Since 2007, we have developed, manufactured and supplied detachable fiberglass protective cases to our Customers.

As of January 1, 2021, more than 3,300 SAFIT protective cases have been installed on gas pipelines in Russia, Belarus and Kazakhstan, which confirms their reliability and high quality!

The cases are manufactured according to TU 22.21.10-010-71653326-2017 (completely identical to TU 2296-010-71653326-2011).

We make cases of any configuration and length (in multiples of 0.1 meters) according to the Customer’s project!

The SAFIT group of companies is the patent holder for the production of protective composite cases for pipelines, oil and gas pipelines, cable and fiber optic lines.

The gas pipe protective casing (GPGT) is designed to protect pipelines, oil and gas pipelines and cable lines from external loads and mechanical damage at intersections with underground structures, as well as for possible detection and removal of gas in the event of damage to the gas pipeline within the protective casing.

Case material – fiberglass. SAFIT cases are available in two types. The first is a standard, which is a monoblock split along the axis with two necks for a certain pipe diameter. The second is a composite sectional case, detachable along the axis, of any length agreed upon by the Customer. Sections of the cases, in this case, are joined to each other using a flange connection.

All protective cases undergo a full cycle of tests for strength and tightness and have a 4-fold safety margin.

The cases are manufactured according to TU 22.21.10-010-71653326-2017 (completely identical to TU 2296-010-71653326-2011), in accordance with the requirements of SP 62.13330.2011* Gas distribution systems. Updated version of SNiP 42-01-2002, passed GAZCERT certification and industrial safety examination of the Federal Service for Environmental, Technological and Atomic Supervision.

Permits

Industrial safety examination

Permission from Rostechnadzor

Approval of technical specifications by Rostechnadzor

Certificate of conformity

Permission for use in Kazakhstan

Letter from the certification center

Installation features

Practice has developed the basic rules for installing thermal insulation protection.

Installation of vertical protection begins from the bottom. If the pipeline is made with a slope, the edges of the elements are placed towards the slope.

First, bends and tees are installed, then straight parts. The bottom of the containers is covered, then the remaining parts.

The cylinder with thermal insulation is installed in such a way that the longitudinal seam is located in front of the installer, the sheet with the stiffener is placed on top.

Connect the seam overlapping with self-tapping screws at a distance of 30 cm from each other.

If the structure cannot be connected, the holes for the screws cannot be aligned, use bandage belts, pressing the edges of the cylinder.

The next shell is installed using transverse zip locks. A convex zig is mounted on a concave one. The longitudinal edges of adjacent casings are spaced apart so that they do not form one straight line.

For more reliable fastening of cylinders and bends, metal tape and bandages made of various materials are used.

This video shows a simple installation of a cylinder on a straight section:

Options for manufacturing protective cases

Detachable fixed length case 6 meters

Fixed length case - 6 meters. Designed for installation on existing gas pipelines at intersections with utilities in a limited space and does not have the ability to increase or decrease the length.

Sectional detachable case with end flanges

It is assembled from sections from 2 to 6 meters long, corner elements and endings. A special rubber seal is installed between the flanges. The flange connection is secured with M10 stainless steel bolts and allows the production of protective cases of any length and configuration to suit the customer’s dimensions.

Axially one-piece case ZFGT-NR based on SAFIT fiberglass pipes

The ZFGT-NR case, which is one-piece along the axis, is assembled on the basis of SAFIT fiberglass pipes up to 6 meters long and additional corner elements and ends. The flange connection of the corner elements and ends is secured with M10 stainless steel bolts.

Corner elements for linear cases ZFGT 150...350 with a rotation angle from 90° to 170° for the protection of gas pipelines of complex geometry.

Protective case FT

Designed to protect any communications, except gas pipelines.

The fitting is not installed on FT protective cases.

Certificate

TU 22.21.10-012-71653326-2017

Purpose and scope

The outer protective shell must be used for communications:

- heating systems;

- cold and hot water supply;

- ventilation ducts;

- underground heating mains;

- sewer pipelines.

Design standards require external insulation of such pipelines. To do this, the pipes are wrapped with special insulating materials (mineral wool, basalt wool, foam polyethylene and rubber, glass wool), and on top they construct a protective layer of aluminum, stainless steel, plastic, but most often of galvanized steel in the form of a cylindrical or shaped element.

The insulating casing is designed to solve the following important tasks:

- protect thermal insulation from precipitation and ground moisture, environmental temperature changes, and external physical influences;

- reduce heat losses in hot water supply and heating systems, maintain a given temperature in pipelines transporting food products, oil, natural and liquefied gas;

- prevent condensation from forming on the internal channel.

Nomenclature of protective cases ZFGT and FT

Marking of protective cases SAFIT: ZFGT-ХХХХ “Protective Case of a Gas Pipe with a conventional standard size XXXX” (for example, ZFGT-300, 300 is a conventional standard size of the case, indicating its unambiguous connection with the diameter of the protected section of the pipeline). Similar markings are used on FT brand cases: FT-ХХХХ. The marking is centered on the top casing of the case.

The length and configuration of the prefabricated protective case can be any and is carried out in accordance with the Customer’s project with a length increment of 0.1 meters.

The table shows the values of the main characteristics of the protective cases ZFGT and FT.

| Case size ZFGT-ХХХХ and FT-ХХХХ | Diameter of pipe with insulation Dt, mm | Case diameter Df in the working area, mm | Case weight, kg/meter |

| ZFGT-150 / FT-150 | 50/65/90 | 159 | 11,0 |

| ZFGT-200 / FT-200 | 80/120 | 219 | 12,5 |

| ZFGT-250 / FT-250 | 125/150/174 | 273 | 14,5 |

| ZFGT-300 / FT-300 | 200/237 | 325 | 16,1 |

| ZFGT-350 / FT-350 | 250/291 | 377 | 17,6 |

| ZFGT-400 / FT-400 | 300/335 | 426 | 19,5 |

| ZFGT-500 / FT-500 | 400/435 | 530 | 23,8 |

| ZFGT-600 / FT-600 | 500/532/630 | 744 | 63,2 |

| ZFGT-1000 / FT-1000 | 635/738/820 | 1024 | 92,3 |

| ZFGT-1200 / FT-1200 | 842/945/1048 | — | — |

| ZFGT-1500 / FT-1500 | 1256 | 1424 | 129,0 |

| ZFGT-1700 / FT-1700 | 1400 | 1624 | 138,0 |

Design and types

Depending on the functions performed and configuration, galvanized shells are produced in the following types:

- ordinary cylindrical sections installed on straight sections of communications;

- tees put on triple branches of pipes;

- bends protecting pipeline branches;

- detachable structures to protect pipe fittings and flanges;

- cone-shaped boxes installed on the top of the chimney or ventilation duct;

- plugs;

- zeppelin casings for protecting containers.

Protective outlet

Galvanized bends are installed on corner and rotary branches of pipelines. These parts are made from segments connected by the seam method (pictured).

They are produced in certain diameters and bending angles, which are specified by the customer.

Protective tee

A galvanized part that is installed on a three-pipe assembly. It must correspond to the dimensions of these channels, taking into account the thermal insulation layer. The insulating outer tee can be a transition if one of the pipes is of a different cross-section.

Stub transition

This part serves to tightly close the pipe. The cross-section of the plug is selected according to the outer diameter of the channel.

In some cases, rotary plugs are used, the design of which allows the channel to be temporarily closed for the period of repair or transition to a backup circuit.

Options for installing protective covers for gas pipelines at the intersection of utilities

Location of the protective cover under the highway SNiP 42-01-2002 “Gas distribution systems”

clause 5.2.1 In places where traffic and agricultural machinery are expected to move, gas pipelines are laid at a depth of at least 0.8 m to the top of the gas pipeline or casing. clause 5.5.2 The laying of an underground gas pipeline at intersections with highways of I-IV categories, as well as main city streets, should be carried out in cases. In other cases, the issue of the need to install cases is decided by the design organization.

Protective casing under tram tracks SP 42-101-2003 “General provisions for the design and construction of gas distribution systems made of metal and polyethylene pipes”

clause 4.53 Cases for gas pipelines should be provided to protect the gas pipeline from external loads, from damage at intersections with underground structures and communications, as well as to allow repair and replacement, detection and removal of gas in the event of a leak. At the same time, at the places where the gas pipeline intersects with the channels of heating networks, as well as at crossings through the railways of the general network, it is recommended to provide cases.

Protection of the gas pipeline under the railway SNiP 32-01-95 “1520 mm gauge railways”

clause 8.12 When laying underground at the intersection, the pipelines are enclosed in a protective pipe (channel, tunnel), the ends of which, at intersections with pipelines transporting explosive and flammable products (oil, gas, etc.), are located on each side of at least less than 50 m from the bottom of the embankment slope or the edge of the excavation slope, and in the presence of drainage structures - from the extreme one; at intersections with water supply lines, sewer lines, heating networks - at least 10 m.

Installation of a protective case on a gas pipeline

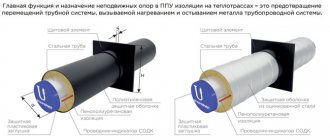

The protective case for the gas pipeline is assembled from two fiberglass casings - lower and upper, tightened together with stainless steel bolts using a rubber seal. Inside the protective case, fiberglass centralizers are installed on the gas pipeline with a pitch of 980 mm. At a distance of 500 mm from the end, a steel fitting D = 32 mm with an inch external thread is molded in the upper part for connecting a gas leakage monitoring tube.

What is it and why is it needed

It is a cylinder or shaped part made of galvanized steel with a thickness of 0.5 mm - 1 mm (pictured).

Designed to protect the thermal insulation of pipelines from the adverse effects of the external environment: rain, snow, hail, mechanical impact.

Testing cases for mechanical strength and tightness

Strength. The prototype is loaded through steel supports with a vertical load of 5.8, 8.7, 11.6 tf. At each stage, a visual inspection of the surface is performed for damage. When loading, record the magnitude of the load at the moment of contact of the protective case with the centralizers.

Tightness. We carry out complete assembly of the prototype. After installing the control tube, the case is pressure tested for tightness with a pressure of 5 kPa. The pressure drop within 5 minutes should not exceed 0.2 kPa.

approximate price

The cost of products depends on the standard sizes: diameter, length of the segment, sheet thickness. You also need to consider how much shipping will cost.

A simple straight galvanized casing with a cross-section of 101 mm, a length of 1250 mm and a thickness of 0.5 mm will cost from 150 rubles. For the same configuration with a diameter of 213 mm you will have to pay 287 rubles.

An outlet with a cross section of 101 mm and at a right angle of 4 segments is sold for 99 rubles, and with a diameter of 213 mm - for 237 rubles.

Installation of a duct for an asbestos-cement chimney

Let's look at how the casing is installed on an asbestos-cement chimney pipe:

- First of all, it is necessary to prepare the pipe for installation of heat-insulating material and duct. To do this, it is necessary to clean it from dust and dirt.

- At the second stage, you need to place the thermal insulation material in a case made of galvanized steel or roofing iron. Mineral wool can be used as a heat insulator. Thermal insulation material is located along the entire length between the casing and the pipe.

Helpful information! When choosing the cross-sectional indicator of the casing, one important factor must be taken into account, namely, the distance between the casing and the chimney pipe must be at least 6 cm. This space is necessary for the free placement of heat-insulating material.

- The upper part of the pipe is mounted with a slight slope.

- The niche between the asbestos-cement chimney and the pipe must be filled with cement mortar. Concrete grade M-150 is perfect for these purposes.

Mineral wool can be used to fill the space between the pipe and the casing

It is recommended to assemble such a case from several parts. This is a necessary measure to simplify the installation of the heat insulator.

Types of pipes in the house

Before upgrading pipes, check their type and operating features. Failure to comply with the rules for using them is fraught with unpleasant and dangerous consequences. Pipes running inside the apartment are usually divided:

| By purpose | water, gas, sewer, ventilation, heating pipes |

| By room type | in living quarters, in the kitchen, in the bathroom, toilet, corridor |

| By type of material | polymer, steel, metal-plastic, non-ferrous metals |

| By location | on the ceiling, along the wall, along the floor. |

| Towards | vertical, horizontal, diagonal |

| By size | long and short |

| By section | round, profile (rectangular) |

A number of pipes are hidden not only for aesthetic reasons, but also for their safety. For example, plastic pipes are vulnerable to mechanical damage, and steel pipes are vulnerable to corrosion. But you shouldn’t hide them “for good” (concreting them, walling them up). You may need access to them at any time to prevent or eliminate malfunctions.

Important: do not allow excessive pressure or tightening of pipes from the outside - especially in the area of connecting seams.

Each type of pipe has its own service life and nuances of use. But there are several general rules for all types of communication pipes. They are unacceptable:

- cover with a permanent box or panels that are difficult to dismantle,

- cut and move by yourself,

- leave without ventilation.

The gas pipe requires especially careful handling. Combustible and explosive materials should not be placed near it. It must not be hermetically sealed and the hoses leading to the stove must not be deformed.

Tip: It’s safest to hide the gas pipe behind a removable ventilated box or false wall made of moisture-resistant plasterboard.

Specifications

Galvanized casing designTerminology: D – diameter of galvanized casing; L – casing length; S—thickness. | Symbol for galvanized casing: Galvanized casing DL Example designation: Galvanized casing 125-500 |

Material of manufacture and color scheme

Additional elements made of metal with polymer coatings meet all requirements: they are lightweight, last a long time, and have a pleasant appearance. In production, we use only high-quality raw materials from domestic and European metal manufacturers; when joining metal sheets, professional fasteners are used, painted in the color of the element.

Materials

| Coating characteristics | POLYESTER | MATTE POLYESTER | PURAL | PLASTIZOL |

| Coating thickness, microns. | 25 | 35 | 50 | 200 |

| Corrosion resistance | * * * | * * * * | * * * * * | * * * * |

| Fade resistance | * * * | * * * * | * * * * * | * * * |

| Resistance to machining | * * * | * * * | * * * * | * * * * * |

| Minimum recommended processing (bending) temperature, °C | -10 | -10 | -15 | +10 |

| Maximum recommended processing (bending) temperature, °C | 90 | 90 | 110 | 60 |

Color spectrum

We have more than 40 metal colors in our arsenal! (attention! most monitors do not reproduce natural color)

Palette RR

| dark brown RR 32 PE, Granite HDX, Velur TM | red RR 29 Granite HDX | dark green RR 11 Granite HDX | light gray RR 21 Granite HDX |

RAL palette

| ivory RAL 1014 PE | light ivory RAL 1015 PE | yellow zinc RAL 1018 PE | red ruby RAL 3003 PE |

| red wine RAL 3005 PE, Granite HDX, Velur TM | red oxide RAL 3009 PE, Velur TM | brown-red RAL 3011 PE, Velur TM | ultramarine RAL 5002 PE |

| deep blue RAL 5005 PE, Granite HDX, Velur TM | water blue RAL 5021 PE | light blue RAL 5024 PE | green sheet RAL 6002 PE |

| moss green RAL 6005 PE, Granite HDX, Velur TM | soft green RAL 6019 PE | green chrome RAL 6020 Velur TM | mint green RAL 6029 PE |

| gray RAL 7004 PE | mouse RAL 7005 PE | graphite gray RAL 7024 Velur TM, Granite HDX | terracotta RAL 8004 Velur TM, Granite HDX |

| brown chocolate RAL 8017 PE, Granite HDX, Velur TM | white RAL 9003 PE | black RAL 9004 PE, Velur TM | white aluminum RAL 9006 PE |

Palette Solano 30

| White Solano 30 | Merlin Gray Solano 30 | Chocolate Brown Solano 30 | Juniper Green Solano 30 |

| Terracota Solano 30 | Burano Solano 30 |

A modern and functional roof is a roof that is equipped with all the necessary structural elements, in particular: original chimneys for heating and ventilation pipes, reliable additional roofing elements at the junctions and transitions of the geometry of the roof segments. For windows, we have slopes of our own production, as well as ebbs that protect the window sill space on the facade side and the foundation from dampness and rain.

Have questions? Call!

8

WHOLESALE and Retail. Delivery to the regions.

We will send a photo or video review of the product you are interested in via WhatsApp, Viber, Skype or write to email!

We also install chimneys and pipe frames.

Properties of insulating casing

Corrugated pipe casings are highly resistant to corrosion and have a long service life. Polypropylene and polyvinyl chloride do not conduct electricity. With a small wall thickness, the material is resistant to mechanical and chemical influences. The use of corrugated casings for metal-plastic pipes is most important for complex pipeline schemes. They can be bent at different angles, changing direction. The main thing is to choose a tube of the desired diameter. To do this, calculate the distance between the pipe and the corrugated wall.

Products are supplied in rolls at a cost per linear meter. The minimum weight makes it easy to transport the corrugated material to the construction site. Most often, corrugated casings for metal-plastic pipes are used when installing heating systems in residential premises, bathhouses, and industrial warehouses. The material easily withstands severe frosts, protecting pipes from damage. The main advantage is the ease of installation and operation - installation can be carried out by a non-professional. You can buy corrugated paper in Moscow in any quantity. The price per linear meter depends on the order volume.

Decor of a steel box for a chimney pipe

Pipe casings are not only functional structures, but also, as mentioned above, affect the exterior of the structure. Today you can easily order a product that will decorate your home and will delight the eye for many years. If we compare the metal box for the chimney pipe with casings made of other materials, then it is the least presentable.

However, this problem can be easily solved with the help of special decorative coatings, which can be purchased at any specialized store or ordered with home delivery using the Internet. Decorative coating for metal casings will give your box a presentable appearance. Today you can find a wide variety of colors and textures of such coatings, so everyone can choose the right option for themselves.

A decorative coating consisting of a polymer material must be applied to the metal. Polymer material imitates the structure of another material (wood, stone, etc.). The use of such decorative coatings allows you to create a brickwork pattern on a metal casing, while a real brick pipe will be reliably protected by this casing from environmental influences.

Sockets and rings for pipes in Moscow

During the process of installing flooring or finishing a wall, questions often arise about how best to route the pipes so that they are perfectly sealed and look aesthetically pleasing. After all, it is not enough to simply cut a hole of the required diameter; you need to leave an expansion gap in order to level out possible expansion of the floor or wall covering under the influence of moisture. A pipe socket will be an ideal assistant in such a situation, providing the opportunity to correctly design the hole, ensuring the required strength and aesthetic appearance.

Decorative sockets for pipes: features of choice

When purchasing a product, you should pay special attention to the following parameters:

- Diameter. It is he who determines which pipe can be used with the product.

- Design features. Pipe rings should fit comfortably and without difficulty onto technological elements, and then be firmly fixed with special latches.

- Material. Parts can be made of plastic or wood. You need to choose based on personal preferences, taking into account the materials with which the walls and floor are finished. A wooden product is better suited for parquet, a plastic product is better for linoleum. The same can be said about the color scheme.

brings to your attention a huge range of decorative rings for pipes from the world's best manufacturers, made of reinforced plastics and carefully processed wood species at a fair price. In order to purchase a product with delivery that matches the specifics of the upcoming work, contact one of our store consultants for support!

Leroy Merlin offers a wide selection of goods at low prices for residents of Moscow, as well as the cities of the Moscow region: Balashikha, Podolsk, Khimki, Korolev, Mytishchi, Lyubertsy, Krasnogorsk, Elektrostal, Kolomna, Odintsovo, Domodedovo, Serpukhov, Shchelkovo, Orekhovo-Zuevo, Ramenskoye , Dolgoprudny, Zhukovsky, Pushkino, Reutov, Sergiev Posad, Voskresensk, Lobnya, Klin, Ivanteevka, Dubna, Yegoryevsk, Chekhov, Dmitrov, Vidnoye, Stupino, Pavlovsky Posad, Naro-Fominsk, Fryazino, Lytkarino, Dzerzhinsky and Solnechnogorsk. You can order the necessary goods online with delivery to all these cities or visit one of our retail stores in Moscow and Moscow Region.