Shut-off valves are an integral part of any plumbing and heating system; the main way to shut off the flow of the working environment is to use various types of taps. Many plumbers, when installing lines for transporting water and coolant to appliances, as well as users when independently connecting various water-consuming devices, often use a 1 2 inch (1/2″, half inch) ball valve to lock the channel.

When purchasing, you should know which crane is best suited for certain operating conditions; for this purpose, its technical and physical characteristics are considered. The brand of the manufacturer of sanitary fittings also plays an important role in the choice, and given that a large number of counterfeits are sold on the market, it is important to distinguish original products from low-quality analogues.

Rice. 1 Examples of operating ball valves in a heating system

What is a ball valve and how it works

A ball valve is a type of fitting that locks the passage channel of pipelines, the executive element of which is a spherical (ball-shaped) valve. Inside the hollow ball there is a through hole, which in the open position coincides with the passage channel of the faucet or closes it when the handle is turned a quarter turn (90 degrees).

Since the inner ball and the seat in which it rotates are made of hard metals, their surfaces in contact cannot technologically provide an acceptable degree of tightness, therefore, elastic washers made of various types of polymers are installed at the points of contact.

Ball valves appeared more than 100 years ago, but at that time, due to the lack of reliable and durable seals, they had a relatively short service life and required frequent replacement of gaskets. With the advent of fluoroplastic and other modern synthetic materials (EPDM, Viton), the durability and reliability of taps has increased significantly.

Rice. 2 Shut-off valves in the pumping equipment piping

Area of application in everyday life

Ball valves are perhaps the only type of fittings that are used in everyday life to block the passage channels of pipelines; they are widely used:

- In autonomous water supply lines when drawing water from wells and boreholes. They are placed in caissons, external outlets from water supply lines for watering gardens and using water for household purposes.

- Ball valves are widely used in internal water supply systems for general shutdown of hot or cold water in an apartment, house, or local shutoff of plumbing fixtures from the water supply - to flexible connections for flush tanks and kitchen faucets.

- In heating systems, shut-off valves are used to drain the coolant, disconnect the working fluid supply pipelines from radiator heat exchangers, and underfloor heating circuits.

- In the gas supply line, each pipeline is equipped with a ball valve to cut off gas from a rigid or flexible supply to the stove.

Rice. 3 Ball valve 1/2 brand TIM design

Plumbing gaskets

Plumbing gaskets or sealing washers are used to ensure the tightness of mechanical connections and water shut-off systems. Plumbing gaskets are made from various materials and various diameters.

It's always best to have a set of plumbing gaskets on hand.

Over time, any gasket becomes unusable and ceases to perform its functions, as a result of which the water tap begins to leak. This gasket must be replaced with a new one.

| Gaskets made from vulcanized fiber are most often used in mechanical screw connections. They can withstand water temperatures up to +80° C |

| Synthetic gaskets are used in mechanical screw connections in water circulation systems. They can withstand temperatures up to +180°C and pressures up to 40 bar. |

| These gaskets are made from Kevlar, which does not contain asbestos. They can withstand temperatures up to +400°C and pressures up to 100 bar. |

| Narrow vulcanized fiber gaskets are used primarily to provide seals in taps and mixers. |

| These gaskets, made of Teflon, are suitable for any liquids and can withstand temperatures up to +250° C. |

| Ring-shaped rubber gaskets are used mainly for sealing moving parts of taps and mixers. |

| Flat rubber gaskets are used to seal joints of plastic parts (hoses, washing machines, siphons). |

| Faucet gaskets come in a variety of diameters and thicknesses and may have a hole or be solid. |

| Gaskets for flush barrels ensure the tightness of the water drainage system. |

These articles may also be of interest to you:

- Replacing the mixer axle box gasket

- Replacing the faucet axle box of the mixer

- Replacing ceramic mixer discs

- Crane seat repair

What else would you like to read?

Tags: Ball valve, Water taps, Built-in faucet, shut-off valves, Stopcock, ceramic discs, ceramic tap discs, Taps, sanitary seals, faucets, single handle faucets, thermostatic faucets, mixer, Drain tap, faucet device, faucet device, mixer device, ball valve

Structural device

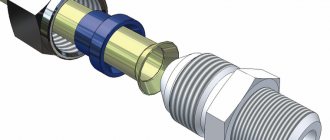

Any ball valve consists of the following elements:

Frame. Usually made of brass, less often stainless steel (bronze), in household communications there are also low-cost polymer varieties made of PP polypropylene. The housing can be collapsible or all-metal with external or internal threads at the ends of the connecting pipes. In municipal and industrial applications, ball valves can be made of other materials (steel, cast iron) and have connections for flanged or welded connections to pipelines.

Bolt ball. Typically, the element is made of corrosion-resistant metals - brass, stainless steel; for connection with the rotating rod, each ball has a protrusion with a recess or a slot. To reduce friction and accordingly extend the service life of the seat rings, the brass ball is polished and coated with sliding materials - adhesive copper and then microporous wear-resistant chromium.

Pen. It is usually made of steel, aluminum (silumin) with a corrosion-resistant protective polymer coating, or plastic. There are two types of handles in shape: butterfly type or console type, which is a lever. To prevent spontaneous opening or closing of the tap, some manufacturers equip the console handle with a movable latch that locks it in a stationary position.

Rice. 4 Manufacturing materials using the example of the Bugatti model

Seat seals. The spherical valve is isolated from contact with the body and rotates in a suspended state supported by two flat ring washers made of durable sealing material. A wide range of sealing polymer materials are used for rings of household ball valves, the most popular are the following types:

- Teflon PTFE. Heat-resistant fluoroplastic (polytetrafluoroethylene), white, soapy to the touch, was developed in 1938, and is widely used as seals in a variety of pipeline fittings. Teflon is superior in chemical resistance to all known synthetic materials, has very low adhesion (stickiness), is environmentally friendly, and is reinforced with carbon fiber to reduce fluidity. Teflon is able to remain ductile and flexible in the temperature range of −70 to +270 °C.

- EPDM. Synthetic elastomer ethylene propylene diene rubber (Ethylene Propylene Diene Monomer rubber) is resistant to aggressive chemicals and oils, works without reducing physical properties in the temperature range from -50 to +150 ° C.

- NBR is an acrylic-nitrile-butadiene rubber elastomer, the distinctive feature of which is its high abrasion resistance, used at operating temperatures from -20 to +90 ° C. Unlike many synthetic materials, it is resistant not only to aggressive chemicals, but also to all types of hydrocarbons: oil, gas, methane, butane, as well as animal, vegetable, mineral fats and oils. NBR has high gas permeability; its modified analogue H-NBR - hydrogenated acrylic-nitrile-butadiene rubber - is often used in seat valves.

- Viton is a trade brand from Du Pont of synthetic fluorinated rubbers (SFK - their Russian abbreviation), obtained by co-polarization of fluorine-containing monomers. As a result of the operation, the material surpasses all types of known elastomers in terms of chemical resistance - it can work in an environment of mineral acids, hydrocarbons (gasoline, lubricants, oils), various solvents (except acetone, ethyl acetate, diethyl ether). Viton or FPM (Fluorinated propylene monomer) and FKM (Fluorocarbon) are wear-resistant and not subject to combustion, operate without loss of physical properties in the temperature range from -40 to +200 ° C. Thanks to these properties, Viton is used when working in an environment of aggressive high-temperature chemicals in conditions where natural or hydrocarbon rubbers cannot withstand. According to some sources, the material is not intended for use in drinking water supply pipelines.

Rod with sealing rings. It is a part that transmits rotation from the valve handle to the bolt ball. Typically, the handle is connected to the upper end of the rod in two ways: it is placed on a rectangular profile and secured on top with an end screw, or it is screwed with a self-locking nut onto the external thread of the spindle.

O-rings are usually made of fluoroplastic, NBR or Viton, and combinations of these materials are often used.

Rice. 5 Ball valve 1/2″ - types of bodies and connecting pipes

Main technical characteristics and markings

The cranes presented to the markets from different manufacturers are designed for operation in various conditions, their main parameters are:

- Diameter of the passage channel. The parameter is indicated on the product body by the letter DN and then by the size in inches - ball valve 1/2″, 3/4″, 1″ and so on.

- Nominal (working pressure). Considering that brass can withstand a pressure of the working environment of hundreds of atmospheres, this parameter directly depends on the material of the seat and rod seals, and the quality of manufacture of the fittings. The range of nominal pressures of household taps is also directly related to their dimensional parameters and lies within the range of 15 - 90 atmospheres (bar).

- Operating temperature range. Depends on the material of manufacture of seat rings and rod seals; product parameters differ between different manufacturers and models. Typically, extreme values do not go beyond -40 °C to +200 °C.

- Number of triggers. The parameter is indicated in the passport data of the taps; in expensive models of European brands, the channel can be closed up to 30,000 times. In most products, the number of on and off cycles reaches 25,000 with a mean time between failures of 55,000 turns of the handle.

- Operational service life. The durability of the fittings has a direct relationship with the chemical and physical parameters of the working environment - pressure, temperature of the medium in the line. Manufacturers of quality products promise reliable operation of their shut-off valves for at least 30 years.

When marking some products on the body they also put:

- Name of country of origin (Made in Italy, Spain);

- company logo;

- material grade (for brass - CW617N);

- name and date of manufacture of the crane;

- product catalog number (for example, ball valve 1 2 1129).

Rice. 9 Models with compression and press couplings for connection to metal-plastic pipes

Table DN to pipe diameter

| Du, (mm) | Nozzle diameter/pipe wall thickness (mm) | GOST |

| 15 | 21,3 / 2,8 | 3262 |

| 20 | 26,8 / 2,8 | 3262 |

| 25 | 33,5 / 3,2 | 3262 |

| 32 | 38 / 4 | 10705 |

| 40 | 48 / 3,5 | 10705 |

| 50 | 57 / 3,5 | 10705 |

| 65 | 76 /4 | 10705 |

| 80 | 89 / 4 | 10705 |

| 100 | 108 / 5 | 10705 |

| 125 | 133 / 5 | 10705/8731 |

| 150 | 159 / 6 | 10705/8731 |

| 200 | 219 / 6 | 10705/8731 |

| 250 | 273 / 8 | 10705/8731 |

| 300 | 325 / 8 | 10705/8731 |

Criterias of choice

There are several hundred varieties of ball valves on the market from domestic, Chinese and European manufacturers; for the optimal choice, the following factors should be taken into account:

A). Conventionally, ball valves can be divided into several groups according to their scope of application in everyday life, depending on the design of their body and handle:

- Console taps with a handle in the form of a lever are always placed near the riser next to water meters for a general shutdown of water supply in apartments or houses. Thanks to the long lever, in conditions of limited access, especially in the presence of small hatches, they are much more convenient to use due to the low application of effort. Also, one-handed taps are installed in any other places with difficult access, for example, near flexible toilet connections.

- To connect the hoses of washing machines and dishwashers, special taps are used, which have an aesthetic appearance due to the identical coating of all elements. Usually their handle is made in the form of a flat short lever.

- In other cases, for example, to supply water to the faucet under the sink, taps with a butterfly handle are installed, which takes up a small space. Also, butterfly valves are installed if they are located in open areas of pipelines, near which people pass and there is a possibility of user contact with the fittings.

Installation

The fittings are easy to install with your own hands.

A ball valve with a coupling design is very easy to install. First you need to choose the size, for this we use the table:

The table of water tap sizes will help you choose the right model.

Then an external thread is cut at the end of the pipe using a die. The threads are sealed with flax and sealing paste, then the tap is screwed on using a wrench 4 - 4.5 turns. Installation is no different from installing a conventional coupling.

The faucet with mixer is also not difficult to install. There are models with wall mounting and sink mounting.

Installation instructions for a wall-mounted mixer look like this:

- At the ends of the extended pipes we cut internal threads and screw eccentrics into them. We seal the thread with flax or FUM tape;

We screw in the eccentrics.

- We assemble the mixer body according to the manufacturer's instructions and bring it to the eccentrics. We set them so that they coincide with the union nuts of the input channels of the device and are at a strictly horizontal level;

We expose the connecting parts.

- We screw decorative overlays onto the threads of the eccentrics;

We screw on the pads.

- We put the housing on the ends of the eccentrics and tighten the union nuts with a plumbing wrench. Do not tighten them too much, otherwise you will damage the rubber gaskets;

Tighten the union nuts.

- We connect the flexible hose of the shower head, the water tap position sensor (if necessary) and other parts. We supply water and test the work.

We connect the shower head and check the operation.

Important! Before installing the mixer, make sure that the rubber gaskets are present in the union nuts, as sometimes they fall out.

Ball valve 1/2 inch - recommendations for installation and operation

When installing ball valves in pipelines, the following recommendations should be followed:

- Any ball valve should operate in only two positions - open or closed; any intermediate placement of the ball in the channel leads to a decrease in service life and breakdown of the product.

- To increase the durability of not only the ball valve, but all fittings, the pipeline must be equipped with filters for coarse and fine water purification from impurities.

- Before installation in the heating or water main, the circuit is cleaned of rust, scale and limescale deposits, washed with special chemicals.

- The valve should not be subjected to mechanical loads after installation of the pipeline for bending, compression, or distortions due to misalignment of the pipes.

- During installation, the valve is installed in the open position, that is, the handle should be located along the body in the direction of movement of the working fluid.

- For prevention and normal functioning of the product, it is recommended to change the position of the faucet handle at least once a month.

Rice. 12 Ball valve 1/2″ Bugatti in section