Pipe adapters are connecting elements made from different materials that are used to join pipes in pipeline structures for various purposes. The operational area of these products extends to almost all pipe communications, including: water supply systems, heating pipelines, gas pipelines, sewer systems, smoke and ventilation pipelines.

In pipeline systems, there is often a need to join pipes of different diameters; in such cases, adapters of appropriate sizes are used

Features of selection and installation

For metal

When assembling metal pipelines for water supply and wastewater disposal, metal fittings are most often used.

They are usually made of steel (for cast iron systems - from cast iron), and to improve anti-corrosion properties they are coated with non-ferrous metals (chrome plating, nickel plating). Also popular are adapters made of technological alloys, which primarily include bronze and brass. Coupling for capillary soldering

According to the configuration, the following products are distinguished:

- Models for welding or soldering. Welded varieties are usually attached end-to-end, but those intended for connection with a soldering iron are most often equipped with sockets at the ends intended for inserting pipe sections.

- Adapters with elastic cuffs. They are used when laying non-pressure systems, most often in sewers. Also, according to this technological scheme, adapters for ventilation pipes of medium and large diameter are produced, but their joint can be reinforced with an additional clamp.

Combined model with crimp and flange part

Flange designs. They are used for equipping large-diameter pipelines and provide high reliability even under significant pressure.

Brass threaded adapter for pipes of different diameters

Fittings for copper pipes, designed for installation of press sleeves. They provide fairly quick and reliable installation through the use of special crimping. The disadvantage of such parts is the impossibility of dismantling without compromising the integrity of the product.

Press sleeve for copper communications

For plastic

Plastic adapters for plastic pipes are also available in a fairly wide range. They are characterized by less reliability than metal ones, but they are much cheaper and much easier to install with your own hands.

Among the varieties are:

Polyvinyl chloride and polyethylene products designed for installation using rubber cuffs. Mounted without additional fasteners, fixation is ensured by an internal elastic ring. Used in non-pressure sewer systems.

Model with cuff

- PVC fittings designed for adhesive installation. More reliable than the previous ones, but also unable to withstand high pressure.

- Threaded adapters made of polymers. They are used relatively rarely because they are not able to provide proper tightness under load. Can be used in low pressure pipelines, ventilation, etc.

- Adapters made of polypropylene, mounted by welding. They guarantee a high level of reliability, but form a permanent connection. To work with such fittings, special soldering irons with sets of nozzles, the size of which corresponds to the diameter of the pipeline, are used.

Press fitting installation instructions

Metal and composite structures, which include plastic housings and steel (sometimes bronze or brass) fixing elements. This group includes crimp adapters for metal-plastic pipes, as well as combined fittings with which you can create a plastic-to-metal transition.

- Almost any transition elements can be used in the sewer system - the pressure inside the pipes is low, so tightness can be ensured almost effortlessly.

- It will be somewhat more difficult with plumbing. Here, the best installation methods would be welding plastic, as well as using threaded connections with metal parts.

- For a hot water supply system, it is advisable to use composite materials reinforced with fiberglass or metal, since they have a lower level of thermal deformation.

System planning

Due to the fact that PPR pipes do not bend, when developing a wiring diagram it is necessary to create as few detours and turns as possible. After all, they are all made using fittings, and they have a significant cost (compared to a pipe). Therefore, we try to optimize the wiring - make as few turns, detours and bends as possible.

Serial (Tee) connection

Installation of water supply from polypropylene pipes with serial connection of consumers (plumbing and household appliances) is used in small systems. Usually they have 5-6 connection points. With this arrangement of the water supply system, one pipe leaves the riser and it sequentially bypasses all connection points. In the case of PPR plumbing, all branches are made using tees, which is why this type is also called tee.

Installation of water supply from polypropylene pipes with serial connection of consumers

The advantage of this system is that a small number of pipes are needed, and the disadvantage is that the pressure on each branch drops. As a result, with one or two working disassembly points, the third, located further from the riser, may simply not have enough pressure.

Parallel (collector) wiring

A parallel connection circuit is also called a collector circuit. This is because after the outlet from the riser, a special device is installed - a collector. This is an element with one input and a number of outputs. Available in polypropylene and metal. For water supply, polypropylene manifolds are more suitable (and cheaper).

The connection diagram is such that a separate pipe runs from each branch to each consumer (sometimes to a small group of consumers).

Parallel scheme for installing a water supply system from PPR pipes

The advantage of such a system is that the pressure at all water points is the same, the disadvantage is that a lot of pipes are required. Another plus is that if any branch fails, only one consumer does not work. The rest of the system is functioning normally. By the way, in order to be able to turn off individual devices, valves are installed at the outlet of the collector (usually ball valves, but if you need the ability to adjust the pressure, you can install a valve).

Plumbing and household appliances

In each method of installing a water supply system made of polypropylene pipes, a pipe is suitable for a specific consumer. There are two ways to connect to the system: flexible and rigid connection.

Rigid liner is more reliable: PPR pipes and fittings have high strength. Moreover, in this case there is only one thread - at the consumer connection point. But this type of eyeliner requires high precision: the error can be only a few millimeters. This is difficult to achieve when installing a polypropylene water supply with your own hands, so flexible hoses are often used. Just be careful, in some cases it is impossible to use it: connecting gas boilers or gas water heaters, supplying water to storage water heaters, water heated towel rails is recommended only using a rigid connection.

Rigid liner options

Soft eyeliner, on the contrary, does not require high precision - errors are leveled out by a flexible stainless steel braided hose or a hose that is used to connect a washing machine or dishwasher. The tubes are removed approximately in the area where the equipment is installed or the plumbing is connected. It ends with an adapter for metal, to which a flexible hose is connected (its other end is connected to the device).

Flexible hoses are connected to the adapters

This option is less reliable, since much depends on the quality of the flexible liner. Also not the most pleasant moment is the presence of two threaded connections, and this is a potential place for a leak to appear.

Types of transitions for plastic internal and external sewerage

Adapters for sewer pipes made of plastic can be welded, glued, threaded, or rubber ring according to the connection method.

In fact, adapters for sewer pipes come in a wide variety, for example, some of them are:

Types of sewer adapters

- coupling, perfect for connecting pipes where there is no socket;

- reduction – allows you to connect pipes of different diameters;

- an inspection with a lid is needed so that you can penetrate the pipe and remove the blockage. If you need to install it for external sewerage, then a design for a manhole is suitable;

Bends change the direction of the main line

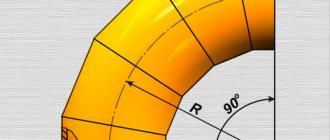

branch, allows you to change the direction of the main line at an angle of 30, 45 and 90 degrees.

Purpose of sewer adapters

Adapter for sections of external pipeline of different diameters.

Many shaped elements have been invented, and each has its own purpose. The general purpose of their use is to create highways of complex configurations and save space without losing quality capabilities.

Using sanitary fittings products:

- switch to another size of pipe section;

- change directions of the highway;

- drain sewage and remove aggressive waste.

Adapters allow you to assemble pipe sections of different sections into a single whole, connect branches made of metal and plastic, and connect any plumbing fixtures. They come in handy if you need to connect threaded elements to the free-flow part of the pipeline, which are used to equip pumps for pumping and treating wastewater. To further save space, products can be corrugated so that they can take any shape.

Features of installing a section of plastic sewerage into a cast iron system

To insert a plastic section into the working system, a sewer adapter and a compensator are used, due to which installation becomes possible without disassembling the entire structure.

Installation is carried out as follows:

- an adapter is inserted into the socket that has been cleaned and treated with sealant;

- there is a plastic compensator in it;

- into the compensator until it stops - a plastic pipe;

- the structure is connected from the other end, gradually releasing the pipe from the compensator.

Whatever sewerage design is proposed, whatever materials are to be used, work should begin with drawing up a plan with a clear outline of all the necessary connections.

If you plan to independently repair or install a sewer system, it is important to study the features of the upcoming work and consult with specialists in terms of purchasing the necessary materials. The existing offer of pipes, adapters and fittings allows us to install even the most complex systems. https://www.youtube.com/embed/SZkwlKi5n5Y

How to properly secure a pipeline

Good heating or plumbing installation is not only about the quality of the connection, but also about the implementation of knowledge on how to install assembled polypropylene pipes.

Proper fastening of plastic wiring to the walls will prevent it from sagging and deformation when heated with hot water.

When making repairs, sometimes you have to forcefully pull the pipe out of the clips, so the dowels must firmly fix this small element against the wall

For fixing pipes, the following are used: clips (single, stacked, with a clamp) and clamps (on a hairpin, paired, wall).

New models are constantly appearing on the market, so it is better to select clamps and clips directly in the store. Clips basically ensure free movement of pipes along the axis, and clamps firmly fix them in one position.

A particularly dangerous consequence of improper installation is neglecting the thermal expansion of pipes.

The length of simple PP pipes can change by 10-15mm/1m when heated. When they are rigidly fixed, deformation occurs at the adhesions, which can lead to rupture of the connection. To relieve stress, the following types of compensators are used:

- Z-shaped;

- U-shaped;

- L-shaped

- ring.

Rules for working with a compensator:

After soldering the expansion joints and attaching the pipes to clamps and clips, you can begin testing the assembled system.

Installation features

The main condition when installing sewerage from any material is the tightness of the connections. For joining pipes and bends, use:

- socket connection;

- glue installation;

- use of special configuration locks;

- argon or gas welding for steel and stainless steel pipes.

At home, the most common type is a socket connection.

To facilitate the work, select bends and pipes of the required diameter that are suitable in configuration. Take into account the angle of rotation, exit from the right or left. In this case, the parts are connected by joining the socket with a smooth end.

Plastic pipes and fittings are equipped on one side with a special chamfer, in which a sealing elastic band with a triangular shape in cross-section is installed. This makes the connection easier.

If the size of the room or the availability of parts for sale make it necessary to cut the pipes, file the smooth end into a cone. The cut part of the part is taken as a sample. Trying to insert a cut and untreated pipe into the socket will most likely lead to damage to the rubber seal. To facilitate docking, especially when purchasing products from different brands, it is recommended to lubricate the O-ring with any liquid product, such as soap solution.

For cast iron pipes, the socket joint is sealed with packing and covered with cement mortar.

Installation of sewer pipes and bends with glue is used for pipes without sockets. Such systems are chosen when there is confidence that no modifications will be required. Otherwise, dismantling is possible only with the destruction of parts and their subsequent replacement with new ones.

Low-pressure propylene pipes are connected with fittings with a tightening nut or special bends using electrical soldering, as described above. In private homes, such pipes are rarely used due to the unpresentable appearance of the connections.

Specifications

Plastic pipes and adapters for sewerage differ from traditional cast iron products in all respects. Features of vinyl parts:

- light weight. Carrying, loading, and assembly do not require special equipment. You can work independently or with one assistant;

- ease of connection. Pipes and fittings are equipped with sockets with rubber sealing rings. The assembly process takes just minutes;

- availability of a large number of components. There are adapters for any part of the system;

- plastic pipes are resistant to water, ultraviolet radiation, and can withstand light impacts without the risk of cracks.

There are two categories of plastic pipes:

- for internal sewerage. They are located inside the building, have less strength and resistance to UV rays;

- for external areas of the system. These elements have increased strength and withstand temperature changes well.

All sizes of PVC pipes or adapters are available for sale. The minimum diameter is 50 mm; pipes of 100 or 110 mm are used for risers. There are all adapters for sewer pipes of different diameters, allowing you to create pipelines of any configuration and length.

What adapters are used to connect plastic and cast iron pipes?

The pipes in question can be connected by using the following adapters:

- Internal rubber adapters are quite often used. They are installed in the socket of a cast iron pipe, after which various cuffs can be used. A special sealant is used to seal the seam.

- An external plastic adapter is also used quite often. The seam is sealed by using a special sealant.

When using adapters, the possibility of exposure to various bending forces should be eliminated

You also need to pay attention to the fact that the absence of a threaded connection determines low strength and resistance to water hammer

Recommendations

PVC pipes

PVC pipes are widely used to create sewer systems due to their ease of installation and performance characteristics. A sewer system can be assembled from modules of different sizes.

The size range includes shaped products for adapting to different pipe diameters (reducers), splitters and corner bends.

The interchangeability of pipe elements allows repair work to be carried out in a short time.

Unlike other plastic analogues, products made from polyvinyl chloride have a convenient assembly mechanism. All components and fittings in the pipeline have a socket connection with an O-ring. Additionally, you can coat it with glue or sealant for strength.

If it is necessary to connect two sections of pipe, use a coupling equipped with rubber seals. All adapters for plumbing outlets from sinks, sinks, showers and bathtubs are equipped with a socket groove.

In addition to the socket connection, an adhesive joining method is used. Pipes differ in the shape of the end and the size of the walls.

When selecting pipe products of a certain size, all fittings must be of the same diameter. This will help achieve tightness in the pipeline.

If the pipes have a diameter of 32–50 mm, then the optimal slope will be 0.03 degrees or 3 cm per linear meter.

A circle size of up to 110 mm assumes a slope of 0.02 degrees or 2 cm. A diameter from 150 to 200 mm should be laid at an angle of 0.008 degrees, corresponding to less than 1 cm.

How to choose

When choosing fittings, several factors should be taken into account. If after installation it is located in concrete, then stray currents will cause the destruction of the metal connection in about 18-20 years. It is for this reason that it is better to choose solder fittings for connections that will have contact with concrete. If you decide to install the water supply yourself, then it would also be an excellent solution to use such fittings. The soldering iron and fittings are inexpensive, so it doesn’t hurt to buy a few more items than you need just to practice welding them first.

If you are looking for fittings of various categories - for example, compression and crimp, then you should pay close attention to the dimensions of the walls and their thickness. In some models, the abbreviation SDR is written, which means the ratio of wall thickness and tube diameter

If this indicator differs for the specified elements, then you will not be able to do something. Either the fitting tube will be larger than the diameter of the pipe from the inside, and it will simply not be possible to install it without damaging the rubber seals, or it will simply not be possible to ensure that it is pressed tightly against the pipe and various seals.

Before choosing different models, you should ask the point of sale for a document of conformity. Everything that is produced or legally supplied to Russia must have documentation and fully comply with GOST. In addition, this will be a sign that this is not a fake. But materials that do not have documents are most likely imported illegally or created illegally, which means it is not possible to check their characteristics.

Varieties

The list of fittings is quite long and varied. Each type has its own purpose. First of all, they are divided into types for internal sewerage and external ones. The first is connected to individual plumbing elements, such as a toilet or bathtub. The second connects the entire pipeline of one house with a common sewer system.

Let's start with the options that apply in both cases.

- The coupling is the simplest type of fitting. Used for direct connection of two pipes to each other. The group is divided into full bore, repair and stop couplings.

- Branch - necessary to turn the pipeline in the other direction. The bends are different, depending on the angle of rotation (30, 45, 90, 120 degrees).

- Tee - designed to connect two branches of a sewer pipeline. It also has several types with different rotation angles (45, 75 or 90 degrees).

- Reduction is similar to a coupling, but has inputs of different sizes. This is necessary for connecting pipes of different diameters to each other. For example, to connect a toilet flush to a sewer system.

- Inspection is a very important element of the pipeline, which is often forgotten. It cleans the system when blockages occur. Otherwise, this process will become noticeably more complicated. This fitting is installed in the pipeline in an easily accessible place. The kit includes a lid to plug the drain.

- The plug is the least necessary part. It is practically not used when arranging home sewerage. Designed to cover the end of the pipeline if you plan to lay an additional branch from it in the future.

- A single-plane cross is a special version of a tee, which has some not so obvious differences. As the name suggests, the pipes are connected in one plane. The part has several varieties, depending on the angle of the joints. The most common are 45 and 90 degrees.

- Saddle - designed for connecting additional pipes to a finished sewer system. Externally, this part is a fragment of the body, which is installed using glue (in the case of plastic pipes) or welding.

Now let's talk about fittings that are used exclusively when installing internal sewerage.

A two-plane cross, just like a single-plane one, is used to connect three or four pipes. However, in this case they are installed in different planes. Such elements are the most at risk due to the complexity of the design. Consequently, leaks are more likely to occur in such places.

But the strength and monolithic manufacturing technology of this fitting reduce this risk to a minimum. Two-plane crosses differ not only in the angles of the sockets (45 and 90 degrees), but also in the diameter of the outlets in order to connect branches of different sizes.

Separate fittings for external sewerage.

- A check valve is necessary for connecting horizontally installed pipes that have a two-centimeter slope. It also prevents fluid from flowing back through the system.

- A two-arm siphon is used in places where waste liquid is received. This fitting serves as a seal and prevents the formation of gases.

- Double socket fitting is used to connect horizontal and vertical pipes. Most often it is used to connect plumbing to the sewer system located a level below. Typically these fittings have a 90 degree angle.

- A three-bell tee typically has a 90-degree bend. Used to connect three different small-diameter pipes to one, wider branch.

Tees, crosses

The main purpose of the products is to join/bend several pipe bends. They are characterized by different angles and configurations. In the case of a heating system, welded fittings equipped with a smooth internal threadless surface are well used. Less often, it may be necessary to switch to another type of material, then there are threads at the ends of the connections.

Transition tee

The use of a fitting is relevant when arranging a pipeline with a transition to a smaller diameter. The operating temperature is 95 degrees, the pressure is 2.5 MPa, the connection is provided by butt welding.

Combination tee with internal thread

The product is used for connections with reinforcing elements, faucets, plumbing fixtures or steel pipes in pipeline branch areas. Operating temperature 95 degrees, pressure 2.5 MPa, butt connection.

Male Tee

Used for joining PVC pipes with reinforcing elements and steel pipes when branching pipes.

Tees with union nuts

The design is used for dismountable threaded connections of PVC pipes with steel fittings or pipes when branching pipes in areas with cold or hot water supply. The maximum heating level is 80 degrees, pressure 2.0 MPa. The connection is formed using butt welding.

The use of plastic products in sewer lines

To equip sewer systems, pipes and fittings are used from materials such as PVC (polyvinyl chloride), PE (polyethylene) and PN (polypropylene). Unlike steel and cast iron products, which are connected by welding, installing plastic pipes is much easier, since their joining does not require special equipment.

The advantages of plastic sewer fittings include:

- low weight, which facilitates their transportation and installation;

- long service life - the service life of a polymer pipeline reaches 50 years, which is achieved due to the material’s complete resistance to corrosion and chemically aggressive substances;

- wide temperature range - PVC plastic sewerage can be used to remove hot wastewater with temperatures up to 95 degrees;

- a wide range of fittings, different shapes and sizes of which allow you to form a sewer pipeline of any configuration.

Range of shaped products for sewer systems

PVC fittings are shaped elements used to connect individual pipes to each other, as well as to connect shut-off and control valves to the pipeline. Fittings for sewerage have dimensions corresponding to the diameter of pipes on the market.

According to the provisions of GOST No. 21.604 “Water supply and sewerage”, for laying internal sewerage it is necessary to use the following sizes of PVC pipes:

- bathtub drain pipe - diameter 40 mm (laid with a slope of 1:30);

- shower - diameter 40 mm (slope 1:48);

- toilet - diameter 110 mm (slope 1:20);

- sink - diameter 40 mm (slope 1:12);

- bidet - diameter 40 mm (slope 1:20);

- sink - diameter 40 mm (slope 1:36);

- combined drain for shower, bath and sink - diameter 50 mm (slope 1:48);

- central riser - diameter 110 mm;

- bends from the central riser - 60 mm.

Large diameter pipes for external sewerage

For installation of external communications it is necessary to use pipes with a diameter of 160-200 mm. PVC sewer pipes and fittings are selected so that their sizes match each other.

Classification of sewer fittings

The variety of connecting elements used for pipeline installation is classified according to two parameters - scope of application and connection method. According to the scope of application, the designs are divided into fittings intended for installation of internal sewerage, and products for external systems.

Depending on the connection method, sewer fittings are classified into:

- bell-type (a rubber O-ring is installed inside the plastic structure), which ensures strong fixation of the pipe and tightness of the entire system;

- for gluing, without sealing ring.

Socket connection of sewer pipes

In terms of reliability and durability of the connection, adhesive fittings benefit, since the rubber seal during operation can lose elasticity and shrink, resulting in a gap forming between the walls of the connected structures, which causes leaks.

Compositions based on a mixture of polyvinyl chloride and tetrahydrofuran are used as glue for installing PVC sewer systems, which, after hardening, form a material with performance characteristics similar to the plastic from which the pipes themselves are made.

Proven adhesive compositions for the installation of polymer pipelines are “Tangit”, “Vinilit”, “Phoenix” and “Marx”, the current VSN 35-86 “Instructions for the installation of plastic pipes” recommends the use of “GIPC-127” adhesive.

Advantages of polypropylene

When creating a new water supply system in an apartment, many people choose polypropylene pipe products. This material, made of plastic, can be easily soldered by welding, and has a lot of other positive qualities:

- Long service life of more than 10 years. During the entire period of operation, these products are not subject to rotting and corrosion processes; plaque forms on the walls of these pipes. Provided high-quality soldering of such pipe products is performed, ideal seams and high tightness are ensured for decades.

- Water supply systems made from polypropylene pipes are easy to install. Their assembly resembles a regular construction set. During work, a minimum number of tools are used. A beginner can master soldering polypropylene pipes in one day.

- The versatility of the material. This quality of polypropylene is expressed in its wide application. It can be used to create cold and hot water supply systems. It is also often used to install heating in a home. Pipes made from this material are offered in stores in a wide range. They differ not only in their size, but also in the level of pressure that the pipe is able to withstand. The weight of polypropylene pipes is insignificant, which facilitates the process of installation work. It should also be noted that such pipes can be joined to any ends, which is how they differ from products made from other materials.

- Low price. If, when creating a water supply system, the owner’s main goal is to install a water supply system with minimal monetary costs, then polypropylene pipes are the best option.

- Convenient and affordable equipment. When creating a water supply system using polypropylene pipes, you cannot do without the use of spare parts and various accessories. There are no problems with purchasing, since they are presented in a wide range in most hardware stores. Depending on his financial capabilities, the home owner can choose affordable domestic or more expensive imported components.

What is an adapter and why is it needed?

Sewer adapters are pipeline fittings that are needed to connect two structures of different diameters.

In addition, the use of adapters is indispensable for connecting sewer pipes made of various materials.

It is worth saying that it does not matter at all what kind of pipeline it is, for external or external sewerage, the use of adapters is indispensable in any case. Today there are many types of adapters, namely, the materials from which they are made

This could be, for example, PVC plastic, polypropylene, cast iron or steel, and so on

Today there are many types of adapters, namely, the materials from which they are made. This could be, for example, PVC plastic, polypropylene, cast iron or steel, and so on.

Sewer adapters

First of all, it should be noted that there are two types of adapters, namely:

- concentric, which are used only for vertical pipelines;

- eccentric, used for horizontally located pipes.

Advantages and disadvantages

The advantages of plastic parts include:

- light weight;

- lightness, ease of assembly;

- installation does not require the use of special equipment or devices;

- connections are sealed, there are no leaks;

- no corrosion;

- it is possible to move chemically active compounds;

- ability to withstand temperature changes;

- long service life;

- if necessary, any section of the pipeline can be easily replaced;

- there are fittings of any kind;

- immersion in the ground to a depth of 16 m is allowed;

- The smooth inner surface prevents the formation of layers and silting.

Disadvantages that sewer pipes and adapters made of plastic show:

- high coefficient of thermal expansion, which must be taken into account during assembly;

- at low temperatures, the elasticity of the material decreases;

- weak bearing capacity. The assembly needs to be secured to a supporting structure;

- at temperatures above 70°, vinyl is easily deformed;

- high noise level.

The disadvantages of PVC products are not considered too serious. Strong heating, like cooling, does not threaten them. Thermal expansions are compensated for with proper assembly, and users are sensitive to noise. Light weight and ease of assembly are considered such important qualities that minor flaws are not taken into account. PVC pipes and sewer adapters are in high demand. When you consider the low cost, user preference becomes clear.

Working with cast iron and ceramic pipes

Since the methods for working with these types of pipes are not very different, it makes sense to study them together.

Such pipes are also equipped with sockets, so they are simply inserted into each other. The connection turns out to be loose, and the gaps should be eliminated using ordinary tow. After this, you should use any waterproofing agent: silicone sealant, mastic or cement.

Cement is most often used, which is due to its low cost. It is preferable to take a building material marked 400. To prevent cracks from forming at the joint, you need to wet a rag and tie it over your joint, and then moisten it. Since cement, when drying, absorbs liquid, such a procedure is necessary.

Properties of adapters installed on cast iron pipes

Many houses still have cast iron items. Therefore, when installing a sewer system, situations quite often arise in which it is necessary to connect pipes made of completely different materials. Most often you have to join plastic with cast iron.

To perform such a technological operation with high quality, it is simply impossible to do without a special adapter for cast iron. He will help you do this work quickly with minimal cost.

To ensure tightness, a rubber cuff is used. It is installed during any transition.

The inner cuff is inserted into the cast iron socket. This makes it possible to insert a plastic pipe of a certain diameter.

The outer diameter of the cuff is equal to the diameter of the socket. Therefore, the connection does not require additional treatment with sealant.

If there is no socket, a special external adapter is used to make the connection.

When the cast iron connection is completed, you can continue installing the plastic sewer system.

Buy concentric transitions GOST 17378-2001

Here you can choose connecting fittings of any diameter you need, including art. 20 for pipelines of various importance, including those controlled by supervisory authorities. Decent product at an affordable price.

GOST 17378-2001 - Design and dimensions of transitions

| Outer diameter, wall thickness, mm | Price including VAT, rub | Weight (mass), kg. | Outer diameter, wall thickness, mm | Price including VAT, rub | Weight (mass), kg. |

| 38x4/25x3 | 70 | 0,2 | 159x5/114x4 | 300 | 2,3 |

| 38x4/32x4 | 60 | 0,2 | 159x8/114x6 | 790 | 3,9 |

| 45x4/25x3 | 80 | 0,2 | 159x10/114x8 | 965 | 4,8 |

| 45x5/25x3 | 95 | 0,3 | 159x12/114x9 | 1040 | 5,9 |

| 45x4/38x4 | 75 | 0,2 | 159x5/133x4.5 | 300 | 2,3 |

| 45x5/38x5 | 90 | 0,3 | 159x8/133x8 | 755 | 3,9 |

| 57x3/25x1.6 | 40 | 0,2 | 159x10/133x10 | 920 | 4,8 |

| 57x4/25x1.6 | 125 | 0,3 | 159x12/133x10 | 990 | 5,9 |

| 57x5/25x3 | 180 | 0,3 | 168x8/57x4 | 890 | 2,7 |

| 57x6/25x3 | 180 | 0,4 | 168x10/57x5 | 1100 | 3,3 |

| 57x3/32x2 | 40 | 0,2 | 168x8/76x5 | 890 | 2,7 |

| 57x4/32x2 | 110 | 0,3 | 168x10/76x6 | 1100 | 3,3 |

| 57x5/32x3 | 160 | 0,3 | 168x8/89x6 | 930 | 4,1 |

| 57x6/32x4 | 160 | 0,4 | 168x10/89x8 | 1140 | 5,1 |

| 57x3/38x2 | 40 | 0,2 | 168x8/108x6 | 880 | 4,1 |

| 57x4/38x4 | 95 | 0,3 | 168x10/108x8 | 1080 | 5,1 |

| 57x5/38x4 | 135 | 0,3 | 168x8/114x6 | 880 | 4,1 |

| 57x6/38x4 | 135 | 0,4 | 168x10/114x8 | 1080 | 5,1 |

| 57x3/45x2.5 | 40 | 0,2 | 168x8/133x6 | 880 | 4,1 |

| 57x4/45x2.5 | 105 | 0,3 | 168x10/133x8 | 1030 | 5,1 |

| 57x5/45x4 | 155 | 0,3 | 219x10/57x4 | 1420 | 4,6 |

| 57x6/45x5 | 120 | 0,4 | 219x12/57x4 | 1885 | 5,5 |

| 76x3.5/45x2.5 | 60 | 0,5 | 219x10/76x5 | 1420 | 4,6 |

| 76x6/45x4 | 215 | 0,7 | 219x12/76x5 | 1885 | 5,5 |

| 76x3.5/57x3 | 60 | 0,4 | 219x10/89x5 | 1475 | 4,6 |

| 76x5/57x4 | 205 | 0,6 | 219x12/89x5 | 1885 | 5,5 |

| 76x6/57x5 | 205 | 0,7 | 219x6/108x4.0 | 1230 | 2,9 |

| 89x3.5/45x2.5 | 75 | 0,6 | 219x10/108x6.0 | 1480 | 4,6 |

| 89x6/45x4 | 300 | 0,9 | 219x12/108x8.0 | 1830 | 5,5 |

| 89x8/45x5 | 385 | 1,2 | 219x6/114x4.0 | 635 | 2,9 |

| 89x3.5/57x3 | 71 | 0,6 | 219x10/114x6.0 | 1480 | 4,6 |

| 89x6/57x4 | 280 | 0,9 | 219x12/114x8.0 | 1830 | 5,5 |

| 89x8/57x5 | 365 | 1,2 | 219x6/133x4.0 | 550 | 4,4 |

| 89x8/57x6 | 310 | 1,4 | 219x8/133x6.0 | 1260 | 5,0 |

| 89x3.5/76x3 | 71 | 0,6 | 219x10/133x8.0 | 1580 | 7,2 |

| 89x6/76x5 | 265 | 0,9 | 219x6/159x4.5 | 550 | 4,4 |

| 89x8/76x6 | 345 | 1,2 | 219x8/159x6 | 1200 | 6,0 |

| 108x4/57x3 | 110 | 0,9 | 219x10/159x8 | 1500 | 7,2 |

| 108x6/57x4 | 385 | 1,2 | 219x12/159x10 | 1780 | 8,8 |

| 108x8/57x5 | 505 | 1,6 | 219x16/159x12 | 2275 | 12,0 |

| 108x9/57x6 | 635 | 1,8 | 219x6/168x4.5 | 1200 | 4,4 |

| 108x4/76x3.5 | 110 | 0,9 | 219x8/168x6 | 1200 | |

| 108x6/76x5 | 310 | 1,2 | 219x10/168x8 | 1500 | 7,2 |

| 108x8/76x6 | 405 | 1,6 | 219x16/168x12 | 2275 | 12,0 |

| 108x9/76x7 | 565 | 1,8 | 273x10/108x6 | 2240 | 8,5 |

| 108x4/89x3.5 | 110 | 0,9 | 273x12/108x8 | 2700 | 10,0 |

| 108x6/89x6 | 300 | 1,2 | 273x10/114x6 | 2235 | 8,5 |

| 108x8/89x8 | 405 | 1,6 | 273x12/114x8 | 2700 | 10,0 |

| 108x9/89x8 | 565 | 1,8 | 273x10/133x6 | 2235 | 8,5 |

| 114x8/57x5 | 535 | 1,7 | 273x12/133x8 | 2700 | 10,0 |

| 114x9/57x6 | 750 | 1,9 | 273x7/159x4.5 | 1100 | 8,3 |

| 114x10/57x6 | 750 | 2,1 | 273x10/159x8 | 2540 | 12,0 |

| 114x6/76x5 | 330 | 1,3 | 273x12/159x10 | 3030 | 14,0 |

| 114x8/76x6 | 430 | 1,7 | 273x10/168x8 | 2540 | 12,0 |

| 114x9/76x7 | 750 | 1,9 | 273x12/168x10 | 3030 | 14,0 |

| 114x10/76x8 | 750 | 273x7/219x6 | 1045 | 8,3 | |

| 114x12/76x10 | 780 | 273x10/219x8 | 2540 | 12,0 | |

| 114x6/89x6 | 330 | 1,3 | 273x12/219x10 | 3030 | 14,0 |

| 114x8/89x8 | 430 | 1,7 | 325x8/108x4 | 1620 | 9,0 |

| 114x9/89x8 | 750 | 1,9 | 325x10/108x4 | 2500 | 11,0 |

| 114x10/89x10 | 750 | 325x12/108x6 | 3000 | 16,0 | |

| 114x12/89x10 | 780 | 325x10/114x4 | 2580 | 11,0 | |

| 133x4.5/57x3 | 175 | 1,3 | 325x12/114x6 | 3000 | 16,0 |

| 133x8/57x4 | 650 | 2,5 | 325x10/133x6 | 2640 | 13,0 |

| 133x10/57x5 | 900 | 3,1 | 325x12/133x8 | 3095 | 16,0 |

| 133x5/76x3.5 | 200 | 1,6 | 325x10/159x6 | 2640 | 14,0 |

| 133x8/76x5 | 650 | 2,5 | 325x12/159x8 | 3100 | 16,0 |

| 133x10/76x6 | 900 | 3,1 | 325x10/168x6 | 2640 | 14,0 |

| 133x4/89x3.5 | 200 | 1,3 | 325x12/168x8 | 3100 | 16,0 |

| 133x6/89x5 | 485 | 1,9 | 325x8/219x7 | 2190 | 11,0 |

| 133x8/89x6 | 580 | 2,5 | 325x10/219x8 | 3090 | 14,0 |

| 133x10/89x9 | 900 | 325x12/219x10 | 3600 | 17,0 | |

| 133x5/108x4 | 375 | 1,6 | 325x8/273x7 | 2170 | 11,0 |

| 133x8/108x6 | 580 | 2,5 | 325x10/273x10 | 2950 | 14,0 |

| 133x8/108x8 | 580 | 2,5 | 325x12/273x12 | 3420 | 17,0 |

| 133x10/108x9 | 900 | 3,1 | 377x10/219x8 | 5570 | 22,0 |

| 133x5/114x4.5 | 200 | 1,6 | 377x12/219x8 | 6270 | 22,0 |

| 133x8/114x6 | 580 | 2,5 | 377x10/273x7 | 5010 | 20,0 |

| 133x8/114x8 | 580 | 2,5 | 377x12/273x10 | 5650 | 24,0 |

| 133x10/114x9 | 900 | 3,1 | 377x10/325x8 | 4760 | 20,0 |

| 159x4.5/57x3 | 275 | 1,5 | 377x12/325x10 | 5380 | 24,0 |

| 159x8/57x4 | 800 | 2,6 | 426x10/159x8 | 10400 | 37,0 |

| 159x10/57x5 | 1000 | 3,1 | 426x12/159x8 | 10400 | 37,0 |

| 159x12/57x6 | 1200 | 3,9 | 426x10/219x8 | 10400 | 32,0 |

| 159x4.5/76x3.5 | 265 | 1,5 | 426x12/219x8 | 10400 | 32,0 |

| 159x8/76x5 | 800 | 2,6 | 426x10/273x8 | 5800 | 25,0 |

| 159x10/76x6 | 1000 | 3,2 | 426x12/273x10 | 6750 | 27,0 |

| 159x12/76x7 | 1190 | 3,9 | 426x10/325x8 | 5510 | 23,0 |

| 159x4.5/89x3.5 | 300 | 2,3 | 426x12/325x10 | 6010 | 27,0 |

| 159x8/89x6 | 835 | 3,9 | 426x10/377x10 | 5260 | 23,0 |

| 159x10/89x8 | 1015 | 4,8 | 426x12/377x12 | 5800 | 27,0 |

| 159x12/89x8 | 1100 | 5,9 | 530x12/325x10 | 23740 | |

| 159x10/108x8 | 965 | 4,8 | 530x12/377x10 | 23420 | 46,0 |

| 159x12/108x9 | 1040 | 5,9 | 530x12/426x10 | 23090 | 46,0 |

Connecting sewer pipes with glue

The strength of this joining method is based on the mutual penetration of polymers at the molecular level. First of all, you should purchase a special glue that is used to coat the edges of the pipes. After that:

- the surfaces to be bonded are cleaned of dirt, sanded and degreased;

- the prepared edges are greased with glue;

- the ends of the pipes are placed inside each other;

- In order to ensure tightness, the joint is coated.

It is necessary to start connecting the pipeline elements immediately after applying the adhesive composition, since it quickly loses its properties in air. Bonding must be completed within 90 seconds.

Transitional coupling for reliable connection

The polypropylene transition coupling, as well as the split polypropylene coupling, are used for the installation of pipelines. It is lightweight, minimizes labor and time costs for pipeline installation, and is characterized by a long service life, practicality, durability and reliability due to the quality of workmanship and the material endowed with special properties.

The polypropylene transition coupling differs in type and diameter; it is selected based on the type and diameter of polypropylene pipes. Its feature is to ensure high connection reliability. Even after a long service life, it will not lose its properties and will clearly perform ozone functions.

Classification

In addition to classification by purpose, fittings can differ in many other ways. First of all, this is the material from which both pipes and fittings for them are made. All the advantages of plastic have already been discussed above. But for one reason or another, Russian residents do not always prefer pipelines made of PVC materials. In our country, metal structures enjoy the greatest confidence.

Cast iron is the most traditional of materials, but has many disadvantages. One of the advantages is the longest service life - about 80 years. Most cast iron sewer systems in Russia have existed since Soviet times. Over the years, numerous growths have formed on the inner walls of such pipes, making it difficult for water to pass through. When replacing them, the same material is rarely used. The reason for this is the significant disadvantages of cast iron: it has a high cost and heavy weight, which complicates installation. Cast iron fittings are rarely used for domestic purposes for the same reasons.

There are alternative options, which also have their drawbacks, which is why they are used less and less in construction. For example, copper is the most expensive of materials. Very resistant to corrosion and alkaline environments. Copper pipes are not used for laying water pipes due to their ability to change the smell and color of water. And for sewerage, you can find cheaper materials. Another alternative is stainless steel, which, on the contrary, is vulnerable to corrosion.

Non-metallic materials include asbestos cement and ceramics. The first option is practically free of the disadvantages that metal pipes suffer from. Asbestos cement systems do not suffer from corrosion, are lightweight and last a long time. But this material is quite fragile and can be easily damaged during installation. Ceramics is the closest option to an ideal material, as it has a long range of advantages. In addition, ceramic systems boast a variety of fittings available. But most of these advantages are negated by one disadvantage - the price is too high.

Due to various disadvantages of the listed materials, PVC pipes, compared to other analogues, look like the most profitable and practical solution. Fittings also differ in size. When choosing them, you should take into account the parameters of the pipes that need to be connected. Their weight and length, for example, do not matter. The main indicators in this case are the internal and external diameters of the pipes. They can vary from 25 to 110 mm or more.

Features of the assortment of polypropylene pipes

Diameters of polypropylene pipes

Polypropylene is a type of plastic produced by cracking petroleum products and petroleum gases. Its basis is propylene gas. Under high pressure with the presence of a catalyst, a polymerization reaction is carried out, as a result of which polypropylene is obtained. Pipes are subsequently made from it. Two types of such products are produced for water supply systems: single and multilayer.

The first option is intended mainly for various types of pipelines through which cold water is transported. Multilayer or reinforced parts are used to construct hot water lines; they are also used for the installation of heating systems. Their main difference is the presence of several layers of polypropylene, between which reinforcing material is laid.

This can be aluminum foil, polyethylene or fiberglass. The parts differ in the thickness of the reinforcing layer and base.

In the manufacture of polypropylene pipes, the following marking of the material used in production is used:

- RR-N. Products for cold water, can be used for ventilation systems.

- RR-V. Material for the production of products with high impact resistance. Designed for cold water supply and floor heating.

- PP-R. Pipes made from it can be used to install any type of water supply system.

- PPs. It is used in the production of low-flammability products intended for pipelines through which hazardous substances are transported.

The classification of materials used in the manufacture of pipeline products from thermoplastics for the construction of communications is given in GOST number 52134-2003.

Single-layer polypropylene pipes are mainly used for transporting cold water

The marking of finished products is different. The following nomenclature designations are used for polypropylene pipes:

- PN10. Products manufactured for the transportation of cold water with an operating temperature of no more than +20º C.

- PN16. Universal products that can be used for the construction of cold and hot water pipelines. However, the temperature of the liquid should not exceed +60º C. It is produced rarely, and in limited quantities.

- PN20. Pipes ensuring normal transportation of liquid tº +80ºС. By analogy with the previous type, it is considered universal.

- PN25. High pressure resistant parts can be used for both plumbing and heating. The pipes are reinforced with aluminum foil and can be used to transport water with temperatures up to +95ºС.

According to the marking of the pipes, the pressure that the PP pipes can resist when water moves through them is determined. For example, PN 10 pipes operate normally at 1 MPa, PN 20 at 2 MPa, PN 25 at 2.5 MPa.

Polypropylene is sensitive to ultraviolet radiation, so pipes are available in different colors. Black parts have the greatest resistance to UV radiation. The production of polypropylene pipes is standardized, so they are produced in certain sizes.

Multilayer reinforced pipes can withstand higher temperatures and pressures. The reinforcing layer can be made of aluminum, as in the picture, or fiberglass

The first thing you need to pay attention to is the internal and external diameters. They can be indicated both in inches and in the usual millimeters

The diameter values determine the selection of the dimensions of the fittings that will be used to connect the pipeline parts.

The outer diameter of the products varies from 16 to 500 mm. The length of the pipes can be from 2 to 5 m, which is quite enough for arranging an internal water supply system. Moreover, the products are easy to process.

The diameters of PP pipes must be taken into account when selecting connecting parts for pipeline assembly. It is assembled using detachable connections using fittings and tees (+)

Dimensions of shaped elements

The cross-section of the laid pipe sections and connecting fittings usually coincides. In transition fittings, the diameters of the outlet holes may differ, but the size of the input is always similar to the corresponding section of the line.

Inside the building, pipes of the following diameters are used to drain wastewater:

- from shower, washbasin, bidet, sink, bath – 40 mm;

- from the toilet and central riser – 110 mm;

- from the main riser – 60 mm.

The combined drain that combines the bath, shower and sink is equipped with 50 mm parts.

For laying communication networks outside the building, fittings with a diameter of 160–200 mm are chosen.

The size ratio of commonly used fittings for PVC sewer pipes is clearly displayed in the table:

| Element | Diameter (mm) | Length (mm) |

| coupling | 110–400 | 120–330 |

| Audit | 50–315 | 167–500 |

| Retraction | 110–400 | 15–90 |

| Expansion pipe | 50–500 | 170–320 |

| Check valve | 110–250 | 300–520 |

| Double siphon | 110–200 | 510–820 |

Tees with an angle of 45 degrees are produced with a diameter of 110–400 mm, the length of their side bells is 140–530 mm, the height from the end to the bell protrusion is 140–500 mm.

Tips for choosing

An important point when installing a sewer system, regardless of whether it is internal or external, is where the installation is taking place and the expected operating conditions. No less attention is paid to the size and quality of the pipeline.

It is quite difficult to independently calculate the appropriate diameter for external sewerage in certain conditions, but there are general recommendations that will help solve the problem.

- A 5-centimeter diameter is quite enough for a shower, drainage from a sink and similar elements.

- From the toilet, drains are discharged into 11-centimeter structures.

- To equip a full-fledged bathroom in apartments and private houses, the minimum size is also 11 cm. If the house is multi-story, then craftsmen often choose vertical systems with a diameter of up to 15 cm. If they are made in accordance with GOST 51613 2000.

- 20 centimeters should be equal to the cross-section of the pipeline, if we are talking about a pipeline in a horizontal plane, which collects and discharges wastewater from the entire house.

- The branch through which drains flow from plumbing fixtures to the pipe vertically should not be smaller than the riser.

Video

Pipes for external and internal sewerage. Recommendations from experts // FORUMHOUSE

PVC plumbing pipes with pressure

Such 50 mm pipes differ from others in that they can withstand pressure of up to 10 atmospheres.

They are relevant for systems in which pumps are responsible for forced circulation of liquid. This creates artificial pressure, and then the flow becomes continuous.

The installation of pumps will be especially relevant where there are many apartments and large premises.

The wall of a pipe with a size of 50 mm increases in thickness, otherwise they will not be able to withstand the increased load. The use of multilayer products is allowed. And here the characteristics are regulated by GOST 51613 2000.

Pressure external pipe materials with a diameter of 50 mm are installed even where the pump will not operate on a permanent basis.

Non-pressure type of PVC pipes

They are most often used in modern sewer systems. Their design is standard. They are not recommended for use in systems with artificially created pressure.

It is possible to install pressure pipes along the entire length of the external sewer system, but this solution is too expensive. Similar non-pressure materials are 25 percent cheaper than pressure materials.

Watch the video

About corrugated varieties

They have the most unusual appearance. The walls look like an accordion. This allows installation even in places where access is difficult.

The structure has an inner and outer layer. A smoother material is used to make the inside so that blockages do not appear inside. The outer layer is standard PVC.

How to connect plastic pipes to cast iron?

Adapter sleeves and fittings will help connect any external pipes. Even if part of the branch is made of cast iron, part remains plastic.

A regular rubber adapter will suffice if you need to connect a system that has a socket. Plastic external adapters are needed where there is no socket.

When using rubber cuffs, replacement is carried out as follows.

- We clean the 250 mm bell from plaque and dirt if they appear on the surface.

- Apply a layer of sealant to the outer surface of the socket. After which the part is inserted.

- A plastic pipe for the sewer system is connected to a cuff.

Plastic connecting elements require a slightly different procedure.

- We level the edge of the pipeline by 250 mm using a grinder if part of it bursts during operation.

- We put a 250 mm rubber cuff on the structure. Its surface is pre-coated with a composition for high-quality sealing.

- A plastic adapter is placed on top.

Video

What is the variety of products in question in the current plumbing parts market?

All existing sewer pipes can be distinguished by the following characteristics:

What does color say?

- Area of operation. Based on this feature, the products in question are for indoor or outdoor use. Products for indoor use differ in color (gray or white), the diameters of such parts are usually small, and the range of thermal loads is high. External products are painted orange, their main feature is multi-layering.

- Terms of Use. Such products can be pressure (designed for use under pressure), non-pressure (for example, for storm drainage) and corrugated.

Common Possible Errors

Often, when preparing for work, specialists or site owners inattentively prepare materials and components of components according to diameters and characteristics

It is important to consider the intended use both in terms of size and temperature characteristics

The work must be planned, also depending on the weather conditions, taking into account the temperature regime of the surrounding air.

When soldering the material, carefully ensure that the existing pipe does not burn through, in order to avoid applying additional patches and unnecessary elements, as this will weaken the insertion site.

HelpfulUseless

What are the main advantages of a sewer system assembled from PVC?

The most significant advantages of the parts in question include the following positive features:

What does the system look like after assembly?

- The impossibility of clogging the system is ensured by the maximum smoothness of the surface inside the product.

- High degree of resistance to the influence of alkalis and other aggressive compounds.

- Low cost when compared with analogues made from other types of raw materials.

- Total resistance to corrosion.

- High melting point. Long heating at a temperature of 70 degrees or short-term heating at 140 degrees remains harmless.

- An impressive service life, which often reaches 100 years.