A distinctive feature of a two-pipe heating system, as one might guess from the name, is the presence of two independent pipe circuits - for supplying hot water and for discharging cold water. If the radiators are connected incorrectly, and the system itself consists of 7-9 batteries, then the heat transfer of each subsequent one will decrease to such an extent that the power of the last will be only 10% of the maximum possible. This is why it is so important to correctly connect a heating radiator to a two-pipe system, which we will discuss in this article.

Connecting a heating radiator to a two-pipe system

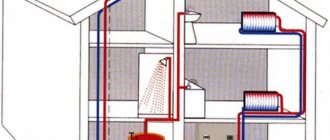

Diagram of a heating and hot water supply system from a gas double-circuit boiler

Place of radiators in the heating system

The use of radiators in heating residential premises plays a key role today.

Not all residential properties, especially apartments in multi-storey buildings, can be converted to underfloor heating. Therefore, the main work of heating internal living spaces is performed by radiators or the good old batteries that are familiar to us. Radiators transfer thermal energy from the coolant to the surrounding space. Heat transfer is carried out due to the large heating surface of the heating device. Modern models have a number of technical improvements, thanks to which it has become possible to connect in a variety of options and with any wiring diagram.

in old cast iron and steel batteries there was only one upper and one lower pipe, through which hot water is supplied and the return is released.

In modern models, in addition to the main supply and outlet pipes, there are built-in air vents. This design of batteries radically changed the quality of functionality of the heating system. If there are air pockets in heating devices, it is enough to open the drain valve and bleed the air.

In many ways, thanks to modern models of heating batteries, it has become possible to choose the most convenient connection scheme and install heating devices in those areas of the living room in which they are most effective. The quality of operation of the heating water circuit depends on correctly installed piping. The process is necessary if you are using a pipeline made from polypropylene pipes.

Important! If there are metal risers, the piping is made from other consumables. It can be metal copper pipes or metal-plastic

The use of polypropylene pipes in this case is strictly prohibited.

The reason for the incompatibility of metal pipes with polypropylene products is the presence of a threaded connection. Considering the fact that propylene pipes have a high coefficient of thermal expansion, when hot coolant is supplied, the threaded connection will lose its tightness and stability. Therefore, if you want to connect a heating radiator made of polypropylene pipes, try to use fittings, adapters and couplings made from similar materials.

the difference in diameters of pipes made of different materials should be taken into account

Ways to increase the thermal inertia of a system

To prevent the batteries from cooling down too quickly, the thermal inertia should be increased.

If the winters in your area are cold and you are concerned that using DHW will cause the radiators to cool down, we will give you some tips on how to avoid this. Of course, first of all you need to take care of good thermal insulation of walls and windows, roof and floor, but this is not the point.

The only way to stop the cooling of the coolant is to increase its heat capacity. This can be achieved by increasing the volume of coolant through the use of larger diameter pipes.

Larger diameter pipes increase inertia.

In addition, you can use massive cast iron batteries with floor installation. Such heating devices take a very long time to cool down, since their weight can reach 100 kg.

Massive cast iron batteries take much longer to cool down.

Finally, as already mentioned, you can integrate a heat accumulator into the system - a tank of several hundred liters (up to 2000), connected between the boiler and the heating system. However, this eliminates all the advantages of the scheme: it will become more expensive and will take up extra space.

Heat accumulator connection diagram.

Radiator connection diagrams

How well the radiators will heat depends on how the coolant is supplied to them. There are more and less effective options.

Radiators with bottom connection

All heating radiators have two types of connection - side and bottom. There can be no discrepancies with the bottom connection. There are only two pipes - inlet and outlet. Accordingly, coolant is supplied to the radiator on one side and removed from the other.

Bottom connection of heating radiators for single-pipe and two-pipe heating systems

Specifically, where to connect the supply and where the return is connected is written in the installation instructions, which must be available.

Heating radiators with side connection

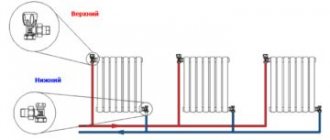

With a lateral connection, there are many more options: here the supply and return pipelines can be connected into two pipes, respectively, there are four options.

Option #1. Diagonal connection

This connection of heating radiators is considered the most effective, it is taken as a standard and this is how manufacturers test their heating devices and the data in the thermal power passport for such a connection. All other connection types transfer heat less efficiently.

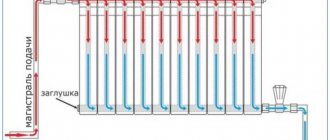

Diagonal diagram for connecting heating radiators with a two-pipe and one-pipe system

This is because when the batteries are connected diagonally, the hot coolant is supplied to the upper inlet on one side, passes through the entire radiator and exits from the opposite, lower side.

Option #2. Unilateral

As the name implies, pipelines are connected on one side - supply from above, return from below. This option is convenient when the riser runs on the side of the heating device, which often happens in apartments, because this type of connection usually predominates. When the coolant is supplied from below, this scheme is used infrequently - it is not very convenient to position the pipes.

Lateral connection for two-pipe and one-pipe systems

With this connection of radiators, the heating efficiency is only slightly lower - by 2%. But this is only if there are few sections in the radiators - no more than 10. With a longer battery, its farthest edge will not heat up well or will remain cold at all. In panel radiators, to solve the problem, flow extenders are installed - tubes that bring the coolant a little further than the middle. The same devices can be installed in aluminum or bimetallic radiators, thereby improving heat transfer.

Option #3. Bottom or saddle connection

Of all the options, saddle connections for heating radiators are the least effective. Losses are approximately 12-14%. But this option is the most inconspicuous - pipes are usually laid on the floor or under it, and this method is the most optimal from an aesthetic point of view. And so that losses do not affect the temperature in the room, you can take a radiator a little more powerful than required.

Saddle connection of heating radiators

In systems with natural circulation, this type of connection should not be made, but if there is a pump, it works well. In some cases, it’s not even worse than the side one. It’s just that at a certain speed of movement of the coolant, vortex flows arise, the entire surface heats up, and heat transfer increases. These phenomena have not yet been fully studied, therefore it is not yet possible to predict the behavior of the coolant.

Which scheme is better to choose?

The selection of wiring is carried out taking into account many factors - the area and number of floors of a private house, the allocated budget, the presence of additional systems, the reliability of power supply, and so on. We will give a number of general recommendations for choosing:

- If you plan to assemble the heating yourself, it is better to opt for a two-pipe shoulder system. It forgives beginners many mistakes and will work despite the mistakes made.

- If you have high requirements for the interior of rooms, take the collector type of wiring as a basis. Hide the comb in the closet, and route the lines under the screed. In a two- or three-story mansion, it is advisable to install several combs - one per floor.

For radial wiring, it is advisable to place the collector in the center of the house

Advice. Heating of a dacha for 2-4 small rooms can be organized using a single-pipe horizontal system with a lower distribution - “Leningradka”.

If the cottage is planned to be heated with radiators, heated floors and water heaters, it is worth adopting a dead-end or collector wiring option. The two indicated schemes can be easily combined with other heating equipment.

Heating in the house

At the first stage, you should decide on the types of radiators and options for their connection, since buildings should be prepared in advance for the selected type of heating. A modern space heating system includes several components.

These include:

Do-it-yourself polypropylene heating wiring without a soldering iron

You can find different versions of them in large quantities in our markets.

General instructions for installing batteries look like this:

- First select a place to place them;

- bring pipes to them;

- connect them together;

- perform a test run, and if everything is in order, turn on the heating at full power.

How to install heating radiators with polypropylene pipes with a jumper for quick shutdown

Modeling the optimal contour geometry

For one private house, several closed water circuits can be designed that will heat different rooms. They can differ significantly from each other in the type of wiring.

When designing, first of all, they take into account the operability of the system, as well as optimal geometry from the point of view of minimizing costs, ease of installation and the ability to fit heating elements into the design of the premises.

Natural and forced water circulation

Heating of the coolant for heating the house occurs in one or more devices located indoors. These can be stoves, fireplaces, as well as gas, electric or solid fuel boilers.

Water pressure in the circuit is ensured either through the use of circulation pumps or by arranging the geometry of the system to create conditions for natural circulation.

Also, the source of hot water can be a centralized heating system for several houses. In case of low pressure, it is possible to connect circulation pumps to create additional pressure and increase the speed of fluid movement through the pipes.

When choosing an option with natural circulation of coolant or low pressure in pipes with centralized heating, you must carefully consider the possibility of maximizing the use of physical laws that allow you to start and maintain fluid movement.

A mandatory element of the wiring in this case is the acceleration manifold. It is a vertical pipe through which hot water rises, then is distributed among heating appliances and, having lost its initial temperature, flows down.

Due to different densities, a difference in hydrostatic pressure between the hot and cold columns of liquid occurs, which is the driving force for water circulation.

Vertical and horizontal wiring

Hot water can be supplied to radiators in different ways. The wiring is conventionally divided into vertical and horizontal, according to the position of the pipes (risers) supplying water directly to the heating radiators.

Vertical circuits with top supply of hot water make maximum use of the difference in hydrostatic pressure between the warm and cold segments of the circuit, so they are almost always used with natural circulation, as well as with low pressure in the system.

In addition, such circuits are operational in case of emergency shutdown of the pump, which may occur due to its breakdown or lack of electricity.

Bottom supply wiring is practically not used for heating with natural circulation. If there is good pressure in the system, its use is justified, since such a scheme has two significant advantages relative to the alternative option.

- smaller total length of pipes used;

- there is no need to run the pipe through the attic or technological niches under the ceiling of the second floor.

The horizontal heating distribution scheme is used for one-story private houses. If the building has two or more floors, then it is often used in cases where vertical risers are undesirable from a design standpoint.

Horizontal pipes supplying and discharging water can be organically integrated into the interior of the premises, as well as hidden under the floor or in niches located at floor level.

Tying polypropylene pipes instructions

Radiator piping can be done using a variety of pipes, but experts recommend using polypropylene pipes. Ball valves for piping are also purchased in polypropylene; they can be straight or angular; this option is the simplest and most inexpensive. Brass fittings are more expensive, and their installation is more difficult.

Polypropylene strapping is done as follows:

- the coupling with a union nut is inserted into the multiflex, which easily connects to any outlet;

- The pipes themselves are attached to the walls at a convenient height; they should not fit tightly to the surface; it is better to leave a gap of 2-3 cm. The pipes are secured using special brackets, which are fixed to the wall with nails or self-tapping screws.

Polypropylene piping to radiators can also be carried out when laying pipes in the wall, in which case they come to the surface only at the connection points.

Radiator piping can be done using a variety of pipes, but experts recommend using polypropylene pipes.

Battery fasteners can be very different, most often it is a pin connection that is fixed to the wall surface. Corner brackets can also be used, which also allow radiators to be suspended at the required height. For panel batteries, fasteners are supplied included; for sectional batteries, they must be purchased separately. Typically, two brackets or pins are sufficient for one section.

The taps are connected as follows:

- the tap is disassembled, the fitting and union nut are screwed into the radiator;

- Use a special wrench to tighten the nut tightly.

As you can see, this process is extremely simple. To perform such work, you only need to purchase a special plumbing wrench for American women, without which it is unlikely that you will be able to simply install a faucet.

To install batteries and tie them, the following materials and tools are required:

- a set of special keys;

- seals for threaded connections;

- tow and thread paste;

- threads for carving.

Features of connecting radiators

Heating installation has some features:

- It is necessary to maintain a distance of 100 mm from the radiator to the window sill. If the gap between the batteries and the bottom of the window sill is different, then the heat flow is disrupted and the effect of the heating system will be low.

- The distance from the floor surface to the battery should be 120-150 mm, otherwise a sharp temperature change will occur.

- In order for the heat transfer of the equipment to be correct, the distance from the wall must be at least 20 mm.

At the same time, we take into account that the installation and efficiency of heating radiators is greatly influenced by the installation method: under an open window sill the efficiency of the heating system is maximum - 96-97%, in an open niche - up to 93%, in a partially closed form - 88-93 %, completely closed - 75-80%.

The heating radiator can be installed using a variety of methods; its piping is done with metal, polyethylene, polypropylene pipes

During installation, it is important to correctly position not only the pipes, but also the batteries themselves, and make the connection in accordance with all recommendations and standards. In this case, the heating system will work very efficiently and will not require repair work.

Share a useful article:

How to calculate pipe diameter

If we are talking about installing a dead-end or collector system, then precise calculations are not needed here. Experts recommend following the following:

- For coolant in a small building you will need a DN15 pipeline;

- To install connections to the battery, you need to use a DN10 section;

- If the work involves installing the system in a two-story house, then the diameter of the riser should be 25 mm (DN20);

- If there are more than 5 radiators on one floor, then it is better to make several heating branches at once.

With the ring and gravity scheme, things are a little more complicated - here you will need a formula and additional calculations. If you want to conduct them personally, then you need to determine the heating load for each room (don’t forget to make adjustments for ventilation), and also calculate the coolant consumption. For this, the following formula is used: G = 0.86 x Q /∆t, where G is the mass flow rate of heated water in a specific section of the pipeline, Q is the heat that is needed to heat a given room, ∆t is the temperature difference when operating two plots - it can be taken at 20 degrees.

Thus, some systems can be installed independently, while the installation of others will require the help of specialists and accurate calculations.

Types of heating systems

The amount of heat that the heating radiator will emit depends not least on the type of heating system and the selected type of connection. To choose the best option, you must first understand what kind of heating systems there are and how they differ.

Monotube

A single-pipe heating system is the most economical option in terms of installation costs. Therefore, this type of wiring is preferred in multi-storey buildings, although in private buildings such a system is far from uncommon. With this scheme, the radiators are connected to the main line in series and the coolant first passes through one heating outlet, then enters the input of the second, and so on. The output of the last radiator is connected to the input of the heating boiler or to the riser in high-rise buildings.

Example of a one-pipe system

The disadvantage of this wiring method is the impossibility of adjusting the heat transfer of radiators. By installing a regulator on any of the radiators, you will regulate the rest of the system. The second significant drawback is the different coolant temperatures on different radiators. Those that are closer to the boiler heat up very well, those that are further away become increasingly colder. This is a consequence of the serial connection of heating radiators.

Two-pipe wiring

A two-pipe heating system is distinguished by the fact that it has two pipelines - supply and return. Each radiator is connected to both, that is, it turns out that all radiators are connected to the system in parallel. This is good because the coolant of the same temperature enters the input of each of them. The second positive point is that you can install a thermostat on each of the radiators and use it to change the amount of heat it emits.

The disadvantage of such a system is that the number of pipes when laying out the system is almost twice as large. But the system can be easily balanced.

Balancing

The horizontal two-pipe scheme in its original form is ineffective: the coolant circulates only through the heating devices closest to the boiler or pump. The problem is solved by balancing - throttling each battery to obtain the same temperature.

Please note: due to the inertia of the system, stabilization of the coolant temperature takes several hours. Hence the obvious instructions: when performing self-balancing, the position of each throttle changes to the minimum value with repeated temperature control after 2-4 hours.

If you close the throttles on the radiators closest to the boiler, water will flow through the ones further away.

What kind of piping can be made from polypropylene pipes

The piping for a home heating system can be very different. The thing is that the consumer is always trying to reduce the amount of consumables, while simultaneously trying to install radiators in all heated rooms.

It should be said right away that these are relics of the past. Unlike expensive metal pipes, polypropylene consumables are much cheaper and easier to install. therefore, it is not worth saving on the length of the pipeline. Choose the type of harness that will bring maximum benefit in your case. The only reasons that may influence the choice of type of harness are the following factors:

- what heating circuit is used (one-pipe system or two-pipe);

- what type of radiator connection you have chosen (diagonal, side or bottom).

As a rule, when using any heating scheme: single-pipe or two-pipe, you can use any type of heating radiator connection.

According to experts, pipeline laying must minimize the number of bends. A smooth highway remains resistant to hydrodynamic loads. The number of zones in which air can accumulate will be reduced in the pipeline.

There are specific features for piping a single-circuit and double-circuit heating system using polypropylene pipes.

- Typically, such a system uses a series connection of radiators;

- A bypass is always installed in front of the battery, connecting the supply pipe and return pipe. During normal operation of the heating system, the bypass is not activated. When carrying out maintenance work or in the event of an emergency, the water supply to the radiator is stopped. The coolant circulates freely through the bypass.

- Both parallel and serial connections of batteries are used;

- Both radiator hoses are connected to different pipes. The upper one is connected to the supply pipe, the lower pipe is connected to the return pipe. Typically, radiators are connected in parallel in two pipe systems, so installing bypasses is not required.

Tying polypropylene pipes with radiators is done in two ways: soldering and using fittings. Radiators are installed and connected using a soldering iron and American-style plumbing wrenches.

Pros and cons of two-pipe wiring

For ease of perception, we have combined the advantages and disadvantages of all the above systems into one section. First, let's list the key positive points:

- The only advantage of gravity flow over other schemes is independence from electricity. Condition: you need to select a non-volatile boiler and install it without connecting to the house electrical network.

- The shoulder (dead-end) system is a worthy alternative to the Leningradka and other single-pipe distributions. The main advantages are versatility and simplicity, thanks to which a two-pipe heating circuit for a house of 100-200 m² can be easily installed with your own hands.

- The main advantages of the Tichelman loop are hydraulic balance and the ability to provide coolant to a large number of radiators.

- Manifold wiring is the best solution for hidden pipe laying and complete automation of heating operation.

The best way to hide pipes is to lay them under the floor screed

Note. The last 3 schemes can be easily combined with water underfloor heating circuits. Combining a gravity radiator network with heated floors is not always advisable - without electricity, forced circulation in heating circuits is impossible.

Let us briefly highlight the general advantages of the beam, associated and dead-end systems:

- small sections of distribution pipes;

- flexibility in terms of laying, that is, lines can run along different routes - in floors, along and inside walls, under ceilings;

- Various plastic or metal pipes are suitable for installation: polypropylene, cross-linked polyethylene, metal-plastic, copper and corrugated stainless steel;

- All 2-pipe networks lend themselves well to balancing and thermal regulation.

To hide the pipe connections, you need to cut grooves in the wall.

Let's note a minor advantage of gravity wiring - the ease of filling and removing air without the use of valves and taps (although with them it is easier to ventilate the system). Water is slowly supplied through the fitting at the lowest point, air is gradually forced out of the pipelines into an open-type expansion tank.

Now about the significant disadvantages:

- The scheme with natural water movement is cumbersome and expensive. You will need pipes with an internal diameter of 25...50 mm, installed with a large slope, ideally steel. Hidden installation is very difficult - most elements will be visible.

- No significant disadvantages were found in the installation and operation of dead-end branches. If the arms differ greatly in length and number of batteries, balance is restored through deep balancing.

- The Tichelman ring wiring routes always intersect doorways. You have to make bypass loops, where air can subsequently accumulate.

The house plan shows that the associated water system crosses 2 doorways

- Beam-type wiring requires financial costs for equipment - manifolds with valves and rotameters, plus automation equipment. An alternative is to assemble a comb from polypropylene or bronze tees with your own hands.

Addition. To automatically regulate the heat transfer of batteries during gravity flow, you will need special radiator valves with an increased flow area.

Advantages and disadvantages of single-pipe and two-pipe heating systems

The main difference between the two heating schemes is that the two-pipe connection system is more efficient in operation due to the parallel arrangement of two pipes, one of which supplies the heated coolant to the radiator, and the other removes the cooled liquid.

The single-pipe system circuit is a sequential type wiring, due to which the first connected radiator receives the maximum amount of thermal energy, and each subsequent one heats up less and less.

However, efficiency is an important, but not the only criterion that you need to rely on when deciding to choose one scheme or another. Let's consider all the pros and cons of both options.

Single pipe heating system

- ease of design and installation;

- savings in materials due to the installation of only one line;

- natural circulation of coolant, possible due to high pressure.

- complex calculation of thermal and hydraulic parameters of the network;

- the difficulty of eliminating errors made during design;

- all network elements are interdependent; if one section of the network malfunctions, the entire circuit stops working;

- the number of radiators on one riser is limited;

- it is impossible to regulate the flow of coolant into a separate battery;

- high heat loss coefficient.

Two-pipe heating system

- possibility of installing a thermostat on each radiator;

- independence of operation of network elements;

- the ability to insert additional batteries into an already assembled line;

- ease of eliminating errors made at the design stage;

- to increase the volume of coolant in heating devices, there is no need to add additional sections;

- no restrictions on the length of the contour;

- coolant with the required temperature is supplied throughout the entire pipeline ring, regardless of the heating parameters.

- complex connection diagram compared to a single-pipe;

- higher consumption of materials;

- installation requires a lot of time and labor.

Thus, a two-pipe heating system is preferable in all respects. Why do the owners of apartments and houses refuse it in favor of a single-pipe scheme? Most likely, this is due to the high cost of installation and the high consumption of materials required to lay two highways at once. However, one should take into account the fact that a two-pipe system involves the use of pipes of a smaller diameter, which are cheaper, so the total cost of installing a two-pipe option will not be much more than a single-pipe one.

Owners of apartments in new buildings are lucky: in new buildings, unlike residential buildings of Soviet construction, a more efficient two-pipe heating system is increasingly used.

How does dual-circuit heating work?

The design of a two-pipe water heating system involves the supply and removal of coolant from each radiator through two separate lines. Simplified: the battery inlet is connected to the supply line, the outlet to the return line. Through the first pipeline, heated water from the boiler is distributed to all heating devices, the second pipe collects the cooled coolant and sends it back to the heat generator.

An example of the distribution and return of coolant from batteries along two lines

Features of double-circuit water distribution:

- if all elements of the system are calculated correctly, then each radiator receives coolant at the same temperature;

- a change in the flow of water through one battery due to adjustment has little effect on the operation of neighboring heating devices;

- the number of radiators on one branch can reach 40 pcs. provided that the pump capacity and the diameter of the supply pipes provide the calculated water flow.

Note. The number 40 is taken on the basis of practical experience in the design and installation of heating in a production workshop. In country cottages, so many devices are not connected to one branch, a maximum of 10 pieces. If it is necessary to make wiring in a multi-storey building, the heat supply network is divided into several two-pipe circuits.

The movement of water through pipes and batteries is ensured in two ways - natural (convection) and forced. There are also several options for supplying coolant, so we suggest considering each scheme separately.

Two-pipe classic closed-type wiring - connection to a floor-standing boiler

Choosing a location and method of installing a radiator

Options for connecting heating radiators depend on the general heating scheme in the house, the design features of heating devices and the method of laying pipes. The following methods of connecting heating radiators are common:

- Lateral (unilateral). The inlet and outlet pipes are connected on one side, with the supply located at the top. The standard method for multi-storey buildings, when the supply is made from a riser pipe. In terms of efficiency, this method is not inferior to the diagonal one.

- Lower. In this way, bimetallic radiators with a bottom connection or a steel radiator with a bottom connection are connected. The supply and return pipes are supplied from below on the left or right side of the device and are connected through the lower radiator connection unit with union nuts and shut-off valves. The union nut is screwed onto the lower radiator pipe. The advantage of this method is that the main pipes are hidden in the floor, and heating radiators with bottom connections fit harmoniously into the interior and can be installed in narrow niches.

- Diagonal. The coolant enters through the upper inlet, and the return is connected from the opposite side to the lower outlet. The optimal type of connection ensures uniform heating of the entire battery area. In this way, correctly connect a heating battery whose length exceeds 1 meter. Heat loss does not exceed 2%.

- Saddle. The supply and return are connected to the lower holes located on opposite sides. It is used primarily in single-pipe systems when no other method is possible. Heat loss as a result of poor coolant circulation in the upper part of the device reaches 15%.

https://youtube.com/watch?v=olrD9qxCAhM

WATCH THE VIDEO

When choosing a location for installation, several factors are taken into account to ensure the correct operation of heating devices. Installation is carried out in places least protected from the penetration of cold air, under window openings. It is recommended to install a battery under each window. The minimum distance from the wall is 3-5 cm, from the floor and window sill - 10-15 cm. With smaller gaps, convection worsens and the battery power drops.

Typical mistakes when choosing an installation location:

- The place for installing control valves has not been taken into account.

- A small distance to the floor and window sill prevents full air circulation, as a result of which heat transfer is reduced and the room is not heated to the set temperature.

- Instead of several batteries located under each window and creating a thermal curtain, one long radiator is chosen.

- Installation of decorative grilles and panels that prevent the normal spread of heat.

Coolant circulation methods

Coolant circulation through pipelines occurs naturally or forcedly. The natural (gravity) method does not involve the use of additional equipment. The coolant moves due to changes in the characteristics of the liquid as a result of heating. The hot coolant entering the battery, cooling, acquires greater density and mass, after which it sinks down, and a hotter coolant takes its place. Cold water from the return flow flows by gravity into the boiler and displaces the already heated liquid. For normal operation, the pipeline is installed at a slope of at least 0.5 cm per linear meter.

Scheme of coolant circulation in the system using pumping equipment

For forced supply of coolant, the installation of one or more circulation pumps is required. The pump is installed on the return pipe in front of the boiler. The heating operation in this case depends on electrical power, but has significant advantages:

- The use of small diameter pipes is allowed.

- The line can be installed in any position, vertically or horizontally.

- Requires less coolant volume.

Equipment

When constructing a system in a private home, you will need some additional equipment in addition to pipes and valves. We will briefly get acquainted with the functions of some of its types.

| Type of equipment | Short description |

| Expansion tank | A container that compensates for the expansion of the coolant when heated. The closed tank is taken equal to 10% of the coolant volume and is installed after the circulation pump. An open tank is mounted at the top point of the circuit. |

| Safety valve | Relieves excess pressure when a closed circuit overheats. |

| Automatic air vent | Removes air and gases from the circuit resulting from electrochemical processes. |

| Mayevsky crane | Device for manual air bleeding. It is mounted in the top plugs of radiators or at the top point of each jumper between the risers. |

| Throttle | An analogue of a screw valve for manual adjustment of patency. |

| Thermal head | Automatic throttle that changes the permeability depending on the air temperature. |

Thermostatic head device.

Video instruction with advice from a specialist

Hello! I have the following problems with heat: 1) In the corner apartment in the children's room there are two supply and return pipes. The supply pipe is fiery and the return pipe is several times colder. The radiators are connected to the return line, is this correct or not? Can I connect radiators in addition to the supply and run them along a cold street wall? 2) There is no radiator or pipe in the toilet at all, although the wall is also cold (outdoor). 3) In the bedroom there is only a pipe (return) with a radiator battery connected to it, and through the wall in our kitchen there is a supply. Is it possible to somehow combine two rooms and install them in two rooms with a supply pipe?

In our 9-story building, the heating system is built like this: one supply pipe goes from bottom to top. Radiators are connected to it on all floors in parallel with jumpers. The coolant enters the radiator from below, and the upper outlet from the radiator is connected to the same pipe. Only part of the radiator warms up. How to properly connect a radiator so that it warms up completely?

Good afternoon. The nine-story building has a two-pipe heating system in every room. In one room, the heating supply pipe runs upstairs past all the radiators. Accordingly, all the radiators from the ninth floor are connected to the return line, and my battery on the second floor is generally almost cold. Tell me whether this connection is natural, or is it just a mistake made by the mechanics?

Hello! Please tell me how correct your data is in determining an effective method for connecting a radiator? And what sources can you refer to to obtain the above data? Thanks in advance everyone!

Embed the valve into the jumper (which is not entirely legal if there are valves on the radiator) or reconnect the radiator in a diagonal pattern. On propylene it is simple and fast, compact and quite aesthetically pleasing. The top insert (outlet) is transferred instead of the top plug opposite. Do not forget that the thread direction of the plugs is mutually opposite.

Obviously, you have a single-pipe heating system in your house, in which some rooms are connected to the pressure line, and other rooms are on the return line. This is a moronic Soviet system - the return water is already cooled and cannot heat the room. But you may be fined for installing additional batteries, because... such alteration of the project is not permitted

Principles of calculation

In order not to make mistakes when calculating heating, you need to first draw a diagram on paper. All components of the structure are indicated on it. It is important to understand how much fluid flows through all the nodes separately, at what speed it moves, how the operation of the entire system changes as a result of changes in the functionality of its individual elements.

During the calculation, you should not miss the hydrodynamic resistance of water as it moves, which affects the pressure inside the system and pressure. To carry out the procedure, special tables and formulas are used. Correct calculation will avoid problems with the functionality of the heating structure in the future.

Important nuances of designing a two-pipe heating system for your own home

Selection of materials

The popularity that polypropylene pipes have gained. associated with a number of their positive qualities:

- Their price is significantly lower than their metal counterparts.

- High durability due to the fact that the plastic does not rust, and there is practically no sediment deposited on it.

- Does not need painting.

However, it should be taken into account that not all types of polypropylene pipes are suitable for heating systems. The fact is that they must have a reinforcing layer that prevents significant thermal expansion of the pipeline.

Reinforced polypropylene pipe

Moreover, it is desirable that the reinforcement layer be aluminum, since fiberglass reinforcement leads to saturation of the coolant with oxygen. This in turn causes rusting of the metal surfaces of boilers and other heating supply elements. Pipes that have aluminum reinforcement and are suitable for heat supply systems are marked PN25.

Note! When choosing pipes, you should pay attention to the uniformity of their wall thickness. To do this you need to look at their cut

As for the diameter, the optimal parameter is 25 mm.

In this case, it is also necessary to purchase fittings, which include:

Single-pipe and two-pipe radiator connection diagram

Primary requirements

The main task is to connect the boiler and all radiators in the most efficient way. It is important to take into account a number of requirements:

- The routing should be laid along the route with the shortest length.

- The hydraulic resistance of pipes, valves and fittings should be reduced whenever possible.

- It is necessary to think through and arrange all functional units on the line with a minimum number of bends, tees and valves. This refers to the safety group, expansion tank, circulation pump, fittings for draining and filling the system, etc.

- Pipes are selected based on the performance characteristics of the material and the heating system.

- The diameter of the pipes is calculated to minimize pressure losses on the one hand and reduce the volume of the pipeline on the other.

Where to put radiators

Traditionally, heating radiators are placed under windows, and this is no accident. The rising flow of warm air cuts off the cold air that comes from the windows. In addition, warm air heats the glass, preventing condensation from forming on it. Only for this it is necessary that the radiator occupies at least 70% of the width of the window opening. This is the only way the window will not fog up. Therefore, when choosing the power of radiators, select it so that the width of the entire heating battery is not less than the specified value.

How to place a radiator under a window

In addition, it is necessary to correctly select the height of the radiator and the location for its placement under the window. It must be placed so that the distance to the floor is around 8-12 cm. If you lower it lower, it will be inconvenient to clean, if you raise it higher, your feet will be cold. The distance to the window sill is also regulated - it should be 10-12 cm. In this case, warm air will freely go around the obstacle - the window sill - and rise along the window glass.

And the last distance that must be maintained when connecting heating radiators is the distance to the wall. It should be 3-5 cm. In this case, rising currents of warm air will rise along the back wall of the radiator, and the rate of heating the room will improve.

Reducing the resistance of pipes and circuits

For systems with natural circulation:

- Any turns and bends along the route are carried out taking into account the minimum permissible turning radius for the type of pipe used.

- Transitions between pipes with different diameters, insertion of risers into the distribution manifold are carried out without narrowing the smaller diameter and, if possible, with a gradual expansion/constriction of the channel.

- In front of shut-off, control valves, radiators or other equipment, a smooth section of pipe should be formed at least 5-6 pipe diameters in order to eliminate unnecessary turbulence and turbulence in the liquid flow.

For a system with forced circulation, the previous tips are not mandatory; it is important that the circuit resistance is less than the pressure generated by the pump. However, if all requirements are met, the load on the pump will decrease and its operating life will accordingly increase. Due to the forced pumping of the coolant, you can use metal-plastic pipes with a small cross-section, a lower two-pipe or one-pipe connection scheme, including packing the pipes into a screed or walls.

We connect the heating radiator to polypropylene pipes

In the private sector, in old housing stock and in new buildings, work is currently underway to re-equip heating systems. Old heating equipment, steel and cast iron heating radiators are replaced with new devices. Modern industry produces bimetallic, steel heating devices with improved parameters and characteristics. Accordingly, in parallel, the old steel pipelines through which the coolant circulates are being replaced with new consumables. Today, polypropylene pipes are taking the lead in creating a heating circuit.

Accordingly, in view of such a large-scale modernization of heating systems, reasonable questions arise. How is a polypropylene water circuit installed at home? What does it look like to connect a heating system radiator to polypropylene reinforced pipes. Let's look in detail and consider what it means to connect polypropylene consumables to heating sources in detail.

Tichelman ring

When using a Tichelman loop connection, it is necessary to use bottom wiring. Most often it is located in an open position along the walls, but sometimes it is carried out in a hidden way along the floor. Experts offer another installation method: the structure is installed in front of the ceiling, while the communications are covered with a suspended ceiling or in the basement, and the pipe connections are brought to the heating device.

- The heating circuit is installed so that it has the shape of a ring;

- A specific method of connecting the battery is used: if the radiator is the first on the supply pipe, then it will end the return part. The same principle also works in reverse order: the last battery in the supply line will become the first for the reverse.

- If you follow the movement of water in both pipelines, you will notice a single direction. This principle of operation gave the second name to the scheme “passing”.

One of the main advantages of this system is the hydraulic balance, which becomes almost ideal. The coolant is distributed in such a way that it travels the same distance. The design can work using 10 or more radiators with minimal balancing.

Tichelman loop, mounting diagram