Here you will learn:

- Reasons for the appearance of condensation in a gas boiler

- Why is condensation harmful?

- Fighting condensation in an atmospheric boiler

- How to avoid condensation in a turbine boiler

- Is it possible to drain condensate into the sewer?

- Requirements for the chimney of gas boilers

- Rules for the operation of chimneys

- How to protect against condensation in the boiler and chimneys

Condensate means a tarry liquid that settles on the surfaces of the chimney under the influence of low temperatures.

The initial temperature of the gases passing through the channels gradually decreases. This causes the water vapor contained in the gases to settle on the walls of the pipes. The liquid mixes with combustion products, as a result of which the process of formation of acids begins, such as sulfuric, nitric, hydrochloric, etc.

The exhaust gases of modern boilers operating on propane have a low temperature. During operation, shutdowns are periodically triggered, which allows the chimney to cool. As soon as the readings drop to 45-60 °C, the process of condensation begins.

Chimney pipes made of stainless steel, due to their smooth walls, allow liquid to flow down, while rolled metal products with a rough surface retain the resulting acids. This in turn leads to the gradual destruction of the smoke removal system.

Reasons for the appearance of condensation in a gas boiler

In addition to condensation in the chimney of a gas boiler, moisture can also form in the water pipes. The main reason lies in the temperature difference.

The appearance of “dew” on pipelines is also affected by:

- improper ventilation operation (insufficiently powerful exhaust hood);

- high level of humidity in the room;

- incorrect operation of heating equipment.

The design of a gas boiler does not allow you to completely get rid of condensate. However, you have the power to reduce the rate of moisture formation and its amount.

Technology and features of thermal insulation

Technologies for proper thermal insulation vary depending on installation conditions. Let's look at each case separately.

On open air

Outdoors, the pipe is exposed to weather conditions. This is expressed in high humidity, ultraviolet radiation and mechanical stress from solid precipitation.

Therefore, insulation for outdoor heating pipes should be:

- Resistant to mechanical damage

- Non-hygroscopic

- Resistant to ultraviolet rays.

On the other hand, there are requirements that are not at all necessary for outdoor insulation, these are biological inertness and resistance to pests. Ideally, outdoor insulation should be hidden in additional casings to prevent any aggressive effects.

In an unheated room

In an unheated room, there are no special requirements for insulation. Pipes in such rooms are insulated in order to save thermal energy, which is wasted, heating completely unnecessary areas. Therefore, in this matter, it is desirable that the insulation be biologically inert and not susceptible to the influence of rodents. Other factors are secondary.

Separately, it is necessary to say about the insulation of risers in heated rooms. Theoretically, heat should enter the room only through radiators. In practice, there is no difference: heat will pass into the room through the radiator or directly through the riser. Therefore, insulating heating pipes in heated rooms is a waste of money.

Underground

Underground, the greatest danger to insulation is mechanical stress and high humidity. No hygroscopic insulation underground will last longer than 2-3 months, so choosing such a material risks costly re-installation. Polystyrene foam is also not suitable for underground insulation, since it is a fragile material.

In addition, the earth is a good conductor of heat. This means that when laid above the freezing level, heat loss from the coolant increases sharply. Therefore, it is necessary to use the maximum possible thickness of insulation, which is defined for each region in SP 41-103-2000.

There is nothing complicated about insulating heating pipes

It is important to clearly understand in what conditions which insulation is most appropriate and remember the first rule of any construction project: Maximum quality at minimum costs. There is no point in overpaying for super expensive insulation and then using it indoors. Such expenses simply will not pay off

Whereas the use of cheap materials underground will lead to repeated insulation and unnecessary expenses. With the right choice of insulation and high-quality installation, no problems will arise

Such expenses simply will not pay for the sowing. Whereas the use of cheap materials underground will lead to repeated insulation and unnecessary expenses. With the right choice of insulation and high-quality installation, no problems will arise.

Why is condensation harmful?

At first glance, there is nothing wrong with the fact that some amount of water appears inside the boiler. Sooner or later it will still evaporate under the influence of high temperatures of the flue gases. However, everything is not so simple here. In fact, the condensate does not contain pure water, but a weak solution of acids. In addition, complete evaporation of condensate may never happen if it appears in too large quantities.

Despite the low concentration, the acids in the condensate can corrode the metal body of the boiler even during one season of active operation of the unit. In a properly configured heating system, this will never happen. But the piping of the heat generator, performed with errors, leads to the formation of condensate during the entire operating time of the boiler. As a result of this, it accumulates and continuously affects metal surfaces, gradually destroying them.

The second problem associated with the appearance of condensation is that soot particles begin to stick to it. During the combustion of fuel, a certain amount of soot is released into the flue gases, most of which leaves the boiler through the chimney to the street. However, if there is any condensation on the surface of the heat exchanger, a small percentage of soot will permanently adhere to these droplets.

As a result, over time, a fairly dense layer appears on the heat exchanger. If, in addition, wet wood is used during the operation of the heat generator, this deposit also contains various flammable resins. The gradual thickening of such a crust leads to a drop in the efficiency of the boiler, since it insulates the metal body of the heat exchanger from the heat of heated gases. The temperature from the furnace to the coolant is transferred worse and worse with each subsequent switching on of the heat generator.

Another danger associated with the formation of soot and resin deposits on the surface of the heat exchanger is the fire hazard of this mixture. The boiler must be cleaned at least once every three weeks. This is necessary to remove residues of fuel combustion products adhering to the walls of the unit. If this standard is not followed, the resulting crust may catch fire and lead to a fire hazard.

There is one feature in heat generator maintenance that is not so obvious at first glance, but becomes the main reason for cleaning the boiler too rarely. The point is that modern solid fuel units have a rather complex structure, which is specially calculated to increase the efficiency of the device.

As a result, a large number of intricate ornate passages inside the boiler significantly complicate the process of cleaning it. As a result, over time, any desire to perform this procedure with the necessary regularity disappears. For the same reason, some parts of the structure cannot be accessed at all, which once again confirms the need to solve the problem with condensation.

Do I need to insulate the outside?

As warm exhaust gases pass through the pipe, they are cooled. When cooling, condensation forms on the walls, which can lead to destruction of the chimney pipe.

Also, the draft force in the furnace or boiler depends on how quickly the pipe walls heat up. If the draft is weak, then carbon monoxide will not rise to the top, but will go down, that is, into the house, and this already threatens poisoning.

Any chimney needs to be insulated, whether it is a stove or a boiler, and regardless of what it is made of (brick, metal, asbestos). Carbon dioxide mixes with condensate to form a weak solution of sulfuric acid. Acid destroys metal chimneys, even though chimneys with oxidation protection are available.

Brick pipes are destroyed when condensate gets into cracks, which expand when moisture freezes in them, which can lead not only to the destruction of the pipe, but also the roof itself. The conclusion suggests itself - it is imperative to insulate.

Video: Chimney insulation

This way we protect it from freezing and destruction. So, the sooner we do this, the longer it will serve us.

How to insulate

For insulation you can use materials such as:

- glass wool;

- fiber insulation;

- broken refractory or red brick;

- plaster.

Plastering is not the best way to insulate. A metal mesh is fixed to the pipe and several layers of slag and lime solution are applied. With this option, you will have to grease up the fallen plaster every year. Therefore, you should think twice about the effort-quality ratio before choosing this method of insulation.

Backfill – thermal insulating bulk materials of different sizes are used. One of the simplest and cheapest options. You can use rubble refractory or red brick, expanded clay, slag, etc.

Mineral (stone) wool - made from rocks of basalt origin, some add glass (glass wool). The most popular and reliable method. But there is a drawback: it requires protection from a steel casing. Without additional protection, cotton wool will not last long - wind and moisture will ruin all your efforts.

When choosing insulation, it is better to focus on the quality of the product, since you don’t need very much material. How long the chimney will last depends on the quality of the insulation and the work performed.

Fighting condensation in an atmospheric boiler

If an atmospheric wall-mounted or floor-standing gas boiler is installed in the house, then the combustion products heat up to 170-200°C. The gases formed during combustion also contain water. However, it does not condense, but turns into steam and is discharged through the smoke channel along with other smoke and volatile soot particles.

When starting up floor-standing gas equipment after a long period of inactivity, a small amount of condensation is allowed to appear, which will evaporate after the boiler warms up. During the cold season, the boiler operates non-stop, so the appearance of liquid is unlikely

If condensation forms in the chimney pipe, then the problem is poor-quality thermal insulation of the chimney. Moreover, the formation of condensate drops on the smoke duct can occur either due to insufficient insulation or due to excessive insulation.

In pipes made of stainless steel, the problem of condensation formation can be solved by installing a condensate neutralizer and adding an element for removing condensation moisture that settles on the surface of the pipe.

When assembling conventional metal chimneys and sandwich chimneys, it is imperative to follow the order of assembly and connection of elements, which provides for spontaneous drainage of condensate outside the smoke channel.

Why insulate pipelines

To begin with, let’s take a closer look at whether the material should be used for insulation of heating pipes or for thermal insulation of heating networks, and if necessary, why and where exactly.

The heating system of any building is designed as follows: the air inside the room heats the coolant (water) circulating through pipelines to the radiators.

Giving off its heat through the walls of the pipes, the water returns back to the boiler, which heats it again. This is in general terms.

However, heat transfer is not necessary over the entire length of the pipe. For example, if the boiler room in your house is located far from residential premises (or even in a separate building on the street) that need heating.

During transportation from the boiler to the area requiring heating, the water will lose some of its heat. As a result, more energy (fuel), and therefore more money, will have to be spent on heating the air for living rooms.

Often boiler rooms are located in basements, where the temperature is significantly lower than in a living room. So Energoflex insulation for heating pipes in the basement will give serious results in saving fuel.

But thermal insulation for heating pipes for an apartment is no longer so important and irreplaceable. The only caveat is that it is important to insulate the heating risers: in this case, more heat will reach the battery. In addition, the pipeline also needs mechanical protection from possible damage.

First of all, this concerns areas along the street - it is about their isolation that you need to think about first of all

In addition, the pipeline also needs mechanical protection from possible damage. First of all, this concerns areas along the street - it is their isolation that needs to be thought about first of all.

How to avoid condensation in a turbine boiler

Models with a closed burner are equipped with a coaxial chimney. It has a slope of 3° in the outward direction, i.e. from the boiler, it ensures spontaneous drainage of condensate to the street.

The internal channel of the coaxial system is constantly cooled by the air flow coming from outside, due to which the temperature difference during normal operation is minimal.

The standard length of a coaxial smoke exhaust system is 1.2 meters. If extension is necessary, (necessarily indoors) the distance should not exceed 6 meters. There must be at least 0.6 m between the outlet of the outer part of the coaxial chimney and the nearest obstacle (wall, large tree, etc.).

If the boiler is equipped with a coaxial chimney, problems with condensation formation arise during frosty periods. They are solved by insulating the part of the smoke duct located outside the house, increasing ventilation or starting the boiler at full power.

When using a boiler with a coaxial chimney in the northern regions, it is advisable to insulate the outer part of the exhaust pipe. This way you can prevent the formation of condensation on the chimney of a gas boiler. After all, the difference between the temperatures of the incoming air flow and the outgoing flue gases will be reduced.

You can temporarily provide the boiler with air flow from the room. Most turbine models of floor-standing and wall-mounted gas boilers are designed for the possibility of installing separate supply and exhaust systems. You just need to find the plug for the hole to which the exhaust pipe should be connected and open it slightly.

With the exhaust duct plug slightly open, you can wait out the frost. Then it should be covered tightly. In these cases, it also helps to increase the boiler power during frosty periods. In automated systems, a temporary reduction in the interval between the boiler activation and shutdown temperatures set by the owners works well.

Installation rules

To prevent condensation from accumulating, the chimney system must be:

- waterproof;

- hermetic;

- protected from corrosion;

- insulated.

These conditions can only be ensured by correct installation of the chimney, selection of its materials, insulation and sealing during the assembly process. A description of the nuances of these processes can be found in the video below, with a brief overview of the types of chimneys and the requirements for their installation.

Key points:

- the lower pipe is positioned with a socket towards the outlet;

- all joints are treated with sealant;

- vertical deviations within 30% are allowed;

- the horizontal distance does not exceed 1 meter;

- The cross-section of the pipes throughout the channel is the same.

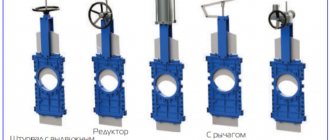

T-shaped condensate trap

Forbidden:

- use of a brick chimney;

- the use of mushrooms and umbrellas at the head of the outlet.

To prevent condensate from collecting, it is necessary to have a condensate collector and drain, ensuring good draft. It is important not to forget about routine cleaning of the gas boiler and preventive maintenance of the condition of the internal walls of the chimney.

Is it possible to drain condensate into the sewer?

During operation of a gas boiler, oxides are formed that react with water vapor. As a result, carbonic and sulfuric acids are formed, the average pH of which is 4. For comparison, the pH of beer is 4.5.

The acidic solution is so weak that there are no restrictions on discharge into public sewers. This rule applies if condensation has formed on the pipe of a gas boiler operating in an apartment.

The only condition is that the condensate must be diluted with wastewater 1 to 25. If the boiler power is more than 200 kW, it is necessary to install a condensate neutralizer. This requirement is indicated by the manufacturer in the equipment passport.

It is impossible to collect condensate into an autonomous sewer system that discharges wastewater into a septic tank with anaerobic bacteria or into a deep treatment station using anaerobes and aerobes. It will destroy the biological environment involved in the cleaning process.

Determining the probability of condensation formation

Calculations can be carried out if condensation is formed as a result of a large release of steam and overheating of the chimney walls, and the power of the operating equipment is known. The average rate of heat release is 1 kW per 10 sq. m.

The formula is relevant for rooms with ceilings below 3 m:

MK = S*UMK/10

MK - boiler power (kW);

S is the area of the building where the equipment is installed;

WMC is an indicator depending on the climate zone.

Indicator for different climatic zones:

- south - 0.9;

- north - 2;

- middle latitudes - 1.2.

When operating a double-circuit boiler, the resulting MK indicator should be multiplied by an additional coefficient (0.25).

Requirements for the chimney of gas boilers

Today, in the construction of chimneys for gas boilers, various materials are used, most of which are impractical. The quality of execution also leaves much to be desired.

Chimney made of asbestos cement. In the past, such chimneys had no alternative. Their main advantage is low cost.

Flaws:

- installation is carried out exclusively on vertical sections of pipes;

- heavy weight and length, which complicates installation;

- joints are not sealed;

- the resulting moisture is absorbed into the walls;

- the temperature of the exhaust gases is not higher than 300 ºС.

It is important to connect the boiler to the chimney correctly. A tee is used for this purpose.

If a tee is used in the chimney, then installation is carried out “through the smoke”. In its absence, “by condensation”

A condensate drain and a cleaning hatch are required.

Brick chimneys. This material is not recommended for installing systems with gas boilers. According to the requirements specified in the collection SNiP 41-01-2003, smoke exhaust channels for gas processing equipment must be smooth and classified as class P in terms of gas tightness.

If a brick smoke duct is quite suitable in terms of gas tightness characteristics, then there can be no talk at all about the smoothness of the walls inside the pipe. Even if the seams of a brick pipe are perfectly sanded with mortar flush with the brickwork, during operation the relief will still appear due to the difference in the density of the material and the binder.

The ideal solution would be to install a metal sleeve inside the brick channel or assemble it from ceramic modules. A brick pipe with a metal or ceramic insert inside can last more than 30 years without problems.

Furanflex lining is suitable for the same purpose. This polymer hose is made of composite (plastic reinforced with high-strength fibers). It is resistant to acid condensate and has low thermal conductivity. Permissible temperature of use is up to 200 ºС.

Ceramic smoke channels. This material is strong and durable. A ceramic chimney is resistant to aggressive acids, easy to maintain and fireproof.

Ceramics can heat up quickly and take a long time to cool down. Installation of such a chimney requires the participation of specialists. The downside is the high cost.

Galvanized and steel. When exposed to moisture, steel rusts. The maximum shelf life of such pipes is up to three years. Galvanized chimneys, protected from rust by a layer of zinc, last for five years or more.

If moisture does not penetrate into the boiler, it accumulates in the lower part of the chimney (in the house), which leads to an unpleasant odor. At the same time, this is a vulnerable place where acid accumulates, which over time will “eat away” this area

Stainless steel pipes. An ideal choice for arranging the smoke duct of a gas boiler. Its installation will cost several tens of times less than the construction of a brick chimney. The walls are smooth, soot and resins will not settle on them, the gas density is quite high.

To assemble a chimney, you can purchase a set of single-layer modules or buy elements of a sandwich system. You can assemble such a structure with your own hands without much effort. The main thing is to follow the direction when forming connecting nodes.

Insulation and finishing of the chimney improve the aesthetics of the building, which gives the house a more well-kept appearance

Advantages of stainless steel chimneys:

- due to the round cross-section and smooth surface they provide good traction;

- sealed;

- they quickly overcome the condensation threshold;

- easy to maintain;

- fireproof;

- durable.

The quality of steel, welding seam, and joints between elements is also important.

When sealing seams, you need to pay great attention to the sealant. Some brands “petrify” and crack during use

The fact that chimney repair is much more expensive than proper installation at the stage of installing gas equipment is often not taken into account.

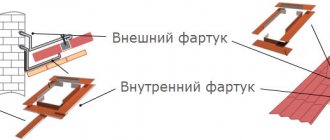

Methods for eliminating leaks at the junction of the chimney and roof

If, during the period of natural precipitation, liquid flows down a chimney or flue, then the prerequisite for the creation of leaks is damage to the insulation at the area where the chimney exits the roof. In cases where the roof is leaking close to the pipe, it is possible to eliminate the leak using the following options:

- Laying bitumen tape.

- Placement of a sealing collar made of heat-resistant rubber materials.

- Installation of an iron apron. Before you make it, you need to decide to purchase a finished product in a retail chain or make it yourself.

Bitumen tape

Making an apron from bitumen tape is a very simple and effective method to eliminate a leak in a pipe or chimney at the point of exit from the roof.

To carry out the sealing procedure you will need:

- Bitumen tape;

- large roofing scissors;

- metal brush;

- roofing gas burner.

Work procedure:

- An iron brush is used to clean the area of the chimney roof near the chimney and the bottom of the chimney.

- Use moistened rags to collect fragments of debris and dirt.

- At the junction of the pipe and the roof, a piece of tape insulation is laid with a layer to the bottom.

- Using a burner device, the tape is heated and pressed against the roof plane and pipe.

- For strength, the apron can be secured with a board or block.

Bitumen tape - a means to eliminate chimney leaks

Rubber cuff

Construction stores suggest using Master Flash rubber aprons or Wakaflex waterproofing tape.

Master Flash is a flexible rubber penetration in the shape of a stepped funnel, with an aluminum reinforced mesh in the middle. It is used for roofs with different slopes and all kinds of roofing coverings. The rubber product thoroughly protects the construction gap from water ingress. In order to accurately attach the apron to the pipe, it is heated and cut to the required diameter. On the roof it is secured with self-tapping screws, and attached to the pipe using an iron clamp.

Wakaflex is a rubber product in the form of tapes on an adhesive base. It is used to isolate the joints of soft roofing and chimney walls. The internal area is reinforced with reinforcing aluminum mesh. It has good extensibility, can take on any configuration, and is simply fixed on the slope. Vakaflex is used in combination with decorative collars.

Laying technology:

A hole is made at the top of the cuff, with a diameter slightly smaller than the chimney. The prepared cuff is put on the outer part of the smoke duct and goes down to the roof level.

In order to eliminate the possibility of a secondary leak, you need to apply sealant at the point of contact between the roof and the cuff. Certain types of cuffs are difficult to glue to the roof; they are allowed to be screwed to the roof with self-tapping screws, but not for tile and slate surfaces.

Metal apron

If there is a roof leak in the pipe area, installing an iron apron will be a safe way to eliminate the leak:

Metal apron installation technology:

- An apron is made from an iron sheet, the dimensions of which are suitable for the outlet chimney. You can also purchase the finished product in a retail chain.

- The upper section of the part is secured to the pipe using a crimp clamp.

- The lower part is fixed to the roof with self-tapping screws.

- In order to ensure greater density, the lower section of the product is strengthened over the roofing material, and the upper section is placed under the sheathing.

Rules for the operation of chimneys

When installing a chimney, it is important to ensure:

- removal of condensate using a condensate collection tank;

- maximum tightness of the system;

- system isolation;

- good traction;

- vertical shape of the chimney;

Important! The head of the pipe must rise above the roof surface by at least 0.5 m so that it does not fall into the wind pressure zone.

Layout of the chimney on the roof

Installation and maintenance of a chimney is a vital process that cannot be neglected. From time to time, professional regular cleaning and inspection of the chimney is necessary. After all, a visit from a specialist will not only help solve immediate problems, but will also reveal shortcomings in the future.