Laying pipes in a trench

External pipeline water supply systems can be installed from almost all types of existing pipes. Naturally, their installation is carried out taking into account the specifics of the material from which they are made, since each type of pipe has its own connection methods and its own fittings.

However, when putting water supply pipelines into operation, the systems must meet uniform requirements. What are they, what are the features of pipeline construction, how are they tested and quality controlled? You will find the answer to many pressing questions related to the installation of external water supply networks in our article.

Requirements for the arrangement of an external water supply network

The internal plumbing system is connected to the external network. Pumps and pipelines are used to transport fluid to the site. Installation work is carried out in compliance with certain parameters. In this case, the soil freezing depth is maintained at 0.5 m.

During the installation of an external water supply system, the following requirements are met:

- preparation of the project and availability of permits to carry out these works;

- availability of appropriate permits from technical supervision;

- control over the implementation of hidden work;

- use of high-quality consumables.

In the process of arranging an external water supply system, it is necessary to carry out proper installation of the network. Damage to other communications that run in this area must not be allowed. Installation work is carried out taking into account SNiP and SES requirements.

General characteristics of plastic pipes made of different polymers

Installation of polypropylene pipes.

- No corrosion.

- Resistance to chemical compounds.

- No formations on the walls.

- Durability (50 years).

- Non-toxic.

- Strength combined with elasticity.

- Resistant to pressure changes.

- Low thermal conductivity.

- Easy to install.

Plastic pipes also have disadvantages:

- All polymers are highly flammable.

- They wear out quickly when exposed to UV rays.

- When heated, elasticity and strength decrease.

- They have high linear expansion during temperature fluctuations.

Types of external water supply

Experts distinguish the following types of external water supply networks:

- Centralized - provides water to a populated area.

- Local - provides water supply to the building if there is no central system.

To equip a central water supply network, you will need:

- water intake - open reservoir;

- complex for liquid purification for subsequent delivery of drinking water to the consumer;

- a pump with the help of which liquid under pressure passes through a pipeline to the final consumer;

- shut-off valves.

We insulate the water supply system

Basic requirements for insulating materials: fire resistance and low thermal conductivity. Gone are the days when pipes were insulated using only one technology – glass wool. Today, the industrial market offers materials that differ in method of application, structure and composition: basalt (expensive), foam plastic, polyethylene (polyethylene foam).

Plastic plumbing systems with insulation must be insulated from moisture. The insulating layer must not be allowed to become wet and compressed by soil, as this will reduce the entire insulating effect to zero. A common and reliable insulation material is foam shells in a shell. Polystyrene foam has a high energy saving coefficient, but moisture easily penetrates into it. To prevent the insulation from getting wet, the foam is placed in a waterproofing shell.

Scheme of insulating a pipe with a heating cable.

The greatest care should be taken to insulate water pipes at the entrance to the building. The distance of the pipeline from the exit from the ground to the entry into the house is subject to the greatest cooling. To avoid freezing in this section, a heating cable is used. The heating wire is wrapped around the pipe in increments of 10 cm (can be increased). To reduce energy costs, a special sensor is installed that monitors the temperature of the pipe - at a critical temperature, the electricity is automatically turned on. The temperature control system is placed as far away from the heating element as possible. The heating cable can be run along (or around) the entire pipeline - this is a 100% guarantee of uninterrupted water supply in winter. Installation of insulation is carried out after installing the self-regulating cable on the pipes.

Hydraulic testing of water pressure system

Testing of pressure water supply systems is carried out to identify poor-quality seams and joints. Hydraulic testing, according to the requirements of SNiP, is carried out as follows:

- the water supply system is filled with water without pressure for 2 hours;

- create water pressure in the water supply and maintain it for 30 minutes;

- inspect the pipeline.

Before use, the water supply system is flushed with drinking water. Flushing is carried out until the water from the pipeline meets all regulatory requirements (free from impurities and odor).

Types of local water supply networks

Taking into account the type of system being installed and the method of its installation, delivery of drinking water in different containers is allowed. This water supply option is considered temporary, until the permanent water supply network is completed.

Since water lies at different depths, preparatory work will be required to “extract” it. To bring it to the surface and use it for personal purposes, experts recommend building a well or well.

If a well is used as a permanent water supply, you will need to dig, removing liquid from the surface layers of the soil. Such waters are distributed unevenly. They can flow along the contour of the earth's surface or lie at different depths.

The water supply method under consideration is inexpensive to install and operate. Its disadvantages include seasonal filling of the well, if during the digging process you get to the lower or upper section of the groundwater flow. On a flat area, the well will fill regardless of the season and weather conditions.

To simplify the process of operating the well, a submersible or surface electric pump is used. He lifts and delivers water to the house. In this case, you can collect water with a bucket.

To construct such a system, different pipes are used. The well itself is constructed as a monolithic structure equipped with a lid. You can make it from a log or special rings.

It is possible to equip an external water supply network by drilling wells of various capacities:

- at the dacha, the approximate liquid consumption is 2 cubic meters per hour;

- in a house with permanent residence, the approximate consumption is 3 cubic meters per hour.

Before drilling begins, you will need to obtain permission for the work being carried out. Groundwater is a strategic reserve of the country, which is protected by the legislation of the country. The received passport for the well contains technical information, including the diameter of the well. Upon completion of installation work, the water is sent to the laboratory for testing.

Initial stage of work

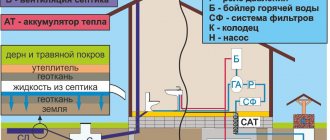

An example of a water supply project for a private house

Before laying a water or sewer pipe underground, you will need to make a project. It must be as accurate as possible, otherwise the pipeline system will not be functional.

The design documentation must include the following information:

- features of the old highway if communications are being replaced;

- soil quality – light, clayey, rocky;

- area of the site where the pipeline will be, taking into account branches and inlets;

- estimate of construction and repair work.

The laying of external water supply is carried out only on a leveled area. Otherwise, problems with water supply may arise due to pipe deformation.

Consumables used

Cast iron, steel and other pipes are used for mains. For local networks - ceramic and plastic products.

More often, the external water supply system is equipped with plastic pipes, which have the following advantages:

- no corrosion;

- high resistance to aggressive environments;

- strength and ability to withstand high soil loads;

- rapid passage of water;

- low weight of pipes;

- easy pipeline installation;

- a wide range of.

If the external water supply network is installed using PVC, then a special tool is used to connect such pipes. Such connections are mounted in a socket or using specialized “cold welding” glue.

PVC products are rigid; to make bends and turns, tees and bends are used. PVC pipes withstand loads well during installation in the soil. Moreover, their price is acceptable for consumers.

If the external pipeline network is equipped with polypropylene consumables, then single- and multi-layer pipes with an aluminum layer are used. To connect polymer pipes, a fitting or welding machine is used. In the latter case, it is necessary to have proper experience working with the equipment. If it is not available, the help of a welder will be required. When performing welding work, it is imperative to take precautions by using a protective mask. It is better to carry out welding work in a “clean area”, without unauthorized persons.

If the system is constructed from low- and high-pressure polyethylene pipes, then a fitting and a welding machine are used to connect them. The consumable material can be used at low temperatures.

The system can be constructed from elastic polyethylene pipes, which are installed in coils. With their help, network rotations are easily performed. To carry out intersections of water supply networks, an angle of 90 degrees is maintained. If cast iron pipes are used, it is recommended to use a steel casing. The local sewer system is installed above the water supply unless a casing is used.

If the networks are laid parallel and at the same level, then the distance between the walls of the installed pipes must exceed 1.5 m. In this case, the diameter of the pipeline must be 200 mm. If the value of the indicator is above 200 mm, then the pipeline is installed at a distance above 3 m. The installation of a water supply system passing below the drainage point is carried out taking into account some deviations. It depends on the type of consumables used and the area.

Suitable pipes for installation in the ground

Marking pipes for drinking water

Traditionally, welded or seamless steel products are used for these purposes, preferably galvanized to protect against rust. However, now they have been replaced by polypropylene and plastic options, for example, HDPE PN10. They have many advantages:

- resistance to corrosion and temperature changes;

- increased working pressure - up to ten atmospheres;

- ease of installation - polyethylene pipes are easy to bend.

An important plus is the budget price. This factor makes the cost of laying a water supply system from propylene pipes in the ground per linear meter lower compared to steel ones.

The diameter of the pipe for laying in the ground according to GOST should not be less than 3.2 cm. The length of the standard product is 240 cm.

Preparation for installation of a water supply network

Installation of an external water supply network is carried out according to a specific scheme. A draft of the future network is being drawn up in advance. The soil type and groundwater level are established. To find out the level of soil freezing, the help of a specialist is required. Then the water consumption and drainage per day is calculated. The value of this indicator will help determine the diameter of the pipes. Taking into account the data obtained, the necessary equipment is selected.

If necessary, the external system is insulated. If the highway must pass through a certain area that is not being dug up, a puncture is made in the soil. To perform it, different tools are used (drill, crowbar, shovel). If you need to make a puncture under the road, special equipment is used.

If the water supply intersects with the sewer, then metal sleeves are installed at the intersection point. Their length in sandy soil is 10 m, and in clayey terrain - 5 m. When crossing, the water supply network is mounted 40 cm above the sewer, and when installed in parallel, a distance of 1.5 m is maintained. The water supply is introduced into a residential building at a distance of 1. 5 m from sewerage and gas pipelines.

To install an external water supply system, you can dig a trench from the water source to the point of entry into the building. Land work is carried out taking into account a previously prepared project. In this case, a certain trench depth is maintained. The value of this indicator should be within 1.5-2.5 m. The trench is dug below the freezing level by 50 cm. A sand and gravel cushion is poured onto its flat bottom. After compacting it, pits are dug (in places where pipes are connected). It is recommended to carry out the above work using plastic pipes. Their diameter is calculated taking into account the length of the water pipe and the volume of liquid consumed. Experts recommend taking extra.

If the length is 10 m, then installation work is performed from 25 mm pipes. If the length is 30 m, then installation is carried out using pipes with a diameter of 32 mm. If the length exceeds 30 m, then pipes with a diameter of 38 mm are used. If necessary, the type of diameter is selected with the help of professionals. Consumables are purchased in reserve, since a certain length is used for connections.

Possible errors and difficulties

Map of soil freezing depth

The main points that can cause problems, experts include:

- incorrectly selected pipes;

- lack of sand and gravel cushion under the highway;

- neglect to assess the composition of the soil and the temperature characteristics of the climate;

- weak screwing of crimp nuts and fittings.

Do not leave the ends of the pipes open, otherwise debris and sand will get into them.

Even in the southern regions, pipes must be buried no less than one and a half meters and insulating material must be used. Otherwise, even a short-term decrease in temperature will lead to their deformation. If frost hits, the water in them will simply freeze.

When connecting the water supply to the house, do not rush to fill the trench. First, you need to do a test run to identify possible problems and correct errors in a timely manner. Immediately before backfilling, thoroughly inspect all connections again to make sure that the system is functioning correctly.

Advantages of polypropylene

Polypropylene is a plastic polymer that is resistant to different temperatures and can withstand mechanical stress. These and other characteristics set it apart from other materials for plumbing. Among the advantages of polypropylene pipes:

- a light weight,

- no rust,

- tightness,

- ease of installation,

- service life up to 50 years.

You can always find the necessary components for pipes. Their installation and replacement take less time than, for example, in the case of steel pipes.

Attention! It is recommended to use elements of polypropylene communications from the same manufacturer. This will ensure the strength of the connections and stability of operation.

It is important to know in advance the pressure and temperature of the water that will be released through the water supply. This will help you select suitable pipes based on their markings. In general, you need to be well prepared for the installation of polypropylene water supply. After all, the quality of his work will depend on this.