Chimney draft is an aerodynamic phenomenon that is caused by the movement of air masses from a point with increased pressure to a point of low pressure. This indicator is very important, as it ensures the normal removal of combustion products from the heating device through the smoke exhaust duct. If the chimney structure malfunctions for one reason or another, backdraft occurs, which leads to smoke in residential premises.

The draft in the chimney must always be sufficient so that smoke does not enter the living space

Reasons for the formation of backdraft

Backdraft in a chimney is a phenomenon that occurs as a result of disruption of natural air circulation in the chimney communication. It is worth noting that if this phenomenon occurs, the normal operation of the chimney is disrupted, and it ceases to perform its main function - removing smoke outside the building.

Important! Normal indicators of natural draft in the chimney vary from 10 to 20 Pa. If there is a decrease in draft below 10 Pa, then in this case the removal of fuel combustion products outside the house is disrupted, and they can enter the living quarters.

Backdraft can occur due to various reasons. Consider these reasons:

- errors in calculating the height of the chimney duct (low design);

- errors in calculating the chimney cross-section;

- sudden change in weather (rain, fog, strong wind, etc.);

- narrow smoke circulation in the chimney structure. This phenomenon causes smoke to be trapped inside a residential building. Such turbulence occurs if the chimney pipe is installed incorrectly in relation to the roof ridge, namely below the ridge. With this arrangement of the pipe, due to the wind, the draft “overturns” ;

- a building located above the level of a specific house with a chimney, located in close proximity to it. In this case, as a rule, there is resistance to draft in the chimney communication;

- lack of air flow;

- problems with the internal ventilation system.

The low position of the chimney pipe leads to a violation of draft

Traction concept

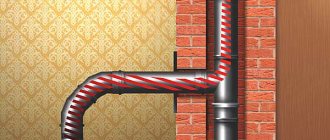

Do not allow dripping condensation to form in the chimney, which gradually destroys the inner surface of the channel. This especially happens in the cold season

when there is a significant decrease in outside air temperature. The process of moisture droplets falling out in the chimney also causes disruption of normal draft. A decrease in the rate of passage of gases from combustion products occurs not only with the internal formation of condensation; the draft force is affected by the humidity of the outside air, which can have different values depending on the weather. A deflector installed above the chimney will help you ignore this indicator.

To find out if there is draft in the chimney pipe

, you should bring a match or a strip of paper to the firebox of the boiler with the door open and the vent half open. The fire of the match should deviate towards the firebox, the strip of paper should also sway towards the mouth of the furnace.

If the opposite happens, then this indicates the occurrence of reverse draft, which prohibits the start of heating.

How to calculate the draft in a chimney pipe?

Calculation of chimney draft is an activity that is usually performed for industrial chimney structures. Such designs require rather complex thrust calculations. For private houses, this indicator is less important.

Ventilation communications and chimneys have one principle that underlies their functioning. This principle is the difference in pressure indicators outside and inside the building. In order to calculate the required natural draft indicator for a specific case, there is a fairly simple formula: the height of the chimney must be multiplied by the difference in the density of the external and internal air.

Let's consider the process of calculating draft in a chimney structure in more detail:

- When using heating equipment, natural draft allows you to get rid of fuel combustion products, removing them outside the structure. The difference in temperature indicators indicates the difference in air density outside and inside the building. It is worth noting that to calculate thrust it is not necessary to take into account such an indicator as dynamic pressure. This is not necessary due to the low speed of movement of air masses . The necessary data to obtain natural thrust in a particular case are necessarily substituted into the formula of Bernoulli’s law for gas.

- At the next stage, you need to calculate the total pressure loss and compare these indicators directly with the thrust. The thrust calculation can be considered ready in the case when the pressure indicators are identical to the thrust value. Such a chimney design will perfectly cope with the tasks assigned to it and will last a fairly long service life. However, if identity cannot be achieved, it is necessary to repeat the calculations again, changing the amount of pressure loss or the amount of thrust.

Calculation of draft is necessary when designing industrial chimneys, where the pipes are very tall

Helpful information! When installing ventilation communications, which also function due to natural draft, you can use the same calculations.

To increase thrust in calculations, there are two main ways. Let's look at them:

- lengthen the chimney;

- increase the temperature difference, which will accordingly affect the external and internal air density. It is worth noting that this method is not always possible.

In turn, pressure loss is reduced by the following methods:

- increasing the cross-sectional area of the smoke exhaust duct;

- reducing the length of the smoke path through the channel (shortening the chimney);

- in addition, pressure losses decrease in direct proportion to the decrease in the roughness coefficient of the internal walls of the chimney;

- reducing the length of horizontal sections that provide resistance to the removal of combustion products from the heating device.

Calculation of gravity gas path

The static pressure in the discharge path must be negative (i.e. there must be a vacuum). The vacuum value is at least 2 mm water. Art. If this condition is not met, the gas pipeline must be constructed taking into account the pressure in it, i.e. in gas-tight design (made of steel). 10 Determination of the efficiency of the smoke exhauster.

Calculation of the power of the smoke exhauster drive motor. For this you need: efficiency of the smoke exhauster, gas compressibility coefficient [1, p.4-3], power consumed by the smoke exhauster [1, p.4-20], power reserve factor [1, p.4-20], design engine power [1, paragraph 4-20].

List of sources used

Aerodynamic calculation of boiler installations (normative method). – M.: Energy, 1977. – 256 p.

Thermal power plants / V.Ya. Girshfeld, G.N. Morozov. – M.: Energoatomizdat, 1986. – 224 p.

Auxiliary equipment for steam turbine power plants / Yu.P. Soloviev. – M.: Energoatomizdat, 1983. – 200 p.

Boiler installations and their operation / B.A. Sokolov. – M.: Publishing House, 2007. – 432 p.

How to increase draft in a chimney with your own hands?

Many owners of private houses equipped with chimney pipes are interested in the answer to the question: how to increase draft in the chimney? As mentioned above, for normal operation of this system it is necessary that the rising air pressure be between 10 and 20 Pa.

To increase traction, you can use different methods, including installing a device such as a deflector

To determine the thrust indicator, you can also use special measuring instruments that can record this indicator - anemometers. The decision to increase or, conversely, decrease thrust depends on the anemometer reading. It is also worth noting that this takes into account one more point - the results of combustion of fuel raw materials in the heating device.

There are several ways to increase draft in a smoke exhaust structure. Consider these methods:

- extension of the chimney pipe;

- deflectors;

- weather vane;

- rotary turbines;

- smoke exhausters operating on electricity.

Note! Often, to increase draft it is only necessary to clean the internal chimney channel.

In addition, there are other methods that can cope with this common problem. It is recommended that you familiarize yourself with all the options for combating weak draft in the chimney system.

Extending the flue duct

This method of increasing draft is considered the simplest, since to carry it out it is only necessary to mount a chimney pipe longer than originally planned. Due to the difference between the boiler and the chimney outlet on the roof, the difference in the pressure of the rising air flow also increases.

The height of the chimney should be no more than 6 meters, then the draft will be normal

It is worth noting the fact that for a chimney structure, the optimal height is no more than 5–6 m (if the minimum distance between the chimney section lying in a vertical plane and the heating device is observed). It is also worth noting that this option for increasing the draft in the chimney is suitable only if the communication is installed without bends, narrowings and other areas that may act as obstacles to the removal of combustion products.

A high roof contributes to the deterioration of smoke removal from the chimney structure. In addition, the location of a taller building in close proximity to the house in which the chimney is installed has a negative impact on the removal of combustion products. Extending the chimney pipe in this case is the surest solution of all.

But do not forget that excessive lengthening of this structure greatly enhances the natural draft, and this leads to heat dissipation outside the residential building. In such a situation, experts recommend using special dampers that reduce the volume of smoke emitted.

Boiler room chimney design

The smoke duct can either be located on the heating equipment or stand separately, adjacent to the boiler or furnace. The pipe should be 50 cm higher than the height of the roof. The cross-sectional size of the chimney is calculated in relation to the power of the boiler room and its design features.

The main structural elements of the pipe are:

- gas outlet;

- thermal insulation;

- anti-corrosion protection;

- foundation and support;

- design intended for the introduction of gas ducts.

Diagram of a modern boiler installation

First, the flue gas enters the scrubber, which is a cleaning device. Here the smoke temperature drops to 60 degrees Celsius. After this, bypassing the absorbers, the gas is purified and only after that it is released into the environment.

Important! The efficiency of the boiler power plant is largely influenced by the gas speed in the channel, and therefore professional calculation is simply necessary here.

Types of chimneys

Modern boiler power plants use various types of chimneys. Each of them has its own characteristics:

- Columned. Consists of an inner barrel made of stainless steel and an outer shell. To prevent the formation of condensation, thermal insulation is provided here.

- Near-facade. Attached to the facade of the building. The design is presented in the form of a frame with gas exhaust pipes. In some cases, specialists can do without a frame, but then they use anchor bolts and use sandwich pipes, the outer channel of which is made of galvanized steel, the inner channel is made of stainless steel, and between them there is a 6 cm thick seal.

Design of a near-facade industrial chimney

- Farm. It can consist of one or several concrete pipes. The truss is installed on an anchor basket fixed to the base. The design can be used in earthquake-prone areas. To prevent corrosion, painting and priming are used.

- Mast. This pipe has ties and is therefore considered more stable. Anti-corrosion protection is implemented here in the form of a heat-insulating layer and fire-resistant enamel. Can be used in areas with increased seismic hazard.

- Self-supporting. These are sandwich-type pipes that are attached to the base using anchor bolts. They are characterized by increased strength, which allows the structures to easily withstand any weather conditions.

Deflectors

A deflector is a device that allows you to stabilize the air flows that occur in the smoke exhaust pipe. The name of this product is translated as a guiding device and fully corresponds to its operational features.

A deflector is a device that helps stabilize air flow in the smoke channel

It is necessary to note one important pattern: the simpler this device is, from a design point of view, the more efficient it is in operation. This is due to the fact that air masses redirected from the roof surface, together with side air flows, help remove smoke from the chimney.

Experts recommend using this device in windy regions, as it is not effective in calm conditions. When choosing this device, you need to pay attention to two main factors. Let's look at them:

- dimensions of the chimney pipe on the roof;

- wind load for a specific case.

In addition, it is worth saying that such a device can be made without much difficulty with your own hands. To do this you will need the following materials and tools:

- square;

- yardstick;

- scissors for cutting metal;

- regular hammer;

- riveter;

- hand-held electric drill;

- set of drills;

- drill-tip screws equipped with a press washer, which has a size of 15 mm;

- sheet of tin or galvanized steel with a wall thickness of 0.3 to 0.5 mm;

- fastening material.

Before assembling such a draft amplifier for a chimney with your own hands, you need to carry out calculations on paper and apply the necessary markings to a tin or galvanized sheet. The assembly diagram for this amplifier can be easily found on the Internet.

The size of the deflector must correspond to the diameter of the chimney

Next, we proceed to the direct assembly of the amplifier for the chimney with our own hands. Let's look at the stages of assembling this device:

- First, you need to cut out the parts of the future deflector from tin or galvanized sheets (based on the markings).

- Then you need to roll up the nozzle body and join the edges together using rivets or self-tapping screws.

- At this stage, the two cones of the product are joined.

- Studs are installed in the lower cone. This is necessary in order to dock the lower cone with the general body of the deflector.

- The lower cone is connected to the device body. It must be remembered that all connections in the device must be strong enough so that the deflector can withstand strong wind currents during operation.

Thus, it becomes clear how to increase the draft in chimneys with your own hands using a weather vane, however, there are still many devices and means that allow you to carry out such an event.

Basic height standards

There are basic options for the length of the chimney in relation to the highest point of the roof. They are optimally designed to provide the required draft and economical operation of the boiler. The height of the pipe depends on four factors:

- specific location of the chimney on the roof;

- roof slope angle;

- the amount of snowfall in the area;

- surrounding buildings and trees.

When choosing a place on the roof, the following options are used, based on the requirements of SNiP 41-01-2003 and SP 7.13130.2009 standards:

- A distance of 500 mm to 1500 mm from the roof ridge will require a chimney height of at least 500 mm above the highest point. This is considered the best installation location, providing good traction, along with the economy of building materials for constructing the structure. Also, this place collects less snow in winter, and therefore reduces the risk of leakage during a thaw. It is important that the total length of the pipe, from the grate to the top, is at least 5 meters. This will ensure proper pressure.

- If the chimney is installed at a distance of 1500-3000 mm from the ridge, and the roof has a slope, then the main criterion for determining the height will be whether the head is above the horizon line relative to the top point. On roofs equipped with parapets, the pipe should protrude beyond them.

- When the distance from the ridge is 3000 mm or more, the minimum height at which the head should be located is calculated along a line drawn 10 degrees downward relative to the horizon. The exact dimensions of the roof on a reduced scale are plotted on the drawing. The desired degree is marked with a protractor and a straight line is drawn. The resulting height value is multiplied by the drawing scale.

- If there are taller buildings nearby, the height of the chimney should not be lower than the top of the roof of the neighboring buildings. If these are very tall buildings or trees, the standard of 45 degrees to the horizon from the top of the obstacle applies. The height of the pipe must be above this line.

After installing the chimney, you should check the draft by lighting a piece of paper and bringing it to the open ash pit. If the flame is sucked in, the system is working correctly. If the fire deviates into the room, then it is necessary to look for an error in the design (height, diameter). If it is autumn weather, with a minimal temperature difference between the inside and outside of the building, and the flame burns evenly, without deviations, forced draft using a fan in the ashpit may be required.

weather vane

A weather vane, like a deflector, enhances traction, depends on the strength of air flows and has a very simple design. However, unlike a deflector, a weather vane does not prevent the removal of combustion products from the chimney in calm weather.

The weather vane is simple in design and protects the chimney from the wind on only one side

Note! From a constructive point of view, a weather vane is a wing that is small in size and protects the chimney from the wind from one specific edge.

This device also has a special element called an auxiliary blade. The auxiliary blade is mounted opposite the place where the weather vane is attached to the chimney pipe.

The main function of the auxiliary blade is to protect the mouth of the chimney from air masses flowing around it and causing the occurrence of rarefied zones. Due to such discharged zones, the draft in the chimney pipe increases greatly, which, accordingly, negatively affects the heating.

Experts recommend using a weather vane in cases where the draft in the chimney is unstable, as well as in strong windy weather, which destabilizes the draft.

Types of chimneys for boiler houses

Today there are several options for chimneys used in boiler rooms. Each of them has its own characteristics.

Metal pipes for boiler rooms

Types of metal chimneys. Each type of pipe must meet environmental standards: a) single-mast, b) two-mast, c) four-mast, d) wall mounting

They are a very popular option due to the following features:

- ease of assembly;

- thanks to the smooth inner surface, the structures are not prone to clogging with soot, and therefore are able to provide excellent traction;

- speed of installation;

- if necessary, such a pipe can be installed with a slight slope.

We advise you to study how to calculate the height of a chimney on our website.

Important! The main disadvantage of steel pipes is that their thermal insulation becomes unusable after 20 years, which causes the destruction of the chimney due to condensation.

Brick pipes

For a long time they had no competitors among chimneys. Currently, the difficulty in installing such structures lies in the need to find an experienced stove maker and the significant financial costs of purchasing the necessary materials.

With proper design and proper combustion, there is practically no soot formation in such chimneys. If such a structure was installed by a professional, it will serve for a very long time.

Chimney made of brick

It is very important to check both internal and external masonry for the correct joints and angles. To improve traction, an inlet is made at the top of the pipe, and in order to prevent smoke in the presence of wind, a durable stationary hood is used.

Rotary turbines

A rotary turbine is a mechanism that increases draft in a chimney using the power of the wind. The nozzle on such a turbine always rotates in only one direction, regardless of which direction the wind is blowing. Thanks to this, the necessary vacuum appears above the chimney, which helps to increase draft in the system.

This chimney draft amplifier has a design that not only facilitates the removal of combustion products from the chimney, but also prevents it from clogging with leaves, branches and other debris.

A rotary turbine uses wind power to increase thrust by rotating in one direction

The main feature of such a device is that in calm weather it does not function, but during the non-heating season it helps remove air from the chimney duct. In addition, in windy weather such devices allow you to increase traction due to the vacuum effect.

It is strictly not recommended to install rotary turbines on chimneys that remove solid fuel combustion products. This is due to the fact that the operating temperature for such devices does not exceed 150–250 °C.

How to calculate the height of a chimney and examples of calculations

where T is the height of the pipe, B is the height of the roof ridge, p is the distance from the roof ridge to the center of the pipe, the number 0.17 is the correction for the distance from the ridge to the chimney.

Having made the necessary measurements, the results are substituted into the formula, and thereby the height of the pipe relative to the roof ridge is determined.

So, for example, if the height of the ridge of the house is 2.6 m, and the distance from the ridge of the roof to the middle of the chimney is 1.7 m, then the height of the pipe should be as follows:

T=2.6-0.17*1.7=2.311 m.

Another example, but with a different distance of the chimney from the ridge - 3.2 m, and the height of the ridge is the same as in the previous example - 2.6 m:

T=2.6-0.17*3.2=2.056 m.

Nearby buildings or other obstacles can affect the draft in heating systems at a certain wind direction. Therefore, when determining the height of the pipe, it is necessary to take into account the wind pressure zone.

Note! The wind pressure zone is the space located below the drawn line at an angle of 45° from the highest point of the obstacle (adjacent building, tree) towards the chimney.

So, for example, to the left of the building there is a tree with a height much greater than the building itself. The wind blowing from right to left hits the tree. As a result, a zone of high pressure with turbulence is formed.

This zone prevents the normal movement of gases in the chimney or reverse draft appears. An overturned draft can extinguish the flame. In some cases, the draft may, on the contrary, increase, as a result, the fuel begins to burn faster and the efficiency of the boiler decreases.

The following formula will help to calculate the height of the pipe relative to the ridge, taking into account the wind support zone:

where T is the height of the pipe, B is the height of the obstacle, P is the distance from the pipe to the obstacle, the number 0.5 is the correction for the distance from the obstacle to the pipe.

After substituting the found measurements, the height of the pipe should be higher than the wind support zone.

For example, the height of the obstacle is 16 m, and the distance from the center of the pipe to the obstacle is 8 m.

The height of the pipe will be as follows:

Note! In order for the chimney to have excellent draft, the pipe must be half a meter above the wind support zone.

Electric smoke exhausters

They are mounted on chimneys that remove combustion products from heating devices operating on solid fuel. The temperature of the working environment for electric smoke exhausters ranges from 650–800 °C.

In addition, an important advantage of these electrical devices is that they are able to fully automate the chimney structure. As a rule, such devices are equipped with special sensors that regulate the intensity of the electric drive. Let's look at what sensors electric smoke exhausters are equipped with:

- sensors that monitor the temperature of the working environment;

- sensors that set the strength of air flow.

In addition to the above options, there are other ways to enhance the natural draft in the chimney.

A decrease in draft in the chimney is often due to its clogging, so if problems arise, you should first clean it

Other ways to increase chimney draft

Let's consider folk methods of increasing draft in smoke exhaust communications:

- cleaning the chimney using a special metal ball, which is attached to a cable;

Helpful information! Garbage plugs in the chimney channel are broken quite simply: a ball, attached to a cable, is slowly lowered along the channel until 1-2 m remain before the expected obstacle. After this, you need to quickly lower this ball onto the blockage, which will allow you to break through it.

- ensuring the tightness of vulnerable areas of the chimney (holes, cracks, etc.);

- cleaning the weather vane from dirt or icing. In addition, it happens that the weather vanes fail, then it is necessary to take care of its repair;

- ventilation of residential premises, which will create the necessary draft support;

- creating additional vacuum through preheating. To warm up the communication, you can use several ordinary newspapers that need to be burned.

Any of the above devices or activities can help in a given situation. When organizing additional measures to increase traction, it is recommended to be careful and follow fire safety rules.