One of the most important parameters that you should pay attention to when selecting pipes for a sewerage system is, in addition to the pipe material, the diameter of the sewer pipe, because for different internal sewerage systems, pipes of different diameters are used. All sewer pipes are manufactured strictly in accordance with the Technical Specifications. At the same time, manufacturers offer a huge selection of products in different sizes. Therefore, it is easy to choose exactly what is required for each specific case. The article below will tell you how to do this.

The diameter determines the purpose of the pipe

The influence of diameter on other pipe parameters

As we have already said, one of the main parameters of any pipe is its diameter. He defines the scope of its application:

- to drain water from a free-standing bathtub or sink, use pipes with a diameter of no more than 75 mm;

- pipes draining wastewater from the toilet should already have a diameter of 100-110 mm;

- Large-diameter sewer pipes are used to drain all collected sewage outside the building.

The diameter of the sewer pipes determines their other parameters:

- Pipe wall thickness . Large diameter pipes (up to 160 mm) have larger wall thicknesses than pipes with a diameter of up to 110 mm. They are 3.9 and 3 mm, respectively.

- Pipe weight . 1 m of pipe with a diameter of 160 mm weighs about 2 kg, while a pipe with a diameter of 110 mm of the same length weighs just over 1 kg.

Effect of diameter on other parameters

cesspool

Cesspool made of reinforced concrete rings

A cesspool is a container in which the side walls are sealed, and all waste flows into the ground through a leaky bottom (the bottom is open ground). A cesspool is suitable for those houses in which the daily volume of wastewater does not exceed one cubic meter.

The walls of the cesspool can be made of ceramic bricks, reinforced concrete rings, or monolithic reinforced concrete. A cesspool works on the following principle: dirty wastewater, entering the cesspool, easily seeps into the ground, and solid human waste products accumulate at the bottom, gradually sealing the soil bottom.

Bottom of the cesspool

A layer of sand 20 cm thick is first poured onto the bottom, and then a layer of crushed stone 20 cm thick, this will allow the sewage to be cleaned before it enters the ground, and will also prevent the soil bottom from hardening.

Ilosos

Over time, solid human waste products decompose under the influence of bacteria and turn into sludge. This sludge is pumped out by a special machine - a sludge sucker , the delivery of which is ordered when the cesspool is filled. In this case, it is necessary to ensure convenient access of the suction pump to the cesspool hatch.

Most sludge suckers and cesspool machines have a standard hose length of 10-15 m, while the hose can be extended to 25 m. However, this does not mean that with a 25 m hose you can pump out sludge and waste from a depth of 25 meters. Vacuum trucks and suction pumps have a special parameter in their characteristics – the maximum lifting depth. For some machine models, the lifting depth reaches 10 meters.

As a rule, external sewer pipes from the house to the cesspool are laid below the freezing level of the soil so that the pipes do not burst from the drains frozen in them. And the useful volume of the pit is calculated from the sewer pipe entering it. Therefore, the bottom of the cesspool should be 2-3 meters below the soil freezing level (depending on the daily water flow), but 1 meter above the groundwater level If this condition is not met (the groundwater level is higher than the freezing depth), then a cesspool with a sealed bottom (storage tank) is installed. You can find out the groundwater level by looking into the nearest well (it is better to do this in the spring, since the aquifer rises to its highest level during this period). If there is no well nearby, then you will have to call a special team of geologists who will measure the exact level of groundwater.

As for placing a cesspool on the site, the following rules should be followed:

- The distance from the water intake to the cesspool, depending on the type of soil, should be: 20 meters, if the soil is clayey ; 30 meters if the soil is loamy (a mixture of clay and sand); 50 meters if the soil is sandy .

- The distance from the house to the cesspool should be 10-15 meters so that water from the cesspool does not moisten the soil under the foundation, which can lead to excessive heaving of the soil in winter, which in turn will lead to the appearance of cracks in the foundation. Also, the distance of the pit from the house will relieve the residents of this house from constant unpleasant odors.

- The distance from the fence to the pit must be at least 1 meter. In general, all buildings on the site should be placed at a distance of 1 meter from the fence.

Inner and outer diameter

Typically, factory markings indicate only the outer diameter of the sewer pipe and its thickness.

Pro tip: In order to determine the internal diameter of the pipe you are purchasing, you need to subtract twice its thickness from the external diameter.

It is necessary to know the internal diameter of the sewer pipe so as not to make a mistake in selecting pipes to perform certain tasks in the sewerage system being installed.

There is an approximate gradation of pipes used in certain cases for internal and external sewerage:

- Pipes with a diameter of 25 mm are used to drain water from the washing machine or dishwasher.

- Pipes with a diameter of 32 mm are suitable for drainage from the shower cabin, bathtub, and sinks.

- The general sewerage distribution in the apartment consists of pipes with a diameter of up to 40-50 mm.

- To drain all wastewater outside, pipes of the largest diameter are used - from 160 to 200 mm.

Basic pipe parameters

Pipes made from different materials are usually used for different types of sewerage. Thus, for the installation of external sewerage, plastic pipes are often used, for example, PVC sewer pipes: their diameter is most often 110 mm.

Cast iron pipes have markings that indicate their nominal (actual) diameter. For example, the designation “DN 100” indicates that the diameter of the “nominal bore” of the pipe is 100 mm. Thus, to determine the nominal internal diameter of cast iron sewer pipes, it is enough to check their markings.

Diameter is determined by marking

Types of sewerage

Two main systems are used:

- pressure;

- gravity flow.

The first is used in limited cases:

- the location of the source of wastewater is located below the main line of the drainage system;

- difficult terrain;

- wastewater receiver located above the building.

The most common type is a gravity drainage system. Due to a number of factors:

- simplicity of design;

- absence of external forced sources of movement of liquid waste (electric pump);

- independence from electricity;

- simplified installation;

- Less durable, therefore cheaper, products are used.

Smallest permissible diameters

According to Sanitary Norms and Rules (SNiP), for various types of sewerage networks, pipes can be used, the minimum size of which is:

- for the drainage of industrial and domestic waters inside the block - 150 mm;

- for the same street networks – 200 mm;

- for a quarterly network that drains rainwater - 220 mm;

- for street stormwater network – 250 mm;

- for networks that discharge sludge under pressure - 150 mm.

In some cases, minimum pipe sizes are allowed:

- for settlements where the volume of wastewater does not exceed 300 cubic meters per day, both for street and neighborhood networks that discharge industrial waters, it is possible to use pipes with a minimum diameter of 150 mm;

- For some production networks, if justified, this diameter may be even smaller.

Material counting

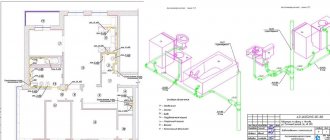

At the initial stage, you need to draw a site plan and transfer all sewerage elements into the project, including a septic tank, pipeline, connecting elements, riser, and drain pipe. The design is carried out taking into account the location of bathrooms and household appliances (washing machine and dishwasher).

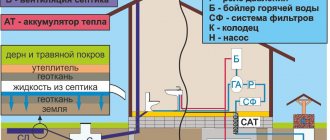

In the private sector, where there is no centralized sewage system, wastewater from the house goes to autonomous biological treatment stations. 98% purified process water is discharged into the ground or drainage ditch by gravity or forced method. The first option is suitable for permeable soils with low groundwater levels. Forced drainage is used in impermeable rocks, quicksand and in areas with high groundwater levels. In this case, you will need an additional pump to supply water in the right direction. To carry out calculations, use ready-made SNiP tables or an online calculator.

14.05.2021 235

Determining the exact pipe diameter

Convert mm to inches

Converting millimeters to inches

It is sometimes not very easy to determine the diameter of the required pipe, since it is often indicated not in millimeters, but in inches. To move from one unit to another, there are various tables that you can use.

The conversion table shown in the figure above is used if it is possible to measure the diameter (the pipe is not fixed) with a ruler or using a caliper.

Measuring a pipe at home

Pro tip: To measure the diameter of an existing (installed) pipe at home, you just need to apply a ruler to it and measure its “thickness”. If the resulting number is about 32 mm, then the fitting diameter of the pipe is 1 inch; about 28 mm is already ¾ inch; 16 mm - ½ inch.

Septic tank

A septic tank is a sealed container divided into two or three sections, or a system of two or three separate containers.

A septic tank, like a storage tank, can be built from monolithic reinforced concrete or reinforced concrete rings, or laid out of brick. You can also order a ready-made septic tank from specialized companies, which is a solid plastic body, the internal space of which is divided by partitions.

Sections or separate containers are connected to each other by a pipe through which wastewater that has passed the purification stage flows from one section (container) to another.

Septic tank operation diagram

In the first chamber, the sewage goes through the stage of initial rough cleaning: heavy particles settle to the bottom, light particles rise to the surface forming a fatty crust, and between these layers the water is clarified. Then the clarified water enters the second chamber for deeper cleaning.

A tee is placed on the inlet pipe , which will direct the incoming wastewater straight down without destroying the fat layer. The lower end of the tee must be constantly recessed into the wastewater, and the upper end must be above the surface of the drains in order to clear the tee from blockages without disturbing the fat layer. Above the tee, as a rule, ventilation is installed in the form of a piece of pipe, which should rise 70-80 cm above the ground surface so that the ventilation of the septic tank does not end up under snow in winter.

A single-chamber septic tank is used when the volume of wastewater is no more than 1 m3. Accordingly, a two-chamber septic tank is used when the volume of wastewater exceeds 1 m3.

Single chamber septic tank

In the case of a single-chamber septic tank , a tee is installed at the outlet of the septic tank, just like at the entrance, only a little lower. The tee at the outlet will allow only clarified water to be discharged outside, leaving a fatty layer in the septic tank. Clarified water from a single-chamber septic tank does not immediately enter the soil, but into special treatment facilities: filtration fields, filter trenches or filter wells, or into sand and gravel filters. And only after filtration does the purified water enter the soil.

Two-chamber septic tank

If you are designing a two-chamber septic tank , then instead of an outlet tee, a bypass pipe is installed at a depth of 50 cm from the bottom. It will ensure pumping of clarified water into the second chamber. In addition to the bypass pipe, a ventilation pipe is installed at a distance of 20 cm from the surface of the wastewater.

Any septic tank, be it single-chamber or double-chamber, is designed only in conjunction with treatment facilities , because... The septic tank carries out only rough mechanical treatment of wastewater.

Two-chamber septic tank with filter well

a three-chamber septic tank on your site, because... two chambers are enough to clean the wastewater to the required level, especially since the wastewater after the septic tank goes through a fine treatment stage in treatment facilities. In addition, to increase the level of purification, it is not at all necessary to increase the number of chambers, because wastewater is purified due to the time spent in the chamber; the longer the water settles, the better it will be purified. In this case, you should increase the volume of the chamber, and not their number.