Underground pipeline communications have become an indispensable attribute of engineering systems of modern megacities. Due to the lack of free space underground, sewer networks, water supply lines, heating mains, and pipe distribution of electrical cables are located. Over time, the task of replacing worn out pipelines or repairing them arises. In dense urban areas, digging a trench or foundation pit for repair work is very difficult, and sometimes even impossible. Therefore, trenchless installation of utility networks became a real technical breakthrough and helped solve a lot of problems of a big city.

General provisions

1.1.

The policy regarding the processing of personal data (hereinafter referred to as the Policy) is aimed at protecting the rights and freedoms of individuals whose personal data is processed by Podzemny Expert LLC, hereinafter referred to in the text as the Operator. 1.2. The policy was developed in accordance with clause 2, part 1, art. 18.1 of the Federal Law of July 27, 2006 No. 152-FZ “On Personal Data” (hereinafter referred to as the Federal Law “On Personal Data”).

1.3. The Policy contains information subject to disclosure in accordance with Part 1 of Art. 14 Federal Law “On Personal Data”, and is a publicly available document.

1.4. The policy states:

- purposes of processing personal data;

- grounds for processing personal data;

- categories of personal data subjects;

- terms of processing and storage of personal data;

- transfer of personal data to third parties;

- information about the processing and security of personal data;

- rights of personal data subjects.

1.5. The operator operates at the address: 192102, St. Petersburg, Fuchika street, no. 4, lit. K, room 16N.

1.6. Olga Evgenievna Korotkova (phone 8(812)3250565, e-mail) was appointed responsible for organizing the processing of personal data.

Insulation of sewer pipeline

The efficiency and durability of external sewerage largely depends on properly performed insulation

This is especially important in northern regions and when pipes are laid above the freezing level. To understand how important insulation is, you need to imagine how the system works in the cold season

During the passage of liquid, which always has a positive temperature, the pipe is partially filled with liquid waste. Water vapor also fills the pipe.

In winter, at subzero temperatures, the part of the pipe located closer to the surface cools, which leads to the formation of condensation, and then frost, which rushes to the center of the pipe, which often causes blockages.

Molded insulation is selected based on the diameter of the pipe, before laying the sewer line, it is simply put on top

Insulation materials can be rolled or molded. The first are wound onto the pipe while it is being laid in the basement. Thermal insulation shell made of foamed polyethylene has a similar application.

They are not used as thermal insulation for underground lines. Mostly molded insulation is used, which is made for a specific pipe diameter. Thermal insulating material of the required diameter is simply placed over the sewer pipe.

One of the most popular insulation materials is Energoflex, which is made from extruded polystyrene foam. The closed cell structure of the material prevents the penetration of groundwater, which can significantly reduce the insulating properties. Foil casing enhances efficiency

If the temperature in the region is very low, then insulation alone is unlikely to be a reliable protection of pipes from freezing. In this case, a heating cable is usually used, which is laid along the outside of the pipe inside the heat-insulating material.

When using a heating cable, you need to ensure that the joints are completely sealed to prevent moisture from leaking inside.

Terms and definitions used

2.1. Personal data - any information relating to a directly or indirectly identified or identifiable individual (subject of personal data).

2.2. Operator - a state body, municipal body, legal or natural person, independently or jointly with other persons organizing and (or) carrying out the processing of personal data, as well as determining the purposes of processing personal data, the composition of personal data to be processed, actions (operations) performed with personal data.

2.3. Processing of personal data - any action (operation) or set of actions (operations) performed using automation tools or without the use of such means with personal data, including collection, recording, systematization, accumulation, storage, clarification (updating, changing), extraction, use, transfer (distribution, provision, access), depersonalization, blocking, deletion, destruction of personal data.

2.4. Providing personal data - actions aimed at disclosing personal data to a certain person or a certain circle of persons.

2.5. Destruction of personal data - actions as a result of which it becomes impossible to restore the content of personal data in the personal data information system and (or) as a result of which material media of personal data are destroyed.

2.6. Blocking of personal data is a temporary cessation of processing of personal data (except for cases where processing is necessary to clarify personal data).

What is trenchless pipe laying and how does it work?

The essence of the method is to draw a highway under the surface of the earth, as opposed to digging surface trenches, which have the following disadvantages:

- Removing soil leads to the destruction of the upper fertile layer not only in the trench, but also by special equipment, as well as to contamination of the surrounding area, which significantly increases the scale of damage.

- With the trench method, plantings (trees, shrubs) are damaged, which cannot always be restored.

- When carrying out work on asphalt roads and pedestrian roads, the asphalt coating is destroyed, the use of the roads becomes impossible and further repairs are required - this brings inconvenience and is not economically profitable.

The advantages of the trench method include the simplicity of the technology, available in households, and the prevalence of the equipment used; also, digging trenches does not require highly qualified workers.

When using the trenchless method, installation and laying of the pipeline is carried out using drilling equipment, pass-through units, hydraulic and pneumatic punches.

Purposes of processing personal data

3.1. The operator processes personal data for the following purposes:

3.1.1. for the execution of a contract to which the subject of personal data is a party;

3.1.2. establishing feedback for processing incoming requests from individuals for the purpose of providing information and consulting services, advertising services, including sending notifications and requests;

3.1.3. to promote the Operator’s information services on the market by making direct contacts with the subject of personal data using communication means;

3.1.4. conducting personnel work and organizing records of the Operator’s employees;

3.1.5. attracting and selecting candidates to work for the Operator;

3.1.6. identification of a visitor to the Operator’s website – https://undergroundexpert.info/;

3.1.7. providing website visitors with information about the company and the services provided;

3.1.8. to achieve the goals provided for by an international treaty of the Russian Federation or law, to implement and fulfill the functions, powers and responsibilities assigned by the legislation of the Russian Federation to the Operator;

How to make a puncture yourself

In domestic conditions, if it is necessary to lay an underground water supply or small-diameter gas line into a house over a short distance, industrial penetration techniques can be used.

One of the effective types is hydropuncture of a hole in the ground; to carry out the following work proceed as follows:

- Take metal pipes of the required diameter of 1 m (a large pipe length will require too large a work area) for the entire length of the hole and cut threads on them from one end, and weld couplings with internal threads of the same cross-section and pitch to the other.

- To supply water, a submersible or surface electric pump is used using an adapter coupling, one end of which is attached to the pipe end, and the output pipe of the pump unit is connected to the other.

- Dig a hole in the ground of the required depth and length, allowing you to conveniently place a steel meter of pipe in it for pushing.

Rice. 8 Do-it-yourself hydraulic piercing - equipment

- They calculate the well's trajectory in advance, connect the pipe to an electric pump, supply water and begin to push it into the ground, controlling the direction and vertical deviation using the building level.

- After deepening the first pipe, turn off the electric pump, disconnect its pipe and screw the second pipe onto the thread, connecting the electric pump from the other end and supplying water to it.

- The operation is repeated periodically until the channel is completely passed to the required length; upon completion of the work, the pipeline is removed and dismantled.

- A HDPE water pipe is inserted into the canal, taken to the desired location, and the work is considered complete.

To vertically lay a shaft in a house, a homemade drill is used, the length of which also depends on the depth of the line; it is turned using a drill or hammer drill.

Homemade drilling devices can also be used for horizontal drilling at home, while the drill is rotated using a power tool, lengthening it with metal rods with a threaded connection.

Rice. 9 DIY horizontal drilling

Trenchless pipeline laying is an effective method for solving problems in cases where digging trenches is impossible or economically infeasible. When carrying out work, a wide range of industrial methods are used using special equipment; some technologies can be successfully used in everyday life.

Grounds for processing personal data

4.1. The legal basis for the processing of personal data is:

4.1.1. Legislation of the Russian Federation in the field of personal data

based on the Constitution of the Russian Federation and international treaties of the Russian Federation and consisting of Federal Law of July 27, 2006 No. 152-FZ “On Personal Data” and other federal laws defining cases and features of the processing of personal data;

4.1.2. consent to the processing of personal data, the conditions of which are confirmed

by the subject of personal data in writing, when working with the feedback form on the Operator’s website, when using the Operator’s website;

4.1.3. any agreements concluded by the Operator, annexes to these agreements.

The advantage of trenchless technology

The main advantages and advantages of this technology, due to which preference should be given to trenchless pipeline laying, are:

- Compared to the open method of laying utilities, the trenchless method will require a significantly smaller amount of material and technical resources.

- Reduced work completion time due to the absence of excavation work and high installation speed.

- The laying of pipelines is provided by a team of workers consisting of three to four workers.

- The technology of laying a pipeline without trenches does not cause damage to the surrounding area.

- Possibility of laying and repairing communications at any time of the year. If in winter it is very difficult to change and lay utility networks in an open way, then trenchless technology is successfully used in conditions of frozen soil.

- Safety of installation.

- Reducing environmental pollution several times.

Another important argument in favor of this technology is the elimination of additional costs for restoring the integrity of the asphalt pavement, removing soil and reconstructing the disturbed adjacent territory.

Terms of processing and storage of personal data

6.1. The processing of personal data is terminated by the Operator upon achievement of the goals of such processing, as well as upon expiration of the period provided for by law, contract, or consent of the subject of personal data to the processing of his personal data. When the subject of personal data withdraws consent to the processing of his personal data, processing is carried out only to the extent necessary for the execution of contracts concluded with him and for the purposes provided for by the legislation of the Russian Federation.

cars and equipment

The laying of utility lines can be carried out using various methods, but their basic principle is the same: it is necessary to create certain efforts to push through the pipe lines. Therefore, the most commonly used are:

- Installations for trenchless pipe laying on pneumatic wheels or on caterpillar tracks;

- Hydraulic jacks;

- Welding machines for joining tubular elements;

- Tractors and bulldozers;

- Drive diesel oil stations;

- Main equipment: well reamers, pipes of the required diameter, rods;

- Additional equipment: surveillance cameras and monitors, remote control panels;

- Mortar mixing plants.

Laying pipeline systems without constructing trenches and foundation pits seemed like a pipe dream several decades ago. With the development of technological progress, the situation has changed dramatically and now we can safely say that this technology has a great future and enormous opportunities.

Transfer of personal data to third parties

7.1. To achieve the purposes of processing personal data and with the consent of the subjects of personal data, the Operator provides personal data or entrusts their processing to the following persons:

7.1.1. government agencies;

7.1.2. individuals who are in labor and civil relations with the Operator's counterparties;

7.1.3. to individuals who are in labor and civil legal relations with the Operator.

7.2. In order to fulfill contractual obligations or requirements of federal law, the Operator receives personal data from the following third parties:

7.2.1. Other persons in accordance with a civil law agreement.

7.3. The processing of personal data is carried out in compliance with confidentiality, which means the obligation not to disclose to third parties or distribute personal data without the consent of the subject of personal data, unless otherwise provided by the legislation of the Russian Federation.

Features of sewerage in a private house

To make life outside the city comfortable, it is necessary to provide it not only with cold water, but also with sewerage. When building a new house, the laying of pipes for cold water and sewerage (like other utility networks) occurs at the stage of constructing the foundation. But if the house was built several years ago, and the opportunity to install a sewer system only recently appeared, you have to use special equipment.

Laying pipes in a private house is not a big problem. Usually, for this purpose, a trench is dug into which the pipe itself is laid. However, if digging a trench is not desirable (to avoid breaking up a cement yard or spoiling a garden with expensive and valuable plants), the no-trench pipe laying method is used.

When laying pipes in a country house, take into account the temperature of the drains and their daily volume; the cross-sectional diameter of the pipe and the materials from which it should be made will depend on this. Most often, sewer pipes with a diameter of 110 mm made of polypropylene are used in household plots (it can withstand sewer water temperatures of up to 80 degrees Celsius). When laying a pipeline using puncture technology, for example, under a busy road, experts recommend using double-layer pipes with a corrugated surface.

Private house pipeline

If it is possible to connect to the main sewer system, do not forget to take into account its depth. This will determine not only the depth at which the sewerage system will pass through the site, but also the maximum possibility of its slope. This information, as well as permission to connect, can be obtained from the organization that services this highway. Otherwise, you will have to dig a cesspool, having previously calculated its depth and dimensions. Usually, when a sewer pipe exits into a septic tank, it is laid at a meter depth.

Remember that laying a sewer pipe without digging a trench will require the use of special equipment, which may affect the final cost of laying sewer in a private house.

Information about the processing of personal data

8.1. The Operator processes personal data on a legal and fair basis to fulfill the functions, powers and duties assigned by law, to exercise the rights and legitimate interests of the Operator, the Operator’s employees and third parties.

8.2. The operator receives personal data directly from the subjects of personal data.

8.3. The operator processes personal data in automated and non-automated ways, with and without the use of computer technology.

8.4. Actions for processing personal data include collection, recording, systematization, accumulation, storage, clarification (updating, changing), extraction, use, transfer (distribution, provision, access), depersonalization, blocking, deletion and destruction.

8.5. Databases of information containing personal data of citizens of the Russian Federation are located on the territory of the Russian Federation.

8.6. The operator has the right to entrust the processing of personal data to another person with the consent of the subject of personal data, unless otherwise provided by federal law.

Such processing of personal data is carried out only on the basis of an agreement concluded between the Operator and a third party, which must define:

- a list of actions (operations) with personal data that will be performed by a third party processing personal data;

- purposes of processing personal data;

- obligations of a third party to maintain the confidentiality of personal data and ensure their security during processing, as well as requirements for the protection of processed personal data.

Advantages of trenchless pipeline laying

The most common method of laying pipeline structures is trench. However, this installation option has its disadvantages, which include:

- digging up the soil entails disruption of the fertile layer;

- elimination of trees and other plantings;

- high cost of installation work;

- long preparatory stage.

Note! When the pipeline channel passes through the road surface, destruction of the asphalt cannot be avoided, so after the work the road will have to be reconstructed. In addition, if it is a fairly busy section of the road, then blocking it may be difficult. In such cases, trenchless (closed) communication installation comes to the rescue.

The trenchless method has the following advantages:

- less material resources are required to carry out work;

- high speed of installation;

- minimum number of workers;

- environmentally friendly;

- the possibility of laying pipes all year round (installation of pipes using open methods in winter is difficult due to frozen soil);

- work safety.

For trenchless pipe laying, it is enough to dig a small pit

If the pipe installation is carried out on a small section, for example, under the road surface, then all the work can be completed without the use of special equipment. This wiring is quite simple. It requires a cylinder of the required diameter and an extendable rod. Thanks to this device, it becomes possible to remove soil manually, however, before this, work is done to dig small pits on both sides of the road. For closed installation over large areas, special machines and units are used.

Information about ensuring the security of personal data

9.1. The operator appoints a person responsible for organizing the processing of personal data to fulfill the duties provided for by the Federal Law “On Personal Data” and the regulatory legal acts adopted in accordance with it.

9.2. The operator applies a set of legal, organizational and technical measures to ensure the security of personal data to ensure the confidentiality of personal data and their protection from unlawful actions:

9.2.1 provides unlimited access to the Policy, a copy of which is posted on the Operator’s website at https://undergroundexpert.info;

9.2.2 in pursuance of the Policy, approves and puts into effect internal local acts;

9.2.3 familiarizes employees with the provisions of the legislation on personal data, as well as the Policy and internal local regulations;

9.2.4 provides access to employees to personal data processed in the Operator’s information system, as well as to their material media only for the performance of job duties;

9.2.5 establishes the rules for access to personal data processed in the Operator’s information system, and also ensures registration and accounting of all actions with it;

9.2.6 assesses the harm that may be caused to personal data subjects in the event of a violation of the Federal Law “On Personal Data”;

9.2.7 identifies threats to the security of personal data during their processing in the Operator’s information system;

9.2.8 applies organizational and technical measures and uses information security tools necessary to achieve the established level of personal data security;

9.2.9 detects facts of unauthorized access to personal data and takes response measures, including restoration of personal data modified or destroyed due to unauthorized access to it;

9.2.10 carries out internal control of compliance of the processing of personal data with the Federal Law “On Personal Data”, regulations adopted in accordance with it, requirements for the protection of personal data, Policy, Regulations and other local acts, including control over measures taken to ensure the security of personal data and their level of security when processed in the Operator’s information system.

Trenchless installation methods

The closed method of replacing pipes is used for wiring various communications. These include:

- communication cable wiring;

- installation of various pipelines (oil, gas, heating);

- wiring of sewer structures and water supply systems (cold and hot water supply);

- repair and replacement of pipes.

Today, there are several methods for trenchless pipeline laying, some have different methods of execution. The technology for trenchless pipeline laying is differentiated into the following options:

- replacing old pipes with new ones (rehabilitation);

- soil puncture;

- soil punching;

- horizontal directional drilling (HDD).

The trenchless method can be used to lay new highways and restore old networks

Rehabilitation is carried out when an existing pipeline needs to be repaired or replaced. In other cases, direct wiring of the pipeline structure takes place.

Trenchless pipe laying is quite common and its use allows you to avoid many of the problems that characterize the open installation option.

Rights of personal data subjects

10.1 The subject of personal data has the right:

10.1.1. to receive personal data relating to this subject and information regarding their processing;

10.1.2. to clarify, block or destroy his personal data if they are incomplete, outdated, inaccurate, illegally obtained or are not necessary for the stated purpose of processing;

10.1.3. to revoke his consent to the processing of personal data;

10.1.4. to appeal the actions or inaction of the Operator to the authorized body for the protection of the rights of personal data subjects or in court.

10.1.5. To exercise their rights and legitimate interests, subjects of personal data have the right to contact the Operator by sending personally or with the help of a representative a request containing the information specified in Part 3 of Art. 14 Federal Law “On personal data at the address specified in paragraph 1.5 of this Policy.

Installation of pipes using the puncture method

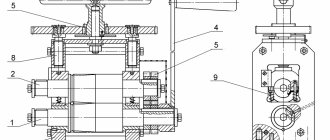

The soils in which the pipeline puncture method is used are usually clayey and loamy. This method allows you to install pipes with a cross-section of up to 600 mm. The distance over which the structure can be laid using this option reaches up to 60 m. As a result of such wiring, the soil is compacted around the pipe in a circular direction. The force required to puncture is between 150 and 3000 kN. This force is produced thanks to a special technique. The most common option for performing a puncture is using a hydraulic jack.

In most cases, to reduce friction and resistance in the soil, a cone-shaped tip is put on the pipe, the base of which protrudes about 2 cm in relation to the pipe itself. If the pipeline has a small cross-section, then the use of such a tip is not necessary. In this case, the puncture is provided by the pipe itself.

To pierce the soil, a special tip is put on the pipe

Note! If you do not use a conical tip, the puncture accuracy will be higher. This is due to the fact that when penetrating through the ground, the cone may encounter natural obstacles and deviate from the puncture line.

The puncture speed usually ranges from 4 to 6 m/h. It depends on the characteristics of the soil and the equipment that is used for this trenchless installation option. In some cases, to increase the speed of movement of the pipe, vibration is used, which, together with the force of the jack, allows it to move through the ground at a speed of 20 to 40 m/h.

In addition, there is another type of pipe laying by puncture, which is used in cases where the soil is easily washed away by water flows. This method is called hydropuncture. This installation is carried out using a stream of water. The directed flow destroys the soil and forms a well into which the communication is placed.

making a hole

installation of PE/PVC pipes

steel pipe installation

Moles are usually used for installation under all kinds of highways, highways, torrents and other types of roads (railroads, highways, etc.). Pneumatic punching machines allow you to perform work without the need for partial dismantling of the roadway and its subsequent restoration (at the end of the work). This allows you to save your budget. The trenchless method of laying communications does not entail serious losses arising from the negative impact on the environment in the form of periodic traffic jams, detours, and excessive noise. The most important thing for drivers is the integrity of the road surface. We understand perfectly well that any intervention in the homogeneous structure of the road surface will sooner or later lead to its inevitable repair in those places where the uniformity of the surface was disrupted.

An example is the photographs, which clearly show that, unfortunately, the installation work was carried out using the traditional trench method.

In these places, a trenchless method of work should be used. However, construction robots for laying communications carried out in the traditional way, as a result of intense traffic, led to a decrease in the level of the road surface in the places where the work was carried out. Over time, the sinking of the roadway will worsen, which at a certain point will lead to the impossibility of traffic on this section of the road and its further closure for repairs. To avoid the situation described, it was enough to use a pneumatic punch.

It is also necessary...

The mole requires compressed air to operate. The most commonly used portable compressors are on wheels. Delivery of such a compressor is carried out by towing the compressor behind the car. The larger the size of the pneumatic punch, the more compressed air it consumes. High-quality, powerful moles require the same amount of air as the most popular construction compressors can provide.

A typical pneumatic punch kit is shown in the illustration.

How

can you use ...

The mole is used to perform an independent puncture. Also, using a pneumatic punch, you can tighten PE and PVC pipes. You can also use a mole to drive a steel pipe into the ground. There is a lot of additional equipment that makes it possible to carry out and install almost every installation using the trenchless method.

The speed of puncture depends on the type of soil and the size of the pneumatic punch. Most often, the pneumatic punch moves at a speed of 0.5 - 1.5 m per minute.

You should know...

Work with a mole pneumatic punch is carried out at a certain depth. It is generally accepted that the minimum depth of work should be equal to 10 diameters of the pneumatic punching machine. This is due to the fact that the mole does not push the soil in front of itself, but compacts it around itself. In extreme cases, when we are dealing with compacted soil, it can lead to pushing out the soil and, as a consequence, the surface under which work is being done.

The mole is a device without the ability to control, which means that there is no possibility of controlling the pneumatic punch during the work being carried out with full penetration into the ground. The correct puncture course can be set by adjusting the position of the mole before its full penetration into the soil. However, one should not be afraid of inaccuracy and its possible consequences. The air punch is designed to cope with even the most difficult conditions. When colliding with an obstacle, it is more likely that the pneumatic punch will crush it than to deviate from the given course.

For beginners, to make it easier to operate the machine, it is recommended to use a starting platform. This simple device greatly facilitates the aiming of the air punch. The aiming itself is carried out using an optical kit, which includes pegs and an optical sight.

Practice…

Most often, punctures are performed on short sections - no more than 20 meters. However, high-quality and powerful machines are able, without much effort, to perform longer punctures, reaching 30 meters or more. Accurately performing a long piercing requires experience.

The basic configuration of the pneumatic punching machine allows you to perform an independent puncture from the entrance pit to the receiving pit. Using the cutting tip for manually tightening pipes, shown in the figure, you can manually tighten pipes with a diameter of 25 - 55mm.

Using this tip, attached to the charging and control hose, a PE/PVC pipe with a diameter of up to Ø55 mm can be manually pulled into the puncture.

It is quite popular to use a mole to tighten installation pipes directly behind the machine. For this purpose, you should equip a pneumatic punch in the pipe tightening attachment, which is attached to the back of the mole. It is necessary to use a nozzle according to the size of the pipe being tightened. For pipes with large diameters, usually 90mm or more, a system of steel cables with a tensioner is additionally used to secure the connection of the pipe to be tightened with the pipe tightening nozzle. For pipes with a smaller diameter, only a nozzle is required, equipped with a special profiled socket for attaching the pipe inserted into it.

Below, in the photo, are examples of additional equipment for the mole, which makes it possible to tighten PE/PVC pipes directly behind the machine.

A situation may arise in which it is necessary to puncture and tighten a pipe with a diameter larger than the diameter of the existing pneumatic punch. Manufacturers of pneumatic punching machines have found a way out of this situation by offering so-called expanders, otherwise known as calibrators. Expanders (calibrators) are steel pipes with a conical end, having a diameter larger than the diameter of the pneumatic punch. First, a pilot self-puncture is performed only with a mole, after which the diameter of the puncture is expanded, performing, so to speak, a second puncture, but with a pneumatic punch equipped with an expander. A simple way to install the installation is to purchase a machine with a large diameter, which makes it possible to tighten pipes with a large diameter directly behind the machine. However, buying a car is not always economically justified. It all depends on the frequency and quantity of work performed. If pulling large pipes occurs only occasionally, it is cheaper, but a little more burdensome, to carry out this type of work using existing equipment: a smaller pneumatic punch equipped with an appropriate expander.

The pneumatic punch can also be used to hammer steel pipes. Such pipes are used in water and sewerage installations as cases for pipelines or directly as a cable carrier. To perform this type of work, cones are used, when using which a pneumatic punch is placed and connected to a pipe previously prepared for driving.

Small steel pipes are driven in with the end covered by a cone. Large pipes, with a diameter of 159 mm or more, are driven open due to soil resistance during driving. After driving the pipe, the soil is removed from the pipe using a plug and a pneumatic displacer.

It is worth noting that in addition to pneumatic punches, which are characterized by great versatility, there is a group of pneumatic punching machines designed specifically for driving steel pipes - pneumatic hammers. Pneumatic hammers have a simpler design, which does not have to ensure accuracy. The hammer does not move underground; its job is to push the steel pipe being driven in front of it.

A group of pneumatic punches with a so-called movable chisel head is also available on the market. However, such moles are not intended for driving in steel pipes and working with expanders. It is necessary to remember this when searching for an effective and universal solution.

Moles, like every construction machine, require periodic technical inspections. Technical inspections are necessary and make it possible to operate the machine for several years. High-quality pneumatic punches can be used for up to 10 years. Some elements of the mole are subjected to such high loads that they require periodic replacement. A properly designed pneumatic punch reduces service and repair costs to a minimum. The cost reduction occurs due to the fact that the fragments of the pneumatic punching machine, the elements subject to consumption, do not represent a single structure with the machine, but are separate parts. An appropriate approach during service is important. A good company should provide high-level service, where maximum effort and effort is applied to each machine.

A high-quality pneumatic punch is a machine that meets all user requirements. A mole is bought once for several years. Therefore, it is worth spending a little time searching for the appropriate machine that meets the scope of work. It is also worth reading reviews from users of the pneumatic punching machine. A good manufacturer is the one who, before purchasing, will allow you to familiarize yourself with the machine and its capabilities in the natural conditions of construction work.

In addition, a high-quality pneumatic punch should be safe to operate, easy to maintain, and be environmentally friendly.

Where to start Knowledge and experience that will allow you to effectively perform both simple and the most complex work takes years to acquire. Modern machines on the market are very convenient and easy to use, so even an inexperienced worker can cope with laying standard water pipes or other types of standard work. There are printed publications devoted to trenchless working methods, and on the Internet you can find many publications and forums on this topic.

It is a proven practice of manufacturers and distributors to organize training courses on the topic of construction, maintenance, and conservation work with a pneumatic punching machine, usually associated with the transfer of the machine to the user. For beginners, the task is greatly facilitated by the use of special devices for correct pointing of the machine, created for pneumatic punching machines. These include: launch platform, optical set.

It should be remembered.

A large number of manufacturers and types of pneumatic punching machines on the market, at the initial stage, may cause difficulties in choosing the appropriate pneumatic punching machine according to the requirements. It is best to base your questions on your current needs and expectations regarding functionality, and ask any questions you may have directly to the manufacturer or distributor. This series of questions will help the manufacturer select a pneumatic punch in accordance with individual preferences, also taking into account the economic aspect of the purchase.

There is a universal set of characteristics that a pneumatic punching machine must have, which are common to all devices of this type.

The most important of them are:

Accuracy

. Without any doubt, this is one of the most important characteristics of a pneumatic punching machine. Inaccurate piercing, in addition to failing the job, can result in significant costs and expenses associated with the need to repair infrastructure damaged as a result of inaccurate piercing. For accurate aiming, the length and weight of the vehicle matter. Conscientious manufacturers, when designing a pneumatic punching machine, consider achieving the accuracy parameter to be one of the most important tasks.

Construction and durability.

features that ensure long-term use of the machine. It is worth paying attention to machines with a simple design that can withstand high-impact work. To produce moles, materials with increased resistance to hard work, corrosion, and friction in the ground should be used. Many well-known manufacturers use movable and sealing elements that are easy to design and replace, which, during mole operation, concentrate the results of work and friction in difficult conditions contaminated with sand, water and dirt. This solution requires periodic replacement of elements and at the same time limits the need for additional costs associated with the restoration or replacement of expensive mole elements, which, as a result of friction, are subject to gradual abrasion. It is worth paying attention to whether the external elements of the pneumatic punch are a single structure, to whether it is possible to dismantle individual parts of the machine, making it possible to replace only the set of parts that have worn out. This will significantly reduce the cost of servicing the pneumatic punch.

Easy to maintain.

The work is greatly facilitated by the presence of a pneumatic punch, which can change the direction of movement in a simple and quick way, and additionally in any conditions. Pneumatic mole control meets this requirement. Pneumatic control of the pneumatic punch consists of changing the direction of operation of the pneumatic punch forward/backward, carried out remotely by changing the position of the control lever located on the oiler (charging and lubricating device). Unfortunately, there are often cases of a machine colliding with an obstacle that does not allow work to continue in this place. A situation may arise in which it will be necessary to quickly return the mole for several reasons. In such a situation, the obvious trump card is the ability to return the mole without the need to block the access of compressed air.

Environmentally friendly.

Modern pneumatic punching machines can be used in any conditions, without restrictions, including in environmentally protected areas.

Such places include: parks, areas for direct water consumption, and other public places. This is achieved by the design of the machine and the materials and technologies used, which allow the use of harmless glycol-based lubricants for lubrication. Functionality.

The type of work that can be performed using this pneumatic punching machine depends on its size. Popular in the market, typical pneumatic punching machines can tighten PE and PVC pipes with a diameter of up to 200mm. Using moles, you can drive steel pipes with a diameter of up to 406 mm into the ground. Pneumatic punches with a static chisel head are widely used. With their help, you can effectively drive steel pipes, and it is also possible to perform work with an expander. According to user groups and some manufacturers, moles with a fixed head bit perform better in typical ground conditions than machines with a moving head. Pneumatic punches with a fixed head consist of fewer moving elements that undergo thinning, which reduces the cost of replacing them.

MAX

Impact Power

A quality, well-known and highly regarded brand for over 14 years.

Thermal insulation of the sewerage system

Before laying a sewer pipe, it is necessary to take measures to insulate it naturally (in the ground), or using insulation. The depth of soil freezing in a given region is determined, the pipes are installed 30-50 cm below this level, which prevents the liquids in the pipes from freezing to ice. If it is not possible to accurately determine the depth of freezing, the pipes are additionally insulated.

Various materials are used as insulation, which are used to “wrap” pipes, or you can purchase already insulated pipes. In places with high negative temperatures, the main line is equipped with a heating cable. It is laid along the entire length of the channel.

You cannot use insulation that has not been treated with waterproofing. The material loses its properties when moisture gets into it.

It is not necessary to dig deep trenches to lay the pipeline. You can use special equipment, reducing the amount of land work and reducing the cost of the entire process.