Pipes made from a symbiosis of metal and plastic are produced for the construction of intra-house highways. The new products made it possible to assemble a water supply and heating system yourself, without involving plumbers. Pipelines serve for a long time, are installed extremely simply and quickly, without creating problems even for inexperienced craftsmen.

By installing metal-plastic pipes yourself, you can save a lot of money, preserving the family budget for more important expenses. To install them, a home craftsman only needs to stock up on an easy-to-use tool, patience and knowledge, which we are ready to share with site visitors.

We will tell you everything about the specifics of using metal-plastic products and methods of connecting pipelines assembled from them. The article describes in detail the negative and positive aspects of their use. Here you will learn how to install trouble-free systems.

Features of metal-plastic products

Metal-plastic (metal-polymer pipes) are composite products for the production of which various types of materials are used. Such elements have an attractive appearance, good wear resistance, elasticity, and strength.

Metal-plastic pipes are distinguished by high consumer qualities (strength, flexibility, resistance to high temperatures and aggressive substances), as well as an aesthetic appearance

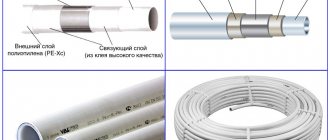

Typically, a pipe consists of five layers. A durable polymer, usually cross-linked polyethylene, is used as a supporting base. It makes the inner surface smooth, protecting it from blockages, and also contributes to the strength of the product.

An adhesive is applied to the core, on which aluminum foil that stabilizes the pipe is attached (it also prevents the ingress of oxygen). The connection is secured by butt or overlap welding.

The design of a metal-plastic pipe involves the use of five layers of different materials: two layers of polyethylene, two layers of glue, a layer of aluminum foil

The fourth layer is also applied with glue, to which the outer covering is connected - white polyethylene, which provides protection to the product and gives it an aesthetic appearance.

Temperature values.

If pipes are operated at constant temperature and pressure, then the products show their intended characteristics for a period equal to:

1.one hour at a temperature of twenty-seven degrees, the pressure is at a minimum threshold of 5.71 milliamps.

2.one hour, if the temperature is ninety-five degrees, with a minimum pressure threshold of 3.3 milliamps.

3.hundred hours at a temperature of 95 degrees, and the pressure with a minimum threshold of 2.93 milliamps.

4. one thousand hours with a temperature of ninety-five degrees, with a pressure at a minimum level of 2.57 milliamps.

Important! Metal-plastic products are resistant to high temperatures; pipes do not deform when reaching 110 degrees above zero for a short time.

Technical characteristics of pipes D 16-20 mm

Here are the data typical for metal-plastic pipes of common diameters (16 and 20 mm):

- The wall thickness is 2 and 2.25 millimeters, respectively; The thickness of the aluminum layer is 0.2 and 0.24 mm.

- One running meter weighs 115 and 170 grams and holds a volume of liquid equal to 1.113 and 0.201 liters.

- The thermal conductivity coefficient is 0.43 W/m K, the expansion rate of metal-plastic is 0.26x104 per 1 degree Celsius, the roughness coefficient is 0.07.

- When the material breaks transversely, the strength coefficient is 2880 N.

- The strength of the connection between the adhesive layer and the foil is 70 N/10 sq. mm, the strength coefficient of the aluminum welded layer is 57 N/sq. mm.

- Metal-plastic pipes can operate even at +95o C, briefly withstanding temperatures of +110-130o C.

- Within the temperature range from 0 to +25o C, the system operates at a pressure of up to 25 bar, and at +95o C it can withstand a pressure of 10 bar.

- The tightness and integrity of the metal-plastic pipe is broken under a load of 94 bar (at +20° C).

With proper installation and compliance with operating rules, products made of metal-polymers can last 50 years or more.

Briefly about the main thing

Metal-plastic pipes can withstand high temperatures up to 95 degrees. They are distinguished by flexibility and increased strength, which ensures reliability and durability of use.

Metal-plastic pipes are used on a wide domestic and industrial scale, for example, in the construction of houses. They are also used for heating, water supply and sewage disposal.

Metal-plastic pipes vary in length, wall thickness, cross-sectional diameter, composition, strength, heat resistance and bending radius, as well as purposes of use.

The main advantage of such pipes is their durability (up to 50 years). One of the disadvantages is the impossibility of using pipes for coolants that are too hot.

The choice of metal-plastic pipe depends on the purpose of application, as well as the type of material. The decisive factor in choosing a product is whether the quality of the pipe matches its cost.

Ratings 0

Areas of application of metal-plastic elements

Pipes made of metal polymers are widely used in the construction of individual houses, in industrial construction and agriculture.

The main areas of their use are:

- transportation of liquids, gaseous agents;

- laying drainage systems, water pipes, heating;

- in structures involving the transfer of compressed air;

- supplying heating components to radiators, installing heated floors;

- installation of air conditioning circuits;

- protection and shielding of wires (primarily power);

- construction of irrigation systems.

Metal-plastic is not recommended for use:

- when organizing central heating systems with the proposed construction of elevator units;

- in places with an assigned fire safety level “G”;

- with the expected supply of hot liquid in the pipeline with a working pressure >10 bar;

- in rooms where it is planned to place sources of thermal radiation with a surface temperature of over 150 degrees C.

In addition, it is undesirable to use metal-polymer pipes in safety, signal, overflow, expansion circuits and in fire-fighting water supply systems.

Metal-plastic products are widely used in private and industrial construction. This photo shows pipes used for laying heating systems

Kinds

There are two types of reinforced plastic pipes: polypropylene and cross-linked polyethylene.

There is no fundamental difference in performance characteristics - both types can withstand water supply pressure of 1.0 MPa (1.6 MPa for heating), both types are quite durable. They differ in appearance and installation method. Polypropylene pipes are usually white or gray, but can be green. Products made from PE-X are white or white with thin stripes. There are products finished with a special anti-diffusion layer.

Three main methods of pipe routing

The wiring of metal-plastic systems can be carried out using different methods, each of which is selected based on the feasibility and possibilities of further access to the system.

Option #1: hidden

In this case, all pipes and connections are hidden deep in the wall under the finishing materials. Only fittings and bends for connecting plumbing fixtures are exposed outside.

The hidden installation method involves installing the structure in the wall, where recesses are specially prepared for pipes, after which the surface is sealed

When using this installation method, the interior design is preserved, in addition, masking communications protects them from accidental damage.

This option has several disadvantages:

- Laying channels for pipes requires a complex and labor-intensive gating process. After laying communications, the surface must be restored again.

- This method is not suitable for load-bearing walls, where gating is prohibited by regulatory documents.

- Quite a high cost associated with additional work.

This method is best used when renovating a bathroom. It is not advisable to install a hidden installation in an already decorated room, since this will require complete dismantling of the wall covering (cladding, plaster).

Option #2: open

If for some reason the pipes cannot be hidden in the wall, they can be laid along its surface. This option is more convenient for visual inspection of joints, which allows, if necessary, to quickly clean the area or replace a component.

With the open method, pipes are laid along the surface of the wall, which allows for control of connections and reduces the cost of work

Open wiring can be used in rooms that have already been renovated, since the installation will not harm the design of the walls. The advantages of this method include its ease and lower cost of work than when laying internal communications.

Option #3: combined

In this case, the pipes are laid along the surface of the unfinished walls, after which they are covered with boxes or false panels. This is a rather complex method, since it requires the perfect fit of decorative elements into the interior, which can also be used as drywall, tiles and other materials.

Production process

The production of metal-plastic (multilayer) pipes is carried out on special automated industrial-type flow complexes. Moreover, during the manufacturing process, not only the products are formed, but also they are computer checked for compliance with quality standards.

- First of all, a metal base (frame) is formed from aluminum foil.

- Then the aluminum billet is sent to the compartment, where its edges are joined using ultrasonic welding.

- By injecting air into the resulting pipe (under a pressure of 4-6 atmospheres), the strength of the weld is controlled.

- After checking, the workpiece enters the extruder, where an adhesive and polymer layer is gradually applied. First, the inner surface of the aluminum billet is processed, then the outer surface. At the same stage, a marking strip - blue or red - is applied to the product.

- At the final stage, the product is cooled: first with air, then in a water bath.

- At the exit, the pipe goes to the so-called quality control department, where the “scanning” and measurement of the geometry of the layers takes place.

- Finally, the product is labeled and wound into coils.

Wiring diagrams for bathrooms and bathrooms

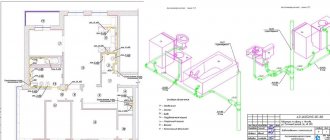

For plumbing work carried out in bathrooms and toilets, three layouts of metal-plastic pipes can be used. For private houses, the most rational option is to use a collector.

Efficient collector system

A reliable and practical option that involves connecting each object to a central pipe through a supply pair. This allows the faucet to regulate or turn off the water supply to each specific plumbing fixture.

With parallel wiring, each plumbing fixture is equipped with its own water line and its own shut-off valve. All branches come out of one device - the collector

All control devices are located in a compact manifold, which is placed in a space specially designated for them (cabinet).

Supply pipes with a minimum of connections do not require special control, which allows for hidden installation. The disadvantage of this option is the rather high cost, since for each connection you will need to purchase a special shut-off valve. Since such a system is quite complex, work must be done carefully and carefully.

In collector water distribution, control devices and shut-off devices are installed on the pipe supplying water to the collector

An important advantage: if a separate item (washing machine, faucet) fails, there is no need to completely disconnect the bathroom from the water supply - just turn off the necessary shut-off valve.

Serial connection system

This option involves connecting each plumbing item to the main pipe using a separate tee. It is more suitable for bathrooms with a minimum number of objects (washing machine, common faucet).

Sequential wiring, shown schematically in the figure, is recommended for use in rooms with a small number of objects that are alternately connected to pipes using tees

A sequential scheme can be implemented after finishing work has been completed in the room, using an open laying system. The assembly process is quite simple: the pipe is laid from one object to another, and at the same time the supply element is removed from the tee.

This option requires minimal financial costs. It should be taken into account that if there are a large number of liquid intake points, the pressure may not be enough, and the system will function with difficulty or even fail completely.

Wiring system with pass-through sockets

The connection of plumbing fixtures is similar to the serial one, but instead of tees, sockets are used. This scheme is usually used only in individual houses, since it requires laying long pipes, as well as installing an additional pump that will help provide the required water pressure.

When performing connecting work with metal-plastic pipes, several important nuances should be taken into account:

- When developing a design, it is desirable to provide a minimum of connections.

- It is important to use pipe and couplings made from the same material.

- It is better to use thermal insulation for the pipeline to prevent condensation from settling.

- It is necessary to provide free access to metering devices, filters, and detachable connections.

Compliance with the rules will allow you to create a reliable system that can last for many years.

Planning a water supply system “on paper”

The most important and paramount thing is the water supply layout plan. If you have never done this, then you can create it from scratch without any particular difficulties, although this undertaking is quite painstaking. But it all starts with the consumer.

- It is necessary to designate the places where the taps will be. This is the kitchen and bathroom. With proper construction, they are usually located nearby, which makes organizing a water supply system easier and significantly reduces the cost. Ideally, if they are located in adjacent rooms, only one pipe will be required, from which branches will go through a tee to different rooms.

- The place where water enters the house is indicated. There are only two options: central water supply or a private well (well). Depending on this, additional equipment may be required. In particular, when using water from a well, it is necessary to install a hydraulic accumulator (above the consumer level). From it, water will flow by gravity into the house. This system is preferable because it does not require the pump to be turned on constantly. The hydraulic accumulator does not have to be metal. It can be “poured” from concrete. And already installed in the house:

- Filter system (configuration depending on water quality).

- Boiler.

Accordingly, if water enters the house from the central water supply system, then only monitoring devices will need to be installed at the entrance to account for consumption.

This is a schematic diagram. It is unacceptable to make recommendations on a filtration system without knowing the quality of the water. The same applies to the water heating system. Depending on the conditions, the boiler can be electric or gas. Using a liquid or solid fuel water heater is not economical and is associated with certain difficulties. Especially in the summer.

Layout of sewer pipes

The work of installing sewer metal-plastic pipes has its own characteristics.

Sewer distribution made of metal-plastic has a number of features. In this case, it is important to use pipes of larger diameter, and also take measures to organize the slope of the pipeline

In this case, to ensure smooth drainage of wastewater and prevent blockages, it is important to comply with the following requirements:

- Maintain a slope (0.02-0.03 of the entire length of the structure) towards the drain manifold.

- It is prohibited to install bends at an angle of 90 degrees when installing structures.

- The need to install special tees with removable covers (revisions) in areas before turns that are prone to blockages.

- When installing the system in a hidden way, it is important to leave viewing windows opposite the revision.

- When assembling a system, it is important to leave a reserve intended for thermal expansion of the product.

For sewer installation, it is necessary to use pipes whose diameter ensures easy passage of wastewater.

For toilets, it is recommended to use products with a diameter of at least 100 mm; for bathtubs and sinks, 50-75 mm is sufficient.

Reviews

| Review of reviews on composite pipes | |

| Positive | Negative |

| Convenient, quick installation | Deformation due to excessively high temperatures |

| Practical and inexpensive | Connections weaken over time |

| Allows you to hide wiring in the wall | Undesirability of hidden installation of pipes for water supply and heating in walls |

| No rust | |

| Aesthetics, easy care | |

Rules for installation of metal-polymer structures

When laying metal-plastic systems, it is important to be guided by the following provisions:

- When laying hidden pipelines from this material, it is important to provide removable shields (hatches) that are free of sharp protrusions. They provide access to compression fittings.

- It is important to lay systems through building structures using sleeves whose internal diameter is 0.5-1 cm larger than that of the pipe. The gap that forms between the elements must be filled with soft, non-flammable material that allows the pipe to move in the longitudinal direction.

- When laying metal-plastic plumbing or heating systems, it is important to avoid damage to the surface of the elements, including scratches or cuts. To unpack the bay, it is better to avoid sharp objects and mark the structure with a pencil or marker.

- Installation of the structure can be carried out using a support or suspension, which are usually present in the range of manufacturers of metal-polymer pipes. They help to attach products to the wall, while metal parts are installed with spacers made of soft material.

All stages of operations must be carried out carefully and carefully, since metal-plastic elements are sensitive to ultraviolet radiation and mechanical damage. External installation of such structures is appropriate only in places where there are no such factors.

The best manufacturers

| № | Manufacturer | Brand | Manufacturer country |

| 1 | Rehau | Rehau | Germany |

| 2 | Kermi | Kermi | Germany |

| 3 | Oventrop | Oventrop | Germany |

| 4 | Uponor | Uponor | Finland |

| 5 | HENCO | HENCO | Belgium |

| 6 | VALTEC | VALTEC | Italy |

| 7 | Unidelta | Deltall-ISO | Italy |

| 8 | Valsir | Pexal | Italy |

| 9 | Valtec | Valtec | Italy/Russia |

| 10 | MPT-Plastik R | Liral | Russia |

| 11 | Nefteprom | Altais | Russia |

| 12 | HydroSta | HydroSta | South Korea |

Tools and materials for laying pipes

Laying metal-polymer systems requires a minimum of devices and materials, but it is better to choose high-quality devices and pipes.

Pipeline installation accessories

To create a structure made of metal-plastic, a very modest set of tools is enough: a pipe cutter, a simple pipe bender, press pliers, a sliding and spanner wrench.

To install a metal-plastic system with your own hands, you need a minimum of tools, which can be purchased in a set or separately from a construction supermarket.

To separate measured sections of pipe from the coil, it is advisable to stock up on a pipe cutter designed for cutting metal-plastic pipes. Since metal-plastic is a fairly malleable material, it can be cut with a hacksaw or even a sharp knife.

However, ideal perpendicularity of the lines, without which it is difficult to obtain a tight connection, can only be achieved by using a special cutter.

Different types of wrenches are important for installing and assembling threaded connections on pipeline fittings. If absolutely necessary, you can get by with one spanner, but for comfortable work it is better to use two spanners and one adjustable wrench.

A gauge is an important tool for creating an accurate and tight connection between a pipe and a fitting: it allows you to center the cut plane and chamfer the inside of the product.

The pipe bender allows you to change the configuration of the element, so you can save on corner fittings. It is especially important to have this tool if the design involves a large number of angular mates.

Before starting work, we advise you to familiarize yourself with the rules and specifics of crimping metal-plastic pipes.

What materials will be needed?

To lay the pipeline, it is important to stock up on the following components:

- pipes (coils, measured sections);

- various fitting options (bends, tees, corners), with the help of which individual sections of pipes are transformed into a single system;

- fastening elements - dismountable clamps and clips, with the help of which metal-plastic structures are fixed to supporting surfaces, most often on the wall.

It is important to select all the necessary materials and tools in advance so that you can carry out all the work smoothly.

This article will introduce you to the range of metal-plastic products for pipeline assembly.

Press fittings

Metal-plastic water supply pipes can be mounted not only on compression fittings, but also on press fittings. What it is?

Structurally, this fitting is distinguished by the absence of threads, a split ring and a union nut. Their functions are performed by a stainless steel sleeve, which is crimped onto the connection using mechanical or electric pliers.

Let me introduce: crimped press fittings

It is believed that this type of connection is much more reliable than compression connections and can be safely used for hot water supply and heating. And this is true, but not because of the magical properties of the sleeve.

The fact is that crimping pliers are a rather expensive tool, and therefore they fall exclusively into the arsenal of professionals. Which, of course, do not save on buying a much cheaper pipe cutter and calibrator.

Manual pliers for crimping press fittings on Valtec metal-plastic (16-32 mm). Retail price - 9500 rubles

Pipe line marking

Before starting work, it is important to think about how the pipes will be placed.

When developing a scheme, it is advisable to:

- Draw pipeline lines directly on the walls of the room where it is planned to be laid, which helps visualize the structure.

- As a starting point, use the connection point of the pipe to the tap or radiator, which must already be installed before installation begins.

- Minimize the number of tees and crosses that affect pressure stability, and also minimize the number of other fittings.

- For corner laying of metal-plastic pipes, you can use a pipe bender or corner fittings.

- All connecting elements should be provided with free access, since threaded fasteners need periodic tightening to avoid leaks.

The installation of connecting elements must be carried out after completion of calculations and marking of the structure.

No. 6. Bonding layer

To connect plastic and metal together, special compounds are used, the properties of which make it possible to turn a multilayer structure into a single whole. It is difficult to say what kind of glue manufacturers use and what components are included in its composition, since companies keep glue formulas secret. All we have to do is check the safety certificates and make sure that the product is non-toxic.

The glue not only binds all layers of the pipe together, but is also responsible for the elasticity of the product. The bonding layer is the most vulnerable point in metal-plastic pipes. When the glue loses elasticity, the product begins to delaminate and flow.

A metal-plastic pipe for heating and piping must have a high-quality binding layer: delamination should not be visible on the cut. If you notice that the layers are not fastened together tightly enough, then such a pipe is unlikely to last long.

Conclusions and useful video on the topic

In the video below, plumbers will tell you how to correctly and quickly install structures made of metal-plastic pipes:

Using the right methods and quality components allows you to create durable metal-plastic systems that will last for a long time without leaks, repairs or unnecessary material waste.

You can talk about how you installed and connected metal-plastic pipes in the block below. Please comment on the information we provide. Ask questions, share useful information and thematic photographs.

Decline

Almost completely, metal-plastic pipes for hot water supply and heating ceased to be used with the advent of polypropylene on the Russian market.

Polypropylene risers and water supply lines

Metal-polymer pipelines were inferior to it in literally everything:

- The price of fittings and pipes;

- In the speed of installation;

- In the reliability of the connections (socket welding of polypropylene guaranteed strength, at least not inferior to the strength of a solid section of pipe). In this case, maintenance-free connections could be laid in grooves or ties.

Metal-plastic has moved to the distant windows of plumbing stores and is gradually fading into oblivion. According to the author, it is absolutely undeserved.