Press fittings;

- Self-locking.

What to look for when choosing

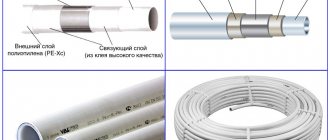

The reliability of a structure made of metal-plastic pipes depends on the quality of the purchased tools. To do this, you need to carefully select press fittings. It is recommended to pay attention to the following important details of press connections:

- Markings on the body. Companies that produce high-quality parts also use expensive molds for markings. The first signal for the buyer is the clarity of the symbols on the product packaging.

- Weight of the part. It should weigh “decently.” The brass from which the fittings are made has an impressive weight. Therefore, if it seems that the part is “like a feather”, it is not worth purchasing.

- Appearance. Only parts that are strong in themselves can create a reliable connection. Therefore, if the fitting is cast from thin aluminum, the quality of the connection will be extremely poor.

- Price. You should not purchase a product in unverified places just because it is much cheaper than others. Most likely it's a fake.

Threaded elements

They are simple and durable, their design does not require modification. The best option for these parts are brass fittings. They are characterized by increased resistance to corrosion, and are installed in those places of the pipeline where fixation to the wall is required.

IMPORTANT! It is not recommended to combine such fittings with pipelines made of plastic, metal-plastic and copper. Because during twisting, this part can easily crush the workpiece made from the specified materials.

Press fittings

Press fitting for steel pipe is a type of compression fitting. They allow you to create a completely permanent connection. This property is considered a disadvantage, because it is impossible to reuse them. In case of leakage, such fastenings must be replaced.

As for crimp structures, they do not have this drawback. The main disadvantage of crimp and press fittings is the not very high reliability of the connection. For these reasons, such parts often need to be tightened during operation.

The main area of application is construction and repair work, where it is necessary to join pipe materials with an external volume of no higher than 6 cm.

Convenient and inexpensive crimping parts have almost no disadvantages and do not create additional problems during operation.

Compression

Situations arise when it is not possible to use open fire, then compression fittings are installed on copper pipelines. They allow you to easily work with workpieces of unequal diameters, and the material may be different.

They come from:

- brass;

- copper;

- metal-plastic;

- plastic;

- become.

They have a crimp ring; it secures the part to the pipe and creates a fairly airtight joint. This ring is tightened manually using a wrench and a connection nut.

IMPORTANT! It is very convenient to work with these elements in areas with difficult access.

Capillary connection elements

They are more suitable than others for pipe products made of copper and steel. On the inside, under the cut thread, they have a very thin wire made of copper, tin, or silver. This wire becomes the solder.

Video

Pressing copper pipes. Water, gas.

The workpiece, which is coated with flux, is inserted into the fitting. The joint is heated with a burner. Heating is carried out until the molten solder fills the space.

After this, the joint is left to cool. After some time, the joint area is cleaned with special cleaning agents for working with copper.

The described connection is considered the most reliable, and for copper products it is better suited than others.

Self-locking connectors

Video

Copper pipe rolling

Self-locking elements are mechanical type devices. It is based on inner rings, and one of these rings has teeth. When pressed with a puller key, they fit tightly into the other ring.

This type of joint is reliable and durable. This part can be used more than once, because with the help of a puller key, it is very easily removed.

This type of fitting is made from copper, and it perfectly holds workpieces of any type of cross-section and different materials together. This is a very convenient way for a pipeline made of various pipe products and fittings.

Welded parts

Fittings for rolled steel pipes for welding are called the most durable among similar parts.

The parts to be welded have a smooth end. Welded fasteners are a non-dismountable system, which means that they are not subject to subsequent disassembly and reuse. The seams that are produced by welding are not very noticeable on the pipe.

The system for selecting such parts is based not only on the similarity of the volume of the fastening element and the pipe itself, but also on the similarity of properties. A mandatory criterion for selection should be the indicators of medium pressure tolerance, which are provided for by GOST, and the fittings must meet this requirement.

Welding options are used in systems; they are placed inside the structure. Replacement of such parts is not provided for a very long period.

How to install crimp fittings on a copper pipe

Video

Radial presses for crimping fittings

It should be noted right away that this type of connection does not require special equipment, and you can make it yourself.

According to European standards, crimp connectors are divided into two types and are marked with the letter A or B.

Type A. Used exclusively for laying above-ground pipeline networks made from semi-solid copper or stainless steel.

Type B. It is used for above-ground and underground communication systems, created from soft and semi-hard types of copper with thick-walled pipes.

IMPORTANT! To get a very reliable joint, you must act strictly according to certain rules and instructions.

How to install fittings for type A crimp:

Video

Pressing copper pipes is quick and easy! (4)

- An element of the required size is selected. This is easy to do because all connecting structures are produced according to the same European standard;

- A pipe blank of the required size is cut and the burrs are removed. The sections are checked with a gauge. Contamination is removed from the workpiece, poorly processed edges and damage are cleaned. A crimp ring is placed on the workpiece.

ADVICE. It is recommended to wet the joint with water, this will prevent the seal from slipping and breaking;

- The end of the pipe is inserted into the connector until it stops. After this, the clamping nut is tightened. First they twist it by hand, and then take a wrench.

ADVICE. There is no need to apply excessive force during these actions. This will not improve the tightness of the connection. If cheap parts are used for work, then there is a risk of extruding the ring, and then the joint will not be reliable.

After such work, the pipe may be slightly deformed. This will confirm that the connection is made airtight.

How to install type B compression fittings

Video

Copper pipes (installation, soldering)

This type of crimp connection elements is mounted in almost the same way as in the first case. The cutting area is thoroughly cleaned of dirt. The thread should also be free of dirt. Only light lubrication of the threads with machine oil is allowed.

This will make it easier to wrap the pipe. It is necessary to ensure that the seal cone is pressed against the inside of the workpiece, and the edge of the workpiece itself must be flared.

You need to choose the right key. It should not become loose; this will damage the nut. For example, for a diameter of 54 mm, you will need a 750 mm wrench.

Features of connecting these fittings to pipes

Video

The cost of a line made of copper pipes is high, so when purchasing materials it is advised to follow the following rules:

- It is necessary to give preference to homogeneous materials, so the entire structure will last longer;

- Do not combine copper and unalloyed steel. Electrochemical processes between them have a detrimental effect on the connection. In this case, the steel elements become covered with rust;

- If it is impossible to do without using dissimilar materials, then steel products are mounted in front of copper ones in the direction of fluid movement;

- Copper pipes go well with their PVC network elements. There are no negative consequences in this situation.

Cast iron fittings

Cast iron fittings for steel pipes are a type of connecting fittings that are used when laying pipelines of different diameters. Malleable cast iron used in production is an unconditional guarantee of practicality and an optimal balance between acceptable cost and quality. Cast iron products are equipped with internal and external threads, for these reasons they can be used in any installation conditions.

Video

Tee 1 1/2″ black EE - buy pipe fittings, cast iron plumbing tee

An undeniable advantage in this situation is that these parts are easy to install and remove. All this work can be easily done with your own hands.

Another advantage of these products is their long service life. Using them you can be sure that they will withstand temperatures up to 175 degrees and pressure of 16 MPa.

All cast iron products are manufactured in accordance with GOST standards.

Extensive selection options, affordable prices and fast delivery make purchasing convenient and simple.

Galvanized connecting elements

Galvanized fittings for steel pipe products are joining elements for individual pipe products. They are the most popular. The thing is that galvanizing significantly increases the anti-corrosion capabilities of the mechanism, as a result it can last more than 50 years.

And this article describes in detail the process of welding galvanized pipelines.

Video

Manufacturer of pipes and fittings KAN-therm

Galvanized reinforcement options are used for various types of joints, so they are divided into:

- square;

- coupling;

- adapter;

- cross.

Like other analogues, galvanized products are connected using several methods. However, working with these parts has some peculiarities. For example, welding can damage galvanizing.

Of all the methods, the most preferred is the threaded connection. Galvanized threaded products make it possible to make a tight and reliable joint. If necessary, these parts can be reused.

Dimensions

The dimensions of the connecting elements for steel pipes play an important role. After all, they are used for highways with a large number of branches and for laying a straight pipeline.

With the correct selection of the dimensions of the connecting parts, you can reliably fasten pipelines and heating devices with different threads and made of different materials.

Video

Press or compression fitting

The diameters of the produced fittings correspond to the diameter of the produced pipes, so their selection is not difficult. To make the right choice, you need to know exactly the dimensions of the pipe materials used for the job. The dimensions of the fastening fittings range from 16 to 110 mm.

Options with a small diameter (up to 63 mm) are used for networks supplying water, supplying heat with a pressure of up to 16 atmospheres. And large-volume elements can be placed in a system operating at a pressure of almost 10 atmospheres.