Laying water pressure systems and sewer routes is associated with difficulties in choosing a specific material. Steel products are noticeably inferior to analogues in strength, mainly due to instability to corrosion. The best replacement for steel structures when laying steel lines is ductile iron pipes. Thanks to various internal and external coatings, the scope of application of highways expands to the chemical and petroleum industries.

Ductile iron pipes with nodular graphite

What does the abbreviation VChShG mean? What is the meaning of the term?

Ductile iron is a high-strength cast iron with nodular graphite. The basis for the structure is cast iron, obtained by soldering crystalline iron lattices, thereby increasing the strength of the structure, as well as reducing the risk of possible deformation to a minimum.

In this situation there is a reverse outcome. By subsequent processing of the alloy, a few days after manufacture, it is possible to obtain high-quality steel with less carbon in the composition. This result is achieved using special melting apparatuses with portioned air access.

At the moment of melting, the structure is saturated with oxygen, and molecular chemical compounds are formed that attract carbon. This industrial method produces 2 types of pipes: low-molecular steel and high-strength cast iron.

The resulting steel alloy has several positive qualities:

- Greater resistance to shock loads due to the uniform distribution of electron clouds in carbon atoms.

- Excellent flexibility and toughness, giving additional strength to the material.

But steel has a significant drawback in the form of corrosion. Hydrophilicity does not allow the pipelines to be used in sewers or large-scale heating systems, which significantly reduces the scope of application in the domestic sphere. In this situation, there is a solution in the form of strengthening the protective layer with special elemental coatings that are not affected by oxygen or hydrogen. But these operations require a large amount of raw materials and costs, so they prefer to refuse low-molecular steel pipes when constructing sewers or heating systems.

Initially, this particular steel was used in ductile iron designs, until in 1943, during a meeting of the American Industrial Steel Association, scientist K. Millis patented a new design plan, using a spherical graphite shape, as well as cast iron products instead of steel. To make the plan work, manufacturers began adding magnesium ions to the melt to increase the strength of the lines.

Thus, the term ductile iron appeared - high-strength cast iron with nodular graphite, which is highly resistant to corrosion.

You can find your way around the prices for such products by following the link: chugun-truba.ru

VChShG: what is it and what are its advantages

The patent for ductile iron was issued to the American K.D. Millis in 1949. The spherical shape of graphite in molten cast iron made it possible to significantly change its properties. The new material turned out to be extremely beneficial due to the combination of a number of parameters:

- physical and mechanical;

- operational;

- economic.

Ductile iron has successfully replaced gray cast iron due to its greater strength and ductility. Unlike steel, the new material practically did not crack and was slightly susceptible to corrosion. Its use instead of steel and non-ferrous metals made it possible to significantly save on the cost of materials. Ductile iron turned out to be inexpensive to manufacture. Other advantages explaining the distribution of the material:

- resistant to cyclic loads;

- high plasticity;

- lends itself well to cutting.

The use of durable cast iron pipes instead of steel allows for significant cost savings

Good to know! The Soviet GOST for high-strength cast iron 7293-85 is still in force today. It extends, in addition to ductile iron, also to ductile iron, where graphite is presented in vermicular form.

Scope of application of ductile iron and characteristics of cast iron construction

Installation of a pipeline from ductile iron High-strength

cast iron with nodular graphite allows you to obtain high-quality products without huge financial investments, constant updates to the design and industrialization of the industry by modernizing technological equipment.

The ductile iron alloy has the following advantages in comparison with steel or iron lines:

- Excellent casting properties: low volumetric shrinkage is less than that of steel, but the fluidity is much higher, which suggests excellent permeability of the internal diameter of cast iron products.

- Excellent strength due to the close covalent polar bond between iron, carbon and oxygen atoms.

- Plasticity and viscosity: these properties are obtained by melting the material during prolonged treatment with high-voltage electric current.

- Resistance to overvoltage, disturbances of electric and magnetic fields, due to the low conductivity and high grounding of the alloy.

- Relative environmental safety and harmlessness to the environment: this property is achieved by melting, when part of the carbon is mixed with oxygen into carbon dioxide.

The use of the material is quite narrowly focused. The structures cannot be used in the domestic sphere due to their massiveness and difficulty of operation, therefore their purpose is determined by industrial and transportation needs. The first thing you should pay attention to is versatility.

The designs can easily replace expensive analogues without loss of quality:

- If there is a need to replace gray cast iron due to its unsuitability, there is a sharp need to improve the strength and durability of structures. This type of alloy is widely used in mechanical engineering for casting machine tools, mechanisms, pistons and other parts of machine structures.

- Replacing steel pipes when supplying natural gas or oil over long distances with the expectation of uninterrupted delivery with minimal delays and maintenance time for pipelines provides the main advantage of cast iron in this situation - low production costs, the shortest production time, lower consumption of industrial raw materials.

- When combined with various non-ferrous metals, it can be used in many areas of production, mainly energy. In this case, the costs of producing the alloy are reduced.

The use of high-strength nodular cast iron is observed in the following infrastructure elements:

- Support for massive heating networks where the air temperature does not fall below 150 degrees Celsius.

- Construction of pipeline communications for the transport of products from the chemical and oil refining industries.

- Creation of a stable protective layer for free-flow and pressure sewer systems.

- Arrangement of fire pipelines.

The average technical characteristics of ductile iron pipes are presented in the following table:

| Dimensions(mm) | Pipe weight(kg) | ||

| Walls | CPP | L=5.9 | L=6.2 |

| 7 | 4 | 92 | 95 |

| 8 | 5 | 138 | 141 |

Loading norm for cast iron pipes

There are 2 ways of transporting ductile iron mains: road transport, represented by huge long-range trucks, and railway transport, through which large industrial trains with spacious wagons transport products. The difference in trade communication systems is the quantity of material that can be supplied and the transit time. Transport routes also play an important factor, since not all places have a railway or an established road route.

Indicators for loading standards in 2 transport directions are presented in the following tables:

| Loading standards for road transport | |||

| Pipe diameter(mm) | Number of pipes per package (pcs) | Production rate(pcs) | Structure weight(kg) |

| 83 | 17 | 227 | 98 |

| 103 | 11 | 188 | 114 |

| 127 | 7 | 144 | 166 |

| Standards for loading into railway cars | |||

| Pipe diameter(mm) | Number of pipes in a package (pcs) | Car capacity (m³) | Structure weight(kg) |

| 86 | 16 | 530 | 99 |

| 104 | 12 | 497 | 108 |

| 133 | 6 | 388 | 129 |

Prices for cast iron pipes VChShG connection "VRS" (RJ)

| Name | Price with cpp | Price with cpp + zinc | weight | Cuff, price |

| Cast iron pipe ChShG 100 L=6 m | 6 265,00 | 6 870,00 | 114 kg | 185,00 |

| Cast iron pipe ChShG 150 L=6 m | 9 370,00 | 10 285,00 | 172 kg | 215,00 |

| Cast iron pipe ChShG 200 L=6 m | 12 695,00 | 13 790,00 | 234 kg | 255,00 |

| Cast iron pipe ChShG 250 L=6 m | 16 990,00 | 17 955,00 | 306 kg | 310,00 |

| Cast iron pipe ChShG 300 L=6 m | 21 480,00 | 22 885,00 | 385 kg | 495,00 |

| Cast iron pipe ChShG 400 L=6 m | 35 285,00 | 36 215,00 | 566 kg | 755,00 |

| Cast iron pipe ChShG 500 L=6 m | 48 450,00 | 49 685,00 | 774 kg | 1160,00 |

To the section : cast iron fittings VChShG

Cast iron pipes for sewer networks, taking into account all the standards in accordance with GOST, are made of gray cast iron, a metal that in itself is quite fragile, namely, in relation to working with it “in tension” or “in bending”.

Technical characteristics of ductile iron pipes

When carrying out calculations for high-strength cast iron pipes with nodular graphite, many different mathematical and physical quantities are used.

This is due to the fact that the alloy contains compounds and metals that conduct electric current. In addition, the difference in composition when launching a new production line forces manufacturers to carry out careful calculations, otherwise there is a risk of damage to the structure. All necessary technical characteristics of ductile iron pipes are presented in the following table:

| Dimensions, mm | Working pressure limit(MPa) | Limit angle of deflection during laying (degree) | Pipe weight(kg) | ||||||

| DN | D | DE | S | S1 | L1 | L=6 | L=6.4 | ||

| 454 | 556 | 492 | 9.3 | 6 | 128 | 4.9 | 3.3 | 667 | 688 |

| 713 | 854 | 755 | 10.6 | 7.7 | 165 | 3.1 | 1.98 | 1319 | 1366 |

Diagram of ductile iron pipes

A visual drawing of high-strength cast iron pipes with a spherical decanter.

As it becomes clear, the design consists of some external and internal elements:

- O-ring: This protective layer is needed to enhance the strength of the structure. It also serves as a fuse in case the pipe breaks or becomes deformed.

- Zinc coating: necessary to significantly reduce the effect of corrosion on the external surface of the structure.

- Cement-sand coating: serves as a kind of grounding against the influence of electricity on the surface of the pipe. In the event of an electrical accident, this protective layer will bear the brunt.

- Ductile iron: actually the main material from which the structure is made.

- The final layer: it contains the least amount of impurities and alloys, since it bears the least load.

This diagram presents physical and mathematical quantities, on the basis of which calculations are carried out and the dimensions of structures are set

. Description:

- Bell, D: physical quantity characterizing the fundamental parameter at the start of production - zero cycle. It represents the basis for the construction of pipe structures.

- Conditional flow, DN: nominal value characterizing the permeability of a transport substance through the internal channels of a pipe.

- Average diameter, DE: a conditional parameter used to calculate the space between the inner, outer and average diameters.

- Pipe wall area, S: a fundamental parameter when calculating the main parts of the pipe.

- L and L1: length of individual sections of the structure.

Production in Russia

In our country, despite the popularity of pipes made of high-strength cast iron, they are produced by only one enterprise - the Lipetsk pipe company Svobodny Sokol. The enterprise’s share in the supply of material for housing and communal services pipelines is 25% - you must agree, this is quite a lot for a single plant.

Pipe plant in Lipetsk.

What else is useful to know about LTK products?

Here is the information from the company's official website:

- The nominal diameter of the products varies from 80 to 1000 millimeters;

- The standard pipe length is 6 meters;

- All products of the Lipetsk plant are manufactured only and exclusively for socket joints with a rubber seal. In this case, the manufacturer uses three types of locks, differing in the operating pressure range:

| Compound | Working pressure, MPa | Diameter, mm |

| Tyton | 3,0 – 6,4 | 80-1000 |

| R.J. | 2,5 – 8,8 | 80-500 |

| R.J.S. | 1,6-3,2 | 600-1000 |

- Locks allow you to install pipes not only on one longitudinal axis, but also with a deviation from a straight line of 1.5 - 5 angular degrees without the use of fittings and without violating the tightness;

- Despite the corrosion resistance, the products are additionally equipped with protective coatings. It makes sense to dwell on them in a little more detail.

External covering

It consists of two layers:

- Zinc metal;

- Bituminous varnish.

The coating is interesting because it is capable of self-healing. How does this happen? The fact is that zinc forms a galvanic couple with iron and alloys based on it, including ductile iron.

If the zinc layer is damaged, the exposed cast iron acts as a cathode, and the galvanized surface of the pipeline acts as an anode. The migration of zinc ions gradually restores the protective layer.

Self-healing protective coating.

Moreover, when laid in the ground, an extremely durable and practically insoluble layer of zinc oxides, salts and hydrates is formed on the surface of the pipeline.

External coating with bitumen varnish preserves ion exchange processes with the environment; the process of slow, extremely prolonged corrosion does not lead to the destruction of walls, but to the formation of a dense layer of corrosion products that performs protective functions.

The outer shell is capable of performing its functions in an extremely aggressive environment.

Inner coating

All Svobodny Sokol products are ductile iron pipes with CPP. What is CPP? This is a cement-sand coating, again protecting the walls from the aggressive effects of the transported environment.

The manufacturer emphasizes that the coating provides passive and active protection. Passive means primitive mechanical protection against abrasive wear and direct contact with an aggressive environment.

The active one consists in the gradual saturation of the pores of the protective layer with cement hydration products, primarily calcium hydroxide. This, in turn, provokes the transformation of the iron in the surface layer into Fe2O3 oxide, which is kept from destruction by the cement-sand coating and prevents further corrosion of the walls.

CPP has a number of additional useful properties:

- despite the relative roughness, it reduces the hydraulic resistance of pipes, preventing the formation of deposits;

- is self-healing under conditions of transportation of the aquatic environment. When cracks occur and the coating is moistened, the same hydration of cement with the formation of calcium hydroxide and carbonate contributes to their gradual filling.

All the advantages of the CPP in one diagram from the manufacturer’s website.

External and internal coating of ductile iron

Since the structure is one large high-strength alloy, certain coatings are applied to protect against internal and external influences. Each has its own composition, purpose, conditions of use and service life.

External covering

To create an outer protective layer, an alkaline earth coating of zinc and bitumen varnish is applied to the outer surface of the pipe. The need for high-quality external pipe equipment manifests itself in the following areas:

- Water supply: mainly for land reclamation and subsequent fertilization.

- Pressure sewers: in conditions of constant humidity, a strong protective coating and high-quality construction are necessary so that the material from which the ductile iron is made does not corrode.

- Fire protection systems: Fluid supply paths during emergency incidents require uninterrupted supply and strong strength, hence the need for strong support.

- Heat supply and heating supply lines: cast iron alloy pipes will only be required in the presence of high temperatures of 115 degrees Celsius.

- Grounding of underground structures.

Inner coating

The inner layer of cast iron pipes is achieved by creating an active and passive barrier using a cement-sand mortar (abbreviated CSP). The reason why it is applied to the inner surface of the pipe is to reduce losses and accumulation of transported liquid and increase the strength of communications.

Application and installation method

Traditionally, cast iron pipes have been used in two areas:

- During the construction of sewer systems . The resistance of cast iron to corrosion was very useful here: the aggressiveness of domestic and industrial wastewater made it impossible to use stronger steel;

- During the construction of main water pipelines . Groundwater and dissolved oxygen in water are almost as destructive to steel as sewage.

This, however, does not prevent the cast-iron water supply system of Peterhof, restored after the Great Patriotic War, from serving for six decades.

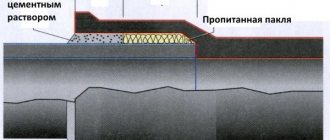

The method of installing socket connections depended on the application:

- The sewerage was embossed with cable (organic fiber impregnated with oil or bitumen) and sealed with cement-sand mortar;

- The sockets of water pipes were filled with sulfur, lead or stamped with lead tape. Sulfur was, however, also used during sewer installation, but much less frequently.

It is clear that high-strength cast iron quickly made room for its predecessor. Currently, it is used both in the public sector and in the construction of oil and gas pipelines.

The installation method is still determined by the area of application:

- Ductile iron pipes for sewerage use the same socket joints, but no longer for hammering, but equipped with rubber seals;

Please note: for diameters up to 250 mm, clamps and levers are used for joining. For large sizes, loading equipment is used for installation.

Large diameter pipelines are installed using special equipment.

- VChShG pipe for water supply and heating mains can be connected with both sockets and flanges. Paronite and, somewhat less frequently, silicone are used as gasket materials;

- High-pressure oil and gas pipelines are installed using welded joints; fortunately, high-strength (as well as gray) cast iron is perfectly welded with special electrodes.

“Tyton”, “RJ”, “RJS” - main connections from ductile iron

When assembling ductile iron pipes, many production methods and technologies can be used to improve the quality of the products. Mobility in a variety of manufacturing schemes is due to the varied composition of the internal and external coatings, which can be constantly changed, adapting to the direction of operation.

"Tython"

Ductile iron pipes “Tayton” connections

This method of assembling high-strength cast iron pipes with spheroidal graphite is the simplest in comparison with others, and, moreover, it is quite effective and efficient. Gained popularity for its resistance to internal pressure. One clearly assembled structure can withstand constant pressure up to 8 mPa/s.

Features of the assembly of ductile iron of the “Tyton” type are the use of several layers of flexible rubber rings that can withstand large internal loads without causing deformation in the structure. Together, they form a durable protective layer at the end of the pipe.

The Tyton assembly system has a number of advantages:

- Greater strength and protection against deformation and corrosion, obtained by layering plastic rubber rings on the structure. Impact resistance is also affected by the material from which the pipes are made - an alloy of cast iron with carbon compounds when polished with nodular graphite.

- Automated and high-speed installation: ease of assembly of the connection and a certain composition help to correctly and quickly process the structure using industrial equipment.

- Cost-effective and energy efficient: due to the ease of assembly and the low cost of the necessary raw materials, a large volume of products is obtained without the need for high costs and production costs.

In view of the above properties, “Tyton” is used in such areas as:

- Heat supply and heating systems.

- Pipelines for mass soil moistening.

- In pressure and non-pressure sewers.

- Fire extinguishing systems.

The assembly of structures occurs in the following stages:

- The smooth end of the pipe is cleaned of dirt and unnecessary parts.

- A special two-line mark is installed on the smooth end of the structure.

- The designated point is lubricated with a certain material, selected individually.

- The bell is cleaned.

- The phased installation and layering of rubber O-rings begins.

- Upon completion, the additional layer is treated with industrial lubricant.

- Several pipes are successfully joined.

"RJ"

“RJ” connection

This connection system for ductile iron pipes ensures the durability of pipelines when laid in extreme terrain conditions. They mean areas of possible soil subsidence, risks of a sharp increase in partial and uninterrupted pressure. The strength of the connection is due to the careful detailing of the joint. The separation of the pipes is prevented by a collar located on the smooth end of the stopper.

The “RJ” connection makes it possible to lay highways using the trenchless method. This possibility is achieved by layering sealing rings and stoppers at the joints of the structure.

Among the advantages of the RJ pipe connection system are:

- The resulting lines can be easily used in difficult conditions without the risk of constant breakdowns and the need for regular maintenance and technical inspection.

- Transport routes can run through any terrain, both open in the form of plains and plateaus, and mountainous and serpentine.

- The scope of application is limited to the narrow focus of the operation of the materials from which the structure is made:

- Delivering water, oil and natural gas across wetlands, mountains and permafrost.

- Construction of huge city-wide sewers.

The assembly of ductile iron pipes using the “RJ” system occurs in the following stages:

- At the same time, the smooth end of the pipes is cleaned and lubricated.

- The bell is cleaned of dirt and unnecessary materials.

- Several O-rings are evenly installed inside the structure.

- The resulting protective layer is carefully treated with lubricant.

- The pipes are joined, and the right stopper is installed at the contact point.

- The left stopper is added and the pieces are brought together using butt wire.

- The result is a mounted connection.

"RJS"

“RJS” connection

A modification of the “RJ” system is a locking connection in which the socket is completely covered with a protective layer. Thick rubber rings that block deformation and third-party penetration of air into the structure provide the greatest strength of the pipe in comparison with the Tyton and RJ types. But this system has one significant drawback - it is not applicable to narrow connections, since it requires a large nominal passage to create.

RJS pipes are used in the same areas as RJ, with the exception of plateaus, since there preference is given to models with a narrow internal diameter. But limitations in characteristics do not prevent this system from occupying leading positions in production. The reason for this pattern is the additional equipment and sealing with Tyton rings and stoppers secured with a special metal tape.

Assembly of ductile iron type “RJS” takes place in the following stages:

- The smooth end is thoroughly cleaned of production residues.

- The outer surface of the smooth end is lubricated with certain alkaline lubricants.

- The bell is being cleaned.

- Protective rubber rings are installed.

- The resulting internal supports are lubricated.

- The pipes are joined, stoppers are installed at the contact point on both sides.

- The stoppers are fixed using a mechanical tape.

Advantage of ductile iron pipes

The close covalent polar bond and density of the crystal lattice allow ductile iron pipes to be durable and strong. Since these products are made by melting an alloy of cast iron and steel with the addition of impurities and applying internal and external coatings, the properties of pipe lines include the parameters of steel and cast iron structures.

Coating the alloy with graphite takes place in several stages. First, lamellar graphite, formed by combining electron clouds of carbon, is introduced into the structure. After which, magnesium melt is introduced, thereby turning the soft plates into hard balls. This material not only increases the strength of the pipe, but also allows it to easily withstand heavy loads.

Cast iron ductile iron sewer pipes

In the modern world, standard buildings are being replaced by exclusive design solutions. More and more bold ideas in housing construction are being implemented. That is why, when selecting building materials, you should rely not only on price, but also on high levels of quality, safety, reliability and, of course, environmental friendliness. Cast iron undoubtedly meets these requirements when it comes to installing sewer, storm and drainage systems.

Ductile iron is non-toxic and resistant to deformation; products made from it are easy to install, cheap, provide tight connections and are resistant to seasonal and daily temperature changes.

Installation

A special feature of the installation of ductile iron pipes is the absence of welding processes during operations. All installation work is carried out with ordinary construction tools, without the use of electronic or mechanical equipment.

Assembly from pipes and ductile iron fittings

The material used for processing structures is ethylene-propylene diene monomer. Compressing the metal collar from several ends of the pipe ensures a complete seal. The resulting gain from the addition of installation systems allows you to establish clear control over the flow of partial and internal pressure, and if a problem occurs, quickly eliminate it. The resulting cuffs allow the structure to feel comfortable under severe deformations and ground displacements.

With the help of elastomeric sealing collars, you can achieve even greater strength and flexibility of the pipe. When the structure deforms or the soil moves, this system allows the transported substance to continue moving through the channels, reducing the risk of material loss to a minimum.

An excellent addition is the absence of the need to dig trenches along the transport route, allowing the use of a trenchless transmission system, since the deflection of pipes under severe impact is only 4-5 cm.

Upon completion of the installation process, coaxial joining of the ductile iron pipes takes place. Before operation, a special operation called angular deviation is performed.

Functional features of socket connections

The manufacture of socket joints is carried out with the expectation of achieving complete tightness of the joint by establishing contact pressure between the sealing ring of the structure and the material from which the pipe is made.

Angular deviation values during deformation

Since the ductile iron socket connection is flexible, the connecting pipes can deviate from 2 to 6 degrees Celsius. At the same time, no physical harm is caused to the structure, since the connection systems “RJ”, “RJS”, laid in places of soil subsidence, do not allow the stoppers to move apart.

The influence of ground movement on ductile iron pipes

The angular deviation that occurs when processing the structure with the “RJ” and “RJS” connection systems allows the pipes not only not to sag, but also to successfully continue the uninterrupted supply of material through the channels. Another positive feature of changing the radius is the ability to rotate the radius without the help of a fitting, industrial equipment or interference in the operation of the transport route.

High-quality installation work and installation of cuffs on opposite ends of the pipe allow you to freely adjust the laying routes without third-party intervention and changing the structure of the alloys.

Regulations

We will leave foreign standards regulating the quality of imported products behind the scenes and focus on domestic regulatory documentation.

A rather funny picture emerged with her:

- a significant part of sellers refer to GOST 9583-75 as the main document;

- however, the only manufacturer – the notorious LTK “Svobodny Sokol” – does not mention it in the list of regulatory documents; but it includes technical specifications TU 1461-037-50254094-2008.

Let's try to clarify the picture and study both documents.

GOST

It regulates the production of pressure cast iron pipes using semi-continuous and centrifugal casting.

For the convenience of the reader, we will highlight only the main points of the standard:

- All pipes are produced with sockets;

VChShG pipe 100 mm with a socket for an O-ring seal.

- The minimum nominal diameter is 65 mm, the maximum is 1000 mm;

Please note: there is a clear discrepancy here with the LTK product range, starting with a diameter of 80 mm.

- The length of the pipes varies from 2 to 10 meters, which also raises certain doubts about the compliance of LTK products with this GOST;

- Finally, the main thing: products must be made from... hold your breath, dear reader... cast gray cast iron containing no more than 0.12% sulfur and no more than 0.7% phosphorus. Not a word about ductile iron.

The conclusion is obvious: the compliance of any domestic ductile iron pipe with this standard is nothing more than a fiction.

THAT

The author of the technical specifications will seem familiar to us: this is a certain Lipetsk enterprise “Svobodny Sokol”. Needless to say, the technical conditions he issued are strictly followed!

However, this document will bring us several interesting discoveries:

- The specifications provide for the presence of not only sockets, but also flanges. There is no mention of them on the company's home page;

Products with flanges are not mentioned on the company’s website, but are provided for in technical specifications.

- Only water and sewerage are mentioned as areas of application. On the main page, a similar list includes oil and gas pipelines and heating mains with operating temperatures up to +120C;

- Pipes can be supplied without a zinc outer coating, protected with bitumen varnish or polymer resin;

- Among the examples of symbols, both a 150 mm ductile iron pipe, 6 meters long, and a pipe with a diameter of 300 mm and a length of ... 5500 mm are mentioned. Despite the fact that the only standard size produced is directly indicated on the company’s website – 6000 mm.

Regulation of ductile iron pipes

The diverse composition of ductile iron pipes and the many procedures before putting them into operation causes many regulations from different regulatory organizations, applicable for different processes or technical details.

The most important document is the GOST 9583-75 resolution on the sizes of ductile iron pipes.

According to it, all products made of cast iron alloys in combination with steel are divided into 3 groups: A, B, LA. This is where difficulties begin for the manufacturer, since the technical data for spherical graphite is regulated by regulations TU-14-161-183-2000 and SP 40-106-202. These documents are presented in the following tables. Ductile iron pipes class LA

| Nominal bore(mm) | Outer diameter(mm) | Wall thickness(mm) | Weight of the pipe at its length (kg) | Weight of one structure (kg) | ||

| 2.1 | 3.2 | 4.4 | ||||

| 67 | 84 | 6.7 | 28.7 | 39 | — | 12.2 |

| 92 | 90 | 7.4 | — | 51.3 | 66.5 | 15.3 |

| 106 | 125 | 7.98 | — | 63.22 | 84.1 | 19.7 |

| 129 | 149 | 8.36 | — | 84.3 | 95.3 | 26 |

Ductile iron pipes class A

| Nominal bore(mm) | Outer diameter(mm) | Wall thickness(mm) | Weight of the pipe at its length (kg) | Weight of one structure (kg) | ||

| 2.1 | 3.2 | 4.4 | ||||

| 69 | 88 | 6.99 | 30.3 | 40.6 | — | 12.8 |

| 96 | 108 | 7.87 | — | 54.33 | 68.5 | 16.3 |

| 108 | 132 | 8.23 | — | 65.22 | 87.2 | 19.98 |

| 134 | 164 | 8.86 | — | 87.6 | 102.3 | 28.9 |

Ductile iron pipes class B

| Nominal bore(mm) | Outer diameter(mm) | Wall thickness(mm) | Weight of the pipe at its length (kg) | Weight of one structure (kg) | ||

| 2.1 | 3.2 | 4.4 | ||||

| 71 | 89.8 | 7.23 | 33.3 | 42.6 | — | 13.28 |

| 96 | 108 | 7.87 | — | 57.93 | 72.25 | 17.13 |

| 112 | 137 | 8.76 | — | 67.22 | 87.2 | 21.23 |

| 138 | 170 | 9.21 | — | 91.6 | 106.32 | 30.87 |

Decree TU -14-161-183-2000 on technical parameters of ductile iron pipes

| Internal patency Dy(mm) | Outer diameter Dн(mm) | Inner diameter Df(mm) | Radius of protective rubber rings Doms(mm) | Pipe wall thickness S(mm) | Structure length l(mm) |

| 102 | 120 | 244 | 216 | 8.44 | 72 |

| 152 | 173 | 310 | 288 | 9.31 | 82 |

| 203 | 226 | 366 | 326 | 10.03 | 88 |

Resolution SP 40-106-202 on standards for installation of ductile iron structures

| Nominal diameter(mm) | Outside diameter | Wall thickness | CPP thickness | ||||

| Nominal(mm) | Deviation(mm) | nominal(mm) | deviation(mm) | nominal(mm) | Minimum average value(mm) | Minimum value at one point(mm) | |

| 102 | 121 | 1.21 | 6.3 | 1.21 | 3.3 | 2.7 | 1.67 |

| 155 | 176 | 1.21 | 6.3 | 1.21 | |||

| 202 | 225 | 1.29 | 6.3 | 1.59 | |||

For steel casting of cast iron, a separate decree GOST 7293-85 is provided

| Cast iron grade | Tensile strength, MPa | Yield strength, MPa |

| HF 35 | 350 | 220 |

| HF 40 | 400 | 250 |

| HF 45 | 450 | 310 |

Cast iron sewer pipe price per meter

This suggests, first of all, that such a material, containing various graphite inclusions in its structure, can only work effectively “in compression,” i.e. form only by casting.

Standard pipe sizes are 60-100 mm, wall thickness is 10-15 mm with a length of 5-7 m. Cast iron pipes have a socket connection, because they cannot be threaded, and the gap when connecting them is at least 4-6 mm. It contains additional insulation. Cast iron pipes are widely used in the construction of water supply systems, sewerage systems, fire protection systems, as well as in the oil refining, chemical, and mining industries.

Features of connection and production of socket structures

Installation of ductile iron pipes produced using the “RJ” and “RJS” technologies is carried out in 2 ways: using crystalline electric welding or introducing electrodes into the structure. The first option makes it possible to obtain a high-quality, durable connection, but causes difficulties in controlling flows during soil movement. The second method implies good design flexibility under the influence of high pressure on the pipes.

The sequence of constructing socket joints is as follows:

- The inner surface of the bell is thoroughly cleaned: blockages, dirt, grease, sand and other debris are removed. The same procedure is applied to the opposite section of the structure. At the end of the operation, it is necessary to lubricate the contact points with a special industrial paste.

- The cuffs are checked for quality and suitability, after which they are laid out in the shape of a heart and pressed into the structure. It is necessary to pour special oil into the resulting holes.

- The end of the second pipe is installed evenly, the contact point is carefully fixed, after which the product is carefully pressed.