Cleaning storm drains or storm drains is a standard maintenance procedure for this engineering structure. How to properly clean trays and pipes? Is it possible to cope without the help of specialists? How to choose a cleaning method? Is there a budget option for preventive maintenance?

In this article we looked at the features of cleaning storm drains. We have also added useful tips from experts: important technical points.

The review contains additional materials such as videos, tables, photos, diagrams, step-by-step instructions for cleaning work.

Purpose of storm drain

Storm sewerage is designed to control the level of ground and surface water. During the period of spring snow melting or heavy summer rains, properly laid sewerage prevents flooding of the site and erosion of the foundation.

Obviously, without this hydraulic system, owners are unlikely to be able to cope with excess water without damaging property. In suburban areas, three types of storm drains can be used:

- open - in the form of trays and storm water inlets;

- closed - deep system or pipeline;

- mixed - a system with surface and deep engineering elements.

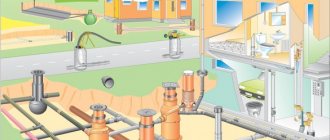

Underground equipment diagram

| 1 - inlet pipeline 2 - waste container 3 - submersible pump 4 - ball valve 5 - storm inlet 6 - overflow pipeline 7 - pressure pipeline 8 - wash water pipeline 9 - waste water supply 10 - sand collection hopper 11 - purified waste water discharge 12 - low resistance drainage 13 - thin-layer block 14 - sediment pits | 15 - rotary pipe 16 - tank for oil products 17 - drainage of wash water 18 - filter with floating load 19 - float level indicator in front of the filter 20 - fire arrester 21 - floating load 22 - high resistance drainage 23 - housing 24 - cover 25 - supply pipeline 26 — sorbent 27 — drainage 28 — discharge pipeline of treated wastewater |

Main problems and features

Open drainage is one of the popular and easy-to-implement ways to solve the problem of excess water. Manufacturers produce trays, gutters and drains of any colors and sizes - choosing the most suitable storm drain design will be quite simple.

Closed systems are more difficult to install. To assemble them correctly, it is necessary to make calculations that take into account the groundwater level and the amount of precipitation in a particular area. Owners are not always able to make such calculations.

Therefore, it is common practice to contact architectural bureaus or city water utilities, whose specialists can help you correctly calculate the diameter and length of pipes, as well as determine the configuration of the system. Sometimes additional installation of pumping equipment is required, without which water cannot flow into the collector.

A mixed type of shower is an ideal solution for saving the family budget. Small plots can be easily served by compact engineering structures located around the house and in the adjacent territory.

Design of treatment systems

The design of treatment facilities is designed based on the following factors:

- Groundwater level. The most important factor for autonomous treatment systems. When installing a septic tank with an open bottom, the wastewater, after settling and biological treatment, is removed into the ground, where it enters the groundwater. The distance to them should be sufficient so that the liquid is cleared as it passes through the soil.

- Chemical composition. From the very beginning, it is necessary to know exactly what waste will be cleaned and what equipment is needed for this.

- Soil quality, its penetrating ability. For example, sandy soils absorb liquid faster, but clay areas will not allow wastewater to be disposed of through an open bottom, which will lead to overflow.

- Waste removal – entrances for vehicles that will service the station or septic tank.

- Possibility of draining clean water into a natural reservoir.

Causes of blockages

During operation, the storm drain periodically breaks down. This is due to the peculiarity of this type of sewage system. When there is an increased load on the water drainage system due to the melting of high snow cover or heavy rains, earth, sand, small branches, grass, leaves, and debris penetrate into the trays and pipes. The resulting blockage can reduce the efficiency of the sewer system to zero.

You can solve the problem yourself - this is relevant for mixed and open (surface) systems. It is also practiced to contact special companies that provide services of this kind. Calling specialists is not a cheap pleasure. Owners turn to them only in extreme cases, when they cannot cope with blockages in underground communications.

It should be noted that any sewer systems require regular preventive inspections, which significantly reduce the risk of blockages. Such inspections are performed once or twice a year. Preferably in autumn and spring. In the spring, there is a high risk of various debris being transferred into the open elements of the system, and in the fall, fallen leaves and small branches get into it. An extraordinary inspection is always carried out:

- in case of repair work on the roof;

- after paving the yard or laying tiles;

- after carrying out cosmetic or any repairs to buildings.

Any construction work carries the risk of bitumen, small brick chips and other construction debris getting into the storm drain.

Local treatment plants (VOC or AC)

During normal operation, autonomous sewerage installations are capable of producing fairly clean water.

It cannot be used as drinking water or for watering the garden, but as a technical one it is very possible. The basis of cleansing is the work of aerobic bacteria (they live in the presence of oxygen). The waste they process turns into sludge, settles to the bottom of a special tank, from where it is then pumped out. Pumping frequency is 1-4 times a year, depending on the intensity of use. In general, an autonomous wastewater treatment plant is a good thing, but it has certain operational features that you must know before deciding what is better for the sewage system of a private house - a septic tank or an AC.

This is roughly what installations for an autonomous sewer system in a private house look like. This is AU Topas

At the outlet, the ACs have water purified by 90-95%. With this quality, it can be poured onto the ground, however, for this you must have laboratory tests on hand. Therefore, many still prefer to use an intermediate settling well from which the water is then used for technical purposes. The second option is to divert the wastewater to filter devices. This, of course, is reinsurance, but in emergency situations it saves.

What is used to clean wastewater?

Waste is processed by anaerobic bacteria (they live only in the presence of air). To provide them with air in the VOC, aerators are constantly running. In addition, during cleaning, the contents are pumped from one compartment to another using built-in pumps. So without electricity, these installations are inoperable.

Inside the AU is also divided into chambers (this is Topas)

If the electricity is turned off, bacteria can survive without air for no more than 4 hours, after which they die, and the wastewater ceases to be processed. To start the system, it needs to be populated with new bacteria, and reaching a working state is possible only after 2-3 weeks. All this time, the wastewater will flow, at best, semi-purified. This is where a sump well or filter unit comes in handy. It will improve the situation at least a little.

Features of operation

Since the volume of autonomous treatment plants is small, they need constant feeding: bacteria need nutrients for normal life. Therefore, this type of device is suitable for private homes of permanent residence - regular receipts are needed. In principle, preservation for a certain period is possible, but the procedure is not pleasant, and it will take a long time to return to the installation mode.

Bacteria that process waste in automatic wastewater treatment plants are also sensitive to active chemicals. Since the chamber volumes are smaller, the release of detergents or disinfectants can significantly damage the recycling process. Moreover, cleaning and antibiotic treatment can negatively affect.

Station after operation 3-6 months

VOCs are much smaller in size than septic tanks. They are calculated depending on daily water consumption, but there is such an indicator as salvo discharge. This is the amount of waste that an autonomous sewer installation can accept at one time. If this value is exceeded, untreated wastewater flows into other chambers, which significantly reduces the degree of purification. So, in this situation, you have to decide which plumbing fixtures and household appliances work at the same time. And if the bathtub is drained, no other devices should work for some time.

Briefly: advantages and disadvantages

Autonomous sewerage treatment plants are certainly convenient; with them, sewerage for a private home is implemented quickly - installation takes 10-12 hours. Pumping out excess sludge is necessary several times a year (1-4 times depending on the intensity of use, but maybe less or more often). The amount of sludge pumped out is very small (5-10 buckets depending on the model) and maintenance can be carried out independently, although the procedure is not the most pleasant. But they are doing this, since the visit of a specialist is not cheap at all.

This is what it looks like on the site

These home treatment plants have some disadvantages: the high cost of the equipment, dependence on the availability of electricity and the need to monitor the condition of the equipment.

Components of a private treatment structure

The treatment system, which is used for domestic purposes, has the following structural elements:

- special container for collecting liquid;

- sand trap;

- oil separator or oil separator;

- sorption device.

Container for collecting liquid

This element of the treatment system is connected directly to the storm sewer. Such a tank is designed to collect wastewater that is formed as a result of heavy rainfall or melting snow.

The wastewater collection container collects liquid. From this container, moisture flows into other parts of the structure, where storm drains are gradually cleaned. The main function of this tank is to protect the cleaning elements of the system from overload.

You can read more here.

Sand trap

This device comes into operation at the first stage of cleaning. The sand trap performs a filtering function and separates large particles contained in wastewater. This part is indispensable, as it is capable of retaining about 65% of the debris that sewage water contains.

When using the sand trap, you must remember that it needs regular cleaning. This equipment should be checked at least once every 3 months, as well as immediately after heavy rainfall.

You can read more here.

Oil separator or oil separator

Any treatment facility must be equipped with an oil separator or oil separator. Such equipment is designed to purify storm water wastewater from oil waste and oils. These substances pollute soil and water and are emitted primarily from cars.

Stormwater treatment

Special filters retain oil and petroleum products contained in the water flowing into the system.

Wastewater purification from petroleum products is carried out through filtration. After the contaminants are filtered out, they are coagulated (combined) into larger components. After coagulation, oily stains fall on the surface and are removed using special equipment.

You can read more here.

Sorption device

The sorption block is the last stage of purification from harmful impurities of wastewater. This device adsorbs small particles that have passed through the first stage of purification, and also collects the remaining petroleum products and oils remaining in the water after the oil trap.

The sorption device is equipped with several filters that capture the smallest particles. These filters must be replaced periodically.

You can read more here.

Features of storm drainage

The work of a storm drain is not limited to simply collecting precipitation. Wastewater must be disposed of, and before that, cleaned of harmful impurities. Water disposal and wastewater treatment is carried out by any sewer network. Harmful impurities that are present in wastewater include:

- gasoline and motor oil;

- various chemical reagents that are used to sprinkle roads in winter;

- a variety of garbage that, one way or another, ends up in wastewater.

Note! These impurities are removed from the water thanks to treatment plants, which include various equipment. Storm water treatment occurs in several stages.

If the system is not equipped with cleaning devices or does not cope with the assigned tasks, the sewer system may become clogged.

Mechanical method of cleaning the system

The most affordable and popular cleaning method, which is perfect for all open storm drains, is mechanical. It does not require any special equipment or special skills, except perhaps caution when working at heights. The essence of the work is the mechanical removal of accumulated debris.

Mechanical cleaning of gutters

Before you start cleaning, be sure to protect your hands with thick gloves to protect yourself from sharp fragments and insects.

To complete this task, you will need simple equipment: a ladder, a brush with bristles made of plastic or synthetic fibers, a spatula or dustpan, a garden hose with a water connection.

You can make an excellent tool with your own hands from an ordinary plastic bottle by cutting a semicircular hole in it along the diameter of the gutter. Just before you start cleaning, do not forget to protect your hands with thick gloves to protect yourself from sharp fragments and insects.

Cleaning should be carried out from the highest point, covering all elements of the system:

- From the gutters laid on the roof, the accumulated garbage must be raked onto a scoop and placed in a bag for further disposal. Just don’t push leaves and other debris into the drainpipes; it’s better to sweep everything out with a broom or brush, and then clean the surrounding area.

- Funnels - connecting elements that connect gutters and rain pipes - are most often equipped with grates that need to be removed and washed. If there is no such protection, you can simply clean the elements under water pressure, removing traces of dirt and small debris, and pre-collect large ones by hand.

- The drainpipes through which waste is directed downwards are also easiest to rinse under good pressure, using a brush to help yourself. If you can’t get the blockage out with your hands and a brush, and it doesn’t respond to water, you can use a plumbing drill or cleaning tapes. Only such equipment must be used with caution so as not to scratch the protective coating of the pipes, which leads to metal corrosion.

- Drainage channels must first be cleared of protective grilles (if installed), cleared of debris and rinsed with water.

- Now inspect the wastewater storage tank (ditch, drainage field), if necessary, remove the sludge and update the filter layer.

- All that remains is to return all the grilles and other elements of the system and check its operation using the same hose with water pressure.

Specialized cleaning machines of the sectional, rod or drum type can make manual labor easier, although they are more designed for removing blockages in pipes rather than cleaning open gutters.

But there is also an option for those who do not want to collect leaves themselves - a robot vacuum cleaner.

Automated robot vacuum cleaner

Such devices can even cope with wet leaves, work in water and are equipped with a recognition system that helps determine how many passes will be required to completely clean the drain.

Once you install this miracle of technology on the roof, it will begin to move around the perimeter of the gutter system, removing dirt and debris accumulations with brushes. Can be powered by electricity or batteries.

Types of autonomous sewers

There are three types of independent sewer systems:

- A cesspool is a closed storage tank without filters that requires periodic cleaning.

- A septic tank is a storage tank that filters waste using bacterial mass. After cleaning, the liquid enters a filtration well with a crushed stone base. The harmless water is then released into the soil.

- Local stations purify wastewater by 95–98%. These include biological treatment pump systems and aeration units with compressors.

Autonomous sewage systems of a private house are divided into internal (installed inside the building) and external (branches from the internal pipe to the storage tank with a filter). External sewers are collected in the form of gravity or pressure structures. Gravity feeders are energy independent, but cannot be located far from home.

According to the method of waste removal, general alloy, semi-separate and separate systems are distinguished. Pressure sewers are equipped with pumps and are installed at a considerable distance from the main building.

Cesspools

The simplest autonomous sewer system for a private home, which you can install yourself, is a closed storage tank with a pipe system. A container in the ground is suitable for collecting household wastewater in the country. The main disadvantage of a pit is the high risk of soil and groundwater contamination on the site.

A closed waste storage tank can be assembled from ceramic bricks, made from a plastic container, reinforced concrete rings or monoliths. A pipeline is laid to the buried container below the freezing level of the ground.

Septic tanks

For installing an autonomous sewer system in a private house, a septic tank is preferable. The settling tank is easy to install and does not cause problems during operation. The flows entering the septic tank pass through several reservoirs, are gradually cleaned, and then go into the ground or into the receiving water.

The cleaning principle depends on the type of structure:

- simple septic tanks are equipped with a filtration well;

- systems with soil post-treatment consist of a settling tank with anaerobic bacteria, a filtration field, and drainage pipes;

- multi-stage septic tanks have wide underground filtration fields and a distribution well;

- settling tanks with infiltrators drive water through several purification chambers.

Local treatment station

Biological treatment stations consist of chambers for mechanical and biological filtration. The main advantage of the installation is cleaning with fine-bubble aeration - saturation of the bacterial environment with oxygen. The system enriches the wastewater divided into fractions with oxygen and mineralizes it in the aeration tank. In the same compartment, microorganisms decompose the organic matter in the water. The processed sludge settles in the settling tank, and the undecomposed fat is returned to the aeration tank.

To speed up the process, the system is equipped with a pump. Water that is 98–100% purified is suitable for irrigation and other household needs.

Flushing storm drains under water pressure

A closed or mixed system can also be cleaned mechanically at the top (above ground) part. True, you will have to make preliminary preparations - remove the nets or grates from the gutters, arm yourself with a brush on a long stick or a blower.

But to clean an underground drain, you may need hydraulic equipment. A simple garden hose is no longer enough here, since its pressure is not enough to break up plugs of sand, dirt and wet leaves. Hydraulics provide a powerful water jet, which perfectly washes out simple debris from the pipeline.

Cleaning with water

The choice of equipment largely depends on the design of the pipeline (straight, winding) and the diameter of the pipes, but in any case, it is worth first mechanically cleaning the ground elements of the storm drain so that the debris washed away under the pressure of water does not clump somewhere on the way to the exit.

And you can detect a blockage through inspection wells or using video diagnostics - modern devices are equipped with a sensor and a cable, which, passing through the pipes, makes a recording or immediately transmits to the display an image that clearly demonstrates the condition of the sewer from the inside.

Typically, systems for country houses and small houses are equipped with elements with a diameter of 20-22 cm. To flush such a sewer, a household car wash with a power of 120-150 bar is sufficient.

But to clean the wide pipes that large cottages are equipped with, you will have to call in specialists with professional hydraulic equipment, which is equipped with a long hose and a powerful pump.

Destruction of blockages using a hydrodynamic method

Hydrodynamic machines for cleaning storm drains and sewer systems are equipped with high-pressure pumps with a power of about 200 MPa, and special nozzles additionally increase the pressure and easily wash away debris deposits.

Professional hydraulic machines are also equipped with nozzles that can cope with both simple and complex types of blockages:

- Universal - used for regular drain cleaning and removal of soft debris.

- Bottom – effectively removes leaves, pieces of polyethylene, soil, silt and other accumulations from storm drains.

- Punching – designed for crushing construction waste, accumulation of leaves and branches, sand, paper.

- Carousel-chain - will cope with old deposits and caked debris that do not respond even to strong water pressure.

To use the hydrodynamic method of cleaning pipes, the site must have an uninterrupted supply of water and electricity. Otherwise, you will have to look for equipment that runs on gasoline, or call a car with a tank.

But this technology, unlike other methods of sewer cleaning, absolutely guarantees the integrity of all drainage elements.

Catalog of storm water treatment stations

Name of BAZMAN series rainwater treatment systems

BAZMAN LOS-PP-C-OKF

- BAZMAN is a trademark;

- VOC - storm water treatment plant;

- PP - polypropylene (body material);

- C - cylindrical (body shape);

- OKF - settling tank, coalescent block, sorption filter

| Name | Productivity, l/s | Volume, l | Diameter, mm | Length, mm | Diameter of pipes, mm | Neck diameter, mm | Number of necks, pcs. |

| BAZMAN LOS-PP-C 1-OKF | 1 | 1600 | 955 | 2300 | 110 | 700 | 2 |

| BAZMAN LOS-PP-C 3-OKF | 3 | 1900 | 955 | 2700 | 110 | 700 | 2 |

| BAZMAN LOS-PP-C 5-OKF | 5 | 3300 | 1250 | 2700 | 160 | 700 | 2 |

| BAZMAN LOS-PP-C 7-OKF | 7 | 4200 | 1250 | 3500 | 160 | 700 | 2 |

| BAZMAN LOS-PP-C 10-OKF | 10 | 6800 | 1250 | 5600 | 160 | 700 | 2 |

| BAZMAN LOS-PP-C 15-OKF | 15 | 9800 | 1570 | 5100 | 160 | 700 | 2 |

| BAZMAN LOS-PP-C 20-OKF | 20 | 16200 | 1570 | 8400 | 200 | 700 | 3 |

| BAZMAN LOS-PP-C 25-OKF | 25 | 20400 | 1900 | 7200 | 250 | 955 | 3 |

| BAZMAN LOS-PP-C 30-OKF | 30 | 24600 | 1900 | 8700 | 250 | 955 | 3 |

| BAZMAN LOS-PP-C 35-OKF | 35 | 26000 | 1900 | 9200 | 250 | 955 | 3 |

| BAZMAN LOS-PP-C 40-OKF | 40 | 27000 | 1900 | 9600 | 315 | 955 | 3 |

| BAZMAN LOS-PP-C 45-OKF | 45 | 30000 | 1900 | 10600 | 315 | 955 | 3 |

| BAZMAN LOS-PP-C 50-OKF | 50 | 31100 | 1900 | 11000 | 315 | 955 | 3 |

| BAZMAN LOS-PP-C 60-OKF | 60 | 33700 | 1900 | 11900 | 315 | 955 | 3 |

| BAZMAN LOS-PP-C 70-OKF | 70 | 36800 | 1900 | 13000 | 315 | 955 | 3 |

| BAZMAN LOS-PP-C 80-OKF | 80 | 37900 | 1900 | 13400 | 315 | 955 | 3 |

| BAZMAN LOS-PP-C 90-OKF | 90 | 44000 | 2200 | 11600 | 315 | 955 | 3 |

| BAZMAN LOS-PP-C 100-OKF | 100 | 48600 | 2200 | 12800 | 315 | 955 | 3 |

| BAZMAN LOS-PP-C 120-OKF | 120 | 58500 | 2200 | 15400 | 315 | 955 | 3 |

| BAZMAN LOS-PP-C 140-OKF | 140 | 67700 | 2300 | 16300 | 500 | 955 | 3 |

| BAZMAN LOS-PP-C 150-OKF | 150 | 70500 | 2500 | 14000 | 500 | 955 | 3 |

| BAZMAN LOS-PP-C 200-OKF | 200 | 80000 | 2500 | 16600 | 500 | 955 | 4 |

| BAZMAN LOS-PP-C 250-OKF | 250 | 108000 | 3000 | 15400 | 500 | 955 | 4 |

| BAZMAN LOS-PP-C 280-OKF | 280 | 124000 | 3000 | 17600 | 600 | 955 | 4 |

Thermal (steam) cleaning method

For mixed and closed systems combined with public sewerage, steam cleaning technology can be used. Blockages often occur here due to fatty growths on the walls of the pipeline, which do not respond to cold water, but literally disappear before our eyes under the influence of hot steam. To do this, water is heated to a temperature of 140 degrees and flushes the pipes.

But keep in mind that the thermal method is recommended to be used as the final stage after mechanical and hydrodynamic cleaning . But it should not be used as an independent method - the risk of injury is high, and the result is unpredictable.

Types of wastewater pollution

Even when choosing autonomous treatment facilities for a country house, the consumer should be aware not only of how the wastewater decomposition process occurs, but also be aware of its chemical and biological composition.

Knowing this allows you to select the optimal equipment option that will allow you to achieve a high degree of purification of such waters.

All wastewater, regardless of its origin, may contain the following types of contaminants in varying proportions:

- mineral, represented by inclusions of sand, clay, also including various types of salts, etc.;

- biological - these pollutants are of an organic nature and consist of a large number of different microorganisms, and the source of their formation can be both human activity and natural factors: such wastewater often contains decomposition products of flora or fauna;

- organic is a separate type of pollution, although it has certain similarities with the previous one. But in this case, the main sources of such waste are organic chemicals, including polymers.

As a rule, biological contaminants prevail in domestic wastewater, while in industrial wastewater it is mainly organic chemicals.

Cleaning with chemicals

In cases where other cleaning technologies are powerless against complex blockages, they resort to chemical reagents.

Such a need may arise if a large amount of greasy waste has penetrated into the system, which has stuck together into dense lumps with the debris present there, or the structure is so complex and tortuous that the plug is technically inaccessible for a cable with punching nozzles, and water cannot cope with the task.

Chemical pipe cleaner

The essence of chemical technology is that soluble reagents are released into the sewer system, which break down accumulations of dense debris and fat deposits into small particles, and then the pipes are washed under water pressure using the hydraulic method.

You should use such chemicals yourself with caution - most of them are toxic and, if they penetrate into groundwater, can cause severe poisoning. Therefore, sewerage can be cleaned using this method only with biochemical preparations, and only on the condition that the contaminated water first undergoes filtration and does not end up in drinking water sources.

How to choose a septic tank for autonomous sewerage

Before directly installing a local sewer system, it is necessary to correctly select the main equipment - a septic tank. This will determine whether the communications system can cope with the amount of wastewater that will be discharged into it during operation.

First of all, the septic tank is selected based on how many people will regularly use the sewer system. Such a parameter as daily productivity depends on this. The average water consumption rate is taken per person, which corresponds to a figure of 200 liters per day. That is, if 5 people permanently live in a house, then the septic tank must be able to process at least one cubic meter of wastewater per day (5 × 200 = 1000 liters, or 1 m3).

Some manufacturers make it easier for users to choose by indicating directly in the name of the septic tank model the number of people it can serve. Others necessarily provide the appropriate parameters in a detailed description for each modification of their equipment.

The second important parameter for choosing an active septic tank is the maximum volume of wastewater that it can accept at one time. The fact is that modern treatment plants are made very compact, plus they are divided into functional compartments, and therefore, if selected incorrectly, they may simply not cope with the volume of wastewater discharged into them. This parameter is always calculated individually by specialists, based on the equipment in the house connected to the sewer.

Review of storm drain cleaning methods: advantages and disadvantages

There are several popular methods for cleaning storm drains, each of which has its own advantages and disadvantages.

The mechanical method involves manually clearing the drainage system on the roof from accumulated debris - branches, fallen leaves. External gutters located near the house are also inspected. To do this, protective grilles are removed, debris is collected, and silt and sand are removed. The trays can be washed with water from a hose or a special device (under high pressure).

Advantages:

- ease of work;

- minimal financial costs (you can do the work yourself, that is, for free);

- in most cases no special equipment is required.

Flaws:

- the method is suitable for surface or mixed systems;

- used to remove simple blockages;

- is a labor-intensive process.

Thermal and chemical methods are additional measures for flushing the system, used in conjunction with mechanical or hydrodynamic cleaning of blockages. To dissolve severe blockages in underground pipes, chemical solutions are pumped into the system that can dissolve fatty accumulations of small debris. The thermal method involves pumping water heated to +110 degrees, which can clean out severe and medium-sized blockages.

Advantages:

- Highly effective against severe blockages.

Flaws:

- the listed methods are included in complex measures and are not used separately;

- special equipment required;

- chemicals can cause poisoning in workers and harm the environment (they are used in extreme cases).

Hydrodynamic cleaning is a classic procedure for washing a storm drain placed in the soil. To carry out the work, special equipment is used that copes with flushing both external and buried sections of the sewer system with equal efficiency.

Advantages:

- high efficiency;

- all work is carried out as quickly as possible;

- The method is suitable for removing blockages of any complexity.

Flaws:

- it is necessary to call specialists to your home;

- relatively high cost of services;

- mandatory use of special equipment;

- compact pumps can only be used in areas with a water supply system.

High pressure pumping units (from 180 to 200 MPa) are used for operation. A special nozzle is installed on the pump hose. The nozzle creates a strong pressure - jets of water wash away and remove any blockage inside the sewer.

There are several main types of nozzles that have characteristic shapes and sizes:

- universal;

- for punching work (removing old blockages of high density);

- chain-rotary for cleaning the most complex and dense dirt plugs;

- bottom for sand, small stones, broken stones, sticks.

They all work on the principle of generating jet thrust - the jets are directed in the direction opposite to the movement of the water flow. Such a thin jet cuts through any dirt accumulated in the pipe literally like a hot knife cuts through butter.

The works look like this:

- The grate is removed from the inspection well, and a hose with a nozzle is inserted inside. A water hose is connected to the pump! It is through this that water is supplied.

- The hose is carefully moved along the pipe. At this time, the dirt washed out by the strong pressure of water is poured into the well.

- Washing is done two to three times in a row. Then the dirty water along with the sludge is pumped out of the well. You can additionally rinse the walls of the well with clean water and drain it with a fecal pump.

Installation of treatment facilities

At first glance, the installation of treatment facilities is no different from the installation of other communications. Therefore, many enterprises, having ordered a project, try to complete the work themselves, without involving contractors, trying to save money. However, this is a fundamentally wrong approach.

How do wastewater treatment plants differ from other systems included in wastewater disposal?

- If the function of sewer networks is only to collect and deliver wastewater, then treatment facilities must rid them of all harmful impurities. For the functioning of many elements, for example, sand traps and sedimentation tanks, it is necessary that the necessary characteristics of the fluid flow through them be strictly observed. If the speed or pressure deviates, these units will not work at all or will be ineffective. Therefore, it is necessary to carefully observe the slopes and sections.

- While leaks from sewers are usually small, easily localized and do not cause much damage to the environment, wastewater treatment plants collect orders of magnitude larger volumes. If there was poor-quality installation and it led to a breakthrough of wastewater beyond the treatment plant, it is much more difficult to eliminate such an accident and minimize its consequences.

- Industrial wastewater may contain substances that are aggressive and harmful to health and the environment. Therefore, special requirements are imposed on the sealing of all system components. Only specialists with extensive experience in the industry can perform such work efficiently.

As can be seen from all of the above, it is best to involve industrial cleaning specialists in the installation. In addition, performing work by them has other advantages.

Preventing blockages

Experts recommend checking the operation of open storm drains and removing accumulated debris at least 2 times a year. After the autumn leaves fall, you need to remove all debris to prepare the drainage system for winter, and in early spring, make sure the integrity of the fastenings after frost and thaw.

But when there are tall trees near the building, you will have to look at the roof much more often if you do not want to find out about the need to clean up the water flowing down the walls and from the roof of the house, bypassing the rain pipes. But if all the gutters are in a closed type structure, one inspection per year is quite enough.

Means for preventing blockages

Rain storage tanks, sand traps, and protective gratings for open gutters will help reduce the frequency and duration of storm drain maintenance.

The following preventive measures will help prevent blockages:

- Special canopies for funnels and fine-mesh meshes/grids covering gutters will help reduce the amount of debris entering the drainage system. If the system is already installed and there is no desire to modernize some of its elements, you can fill the gutters with porous foam. It is applied by spraying, takes the form of a drain and does not allow large debris to enter the pipes (however, such protection needs to be updated every 3-5 years).

- Since an external storm drainage system is much easier to clean than an underground one, you can equip the drains with several catch grates that will stop soil particles, sand and leaves. To prevent blockages, it will be enough to regularly check the “control points” and remove debris from them.

- If a closed or mixed type system is installed on your site, it is worth installing grease traps in the pipes that lead household wastewater out of the house. This will help avoid difficult-to-remove formations on the walls of the sewer.

- If the underground part of the system has complex turns, it is worth installing inspection wells in potential places of blockages, so that if problems arise, you do not have to dig up the pipes.

In addition to additional protection of the system, it is worth taking care of wastewater treatment. To do this, you need to equip sedimentation tanks with drainage fields or separators that mechanically separate water from sediment and other impurities, or install an autonomous sewage system.

To avoid unscheduled cleaning of drains and sewer pipes, you need to take care to prevent blockages. Such complex measures include:

- installation of special filters in storm water inlets that ensure screening out large debris and organic residues - pine needles, leaves, dry grass;

- installation of sand catchers at the entrance to the collectors - this type of filter can also easily cope with sludge (all dirt will accumulate in a special sump located below the water drainage level);

- If oil products enter wastewater, it is necessary to additionally install sorption filters, settling tanks and separators.

Design and installation

Now let's look at some aspects of the design and installation of such structures. If we talk about design, then the correct calculation of the volume of the station, which will depend on the number of people, will be important. As already mentioned, according to SNiP 2.04.01-85, 200 liters per day are provided for one person. That is, for example, for a family of 5 people, a septic tank for 3 days of wastewater in it requires a volume of 3 cubic meters.

Another important aspect regarding productivity is the volume of the so-called salvo discharge. It makes it possible to know the maximum possible volume of waste that the tank can clean in a given period. We are talking about the discharge of wastewater from various sources. By the way, if you plan to discharge from the bathroom sink, it would not be superfluous to use a model with a grease trap. If the volume of the expected and actual salvo discharge is higher in favor of the latter, the quality of water purification will significantly decrease.

Another important point that should be taken into account when designing is the method of drainage. There are three of them.

- Output to a filtration field or filter type well. If we are talking about filtration fields, then they should contain a cushion of gravel or crushed stone at the bottom. This method is possible only in the presence of sandy or sandy loam soil, in which the excess volume of wastewater is absorbed by the ground.

- Using an intermediate well, which is made of reinforced concrete with a capital-type bottom with further access to the relief. This option will be relevant for several cottages that do not install individual VOCs each, but use one system. Water from the intermediate well does not go into the ground. After purification using a drainage pump, the water is sent to the terrain.

- Drainage into a storm sewer or pond is used when the groundwater level is high, or when there are clay soils that do not absorb water very well. This option is only possible for those who have biotreatment stations with a purification degree of 95-98%.

When designing, one should also take into account such a parameter as the depth of soil freezing. The exact values in a particular area can be found in SNiP 01/23/99. As an example, we can say that in the Moscow region the soil can freeze to a level of 1.4 m. And if the station will be used in winter, then the input pipe should be located below the freezing level of the ground.

Another important design consideration will be the frequency of application. If you plan to use the system all year round, then it would be better to use aerial septic tanks. The organic matter in them will be a source of nutrition and energy for microbes.

By the way, you can use them from time to time. Only then should there be food for microbes in the sewer.

The last important point to consider when designing is cost. The models are not very different in design. More expensive options usually have the same functionality, but can simply process large volumes of waste. And the most expensive systems are combined solutions that can be used in different conditions and at different intervals.

From an installation point of view, the best solution would be to use a septic tank, which usually consists of filter media and a tank with several chambers. They are distinguished by their small size and the presence of everything you need for high-quality wastewater treatment. By the way, the tank is usually made of durable polymer, it is lightweight, which allows you to install it even alone.

It should be added that the septic tank copes well with temperature changes, exposure to aggressive substances and has excellent resistance to physical impact. Reinforced concrete is best suited for the construction of storage tanks.

To reuse water in this case, you should supplement the septic tank with a deep cleaning filter. Otherwise, the treated water cannot be used, because the septic tank is an incomplete type of VOC.

What is the danger of system clogging?

If, after studying all the technologies for cleaning storm drains, you are seriously thinking in the direction of “do I need it,” take note of the list of problems that can result from lack of care for the system.

Stagnation of water masses in pipes and gutters creates additional stress on fastening elements. They may simply not be able to stand it and bring down the system.

The accumulated debris clogs the drains, and water not only erodes the foundation of the house, but also penetrates through the ceilings and walls - yes, damp spots and moldy trim can be a clear indication of problems on the roof.

Fallen fruits and berries create favorable conditions for the settlement of entire colonies of wasps, hornets, ants, and moss, mold and even mushrooms can grow under wet leaves.

In dry summers, debris on the roof may well cause a fire.

As you can see, regular cleaning of storm drains is not only a matter of comfortable living in the house, but also of your safety.