Metal pipes are gradually becoming a thing of the past. They are being replaced by various materials; metal-plastic is rightfully considered one of the most popular. Thanks to the successful combination of many advantages, such parts can be used to equip a wide variety of communication systems. They are successfully used in production systems as highways intended for transporting various chemical products. And also in households, where they are used as pipelines for heating systems and for supplying hot water. For installation, special press fittings for metal-plastic pipes are most often used, providing a strong and reliable connection.

- 2 Advantages of permanent connection

- 3 Secrets of proper installation of such parts

3.1 How to choose press pliers?

- 3.2 What to look for when purchasing connectors

- 3.3 Installation secrets from specialists

What is it like?

A press fitting is a special device that serves as a permanent connector of metal-plastic pipes or system structures with metal elements. With the help of such structures, it is possible to quickly and durablely install a system using metal-plastic pipes consisting of cross-linked polyethylene with pipelines, mixers and heating devices.

Such press connections are made of stainless steel or brass - a material that can be deformed during compression, but which is, at the same time, strong enough in structure for use in such structures.

Depending on the type of connections of metal-plastic structures, there are two main types of press fittings:

- Crimping. Used to strengthen the detachable type of communication connections made of metal-plastic. In this case, the press fitting has a union nut that serves as a press. This type of part is also called compression.

- Sliding. Used to strengthen permanent connections. Such parts do not have threads, and instead of a nut, a sleeve serves as a press. As a result of installation, a deformation effect is exerted on the sleeve. Subsequently, it no longer regains its original form.

Compression fitting

Aluminum press fittings are also in demand on the market, but they are not suitable for connecting metal-plastic products due to the fact that aluminum parts are too soft to compress the pipe with sufficient force.

Press-on method

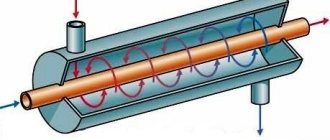

The most correct method for installing cross-linked plastic pipes, which takes full advantage of the material’s qualities such as flexibility and molecular memory. When working, put a sleeve on the pipe and press the fitting into the pipe hole.

The connection is distinguished by the highest degree of sealing, in contrast to the methods discussed above, and ensures high reliability of the pipeline. The technology consists of flaring the pipe edge, after which a compression-type fitting is inserted into it. It is fastened using a metal sleeve, which is pulled from above onto the pipe at the location of the fitting.

Rice. 9 Compression method of connecting PE-X pipes

Advantages and disadvantages

Press fittings have already proven themselves as reliable and durable fasteners for metal-plastic structures.

Let's look at other positive aspects of using press fittings:

- The operation of the system does not require monitoring or additional maintenance. You can install a hidden pipeline, or completely fill the system with cement.

- When temperatures fluctuate, there is no effect of pipe expansion. Thanks to this, press fittings can be used for pipes supplying hot water.

- Quick installation. In order to install such a system, it is enough to arm yourself with special press jaws. No special skills are required for installation.

- There is no need for a large amount of fittings. Pipeline installation is simplified. Material costs are reduced.

In addition to the advantages, however, there are also some disadvantages of press fittings:

- "Disposability" of the system. This structure cannot be disconnected. If the press fitting is pressed incorrectly during installation, the only thing you have to do is disconnect it and throw it away.

- Brass products tend to become covered with an unpleasant patina and darken over time. However, users advise covering such a structure with nickel or chrome to make it decorative.

- Press connections made of brass are designed to operate at a pressure of 16 atmospheres. But in city apartments the pressure mainly varies within 2-3 atmospheres.

Features of selecting pipe diameter by type of use

The main point of calculation for heating systems is the size of the outlet pipe from the boiler. The indicator determines the internal diameter of the pipe; selecting products by external diameter is the wrong decision. In this case, different wall thicknesses will lead to discrepancies in the indicators, and you will have to buy another material.

Selection rules - before the first branch, the pipe Ø indicator must be equal to the size of the inlet and outlet pipes on the boiler, and after the first division of the circuit, decrease by 1 step, after each subsequent branch, also decrease by 1 step. If the output is Ø 24 mm, then after flow to the second device or another branch you need a Ø of 18 mm, then from the branch to the devices or branch the diameter should not be more than 12 mm. The coolant return flow line is assembled in the reverse order - from small to large diameter, also with an increase of 1 step.

Rules for choosing diameter sizes by area of use:

- For water supply systems Ø (external/internal) 16-12 mm with a wall thickness of products no more than 2 mm.

- In autonomous heating systems of a private house, you need to take pipes with Ø 26/20. Wall thickness no more than 3 mm. The pipeline is suitable for the circuit of heated floors, the formation of risers and the distribution of hot water.

- When installing heating risers with a low pressure indicator, products with Ø 32/26 and a wall thickness of 3 mm are needed.

- In centralized heating systems and circuits with high pressures, elements with Ø 40/32 and a wall thickness of 3.9 mm are used.

A larger diameter of metal-plastic pipes for heating in domestic conditions is not required; such products are suitable for laying pipelines in public and social institutions.

Comparison with other connection methods

There are several main types of fittings:

- Radial and axial press fittings, used primarily by professional installers;

- Push fittings, which can be used independently, without special training;

- Crimp – “manual” – fittings.

In order to choose the right connecting tool, the following parameters are taken into account: what is the purpose of the fitting (what and in what area will it connect), price, experience in installation.

Press fittings (radial and axial) are generally reasonably priced and have a high degree of strength, but require some experience to install. Push fittings are most effective when a large number of connections are required. They are easy enough to install even for inexperienced beginners. But, on the other hand, such fittings are often used by experienced installers when it is necessary to complete a large project in a short time.

Compression fittings are ideal for connecting to radiators and other engineering equipment. They are used in their work by both professionals and inexperienced installers.

What to look for when choosing

The reliability of a structure made of metal-plastic pipes depends on the quality of the purchased tools. To do this, you need to carefully select press fittings. It is recommended to pay attention to the following important details of press connections:

- Markings on the body. Companies that produce high-quality parts also use expensive molds for markings. The first signal for the buyer is the clarity of the symbols on the product packaging.

- Weight of the part. It should weigh “decently.” The brass from which the fittings are made has an impressive weight. Therefore, if it seems that the part is “like a feather”, it is not worth purchasing.

- Appearance. Only parts that are strong in themselves can create a reliable connection. Therefore, if the fitting is cast from thin aluminum, the quality of the connection will be extremely poor.

- Price. You should not purchase a product in unverified places just because it is much cheaper than others. Most likely it's a fake.

Crimping press fittings. How to do it right

Press fittings are different in appearance and design. But the part that is placed in the pipe cavity during operation remains unchanged. The ferrule that holds this pipe together is also an integral part of the fittings.

Thanks to crimping, it is possible to achieve a tightness effect without the use of additional fastening parts.

In order for the connection of metal-plastic pipes to be as effective as possible, it is necessary to follow specific steps:

- Prepare the pipes for connection. The required length is cut with special cutters. This element is performed by applying firm pressure while slightly turning the pipe until it is neatly cut.

- Calibrate pipes. A special calibrator will ensure that during installation and cutting the pipe does not become oval (as is usually the case). The ends of the pipe are made rounded using rotational movements, after inserting the calibrator into the internal cavity.

- Crimp coupling. It is almost always presented in the form of a wide puck.

- The fitting must also be inserted into the pipe. There should already be an o-ring inside, as well as special gaskets that serve as fixatives.

- After all the preparatory work, you can begin crimping. It is performed with a special mechanical or electric crimping press. Mechanical press jaws are increasingly used at home.

- With the handles of the press pliers apart at 180 degrees, the bushings are inserted into the open crimping head.

- Bushings are selected for each job individually, according to the diameter of the pipe.

- Next, you need to place the tool on top of the coupling and connect the handles. This is how the fitting and plastic pipe are crimped and connected.

- You can remove the press tongs to move to the next section by again moving its handles to the sides.

Pipes connected by this method become durable and airtight. It is considered universal for use both at home independently and for large objects installed by professionals.

Crimping rules

Despite the ease of installation of compression fittings, there are several subtleties that must be taken into account during operation. Press jaws have a set of inserts of different sizes. The crimping insert is selected according to the caliber (diameter) of the pipe. Provided that the positioner insert is selected correctly, after crimping, two identical annular strips are obtained. An insert that does not match the pipe caliber will not allow proper compression, as a result of which the joint will be leaky.

The coupling can only be crimped once. Repeated compression is prohibited. If during work the fitting was installed incorrectly, it will have to be completely dismantled and a new one installed.

The design of crimp connectors may vary slightly between different manufacturers. The main difference is the installation of the ferrule. In some models it is initially fixed to the fitting. Installation of such components is carried out in a slightly different sequence, since there is no need to install the sleeve on the end of the pipe. Immediately after calibration, the pipe is placed on the fitting and the compression process is carried out.

Tool for press fittings

There are now more than enough varieties of tools and companies that sell them for installing connecting metal-plastic structures. They are all different, but they are designed to serve for durability and do the job.

- Regular hand pliers for home use are more similar in appearance to pliers. However, they are heavier, more complexly designed and larger in size. On one side, such a tool has space for special removable nozzles, on the other, a blade for installing the fitting.

Manual pliers for metal-plastic pipes

- Hydraulic press jaws. They are capable of connecting not one, but several sections of pipe and are used, as a rule, by professionals in large areas. Such a tool will not be very convenient for home use, and it will also be more expensive.

Hydraulic press connections

When choosing pliers for the job, it is important to consider several factors. One of these may be the purchase of a tool with an additional set of attachments. This will allow you to connect metal pipes of different diameters simply, without wasting time.