Anyone who has ever encountered repair work on a household pipeline knows what a VGP pipe is. Rolled steel used for pressure and non-pressure water and gas pipelines is available on the market in a wide range, and, obviously, is not going to give up its leading position to plastic pipes. VGP pipes are especially successfully used in areas where the influence of corrosion is minimized: in above-ground areas and indoors. However, galvanized steel products can resist corrosion quite well even in the most unfavorable conditions.

VGP steel pipes are used for installation of gas and water mains under different operating conditions

Briefly about VGP

All that remains is to clarify the very concept of a VGP pipe: what it is, and how the product differs from other steel pipes. In principle, a water and gas pipe is a special case, one of the widely used varieties, of electric-welded metal, produced in accordance with GOST 3262 standards. Its main difference from its “brothers” is the reinforced seam, a feature that allows it to withstand greater pressure than other materials. In addition, the VGP pipe is distinguished by increased anti-corrosion qualities, which is also an important factor in the technical operating conditions.

Options for laying gas pipes

With above-ground installation, it is easier to make repairs, but there is a greater likelihood of external damage.

There are several ways to lay a gas pipeline. The choice is made taking into account the characteristics of the site, pipeline material, and gas pressure.

Underground

It is considered the safest, as it eliminates mechanical stress and the influence of sunlight. This method is ideal for plastic pipelines. Not the best for steel ones, since the latter require periodic inspection and maintenance.

The method is expensive. The pipes are laid to a depth below the freezing level of the ground - at least 0.8 m. In cold regions, the depth of the trench increases to 1.2 m.

Overhead

Less secure method. The pipeline is installed on metal risers of different heights. This method is used when there is a high relief and complexity of the site, with a large number of buildings, where it is difficult to fulfill all the requirements of SNiP. Only steel pipes for gas can be used.

Interior

Inside the building, the gas pipeline is installed in an open way. It is allowed to hide communications in pre-made grooves in the wall, but they can only be covered with easily removable panels. Free access to pipes is a must.

VGP steel pipe: what is it?

Pipes classified by the abbreviation VGP are considered very durable and wear-resistant. Their rigidity is equal to the qualities of an all-metal beam of the same diameter. The purpose of the steel VGP pipe lies in the decoding of the name - “water and gas pipeline”. Accordingly, these products are used to create pipelines for gas and water: both domestic (domestic) and main ones.

The advantages of water and gas pipes include the following:

- low linear expansion rate. VGP pipes do not deform under the influence of temperatures approaching boiling water. They are able to withstand temperatures at which polymer materials begin to soften and melt. Also, the steel pipe does not deteriorate when the coolant (liquid) freezes;

- high strength. The strength indicators of VGP steel pipes are higher than those of copper and polypropylene products. Their limit of permissible internal pressure allows the use of steel pipelines in pressure networks. Galvanized VGP pipe is also resistant to corrosion;

- thermal conductivity. The media in steel pipes maintain the required temperature for a long time;

- tightness. Transportation of gaseous and volatile substances, as well as acids and other chemically active components is allowed.

Pipes made of ordinary steel and non-galvanized steel quickly become rusty

Important! On the other hand, high thermal conductivity can cause heat loss in the system, but this disadvantage can be easily overcome with insulating materials.

Selection of pipes for a gas pipeline

Plastic pipes can be installed in a room protected from ultraviolet radiation.

Which pipes and why are used for internal gas pipelines depends on many factors:

- Purpose – gas is supplied to the consumer with minimal pressure. When installing gas supply, you can use metal-plastic, steel and copper pipes.

- Effect of ultraviolet radiation - steel and copper products can be installed anywhere inside and outside the house. Plastic ones are sensitive to sunlight, they are located in shaded areas.

- Laying method - a steel or copper gas pipeline is laid above the ground, underground, in walls, in open areas. Plastic can only be laid underground outside the house and only in open areas indoors.

- Durability – copper ones last the longest. Steel gas pipes are susceptible to corrosion and need protection. Their service life is shorter.

- Difficulty - plastic pipes are flexible and are connected by soldering. In this way, contours of any complexity can be constructed. Steel ones need to be welded and connected through fittings. This makes gas supply difficult.

The laying of gas pipes is carried out at the expense of the home owner, so the cost must be taken into account when choosing. They consider the price of the pipeline, meter, shut-off valves, as well as the cost of installation.

Which pipes are best to use for gas?

Copper has the longest service life.

Domestic gas pipes are made of steel and copper. Bronze and brass are also found, but extremely rarely.

Both materials have the main quality for a gas pipeline: they do not allow gas to pass through at all. Options are evaluated based on the following characteristics:

- Copper does not corrode. The service life of the gas pipeline is 50–100 years. Steel is susceptible to corrosion and, with the most careful care, will not last more than 20 years.

- Copper is ductile. Small diameter tubes can be bent. Steel ones need to be welded.

- The cost of a copper pipeline is noticeably higher. The steel gas pipe has the lowest price.

Copper pipes are much nicer. They do not require periodic painting and often act as part of the kitchen interior.

How are steel VGP pipes made?

Such pipes are made from carbon steel using the following method:

- Strips (blanks) go through preparation and molding;

- The seam is made using electric welding.

The rules for manufactured water and gas pipes are regulated by GOST 3263-75.

The most fragile place on a VGP pipe is the seam. It must be examined using radiography. The presence of a seam does not refer to pipe defects.

Good to know! The service life of the GOST 3262-75 pipe is most influenced by operating conditions.

The safety of the pipe is influenced by whether it is used for a gas pipeline or a water pipeline, how active the substances that move in it are from a chemical point of view, and what external factors affect the pipe.

Standards for electric-welded water and gas pipes

Electric welded pipes are regulated by GOSTs 10705-80 and 10704-91. In their production, steel grades 20, 10, ZSP, ZPS are used. According to the manufacturing method, electric welded pipes are divided into heat-treated and non-heat-treated.

The unmeasured length is in the range of 4–11 m, the measured length is 9–11.7 m.

The length and diameter determine the dimensions of the water and gas pipes.

By agreement with the client, the dimensions of the VGP pipes may deviate from the norm. These deviations are also limited. The following pipe modifications are possible:

- up to 5% for VGP pipes 1.5–4 m long;

- up to 10% reduction in the diameter of the galvanized pipe throughout the entire area where the rolled thread is located;

The mass of the water and gas pipe is calculated using a steel density of 7.85 g/cm3. It has already been said above: galvanized pipes are 3% heavier than non-galvanized ones.

Principles of production of VGP pipes and GOST

Carbon steel is used for water and gas pipes. The technology of their production fits into several stages, which are quite simple and technologically determined.

- Production of strips - steel blanks in the form of strips with a thickness and width that meet the requirements of GOST. Strips are made by hot rolling.

- The steel strip is bent into a pipe using special equipment.

- The resulting joint is welded using electric welding.

As you can see, there is nothing complicated from a technology point of view. The qualitative characteristics of VGP pipes are set out in GOST 3262-75, but, it must be said, quite stringent requirements are imposed on water and gas pipes, since they will have to operate under conditions of high loads and fairly harsh environmental conditions. Particular attention is paid to the weld: it is necessarily checked by radiography for integrity and absence of gaps. In this case, seam defects are unacceptable!

In addition, VGP steel pipes must meet the following requirements:

- absence of swellings, declines, cracks, chips on the surface;

- absence of delaminations and cracks at the ends of the water and gas supply material;

- cutting should be done at right angles; deviation from it is allowed no more than 2 degrees;

- burrs after cutting should not exceed 0.5 mm.

GOST allows the presence of minor defects on the VGP pipe, such as ripples and dents, but only if their presence does not affect the performance of the product.

Anti-corrosion characteristics are an important detail

The next indicator is the ability of this material to resist rust. To improve the anti-corrosion characteristics of the product and extend their service life, the industry produces galvanized pipes. GOST regulates the thickness of the coating: the minimum zinc layer is allowed to be 30 microns. It may be absent exclusively at the ends. The entire remaining area of the pipe is carefully covered.

There are certain requirements for the galvanized surface as a whole. It should be smooth, without peeling, blistering or inclusion of foreign materials. Rust should not get through possible micro-holes, so this process is also scrupulously controlled by engineering methods.

For heating installation

Description and explanation of the abbreviation VGP

For a long time, VGP pipes have been indispensable elements in the construction of many facilities. They are used for supplying communications:

- gas pipeline;

- heating;

- water supply

The abbreviation VGP stands for water and gas pipes . They are considered very durable and are equal to the strength of an all-metal beam of identical diameter.

These products are made from carbon steel . They are always in demand, despite the fact that pipeline materials made of plastic and metal-plastic have now appeared. This is due to the fact that there are areas of communication networks where products made from other materials cannot be used. For example, gas pipelines cannot be laid using plastic products.

VGP products are produced using the technology of welding and forming metal strips. Rolled sheets are used as a workpiece. It is made from carbon hot-rolled structural steel. To ensure that such a material can withstand maximum loads, special attention is paid to the weld seam during the production process. Such finished products must be gas and waterproof. Depending on the wall thickness, products are divided into separate types :

- lungs;

- ordinary;

- reinforced.

They are produced in the form of material in measured and unmeasured lengths. Eight-meter long pipes are considered the most popular. There are also products with a length of 5.8; 7.8; 9 and 11.75 meters. Such parameters are related to the peculiarities of transportation and installation.

Specifications

First of all, you need to understand the difference between a water and gas pipe and an electric welded one.

An electric-welded metal pipe has the official abbreviation ES; it is a straight-seam structure, which is made from high-strength steel by electric welding. Such products roll out rather poorly and do not stretch. The edges of the ES pipes are connected strictly parallel to the axis.

These types of rolled pipes are widely used in construction because, thanks to the reinforced longitudinal seam, they are characterized by exceptional durability and tightness.

VGP pipes are a kind of electric-welded model, but more advanced, since the seam here is maximally reinforced, as well as increased strength and an anti-corrosion coating. That is why VGP is used in construction more often than electric-welded versions of rolled pipes.

The materials used and production technology determined the physical and technical characteristics of VGP pipes. Such designs can be used with hydraulic loads in the range from 25 to 32 kgf/cm2.

The products have increased resistance to heat, in some utilities there is transportation of gas and liquid flows heated to 140-150 degrees, it is obvious that if such a substance gets into the networks located inside residential buildings, then no polymer will withstand such strong heat, and it will simply begin to melt, and in some cases a pipe may even burst.

Galvanized VGP pipes do not have this drawback. In addition, they are characterized by increased strength and resistance to mechanical loads, this has led to the widespread use of the product when laying main pipelines, where there is a maximum flow of moving vehicles.

It should be noted that VGP pipes are characterized by a relatively low price, this is primarily due to the availability of raw materials used for their production and manufacturing technology, which does not require the introduction of advanced technologies and scientific and technological advances.

Carbon galvanized steel is not prone to rust, it has good anti-corrosion properties, so pipes can be used for industrial needs.

If we compare VGP with seamless analogues, we will not find a large variation in consumer characteristics, which allows us to conclude that the products are interchangeable. This is true, but the basic advantage of water and gas pipes is their low cost - it is this factor that has allowed these products to remain leaders in their segment for many years.

Installation and Installation

The optimal way to connect pipes is to use welding. This technology ensures high quality connections and leaves no gaps, which minimizes the risk of cracks. Upon completion of welding, it is recommended to apply a layer of paint or primer to the seam with the addition of anti-corrosion components. In the case of chrome-plated pipes, the anti-corrosion compound does not need to be applied, since the risk of rusting the seam is minimal. For delivery, they are packaged and fixed on platforms (usually made of wood). Any transportation is allowed (cars, trains, ships, airplanes, river transport, and so on).

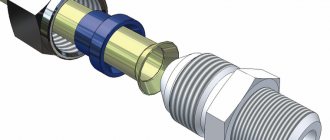

If there is a thread, the structure can be assembled using threaded fittings. The threaded-fitting connection method is less reliable, however, in the case of high-quality assembly, the risk of leaks and cracks is minimal. Assembly of threaded fittings is carried out according to the following algorithm:

- The threaded fitting is treated with a sealant to ensure a high quality connection. Then a lock nut is mounted on the squeegee, which will act as a lock.

- The squeegee is inserted into the fitting, and then the locknut is tightened. The locknut must be installed tightly so that it fits tightly to the metal (otherwise the structure will leak).

- The structure is re-lubricated with sealant to seal the smallest cracks, cavities and irregularities that can make the structure unreliable.

Kinds

The main types of VGP pipes, their weight and dimensions are indicated in the current GOST 3262-75.

In accordance with the standards, the entire range of pipes is conventionally divided into two types depending on the method of their manufacture:

- galvanized;

- non-galvanized (black).

Galvanized ones have the highest performance characteristics:

- do not corrode;

- are characterized by high strength and strength;

- show resistance to mechanical damage;

- when transporting liquid inside galvanized pipes, deposits form 10 times slower than in non-galvanized products;

- have an aesthetic appearance.

The disadvantages include:

- high cost - galvanized pipes are much more expensive than non-galvanized ones;

- in case of deformation, the galvanized layer is destroyed first;

- When moving cold water, condensation often forms;

- For smooth operation and stable use, an uninterrupted water supply is required.

This is interesting: How to clean copper from oxide, blackness and deposits at home.

The advantages of non-galvanized pipes include:

- high strength and resistance to mechanical damage;

- the ability to transport liquid and gaseous media under high pressure;

- vibration resistance:

- the possibility of steel deformation under the influence of high temperatures is completely eliminated;

- low cost compared to galvanized models.

Not without its drawbacks:

- susceptibility to corrosion;

- the occurrence of condensation during transportation of cold liquid;

- low throughput;

- the need for constant coloring and maintaining appearance;

- The service life of such models is much lower than galvanized ones.

In addition to this classification basis, in the production of rolled pipes, indicators such as nominal bore and wall thickness are also taken into account and varied - all these parameters must necessarily comply with GOST.

Depending on the resistance to hydraulic pressure, HSVs are divided into:

- light – used in conditions where the pressure does not exceed 25 kg/cm2;

- conventional - the pressure is at the same level of 25 kg/m2, but periodic hydraulic shocks are possible;

- reinforced - withstand pressure up to 32 kg/cm2; upon individual requests, pipes with a maximum pressure of 50 kg/cm2 can be produced.

Based on the type of readiness, the following are distinguished:

- pipes with threaded ends (cut or knurled);

- ordinary - without thread.

According to the accuracy class, several typical modifications of VGP are also distinguished.

- The first group includes standard precision products. In the production of such pipes, the chemical composition and mechanical characteristics are not standardized in any way. The products have found application in the arrangement of water and gas utilities for domestic purposes.

- The second category includes high-precision products, which also includes galvanized pipes.

In the manufacture of these varieties, VGP strictly follows the requirements for the composition of the material and the mechanical characteristics of the finished products. Pipelines for industrial use are made from such pipes.

Dimensions

Water and gas pipes are manufactured in accordance with GOST, which sets clear requirements for their sizes and basic characteristics:

- the wall thickness should be 2.5-4.5 mm, the permissible deviation is minimal and only on the condition that it does not reduce the reliability of the product and the quality of the product;

- the conventionally accepted DU for steel VGP pipes is 6-150 mm, while with a length of more than 20 mm, a deviation from the established standard of 2 mm is allowed; if the length is less, then the deviation should not exceed 2 mm;

- the outer diameter of the water and gas pipe can be from 10 to 165 m, the total number of standard sizes is 14, and the basic classification of products is carried out precisely on this basis;

- the length of the pipes varies from 4 to 12 meters, while for each linear meter a two-millimeter curvature of the pipe is allowed;

- Pipe threads must be applied with a aligned cylindrical or knurled end.

Production Features

Water and gas pipes are made from a pipe blank - strip, which is molded and then welded with a longitudinal seam using furnace or arc welding. The seam is usually located parallel to the longitudinal axis of the tubular product. At the welding site, the standard allows some thickening, leading to a slight decrease in the internal diameter. Each pipe undergoes a weld inspection using non-destructive testing methods, after which hydraulic testing becomes an optional activity.

Strips are produced by hot rolling from carbon steels of ordinary quality and high-quality structural ones. Ordinary quality steels are manufactured in accordance with GOST 380-2005. They combine affordable cost, good strength, and weldability without restrictions.

To increase corrosion resistance, pipe products are galvanized using the hot-dip galvanizing method. The thickness of the zinc coating must be at least 30 microns. There is no protective layer at the ends. Such products are used for laying in conditions of high humidity. There is another option for protecting a pipe product from corrosion damage - priming, and then coating with paints and varnishes for metal. Also used for coating are “two in one” enamels (primer + coloring composition) or “three in one” (rust converter + primer + paint).

Classification of pipes according to their accuracy class

Water and gas pipes are divided into two main categories according to their accuracy classes. The first category includes tubular products of ordinary precision. When producing products of this category, the following parameters are not standardized: the chemical composition of the manufacturing material, its mechanical characteristics. Pipes of this category are quite successfully used for arranging gas and water communications for domestic purposes.

The second category includes water and gas pipe products of increased precision. Galvanized pipes also belong to this category. From such pipes, for which both the chemical composition of the manufacturing material and its mechanical characteristics are standardized, parts for industrial pipelines are made with increased requirements for their reliability.

Requirements for high-precision pipes

Categories of steel pipes and types of gas pipelines

To lay pipelines, different types of pipes for gas pipelines are used, which are divided into two categories:

- Seamless gas pipes can be hot or cold deformed.

- Welded pipes are distinguished by the type of seam; it can be straight or spiral.

In the production of both categories, the basis is carbon steel, the grades of which are specified in GOST 380-2005.

The chemical composition of the steel, as well as the type and size of the gas pipeline, are determined by the following factors:

- The value of the working pressure . This parameter can have a high, medium and low value.

- Pipeline location . It can be underground, above ground, underwater, or located indoors.

- Purpose of the system . The network can be backbone, distribution and backup.

Trunk gas pipelines transport an explosive mixture with a working pressure of about 10 MPa over long distances. Their installation is carried out from large-diameter steel pipes, the quality of which must meet the highest requirements.

Main advantages

VGP pipes are in demand for the construction of main lines and domestic pipelines. They use gas or water as a working medium. The main advantages of such products are the following indicators:

- low coefficient of linear expansion, which prevents deformation of the structure under the influence of high and very low temperatures;

- high strength compared to polypropylene and many other materials;

- possibility of use in pressure-type structures;

- good thermal conductivity, which has a positive effect on maintaining the temperature of the transported working environment;

- tightness allows the delivery of volatile and gaseous substances, acids and many other chemically active substances through pipes.

A high thermal conductivity coefficient can lead to cooling of the transported working medium. To avoid this, VGP pipes are used with additional thermal insulation materials.

Application area

VGP products are able to withstand strong hydraulic shocks, as well as thermal deformation of the transported liquid. For domestic purposes they are intended for transportation:

- water (cold and hot);

- low pressure gas.

For water supply, VGP pipes are connected by welding, as well as using threaded connections and other additional parts.

The products have found application in the creation of various metal structures: fences, small architectural forms, scaffolding, cabinets, weights, whatnots. Most of the products are used in the housing and public utilities sector. Almost all apartments and houses use such material to provide them with water, heat and domestic gas. Modern manufacturing companies have the appropriate certificates. This suggests that manufacturers adhere to the standards in a particular GOST.

There is also a hygiene certificate. It is obtained after passing a sanitary and epidemiological examination. Certificates apply to the entire range of products.

Gas pipeline security zone

When laying communications, one more condition is observed - they organize a security zone. Its value depends on the methane pressure in the pipeline and its diameter:

- To supply gas to a private home, pipes with a cross-section of no more than 80 mm are used. The security zone is 2 m on each side if the pipes were laid above-ground or above ground.

- For circuits made of polyethylene products, the security zone is 3 m from the axis of the pipeline.

- If communications are laid through a forest belt or an area with bushes, the dimensions increase to 3 m.

- If the gas pipeline is installed above the ground, the distance from the tree to it should be equal to the height of the tree.

In the protected zone, you cannot light a fire, loosen the soil to a depth of more than 30 cm, store chemical compounds (acids, alkalis) or any household waste. Also, it is not allowed to erect any buildings within the zone.

What is the difference between a VGP pipe and an electric-welded pipe?

Of course, such a question is not entirely correct, but for a non-specialist it is quite important. In general, VGP pipe is a type of electric welded product category. Visually, a water-gas pipe differs from an electric-welded pipe only in size, but the state standard dictates different requirements for these two types of pipes. Electric-welded pipes are more often used in main structures, and can also serve as support pillars, frame structures for furniture, fences or enclosures. As with the production of VGP, galvanized steel can be used in the manufacture of electric welded pipes.

The main differences between these types of pipes, according to the relevant GOSTs, are presented below.

Steel VGP pipe: GOST 3262-75

Straight-seam electric-welded steel pipe: GOST 10704-91 (TU according to GOST 10705-80)

No more than 0.4 mm for d 50 mm

2.4 MPa – ordinary pipes 3.1 MPa – reinforced pipes

6 MPa – at d 102 3 MPa – at d >102 mm

It is allowed to produce analogues of steel VGP pipes in accordance with GOST 10704-91, provided they fully comply with the presented standards.

Welded VGP pipes can have both a spiral and a straight seam.

Sheet metal

- Hot-rolled sheet

- Cotton sheet

- Galvanized sheet.

- Profiled sheeting.

- Expanded metal sheet (PVL).

- Stainless steel sheet.

Long products

- Rebar, wire rod.

- Beam, channel.

- Corner.

- Circle.

- Stripe, square.

Stainless steel

- Circle, square, hexagon.

- Stripe, corner.

- Stainless steel pipes.

- Stainless steel sheet.

- Stainless steel hardware.

- Accessories for stair railings.

- Pipeline details.

Hardware and metal raw materials

- Calibration, silver.

- Wire, ropes.

- Mesh, tape.

- Radiators, electrodes.

Non-ferrous metals

- Aluminum, duralumin.

- Copper, bronze, brass.

- Tin.

- Lead.

- Zinc.

There are two types of pipes: solid and welded type. The VGP steel pipe can be made in a standard design or with increased precision; in the latter case, it is used for the manufacture of pipeline fittings; the bodies of gate valves, valves and other regulatory bodies are made from it. The first type of pipe has no seams and is widely used in boiler rooms and heating systems; it has no threads and is tightly welded into the system. The production of all kinds of structures using welding or mechanical connections, where VGP pipes of various lengths and diameters are used as a building material, is as popular as the use of other types of pipe rolling for these purposes. Pipes are characterized by the following characteristics: By type of production. The VGP product is made of high quality steel, it can be of conventional type or high precision. Such pipes are used to transport hot and cold water and gas.

VGP galvanized pipes, types, purpose, characteristics. In many ways, the price of a pipe is determined based on the qualities described above, while the manufacturer’s brand does not have a significant impact on the cost. In everyday life, the use of non-galvanized pipes will lead to the fact that after a few years, as a result of overgrowing, the bore diameter will significantly decrease, and using galvanized pipes is very expensive, and in terms of sanitary indicators it is significantly inferior to PVC pipes. By the presence of anti-corrosion coating: By wall thickness: In addition to these parameters, the consumer can choose the type and presence or absence of threads, pipe length and other parameters, which actually explains the popularity of this material. The use of pipes for installing gas pipelines remains unchanged, and even then, increasingly, the metal pipeline ends after entering the apartment, since it is now allowed to use flexible hoses to connect gas stoves.

This is interesting: Description of steel 40X

The pipe is made of durable steel and is used in public utilities and in various fields of production. All products have a passport, which indicates the norms and standards of the product, the results of tests and trials. A hollow pipe is not inferior in rigidity to a solid metal rod, therefore it is quite often used not only for its intended purpose. For cold water pipelines, a medium-reinforced pipe is used, and then mainly to counteract hydraulic shocks, but gas pipelines are installed from light pipes. High-precision pipes are used for the manufacture of valves, valves, and other fittings.

The production of VGP pipes is regulated by the provision “Steel pipes GOST 3262-75”, which provides for a fairly large range of these products. Water and gas pipes (WGP) at low cost. Electric-welded metal pipe VGP. The connection of seam pipes is carried out both by welding and mechanically through a coupling. Reinforced products are used to transmit hot water, steam, and compressed air. For pipes connected by welding, the outer diameter ranges from 10.2 to 165 millimeters, the nominal diameter ranges from 6 to 150 millimeters, and the weight of one linear meter of pipe ranges from 0.37 to 21.63 kg.

One of the main characteristics is the strength of the pipes relative to the withstand pressure; they are divided into light, regular and reinforced; the choice of one or another material depends directly on the transported medium. If a manufacturer uses its own standards (TU) for production in order to reduce the cost of the product, then this must be indicated in the passport. Electric welded steel pipe is the most commonly used type of pipe for the transmission of water and gas, produced by rolling rolled sheets into a cylinder and further welding. Application. Since pipelines are qualified as vessels operating under pressure, the use of products at civil and industrial sites of increased danger, developed taking into account any other regulatory documents except GOST 3262-75, which regulates everything, including the steel grades used, is strictly prohibited. The standard regulates the maximum test pressure values: for ordinary and lightweight pipes up to 2.4 MPa, for reinforced pipes the pressure value is 3.1 MPa.

The pipes in the system are assembled by welding, which is why the pipes are called electric welded. Pipes can be thick-walled, medium-sized or thin-walled, some of them are galvanized, others are not. Cutting can be done externally with dies or internally with taps; if large volumes of threads are required, cutting can be done on lathes. VGP pipe. A VGP pipe is a cylindrical hollow product made from various grades of steel, including stainless steel, intended for use in energy production and distribution systems. Seamless - characterized by increased resistance to hydraulic shock due to the absence of a welded seam, used mainly in heating systems.

Frame structures are welded from pipes - these are well-known greenhouses, hangars, sheds, light structures; it is used as electrical wiring. In water supply systems, metal pipes are increasingly used only on main lines where a large diameter is required. Depending on their purpose, conventional and lightweight reinforced pipes are used. VGP pipes are used to transport cold and hot water, compressed air, steam, natural gas and other liquid and gaseous media, the chemical composition of which does not affect the integrity of the pipeline walls. The fact is that gas, even despite the moisture content in it, has little effect on the corrosion process from the inside, and if the outside of the pipeline is regularly painted, it will not be replaced soon. Such electrical wiring reduces the risk of electric shock, since the metal body of the pipe also serves as a grounding connection. Technical characteristics of VGP metal pipes, pipe price.

Electric welded pipe or VGP

It is used not only for the transmission of water and gas, but also as a building element. The pipe has a hollow structure, it is stable and in terms of rigidity it can easily replace a metal beam. VGP pipe (Water-Gas-Pipe) - these pipes are used to create heating, water supply and gas pipeline systems. The diameters of VGP pipes are determined according to the assortment, and this also determines the limits on weight and size. In water supply systems where cold water is used, pipes of the usual type are used, and for the transmission and transportation of gas, light pipes are used. Before buying a steel pipe, you must inquire about the passport data, which must indicate the results and date of the hydraulic tests carried out during the production of pipe rolling.

It is connected exclusively using electric welding without the possibility of threading. Types of water and gas pipes, which pipe to buy. A welded steel pipe is obtained by welding a metal sheet in the form of a cylinder. Regular and lightweight pipes are tested at a maximum pressure of 2.4 MPa, reinforced type pipes at a pressure of 3.1 MPa. The hollow design allows alarm and electrical wires to be laid in pipes, protecting them from damage and deformation.

It is a hollow cylindrical product used to supply hot and cold water, steam and gas. Since the weight of the pipe itself is small, it is quite often used to create frame structures, for example, greenhouses. Round pipes are also constantly used for electrical installations; a lightweight version is used here; to protect electrical wiring or alarm wires, lines are laid on top, along the walls of buildings, or in the ground, the pipe body supports the weight of the soil and the cables remain undamaged. Pipes connected using threads are limited in outer diameter from 16 to 74 millimeters, wall thickness ranges from 2 to 3.2 millimeters, while a meter of pipe weighs from 0.69 to 5.59 kilograms. Reinforced ones are used in compressed air systems, steam pipelines and hot water supply pipelines, as well as in boiler piping.

Standards and restrictions when laying pipes

SNiP 42-01-2002 regulates the construction of gas pipeline structures serving the end consumer. The rules are mandatory, as they ensure fire safety and compliance with sanitary standards.

In the apartment

Flexible gas hoses must be less than 3 meters.

The gas pipe is laid according to a pre-developed scheme. Its task is to supply fuel to gas equipment: stove, boiler, boiler. Usually all equipment is placed in the kitchen. Installation rules in homes are very strict:

- installation in residential premises or ventilation ducts is strictly prohibited;

- crossing window or door openings is not allowed;

- the gas pipeline can only be laid in rooms with a height of at least 2.2 m, well ventilated or equipped with ventilation;

- the distance from the pipe to the floor is at least 2 m;

- if structures with flexible hoses are used, their length should be less than 3 m;

- surfaces near gas appliances are insulated or finished with panels that are insensitive to temperature;

- Installation of a gas pipeline in a wall or behind decorative trim is prohibited; it must be freely accessible.

When designing gas supply, a gas meter is provided.

In a private house

The higher the pressure in the gas pipeline, the farther it is installed from the house.

Inside the building, they are guided by the rules described above. When laying an external gas pipeline, follow the following recommendations:

- The higher the pressure in the supply gas pipeline, the further it is laid from the house. The distance between the low pressure circuit and the foundation of the house is at least 2 m. If a medium pressure line runs next to the building, the distance increases to 4 m.

- There must be at least 50 cm from the gas pipeline to the door or window opening.

- From the pipe to the roof is at least 20 cm.

- A plastic gas pipeline is laid underground. Steel allows both above-ground and underground installation.

The fewer turns and bends the gas circuit includes, the more reliable it is.

Directory of rolled metal products

There are two types of water and gas pipes - black water and gas pipes and galvanized water and gas pipes. Their main difference is the presence/absence of a galvanized coating, thanks to which the water and gas pipe acquires amazing anti-corrosion properties and becomes more resistant to aggressive external factors. Practice shows that non-galvanized pipes are lighter than galvanized pipes by an average of 3 percent.

Possessing high strength, excellent performance characteristics and a relatively simple manufacturing procedure, water-gas pipes are widely used today not only in construction for heating distribution and supplying household gas, but also in mechanical engineering, aircraft manufacturing, the automotive industry, the agricultural industry, and in the construction of various types of metal structures.

As a rule, water and gas pipes are used together with such additional products as bends, tees, valves, bends, transitions, barrels, plugs and other pipeline fittings.

Depending on the length, the water-gas pipe can be of measured length or unmeasured in the range from 4 to 12 meters. If we are talking about measuring pipes, then an allowance of 5 millimeters is allowed for each cut and a longitudinal deviation over the entire length of about 10 millimeters. In the case of unmeasured pipes, subject to an agreement between the manufacturer and the consumer, it is allowed to have up to 5 percent of pipes in one batch, the length of which ranges from 1.5 to 4 meters.

The accuracy criterion also affects the classification of water and gas pipes. And here there are two types of pipes:

Water and gas pipes of standard precision (manufactured from steels that comply with GOST 1050 and GOST 380).

High precision water and gas pipes (made from steel that complies with GOST 1050).

Products of the first group are in most cases used for the construction of gas pipelines, water pipelines and heating systems. The latter find their application in the production of parts for gas and water supply structures.

This is interesting: Classification of metal threads

The letters after the word “pipe” in the symbol deserve special attention.

Thus, a water-gas pipe with a length of thread is designated by the letter “D”, a water-gas pipe going under thread rolling is marked by the letter “N”, and the letter “P” placed after the size of the nominal bore indicates a pipe with increased manufacturing precision.

When producing water and gas pipes, small deviations in weight (maximum 8 percent) and curvature are allowed. At the request of the consumer, maximum mass deviations for a batch should not exceed 7.5 percent, and for an individual pipe - 10 percent. If we talk about curvature, then it does not go beyond 2 millimeters per meter of pipe length (if there is a nominal bore up to 20 millimeters inclusive) and beyond 1.5 millimeters if the nominal bore exceeds 20 millimeters.

| Name | Diam. mm. (int.) | Thickness Art. mm. | Length mm. | Unit change | Weight 1m, kg |

| Water and gas pipe | 15 | 2,5 | 6000-8500 | tn. | 1,16 |

| Water and gas pipe | 15 | 2,8 | 6000-8500 | tn. | 1,28 |

| Water and gas pipe | 20 | 2,5 | 6000-8500 | tn. | 1,5 |

| Water and gas pipe | 20 | 2,8 | 6000-8500 | tn. | 1,66 |

| Water and gas pipe | 25 | 2,5 | 6000-8500 | tn. | 1,39 |

| Water and gas pipe | 25 | 2,8 | 10000 | tn. | 2,12 |

| Water and gas pipe | 25 | 3,2 | 10000 | tn. | 2,39 |

| Water and gas pipe | 32 | 2,8 | 10000 | tn. | 2,73 |

| Water and gas pipe | 32 | 3,2 | 10000 | tn. | 3,09 |

| Water and gas pipe | 40 | 3 | 10000 | tn. | 3,38 |

| Water and gas pipe | 40 | 3,5 | 10000 | tn. | 3,84 |

| Water and gas pipe | 50 | 3 | 10000 | tn. | 4,22 |

| Water and gas pipe | 50 | 3,5 | 10000 | tn. | 4,88 |

| Water and gas pipe | 65 | 4 | 6000 | tn. | 7,05 |

| Water and gas pipe | 80 | 4 | 6000 | tn. | 8,34 |

| Water and gas pipe | 100 | 4 | 10000 | tn. | 10,65 |

| Water and gas pipe | 100 | 4,5 | 10000 | tn. | 12,15 |

Parameters of water and gas pipes (GOST 3262-75)

| DU Symbol. | Outer diameter, mm | Lungs | Regular | Reinforced | ||||||

| Wall thickness, mm | Weight 1m, kg | Meters per ton | Wall thickness, mm | Weight 1m, kg | Meters per ton | Wall thickness, mm | Weight 1m, kg | Meters per ton | ||

| 6 | 10,2 | 1,8 | 0,37 | 2681,8 | 2,0 | 0,40 | 2472,5 | 2,5 | 0,47 | 2106,4 |

| 8 | 13,5 | 2,0 | 0,57 | 1763,0 | 2,2 | 0,61 | 1631,1 | 2,8 | 0,74 | 1353,4 |

| 10 | 17,0 | 2,0 | 0,74 | 1351,6 | 2,8 | 0,98 | 1019,8 | 2,8 | 0,98 | 1019,8 |

| 15 | 21,3 | 2,5 | 1,16 | 862,7 | 2,8 | 1,28 | 782,8 | 3,2 | 1,43 | 700,1 |

| 20 | 26,8 | 2,5 | 1,50 | 667,5 | 2,8 | 1,66 | 603,4 | 3,2 | 1,86 | 536,9 |

| 25 | 33,5 | 2,8 | 2,12 | 471,7 | 3,2 | 2,39 | 418,2 | 4,0 | 2,91 | 343,6 |

| 32 | 42,3 | 2,8 | 2,73 | 366,6 | 3,2 | 3,09 | 324,1 | 4,0 | 3,78 | 264,7 |

| 40 | 48,0 | 3,0 | 3,33 | 300,4 | 3,5 | 3,84 | 260,3 | 4,0 | 4,34 | 230,4 |

| 50 | 60,0 | 3,0 | 4,22 | 237,1 | 3,5 | 4,88 | 205,1 | 4,5 | 6,16 | 162,4 |

| 65 | 75,5 | 3,2 | 5,71 | 175,3 | 4,0 | 7,05 | 141,8 | 4,5 | 7,88 | 126,9 |

| 80 | 88,5 | 3,5 | 7,34 | 136,3 | 4,0 | 8,34 | 120,0 | 4,5 | 9,32 | 107,3 |

| 90 | 101,3 | 3,5 | 8,44 | 118,5 | 4,0 | 9,60 | 104,2 | 4,5 | 10,74 | 93,1 |

| 100 | 114,0 | 4,0 | 10,85 | 92,2 | 4,5 | 12,15 | 82,3 | 5,0 | 13,44 | 74,4 |

| 125 | 140,0 | 4,0 | 13,42 | 74,5 | 4,5 | 15,04 | 66,5 | 5,5 | 18,24 | 54,8 |

| 150 | 165,0 | 4,0 | 15,88 | 63,0 | 4,5 | 17,81 | 56,1 | 5,5 | 21,63 | 46,2 |

Water and gas pipes are widely used in the installation of water supply, gas and heating systems in residential buildings. Galvanized water and gas pipes are used for installation in aggressive and humid environments, as well as for the manufacture of various structures, machines and mechanisms.

In fact, this type of pipe has become the basis for the work of not only the entire gas service, but also the entire public utility sector. Without them, today it is impossible to put into operation either residential or industrial facilities. All pipes have a specified service life, after which they are replaced with new ones as planned. This is due to the peculiarity and enormous importance of the media transported through them for the life support of residential areas.

Any damage to the integrity of the pipe can lead to a leak of natural gas, hot or cold water. Of course, these accidents differ from each other in terms of the level of danger, but the way to prevent them is the same: timely replacement of water and gas pipes with new ones.

At the same time, old dismantled pipes often do not have any external damage, and their level of wear allows for further use in less critical areas of the national economy. For example, in agriculture for the construction of irrigation systems, or in the manufacture of various landscape structures, gazebos, benches and fences.

Water and gas pipes are made from metal blanks, called strips, by special molding and further welding of the seam. For this purpose, ordinary carbon steel is used without further heat treatment. All water and gas pipes are manufactured using electric welding and mandatory quality control of the weld. It is the seam, as a source of increased danger to the integrity of the entire pipeline, that receives increased attention. To do this, an X-ray examination of its surface is carried out.

Water and gas pipes vary in size. In construction and public utilities, almost the entire range of products of this name is used at the same time. By the way, prices for pipes are based on their weight, or rather per ton.

The dimensions of water and gas pipes are determined by the nominal diameter, expressed in millimeters or inches. In this case, the external size of the pipe remains unchanged, and only the size of the nominal diameter and the wall thickness of the product change. The length of finished products can range from four to twelve meters. In this case we are talking about the measured length. If the pipes have a length from 1.5 meters to 11.5 meters, then we are talking about an unmeasured length. In addition, pipes can have a length that is a multiple of the measured length with a seam allowance of 5 mm. All this allows you to select pipes in accordance with the intended further use. It is more convenient to use ready-made pipes without cutting them specially.

All products are manufactured in accordance with GOST. For ease of installation, cylindrical threads are applied to both ends of the pipe. The pipes are connected using special couplings or welding.

Our country not only produces water and gas pipes in quantities sufficient for domestic consumption, but also supplies them to the foreign market. When choosing such pipes, you should know that a galvanized water pipe weighs three percent more than a black pipe of the same diameter.

In the production of water and gas pipes, a distinction is made between products of normal precision and products with an increased level of precision. In the first case, we are talking about the installation of water supply or heating systems, and in the second case, about the use of pipes in the manufacture of various structures. When marking finished products, the letter “P” must be added, which means increased accuracy of the pipe diameter. These pipes also differ in wall thickness. Accordingly, there are products with a thin wall, called light, or with a thick wall, called reinforced pipes.

Production of VGP

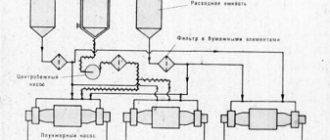

Galvanized VGP pipes are made from metal strips by direct welding. Strips are a long steel strip that is packaged in rolls. To begin production, the strips are delivered to the workshop in the form of a roll, and then unwinding is performed. On average, several hundred meters of metal are obtained from one strip. Sometimes a manufacturer buys strips that have a large width (say, because of the low price). Wide strips are cut on slitting machines to obtain a workpiece of the required width).

Before production, the strips are unwound and fixed on conveyor platforms. When the workpiece reaches its end, its edge is welded to a new workpiece. This ensures uninterrupted operation of the production workshop. Welding of the ends is carried out using a device called a looper or accumulator. The actual production is carried out in two stages.

Forming stage

At this step, rectangular sheets of the desired size are formed from metal strips. After all, the thickness of the strips may be too large, so it needs to be reduced. To form strips, rollers are used, when passing through them the thickness of the product decreases. To obtain a product of the required thickness, it is necessary to pass through several forming shafts. When passing through the shafts, the strips change their shape and bend. This leads to their rounding (the more shafts, the more rounded the strip is). After passing through all the shafts, an almost round pipe blank with smooth edges is formed.

Welding stage

After passing through the forming rollers, the edges of the metal strips must be welded to form a cylindrical hollow tube. Large metallurgical and manufacturing plants usually use electric arc welding because it is accurate and reliable. Before welding, the edges of the workpiece can be melted using an electric current. This ensures higher quality welding, which has a positive effect on the shelf life of the product. Welding works like this: the edges are melted using electricity, and then the half-formed object is passed by a fixed welding machine, which forms the seam (but not vice versa).

After welding, the product is sent to the storage workshop for drying. After the weld has cooled slightly, initial inspections are performed (usually using an ultrasonic flaw detector). If there are defects, the VGP is sent for re-processing. Even the smallest cracks and welding errors can pose a danger during VGP operation. To obtain the product of the required length, the pipe is cut.

Quality control

If necessary, hardening, strengthening, heat treatment of the seam and other operations are performed. At the customer's request, additional measures can be carried out - control, hydroscaling, hydrotesting and others:

- An ultrasonic flaw detector is used for testing - it allows you to obtain information about the surface of the material. There is no practical benefit in this procedure, since flaw detection is often carried out immediately after welding the edges, and after cooling, the seam rarely changes its shape. However, re-inspection may be warranted when assembling large pipeline systems that will transport gas under high pressure. Repeated control may be justified if the VGP will be laid in the territory of flammable facilities (say, in industrial workshops).

- Hydroscaling is a procedure in which various debris is removed from the inner surface. Typically, the debris is scale, which is actively formed during welding (scale is small particles of metal oxides that are formed when metal comes into contact with oxygen during welding air heating). Descaling is typically performed using a high-pressure stream of water to remove even the smallest particles of debris.

- After descaling, a hydrotest is performed. To do this, a stream of water under high pressure (>150 atmospheres) is pumped into the insulated product. Hydrotesting is another reason why repeated ultrasonic flaw detection has no practical meaning. After all, hydrotesting will already show whether the product will be of high quality or not. After hydrotesting, a layer of paint or sealant is applied to the product.