When dealing with sewerage, you cannot do without such a process as soldering PVC pipes. It has its own nuances, like any work with the sewer system.

Joining pipes made of this material is easy to do with your own hands, if you take into account the main nuances. But welding must be treated responsibly in order to avoid serious mistakes.

About the main methods of soldering PVC pipelines

To perform welding, craftsmen use the following basic techniques.

- "Butt".

- "Electro coupling".

- "Muff" The connecting coupling is purchased separately.

- Using so-called aggressive glue. One of the safest methods, which is simple.

- The most common options are using a specialized soldering iron.

These are different options, but their essence remains approximately the same. Due to the fact that diffusion occurs, polyvinyl chloride compounds are very durable.

This happens when the material is coated with glue, or one part of it is welded to another. Any do-it-yourself soldering of PVC elements consists of these stages.

Each welding process has its advantages and disadvantages. Conventional soldering technology is suitable for structures with different characteristics. An excellent choice for those who do everything themselves is the use of special glue.

There are exceptions, but special glue in most cases will not be suitable for a system that may have high pressure. The coupling also allows its use.

We purchase the necessary equipment

Video 1. DIY PVC soldering process and what tools are needed

Soldering polypropylene pipes, technology, tools

This kind of work can be done almost alone, without special equipment. But the procedure requires minimal equipment. This:

- A soldering iron that comes with several attachments. The main thing is that there is a correspondence between the soldering iron nozzles and the diameter of the pipeline.

- Scissors for cutting. The main thing is that the tool is sharpened, then the parts will not be deformed.

Every action and decision must be verified. Soldering technology gives up to 15 years of uninterrupted operation of the system if done correctly.

Therefore, it makes sense to thoroughly understand how to properly solder PVC pipes.

Video 2. Soldering a PVC pipeline with a Chinese soldering iron

Soldering iron for plastic pipes/Soldering of polypropylene pipes. You have never seen anything like this before)))

Features of PVC products

Production and scope of use

PVC products are widely used for laying hot and cold water supply systems, and are also indispensable for organizing the installation of both internal and external sewerage systems. Such pipes are also suitable for transporting aggressive working media and gaseous substances.

PVC pipes are made from polyvinyl chloride (unplasticized) in the form of single-layer or three-layer pipeline products. All PVC pipeline products are classified according to their stiffness class and are produced in different diameters to solve the maximum number of problems associated with pipeline installation. Pipes are supplied in standard lengths of 50, 100, 200, 300 and 600 cm.

Positive qualities of PVC products

The positive qualities of polyvinyl chloride pipes determine the range of their use. The demand for these products is due to:

- long service life;

- immunity to ultraviolet radiation;

- resistance against aggressive chemical environments and corrosion;

- full compliance with modern requirements for pipeline systems;

- very low coefficient of linear expansion;

- operating temperature of the transported medium up to 55ºС;

- relatively low cost;

- light weight of pipes;

- resistance against the establishment of bacteria and fungi;

- absence of deposits on the internal surfaces of tubular products;

- good throughput;

- anti-toxicity and explosion safety;

- fire safety.

Features of the welding process

There are some nuances, observance and consideration of which will help achieve maximum results, regardless of how you solder.

- It is necessary to thoroughly clean all connection points from dirt and dust.

- The joint will need to be degreased. Without this it is impossible to solder.

- The pipes do not need to be inserted into the structure all the way. Fitting joints require careful preparation. The coupling is no exception.

- Chamfers are always removed. This is necessary so that the pipe fits tightly into the fitting without additional effort.

The soldering itself begins when the preliminary stages of preparation are completed. Adhesion can be divided into four stages. It doesn't matter whether a coupling is used or not.

- Slicing.

- Warming up.

- Compound.

- Cooling.

For slicing, special types of scissors are used, designed specifically for this purpose. If you use the right tool, the pipes will not become deformed in the future.

The apparatus used for soldering must also be oriented to the desired diameter.

Be sure to use thermal gloves to protect yourself. Welding PVC pipes with your own hands is not such a difficult process.

Brief instructions

First, fittings and pipes that require processing are prepared for welding. The foil layer must be removed if we are talking about reinforced products. It is necessary to degrease all parts that will need to be soldered later.

Video 3. Soldering a PVC pipeline on the wall with a soldering iron

Welding polypropylene pipes on the wall. How to securely secure a soldering iron for pipes?

Then a mark is applied to the pipe, which is placed at the melting depth plus 2 mm. We take a soldering iron and install suitable sized nozzles on it.

On one side, a connecting element is mounted on the welder’s heater, and the pipe itself is fixed on the other end. The coupling is used somewhat differently.

The main thing is to observe when welding the time required to process certain parts. Rearranging, fixing and heating with your own hands requires compliance with certain time intervals.

Parts will not be deformed only if each action is performed smoothly. On the welding machine you need to set the operating melting temperature. Usually it is equal to 260 degrees. Otherwise it is impossible to solder.

You need to wait some time after the process is completed for the structure to cool down. Observe the same requirements when using a coupling.

Video 4. Do-it-yourself soldering of PVC pipeline

Soldering of polypropylene pipes

Advantages and disadvantages of such soldering

Considering options for how to solder this or that part of polypropylene pipes without a soldering iron, you can see that each method has its own advantages and disadvantages. The advantages of this method include:

- No need to purchase a soldering iron if it is not available;

- Ability to use simple available tools;

- A cost-effective process for creating a connection that is cheaper than using a soldering iron;

- The ability to work with pipes of any diameter, both the smallest, which is quite easy, and larger ones, which will require more patience and experience.

About cold welding technology

This welding method involves the use of so-called aggressive glue. It is simpler compared to the previous one. Almost all the work is done independently, without assistants.

- Pipes and fittings must be prepared as if work would need to be done for reinforced polypropylene products. First, we apply a mark to the surface of the structure that corresponds to the correct location of the elements.

- Glue is applied to the parts involved in the joining process. They need to be pressed against each other very quickly and quite firmly. The coupling is processed in the same way.

- We fix the pipes in the desired position with our own hands for literally fifteen seconds.

- You need to turn on the water one hour after the end of the process. Until the specified time has passed, the system must remain absolutely motionless. The video lessons presented on our website will add clarity to the explanations.

Video 5. Soldering PVC pipeline with a minimum set of tools

Simple and quick installation of CPVC pipes!

Butt welding

This is one of the popular methods of connecting between polymer pipes, however, for PVC pipes this method is used less frequently than for products made from other polymers. This is due to the fact that the time allotted for the welding process in the case of plastic pipes is very limited and is calculated literally in seconds. In order to do everything correctly in such a short period of time, considerable skill in work is required, which not everyone can boast of.

To carry out butt welding, a special manual welding machine for PVC pipes and nozzles for it are required. Before joining, the pipes themselves are cut with special scissors, which must have good sharpness (otherwise cutting leads to deformation of the walls of the products).

Butt welding stages:

- The pipes are cut into pieces of the required length.

- The ends of the pipes are cleaned of dirt and grease.

- Marks are applied to the pipes and they are trimmed and chamfered.

- The connected areas of the products put on the welding machine are heated to the required temperature (for products made of polyvinyl chloride it is +250 ˚C).

- The welded products are quickly connected to each other.

- The resulting structure is cooled, and after a short time it is ready for use.

What mistakes do masters make most often?

Haste and lack of experience lead to the fact that even such a process as soldering polypropylene products is performed incorrectly. We will describe the most common problems and their features.

- Most often, defects on products appear due to incorrect placement of connecting elements during soldering. For example, gaps appear when the structure is not inserted into the fitting all the way. Because of this, the working pressure and wall thickness decrease. The problem is especially pressing for those who, immediately after heating, insert the pipe into the fitting with their own hands, without making sufficient effort.

At the same time, excessive force is not allowed during soldering. Otherwise another problem appears. From the gap, along the edges of which the end and internal stop of the structure are located, excess molten material begins to be squeezed out.

Such surpluses are also called “grat”. After which the flow of the working substance through the system decreases. The connecting element begins to experience more serious load.

- Some people don't always set the temperature correctly. The required temperature is 260 degrees. The deviations that are allowed are minus/plus ten degrees. This value is optimal for any type of product, regardless of diameter. The main thing is that the soldering iron does not overheat. Then it will be possible to maintain the required level of pressure in the material. In this case, the surface should not cool down too much before all the elements are connected to each other.

- Another common problem is incorrectly selected equipment. Soldering irons must be selected according to power, depending on the diameter of the pipe to be processed. For example, a power of 500 watts is the best option for a 50mm design. 1000 Watts are needed if a 100 mm pipeline is being processed.

Video 6. Errors in selecting connecting fittings for soldering + welding time table

How NOT to solder polypropylene pipes!

Tips for choosing a welding machine

Before purchasing the right equipment, it is recommended to pay attention to the following several characteristics:

- Manufacturer. What determines the cost of the device and the quality of workmanship.

- The material from which the device is made, the build quality. Soldering cannot be done without taking this factor into account.

- Complete set, additional attachments.

- Power. Depends on the diameter of the parts being soldered.

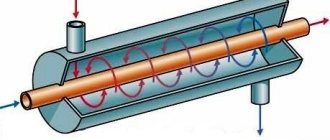

A soldering iron for PVC pipes is a tool with the simplest operating principle. The heating element is located in the very middle. It is responsible for creating the optimal temperature during soldering.

Video 7. Review of a soldering iron for PVC welding

Review of the welding machine for plastic pipes Patriot PW 205

The tool for soldering PVC pipes is equipped with additional attachments so that you can work with your own fittings of different shapes and sizes.

It is better to perform the procedure not alone, but together with an assistant. Someone must operate the tool, while another prepares and puts the parts in place.

Only experienced specialists can independently solder everything from start to finish.

About power

Equipment with a power of 1.5 to 2 Watts is most often found on the market. This may even be a lot for those who use the tool at home.

680 Watts are enough to solve this problem. At least for working with products with a diameter of 16-63 millimeters. 850 Watt is the optimal solution for ∅ 63-75 mm. Finally, from 1200 Watts will be needed for products with a diameter of 125 millimeters, so soldering will be easier.

What about the nozzles?

It is better to purchase larger sets. The optimal choice is tools with attachments for almost every diameter, a couple of pieces. Many soldering irons allow you to install two or more at the same time. But these are professional units, so they are not cheap.

How to warm up frozen plastic pipes

Country houses and country houses are in a kind of risk zone. Every few years, nature brings surprises, and due to severe winter frosts, the plastic water supply system, laid according to standard recommendations, becomes clogged with ice. The situation is especially unpredictable if steel pipes are laid instead of plastic ones, or if no one lives in the house for a long time.

In order to avoid this problem, the metal must be replaced with polyethylene pipeline. All plastic water supply systems in the ground and in the open air are dressed in a kind of cover made of PE sewer pipes with a diameter of 50 mm. The air gap will allow you to thermally insulate the water supply, and if freezing occurs, you can always warm it up with hot air using a hairdryer or heat gun.

A regular supply can be melted using a low-voltage transformer. First, before heating the water supply from plastic pipes, you will need to do a little preparation:

Disassemble the two plastic tap pipes closest to the frozen section; Pour a small amount of boiling salt brine into the water supply and leave for 20-30 minutes; Inside the plastic pipe, through the mounting sockets of the disassembled taps, insert short steel electrodes, or pieces of reinforcement, and connect them to the terminals of the transformer.

As the salt penetrates into the ice, the ice plug inside the pipe will melt, but this process is quite slow. To speed up the thawing of a plastic water pipe, you need to apply an electric current of 10-15A; hot water will quickly wash away the plug. Hot brine will in no way affect the plastic water supply, but after thawing, the brine must be rinsed with a stream of water.