09/03/2015 Updated 08/15/2019 13:25

In the photo from left to right: galloon mesh, mesh woven from plastic threads, polyethylene fiber filter, slot filter

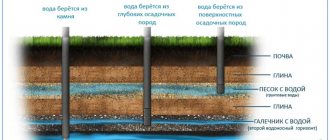

There are two types of sand well designs: filter and filterless. In filter wells, a special filter section is installed on the casing pipe. It is through this section that water enters the cavity of the casing pipe. The filter section is installed exactly in the aquifer. It ensures water purification from the layer from solid particles. A well mesh is used to make the filter section.

Order sand well drilling

Interesting: sand drilling

The well filter mesh can be made of metal or synthetic materials. Previously, various metals were used to make filter meshes. At the moment, there is practically only one option left in practice - galloon mesh for wells made of stainless steel. Synthetic mesh for wells can also be different. Often, sieve fabric is used as a mesh. In addition, there are special filtration meshes for wells, woven from plastic material. But progress does not stand still. In addition to traditional synthetic materials, various new solutions are also produced. Such solutions include an EFVP filter.

Water well with stainless mesh filter

Specialist consultations

Possibility of using stainless steel galloon mesh:

The good old stainless steel galloon mesh for wells is good for its reliability. It filters water from the layer efficiently. Moreover, such a mesh can hardly be damaged when installing a casing pipe (and such situations happen with synthetic meshes when working in rocky soils). The disadvantage of stainless mesh for wells is its limited service life. Practice shows that such nets last no more than 20 years. After this period, in most cases, the stainless steel is destroyed, and the wells begin to become sandy.

Order a well

Specialist consultation

Well casing

Any well cannot do without such a structural element as a casing pipe, the main purpose of which is to maintain the safety of the walls.

Traditionally, steel pipes (electric-welded or seamless) were used for these purposes, but their use had a number of disadvantages:

- Seamless pipes are characterized by increased strength, but the cost of such material is quite high. Electric-welded pipes very often fail (burst at the seam), this leads to failure of the well.

- Steel is susceptible to corrosion, this leads not only to a decrease in service life, but also to a deterioration in the quality of water, its saturation with iron, and no filtration mesh can save you from this.

- Steel pipes have significant weight, especially for thick-walled modifications, which leads to the complication of casing technology.

- The cost of metal pipes is quite high, this in turn leads to an increase in the price of the entire structure.

Nowadays, polymer pipes are increasingly used for well casing, which do not have the disadvantages inherent in steel casing:

- PVC pipes are not subject to corrosion, this has increased their service life, which allows the use of a well with such casing for 50 years or more.

- PVC pipes have less weight and relatively low cost, while all strength characteristics are at a high level. Such casing can even withstand ground movements (due to some plasticity of the material).

- The internal surface of such a pipe is not predisposed to the formation of deposits, therefore the diameter of the well remains constant throughout its operation.

When choosing such casing pipes, it is worth remembering that wells intended for drinking water supply are best installed using food grade PVC pipes.

Wells for water supply with plastic mesh on the filter

Water wells with plastic mesh:

Synthetic mesh for wells copes with the task of water purification no worse than stainless steel. At the same time, according to forecasts, hopes are very high that such a mesh will last longer than stainless steel. But when working with this type of filter mesh you need to be very careful. Synthetic filter mesh can easily be damaged during casing installation or due to geological processes and pressure on the casing.

Order a well

Specialist consultation

Specialist consultations

- Popular on the topic: drilling sand wells with small installations

By the way: it is possible to save such wells. To do this, you need to contact specialists and order well repair.

- Useful on the topic: sand drilling well options

Primary water purification

All water entering the working area of the well from the aquifer contains a certain amount of mechanical impurities. For preliminary water purification, filters of various designs are used, this can be a filter mesh for casing pipes or other models of cleaning devices.

The most commonly used filters are the following designs:

- Gravitational

- Gravel

- Slotted

- Wire

- Reticulate

The choice of a specific design should be based on the characteristics of the soil in which the well is drilled:

- For soil with a high content of clay and loam, a gravity or gravel filter is best suited; in such conditions, the mesh will quickly become clogged, which will lead to a decrease in water inflow.

- For gravel soil, it is best to use a slotted structure, the main element of which will be a metal filter mesh.

- For sandy soil, it is best to use a mesh with a small cell size (the so-called galloon weaving is considered the ideal option).

In any case, it is best to entrust the choice of filter design to a specialist who can take into account all the nuances that may affect the quality of water purification.

If you drill a water well yourself, this is possible when the depth of the aquifers is insignificant, you can select a grid in the following way.

The soil extracted from the well must be sifted through several types of filter mesh. The one through which the minimum amount of soil will be sprinkled should be given preference.

Water well with a filter made of polypropylene and polyethylene fibers

Specialist consultations

A promising solution is fibrous polypropylene and polyethylene:

EFVP as a filter material is a reliable and durable solution. These filters are manufactured in the form of pipes for standard casing diameters. Externally, the filter element consists of connected polyethylene and polypropylene fibers. These materials have a high degree of chemical inertness, which allows the use of EFVP filters even in food production. The mechanical strength of this filter material is also high, which makes it possible to use tubular filters when creating water intake wells.

Note. EFVP stands for fibrous-porous filter element

More information about water wells with EFVP filters

Order a well

Specialist consultation

Design and purpose of a well filter

The main purpose of a well filter is to purify water from mechanical impurities (sand, pebbles, limestone, clay) at the entrance to the source. The number and size of rock particles is difficult to predict.

But if they are not detained, the following will happen:

- unstable rocks will crumble, accumulate, and water will stop flowing into the well;

- the submersible pump will quickly break down, because it is not designed to move water with large suspended matter and impurities.

The well filter cannot be replaced ; it is installed once. Therefore, it is important that it performs its function as long as the well is in operation (20-30 or more years). The structure is installed in the working part of the casing, purified water passes further, and contaminants accumulate in the filter sump or remain outside the column.

Device (top to bottom):

- above-filter section - serves as a connecting element when attaching the device to the casing pipe;

- filter unit - is a perforated partition that does not allow dirt to penetrate inside the device;

- settling tank - a container for collecting large particles that have penetrated into the casing.

Wells for water supply with slot filters on plastic pipes

Water intake wells with slotted filter sections:

It's a fairly old idea to create a filter from the casing itself. Initially, slot filters were even made on steel pipes. However, creating such a structure is a very labor-intensive process.

Slot filters based on uPVC and HDPE pipes are widely used in the creation of water wells. Small slots of 0.3 - 0.8 mm (depending on the composition of the water-containing layer) are formed on the surface of a plastic pipe, usually in a factory setting. The advantage of such a filter is its increased reliability, both during casing and during operation. However, slot filters weakly cut off small fractions of water-bearing rocks.

Order a well

Specialist consultation

Specialist consultations

Making a filter for a well with your own hands - instructions

The design is selected depending on the geological characteristics of the aquifer, the expected drilling depth and the cross-section of the well pipe: the diameter of the filter pipe should be approximately 2/3 of its diameter.

To make a filter you will need the following tools:

- drill;

- hammer, metal scissors;

- stainless steel staples;

- slotted screwdriver;

- wire cutters;

- pliers;

- screws (trimmed so as not to stick out);

- screwdriver;

- gloves.

Manufacturing of perforated mesh filter

The mesh filter consists of the following elements:

- a hollow pipe with holes drilled in the walls;

- grids;

- wire winding (2 layers).

The mesh is selected depending on the type of soil rocks:

- on gravel sands and coarse-grained soils - with square cells, multilayer;

- in rocks of medium and fine grain - galloon weaving P48 or P52.

The mesh piece should be 4-5 cm wider than the diameter of the pipe. This excess is bent on both sides in order to secure it to the pipe with a reliable roofing lock.

The filter is done like this:

- In a pipe with a diameter of 120 mm and a length of 300 mm, at a distance of 55-65 cm from both ends, holes with a diameter of 22 mm are drilled in a checkerboard pattern. There should be 90-95 of them in total. Too many holes will weaken the structure; if there are few of them, not enough water will flow.

- The pipe is wrapped with wire with a diameter of 1.7-2.3 mm with a distance between turns of 7-9 cm. The thinner the wire, the more often the turns should be.

- The mesh is connected into a roofing lock, clamped with pliers every 2 cm and beaten with a hammer, while it is stretched and the wire relief appears on the surface. The next sheet is overlapped by 3 cm, so that the longitudinal connection is on the opposite side of the pipe relative to 1 sheet.

- The staples are attached over the mesh in 3 places: along the edges and in the center of the pipe, a total of 6 staples are needed.

- Bend the end of a wire with a diameter of 2 mm into a loop, attach it to the bracket and wrap it several times around the pipe so that it lies in tight rows inside the bracket, then increase the distance between the turns to 7-10 cm until the next bracket, repeat everything.

After all the holes in the pipe have been drilled, they must be sanded and cleared of burrs so that in the future the debris does not interfere with the operation of the pump.

Making a slot filter

Making a slotted filter differs from making a perforated one in that transverse strips are made in the pipe using gas cutting. In the lower part they retreat 10-15 cm (this will be a sump) and mark the position of the slots - one above the other or in a checkerboard pattern.

The length of the cuts is 2.5-7.5 cm. Well-made holes will not affect the pipe’s ability to withstand rock pressure.

The pipe must be secured with clamps, then it will be convenient to turn it during operation.

How to make your own filter for an Abyssinian well

For an Abyssinian well filter, a pipe with a length of 1-1.1 m and an internal diameter of 25 mm is required. Stepping back 10 cm from the edges, drill holes with a diameter of 1-1.5 cm in a checkerboard pattern. The perforation area should not exceed 25% of the total area of the pipe. The recommended drill angle is 30-60°, direction is from bottom to top.

Further fastening of the elements occurs in the same way as described above. The exception is the filter tip.

If an Abyssinian well is made by hydrodrilling, a plastic pipe and a flat tip are most often used.

How to make an igloo filter

For a downhole well, an igloo filter with a spear-shaped tip is used, which penetrates well into the soil. Its diameter in the wide part is 2-3 cm larger than the diameter of the filter, which reduces friction between the device and the pipe when moving through the soil. The needle is screwed into the filter and welded. The product must be durable to withstand the stress of clogging pipes. The length of the needle tip is 10 cm.

It can be turned from steel on a machine or made from a piece of pipe with a wall thickness of 50 mm as follows:

- At a distance of 4 cm from the edge of the pipe, draw a circle and divide it into 4 equal parts. The same markings are made with an offset of 1/8 of the circle.

- Cut 4 identical triangles 70 mm high and bend them inward so that they form a cone.

- Weld the seams inside and out.

- Grind.

- On the opposite side, weld a plug and a coupling under the thread on the filter pipe.

- Screw onto the filter and tighten.

Water well with stainless steel slotted wire filter

Specialist consultations

A promising solution is wire filters:

One of the modern solutions for organizing a well filter section. In this version of the filter, a slotted grid in the shape of a pipe is formed from wire. In this case, the distances between adjacent turns of wire can vary from 0.025 to 20 mm. To create slotted well filters, slotted grids with a slot width close to the lower limit of the specified range are mainly used.

Significant advantages of such filter elements include a high level of reliability in terms of maintainability and durability. The use of thick stainless steel wire makes such filters resistant to operation in water carriers with harsh operating conditions in terms of electrochemical processes. This type of filter is also convenient in terms of maintainability. They are easy to wash. They can be treated with aggressive compounds to remove the build-up of hardness salts and other foreign objects.

The disadvantage of the slotted wire filter is its high cost. For this reason, filters are mainly used for well water intakes for centralized water supply or water supply to industrial enterprises.

Order a well

Specialist consultation

What requirements must a well filter meet?

The material of the device should not impart a taste to the water. Drillers may offer a device with some elements (for example, frame, external fastening) made of galvanized steel, included in the cost of work. It will last no more than 7 years and will gradually begin to release zinc oxide, which is hazardous to health, into the water column.

The best material for the filter device frame is stainless steel. If all elements are made from it, it is provided with the highest characteristics in terms of strength and durability. Plastic, nylon or polyethylene frames and meshes are less resistant to mechanical loads.

If you want to make a device by combining different materials, you must take into account that steel and plastic have different properties, so a gap may form over time at the junction of the stainless steel filter surface with the polyethylene base pipe. Loss of tightness of the connection can lead to unusability of the well.

Filters of all designs must meet the following requirements:

- environmental Safety;

- corrosion resistance;

- good throughput;

- affordable price.

The design should ensure maximum water flow into the well. When making homemade products, you need to pay attention to the level of complexity of the project and calculate its cost.

In order for the filter to work effectively, it is necessary to select its dimensions correctly, make it correctly and install it correctly.

Wells for water supply with a slotted wire filter and filling with a sand-gravel mixture

Water intake wells with sand and gravel mixture:

A filter design for a well that provides a high level of cut-off even for dusty fractions. This filter consists of two slotted wire filters of different diameters in the gap, between which a sand-gravel mixture is filled.

Such a product is developed individually for the conditions of a specific well. Indeed, to achieve the optimal ratio of cutting off dust fractions and duty cycle, it is necessary to correctly determine the composition of the fill and the design of the external and internal slotted wire filters.

A significant limitation for the use of such filters is their high cost. Prices can reach tens of thousands of rubles per linear meter of filter.

Order a well

Specialist consultation

Specialist consultations

Frequently asked questions about well meshes:

Where is the well grid available in the Vladimir region?

Galun mesh for wells in Vladimir is sold in our online store. Detailed information can be found here.

What meshes for well filters exist?

The mesh for a water well can be made of stainless steel or plastic. These two options are the most reliable, durable and safe. In addition, meshes made of other types of metals were previously used, but as practice has shown, it is better not to use them.

Answer to the question: how to drill a well in sand?

What is well pattern density?

Well mesh density is the ratio of the number of threads per inch of mesh. For wells in the Vladimir region, grids marked P52 or P54 are usually used. Accordingly, 52 threads of wire with a diameter of 0.45 m are placed in the first mesh at 2.54 mm, and 54 threads of wire with a diameter of 0.4 mm are placed in the second grid at 2.54 mm.

In addition, the density of a well pattern is sometimes understood as the number of wells per unit area. This interpretation of the term is typical for estimating the number of wells in a field or during drainage work.

How is the well pattern density calculated?

To determine the density of a well pattern, the formula has a very complex form. To select a grid mathematically, you need to obtain a lot of initial data on the parameters of the aquifer. For this reason, we recommend using meshes marked P52 or P54.

Additional Information:

Here you can buy a well mesh

Ordering drilling of a water well for sand using different types of filters in the Vladimir region

Mounting methods

There are several ways to attach well filters. Here a lot will depend on what material they are made of.

Before attaching the filter mesh, you should watch the training video in advance

The following types of fastening are used:

- Welding - the steel mesh is secured to a metal pipe. First, one edge of the mesh is welded, after which it is tightly wrapped several times around the casing and secured to the other edge by welding;

- Soldering is similar in principle to welding, but its main feature is that it can also be used to connect plastic pipes;

- Stitching is used when it is necessary to simply connect the edges of the mesh with a special thread to each other; you can also use thick wire;

- Winding involves winding a dense mesh or wire onto a pipe; the turns must be made using force.

All these fastening methods are simple, and any master can perform them.

Making a filtration system yourself is easy and realistic; the main thing is to choose high-quality materials.

If you follow all the requirements according to the instructions, the well will produce only the best quality water. And most importantly, a homemade filter will not be inferior in quality to expensive factory models.

We offer drilling of wells for water on sand throughout the Vladimir region

- Vladimir

Alexandrovsky district

- Alexandrov city

- Karabanovo city

- Strunino city

- Balakirevo village

Vyaznikovsky district

- Goro Vyazniki

- Mstera village

- Nikologory village

Gorokhovetsky district

- City of Gorokhovets

Gus-Khrustalny district

- City of Gus-Khrustalny

- Kurlovo city

Kameshkovsky district

- City of Kameshkovo

Kirzhachsky district

- City of Kirzhach

Kovrovsky district

- City of Carpets

- Melekhovo village

Kolchuginsky district

- Kolchugino city

Melenkovsky district

- Goro Melenki

Muromsky district

- Goro Murom

Petushinsky district

- City of Kosteryovo

- City of Pokrov

- City of Petushki

- Volginsky village

- Gorodishchi village

Selivanovsky district

- The village of Krasnaya Gorbatka

Sobinsky district

- City of Lakinsk

- Sobinka city

- Village Stavrovo

Sudogodsky district

- Goro Sudogda

Suzdal district

- City of Suzdal

Yuryev-Polsky district

- City of Yuryev-Polsky

Site publications

Drilling a well for water supply in Spassky

Drilling wells for water in Spassky

Turnkey well: price in the Vladimir region. Addiction…

What does the price of turnkey wells depend on in the Vladimir region? The price of a turnkey well...

Wells for deep sand - general information

Water wells for deep sand In a number of areas of the Vladimir region, due to hydrogeological conditions…

Drilling water wells: what casing pipes are used?…

Water wells with different casing pipes To strengthen the walls of the wellbore, we use...

Well for irrigation at the dacha

from 2000 rub./p.m. + ~10 t.r. Turnkey order

- < Back

Wells for water

- Well Repair

- Safe materials

- Wells on uPVC pipes

- Well development

- Turnkey wells

- To the deep sands

Drilling of the wells

- Drilling Sand well drilling

- Water supply

- Technologies

- Drilling wells in the country

Answers on questions

- IN!

- About Us

- How?

- Which?

- What?

New on the site

PrevNext Drilling for sand in the Vladimir region Drilling wells for sand:...

Drilling for sand in the Vladimir region Drilling wells for sand...

Sand drilling in the Vladimir region Sand drilling is available…

Drilling for sand in the Vladimir region Drilling wells for sand...

Sand drilling in the Vladimir region Deep well drilling…

Drilling for sand in the Vladimir region Drilling for sand - different...

Drilling for sand in the Vladimir region Drilling wells for sand...

Drilling for sand in the Vladimir region Drilling wells for sand...

Popular on the site

PrevNext Drilling for sand in the Vladimir region Drilling wells for sand:...

Drilling for sand in the Vladimir region Drilling for sand available...

Drilling for sand in the Vladimir region Drilling wells for sand...

Drilling for sand in the Vladimir region Drilling wells for sand...

Drilling for sand in the Vladimir region Drilling wells for sand...

Drilling for sand in the Vladimir region Drilling wells for sand...

Drilling for sand in the Vladimir region Drilling for sand - different...

Sand drilling in the Vladimir region Deep well drilling…

The editors recommend

PrevNext Drilling for sand in the Vladimir region Drilling wells for sand...

Drilling for sand in the Vladimir region Drilling wells for sand:...

Sand drilling in the Vladimir region Deep well drilling…

Drilling for sand in the Vladimir region Drilling for sand - different...

Sand drilling in the Vladimir region Sand drilling is available…

Drilling for sand in the Vladimir region Drilling wells for sand...

Drilling for sand in the Vladimir region Drilling wells for sand...

Drilling for sand in the Vladimir region Drilling wells for sand...