Edge preparation can be done with a grinder or file. You should also pay attention to specialized equipment - edge cutters (bevelers, edge splitters, bevel cutters) . Our article will be devoted to this equipment. We will tell you what types of edgers there are and review the most popular models.

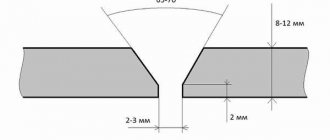

In some cases, to obtain a high-quality and reliable welded joint, it is necessary to cut the edges:

- work with thick-walled products , the thickness of which exceeds 4 mm;

- pipe welding ;

- multilayer welding;

- to avoid overheating of cast iron parts, the edges should be cut;

- aluminum products , the thickness of which is more than 2.5 mm, when welding with uncoated electrodes.

Manual

The manual chamfer is a portable, fairly lightweight and compact unit. This type of equipment is used for chamfering holes and effectively processes straight and radius edges. This equipment is suitable for working with sheet metal and pipes.

The equipment is versatile , can work with various materials, and perform a variety of tasks. Due to its productivity, it is actively used on construction sites, for small-scale work, and is excellent for domestic use.

Manual type equipment has the following advantages :

- ease of control , a specialist without prior training can perform high-quality edge processing, easily change the angle and width of the chamfer;

- small dimensions ensure mobility ;

- during work less electricity than when using stationary analogues;

- manual bevelers for pipes and sheet metal consume much less electricity than stationary models;

- no additional space is required to locate the device, the welder does not need to worry about preparing the site for installation of the unit;

- wide possibilities for adjustment , i.e. work can be performed from different angles;

- ergonomics : the presence of special handles ensures comfort and convenience for the performer; the absence of vibration is guaranteed by the rubberized coating.

Also, manual bevel removers have some disadvantages :

- designed for working with small-sized workpieces ;

- lower productivity compared to stationary analogues;

- the need for additional processing of pipes before using them; sheets can be welded immediately;

- fixation is required .

Video

The following video allows you to visualize the work of manual bevel removers.

Mongoose

Russian-made equipment of the “Mongoose” is designed to work with pipes whose diameter varies from 16 to 325 mm. The most popular equipment model of this brand is a manual chamfer for metal pipes Mongoose-2-Electro , the technical characteristics of which are presented below.

- Power source – 220 V.

- The weight of the machine equipped with spare parts is 16.3 kg.

- Electric drive power consumption/input – 1.4/1.0 kW.

- Rotation speed – 40-150 rpm.

- The maximum processing length is 50 mm.

- Minimum pipe length required to secure the unit: straight pipe – 5 mm. + processing length;

- pipe with deflection - 48 mm. + processing length.

Pipe edgers of this brand are in high demand among performers, which is why the Magust beveler is sold by many companies. [ads-pc-2][ads-mob-2]

VM-20

The BM-20 chamfer is a manual edge cutter, which is produced by the Promotech company (Poland) , designed for processing the edges of pipes and sheet workpieces, it allows chamfering in the range from 15 to 60°, chamfer width – 0-20°.

- The weight of the unit does not exceed 21 kg.

- Convenient to use.

- Movement along the surface to be treated is carried out by rollers; a small force is required to carry out the treatment.

- Power source – 220-240 V / 50-60 Hz.

- Current consumption – 12-14 A.

- Processing speed – 1.5 m/min.

- The drive motor is electric, single-phase, induction, with a working capacitor W-1.8 kW.

- Rotation speed – 2820 rpm.

- Fuse – 2 A / 250 V; degree of protection – 1Р54.

- Two milling heads with carbide inserts provide edge processing.

FS-10

The manual edge cutter for sheet metal FS-10 effectively, quickly and cleanly removes chamfers up to 10 mm wide. from products made of low-carbon, low-alloy and stainless steels, produced by Hitech Instrument (Russia). Can also be used for processing perpendicularly cut pipes with a diameter of 600 mm or more.

The FS-10 chamfer has excellent technical characteristics:

- The maximum chamfering angle is 60°.

- The weight of the unit without equipment is 15 kg.

- Supply voltage – 220 V.

- Rotation speed – 3000 rpm.

- Engine power – 570 W.

- Processing speed – 1 m/min.

- Equipped with five carbide inserts.

- Electric drive.

EKF-300/450

The EKF-300/450 portable chamfer is used for removing straight and curved chamfers from internal and external, straight and radius edges, as well as pipe ends. Suitable for processing black and stainless steels, non-viscous alloys of non-ferrous metals. Manufacturer – BDS Maschinen (Germany) .

- The maximum chamfer depth is 8 mm.

- The chamfer angle is 30/45°.

- Supply voltage – 220 V.

- Power – 1500 W.

- Rotation speed – 6000 rpm.

- Weight – 4.6 kg.

- The thickness of the processed product is any.

- Electric drive.

Rothenberger

The Rothenberger manual beveler is a line of equipment produced by the German company of the same name. These edge cutters are divided into external and internal, they are versatile, they quickly and cleanly remove internal and external chamfers, and also clean the surface.

- The weight of the unit does not exceed 100 g.

- The bevelers are suitable for processing pipe edges with diameters ranging from 3 to 54 mm.

Manual chamferers are divided into two types, depending on the drive used: electric and pneumatic. Each type of equipment has its own advantages and disadvantages. In addition, there are differences in technical characteristics between these two types of equipment, which can be found below. [ads-pc-3][ads-mob-3]

Let's look at the purpose of the bevel remover

Unlike conventional chamfering machines, chamferers for steel pipe products solve the following problems:

- Cleaning uneven areas, burrs and chamfering only on the edge part.

- Calibration of metal pipe products.

- Creating a chamfer that allows two metal pipes to be hermetically joined without much effort.

Such chamfers are widely used when laying pipelines from pipes for various purposes.

The device also allows you to remove the chamfer for precise installation of the metal-plastic pipe into the fitting, this makes it possible to save the gaskets - seals inside. Subsequently, this becomes a guarantee of high tightness of the joint.

Electrical

Electrically driven chamfer removers operate from appropriate networks. The main advantage is that electrical networks are ubiquitous, finding a power source and connecting the unit is easy and simple. As a disadvantage, it should be noted that it is necessary to comply with safety precautions, otherwise the performer risks receiving an electric shock.

RIDGID (video)

This model can work with both pipes and sheet metal.

GTW-2100

GTW-2100 is an electric beveling tool for pipes and flat surfaces, suitable for working with steel, stainless steel, non-ferrous metals and other materials.

- The maximum chamfering angle is 90°.

- The maximum chamfer width is 22 mm.

- The maximum chamfer depth is 15 mm.

- The minimum pipe diameter is 101.6 mm.

- Power – 1700 W.

- Unit weight – 6.5 kg.

- Three cutting inserts.

K1755

K1755 – electric chamfer for metal pipes with an outer diameter of 28-42 mm.

- Power – 1200 W.

- Frequency – 50 Hz.

- Supply voltage – 220 V.

- Axial movement of the cutter is 15 mm.

- The rotation speed does not exceed 200 rpm.

- The weight of the device is no more than 11 kg.

FS-22M

Bevel remover FS-22M is an electric device for processing the edges of sheet materials.

Specifications:

- Engine power – 1100 W.

- Supply voltage – 220 V.

- Rotation speed – 3000 rpm.

- The weight of the device without equipment is 20 kg.

- Processing speed – 1 m/min.

FS-22

FS-22 chamfer is designed for processing sheets and pipes made of the following materials: steel, stainless steel and light alloys. Multifunctionality makes this unit popular, so you should familiarize yourself with its technical characteristics.

- Motor power – 100 W.

- The maximum chamfer width is 22 mm.

- Chamfer depth – 11.5.

- The chamfering angle is 15-60°.

- Rotation speed – 3000 rpm.

- Weight – 20 kg.

- Processing speed – 1 m/min.

Device design

The main structural elements of such devices are: a housing (plastic or aluminum) and a roller cutting mechanism. Their specially shaped blades quickly and easily chamfer only the outer surface of the pipe before socket or electrofusion welding, or both outside and inside. The cut area becomes smooth and evenly beveled. Most models are also capable of removing flash resulting from socket welding. They are easily adjustable, adapting to the diameter of the workpiece and its wall thickness.

Pneumatic

Pneumatically driven edgers are an excellent option if there is no electricity or there is a danger of damage to wires. The main disadvantage is that the contractor will need additional equipment - a source of compressed air, for example, a compressor.

IMPORTANT! Sometimes edge processing must be carried out in conditions where the use of electricity is prohibited. Here pneumatics will be indispensable.

TT-80

The TT-80 chamfer is a pneumatic edge cutter designed for internal and external chamfering of pipes. Fastening to the product is carried out using three self-centering cams.

- The internal diameter of the pipes is 28-76 mm.

- The outer diameter of the pipes is 32-80 mm.

- The maximum pipe wall thickness is 15 mm.

- The cutter stroke is 35 mm.

- Rotation speed – 55 rpm.

- Pneumatic drive – 960 l./min.

- Voltage – 220 V.

- Unit weight – 16 kg.

NT1738M

The NT1738M chamfer remover is equipped with a pneumatic drive and is used for processing the edges of pipes with an internal diameter of 60-102 mm.

The device is fastened from the inside of the product.

- Engine power – 200 W.

- Axial movement of the cutter is 15 mm.

- Rotation speed – 220 rpm.

- Equipment weight – 12 kg.

Video (FUJI)

A short video review of equipment from the manufacturer FUJI.

For metal pipes

Pipe edgers are actively used in the construction industry . Without this equipment, it is quite problematic to imagine the installation of various systems, be it a heating main or a water supply system. The pipe chamfer has several features :

- compact dimensions allow the installations to be used in various situations;

- equipping the devices with replaceable cams for reliable fastening;

- pipe chamfer for metal pipes has a fairly low weight, no more than 20 kg;

- ability to work with large diameter pipes.

Despite the growing popularity of plastic pipes, today performers often use metal structures. Thus, steel pipe bevelers are popular.

Rothenberger 11006

Rothenberger 11006 beveling tool is designed for deburring surfaces; however, it is also suitable for removing edges. These edge cutters are divided into external and internal, they are versatile, suitable for working with pipes made of steel, copper, and stainless steel. For performers who are looking for a high-quality chamfer for copper pipes, it is recommended to pay attention to this model.

- Weight – 40 gr.

- The minimum pipe diameter is 3 mm.

- The maximum pipe diameter is 36 mm.

- Alloy steel knives are additionally ground, which increases sharpness.

AGP

The line of equipment under the AGP includes a wide variety of edge cutters, produced by the company of the same name. The most popular unit is the electric pipe beveller AGP EB24 .

This machine is suitable for processing various materials: steel, stainless steel, copper, aluminum, plastic and others. The functionality of the device makes it in demand among professional performers. Therefore, those who want to purchase a bevel remover for stainless steel pipes should pay attention to this model.

Specifications:

- The maximum chamfer thickness is 21 mm.

- The chamfering angle is 15-60°.

- Pipe diameter – 150-350 mm.

- Power – 1100 W.

- Voltage – 220-240 V / 50-60 Hz.

- Rotation speed – 3000 rpm.

- Weight is approximately 20.5 kg.

Huawei

The manufacturing company “Huawei” produces and offers end edge cutters of the ISY : ISY-80; ISY-150; ISY-250; ISY-351; ISY-630. Huawei beveller is used for processing pipes with an outer diameter ranging from 32 to 630 mm, and an inner diameter ranging from 28 to 600 mm.

- The wall thickness of the workpiece should not exceed 15 mm.

- Electric drive.

- The chamfer angle is no more than 60°.

- Supply voltage – 220 V.

- Power – 1600-4500 W.

- Rotation speed – 10-54 rpm.

- Two carbide cutters.

- Weight – 18-51 kg.

[ads-pc-4][ads-mob-4]

Areas of use

A pipe chamfer is used in the following cases:

- The technology for properly welding steel pipes consists in the formation of a weld pool between the joined sections, in which the molten metal from the electrode is located. To obtain free space for placing the melt, the ends of the pipe blanks are cut at a certain angle, using various tools.

- Chamferers can be useful when cutting various types of threads. In this case, it is much easier to put a die or pipe clamp on the beveled end.

- Some types of industrial tools for installing pipelines simultaneously level the end cut, for example, with a gas torch, and chamfer.

- In addition to being used on tubular products, chamferers can be used in preparation for welding of straight sections and processing of holes in metal products for countersunk screw heads.

- The mobile chamfer can be used to round edges, remove burrs and sharp corners on any workpiece.

- When installing climate control equipment, copper pipes are flared for a compression connection. Before carrying out this operation, be sure to remove the internal chamfer from the pipes using a hand-held device - a rimmer.

- Steel is considered one of the toughest and hardest metals. Therefore, using any bevel remover for steel, it is easy to carry out similar operations on products made of softer metals (stainless steel, copper, brass, aluminum) and any types of plastics.

Rice. 2 Types of fastening and drive of bevel removers

For sheet metal

Sheet metal is widely used in various fields and areas. Therefore, the sheet beveler is in demand among performers of various levels. Equipment of this type has design features : the presence of support rollers allows the edger to be held on a flat surface, pressed against the end and processed; The ergonomic handle guarantees convenience and ease of moving the unit without much effort.

MT-24

The MT-24 chamfer is designed for processing the edges of sheet metal materials and is used in the manufacture and installation of metal structures.

- The maximum chamfer width is 22 mm.

- The maximum chamfering angle is 60°.

- Power – 1100 W.

- Rotation speed – 3600 rpm.

- Weight – 19.3 kg.

- Number of cutters – 2 pcs; number of plates on the cutter – 12 pcs.

CHP-12

CHP-12 is a chamfer tool used for processing single- and double-sided edges of sheet materials made of stainless and carbon steel, aluminum and its alloys.

The manufacturer of this universal installation is the company “CeVisa” (Spain).

- The maximum chamfering angle is 45°.

- The maximum chamfer width is 12 mm.

- The maximum removal depth is 8.7 mm.

- Processing speed – 2.6 m/min.

- The thickness of the workpiece being processed should not exceed 40 mm.

- Drive power – 2200-3000 W.

- Supply voltage – 380 V.

- Rotation speed – 1400 rpm.

- Weight – 65 kg.

It should also be noted that this installation can also be used to work with pipes from 100 mm.

UZ-12

The automatic bevel remover UZ-12 is manufactured by NKO Machines (Czech Republic) . This machine is designed to work along the top and bottom edges, used for processing cast iron, stainless steel, copper, aluminum and brass, and has a high level of productivity. The unit can be installed on a sheet in a vertical or horizontal position.

- The maximum chamfering angle achieved using the equipment is 50°.

- The maximum chamfer width is 12 mm.

- The maximum sheet thickness is 35 mm.

- The minimum workpiece size is 60 x 60 mm.

- Processing speed – 1.8 m/min.

- Engine power – 400 W.

- Important! Light weight 30 kg. allows the installation to be used as both a mobile and stationary machine.

What types of devices are there?

There is currently a wide range of these tools available on the market. But, before going to the store, you should decide what characteristics it should have.

We should also take into account the material that we will process. The types and purposes of these devices are as follows:

- Used for finishing plastic pipes.

- For metal pipes.

- For polyethylene pipes.

According to the complexity of the actions performed, chamfer removers are divided into:

- Hydraulic type devices.

- Pneumatic mechanisms.

- Electrical type devices.

- Manual units.

Incisors

Cutters are the main part of the chamfer, which cuts edges. Equipment models are equipped with steel replaceable cutters.

Welders are offered 2 types of cutters:

- shaped ones are used for processing internal and external, as well as end surfaces of complex configurations;

- end ones are used when processing simple-shaped products.

Thanks to replaceable cutting parts, the machine can produce chamfers at different angles :

- flat cutters process edges at an angle of 0°;

- conical cutters: 15; thirty; 37.5; 35; 60°;

- internal conical cutters – 15°.

After reviewing this information, the contractor will be able to select the required model of chamfer and cutters for the equipment.

Nuances worthy of attention

When choosing a model, it is necessary to determine the optimal type of device. You also need to pay attention:

- on the ergonomics of the device (location of handles, design of the guide);

- accessibility and convenience of controls;

- overall dimensions and weight;

- simplicity and accuracy of adjustment for different pipe diameters (preferably a stepless system);

- the ability to change the cutting depth and chamfer angle;

- geometry, number and fastening of blades (fixed or rotating);

- the presence of a non-stick coating on the working surface;

- complete set (replacement blades, cutters, storage box, inserts).

The use of a chamfer remover increases the efficiency of processing polymer pipes. His fast and high-quality work is the key to maximum productivity and business success.