Added: 02/13/2017

The construction of a swimming reservoir is always accompanied by the laying of pipelines and the installation of embedded elements, such as return nozzles, bottom intakes, skimmers... If the diameter of the pipes is less than necessary, the intake and supply of water will occur with increased friction losses, causing the pump to experience loads that can lead to it is out of order. If pipes are laid with a diameter larger than required, the costs of constructing a reservoir increase unjustifiably.

How to choose the correct pipe diameter?

How to choose the correct pipe diameter

When laying pipes for plumbing or heating, you need to choose a size that will provide the right pressure, but will also be loose enough for water to pass through easily. It is important to take into account the following:

- Pipe cross-section diameter.

- The amount by which the pressure in the area under consideration will decrease.

- The speed of water flowing through a pipe.

- The highest possible pressure that the pipe must withstand.

- The length of the pipe sections and the material from which they are made.

In practice, the diameter is often selected based on the use of a special table. This method is simple, however, it is one of the least accurate.

Steel pipes Source www.1metallobaza.ru

How to calculate cross-sectional area

Formula for finding the cross-sectional area of a round pipe

If the pipe is round, the cross-sectional area should be calculated using the formula for the area of a circle: S = π*R2. Where R is the radius (internal), π is 3.14. In total, you need to square the radius and multiply it by 3.14.

For example, the cross-sectional area of a pipe with a diameter of 90 mm. We find the radius - 90 mm / 2 = 45 mm. In centimeters this is 4.5 cm. We square it: 4.5 * 4.5 = 2.025 cm2, substitute it into the formula S = 2 * 20.25 cm2 = 40.5 cm2.

The cross-sectional area of a profiled pipe is calculated using the formula for the area of a rectangle: S = a * b, where a and b are the lengths of the sides of the rectangle. If we consider the cross-section of the profile to be 40 x 50 mm, we get S = 40 mm * 50 mm = 2000 mm2 or 20 cm2 or 0.002 m2.

Application of the tabular method

In this case, the most typical values of the main parameters were used to create the lookup table. To calculate water flow by pipe diameter and pressure, the table should be used as follows:

- The top line of each column lists the nine most common pipe diameters.

- The lines indicate the pressure value.

- The left column contains values expressed in Pascals per meter, the next column in millibars per meter (atmospheres).

- Selection can be made taking into account the speed of water flow. The table shows water consumption in accordance with the pipe diameter and other parameters.

Table for determining the pipe capacity Source vannayasovety.ru

In most water supply systems, the pressure is in the range of 1.5-2.5 atmospheres.

In houses with large number of storeys, it is common to use several separate segments. Therefore, these tables also apply to multi-storey buildings.

How to Calculate Bandwidth

The tabular method is the simplest. Several calculation tables have been developed: you can choose the one that is suitable depending on the known parameters.

Calculation based on pipe section

SNiP 2.04.01-85 proposes to find out the amount of water consumption by the girth of the pipe.

| External section of the line (mm) | Approximate amount of liquid | |

| In liters per minute | In cubic meters per hour | |

| 20 | 15 | 0,9 |

| 25 | 30 | 1,8 |

| 32 | 50 | 3 |

| 40 | 80 | 4,8 |

| 50 | 120 | 7,2 |

| 63 | 190 | 11,4 |

In accordance with SNiP standards, daily water consumption by one person is no more than 60 liters. This data is for a home without running water. If a water supply network is installed, the volume increases to 200 liters.

Calculation based on coolant temperature

As the temperature rises, the permeability of the pipe decreases - the water expands and thereby creates additional friction.

You can calculate the necessary data using a special table:

| Pipe section (mm) | Bandwidth | |||

| By heat (hl/h) | By coolant (t/h) | |||

| Water | Steam | Water | Steam | |

| 15 | 0,011 | 0,005 | 0,182 | 0,009 |

| 25 | 0,039 | 0,018 | 0,650 | 0,033 |

| 38 | 0,11 | 0,05 | 1,82 | 0,091 |

| 50 | 0,24 | 0,11 | 4,00 | 0,20 |

| 75 | 0,72 | 0,33 | 12,0 | 0,60 |

| 100 | 1,51 | 0,69 | 25,0 | 1,25 |

| 125 | 2,70 | 1,24 | 45,0 | 2,25 |

| 150 | 4,36 | 2,00 | 72,8 | 3,64 |

| 200 | 9,23 | 4,24 | 154 | 7,70 |

| 250 | 16,6 | 7,60 | 276 | 13,8 |

| 300 | 26,6 | 12,2 | 444 | 22,2 |

| 350 | 40,3 | 18,5 | 672 | 33,6 |

| 400 | 56,5 | 26,0 | 940 | 47,0 |

| 450 | 68,3 | 36,0 | 1310 | 65,5 |

| 500 | 103 | 47,4 | 1730 | 86,5 |

| 600 | 167 | 76,5 | 2780 | 139 |

| 700 | 250 | 115 | 4160 | 208 |

| 800 | 354 | 162 | 5900 | 295 |

| 900 | 633 | 291 | 10500 | 525 |

| 1000 | 1020 | 470 | 17100 | 855 |

For plumbing, this information is not extremely important, but for heating circuits it is considered the main indicator.

Find data based on pressure

When selecting pipes for installing any communication network, you need to take into account the flow pressure in the common line. If pressure under high pressure is provided, it is necessary to install pipes with a larger cross-section than when moving by gravity. If these parameters are not taken into account when selecting pipe sections, and a large water flow is passed through small networks, they will begin to make noise, vibrate and quickly become unusable.

To find the highest calculated water flow, use a table of pipe capacity depending on the diameter and various water pressure indicators:

| Consumption | Bandwidth | |||||||||

| Pipe section | 15 mm | 20 mm | 25 mm | 32 mm | 40 mm | 50 mm | 65 mm | 80 mm | 100 mm | |

| Pa/m | Mbar/m | Less than 0.15 m/s | 0.15 m/s | 0.3 m/s | ||||||

| 90,0 | 0,900 | 173 | 403 | 745 | 1627 | 2488 | 4716 | 9612 | 14940 | 30240 |

| 92,5 | 0,925 | 176 | 407 | 756 | 1652 | 2524 | 4788 | 9756 | 15156 | 30672 |

| 95,0 | 0,950 | 176 | 414 | 767 | 1678 | 2560 | 4860 | 9900 | 15372 | 31104 |

| 97,5 | 0,975 | 180 | 421 | 778 | 1699 | 2596 | 4932 | 10044 | 15552 | 31500 |

| 100,0 | 1000,0 | 184 | 425 | 788 | 1724 | 2632 | 5004 | 10152 | 15768 | 31932 |

| 120,0 | 1200,0 | 202 | 472 | 871 | 1897 | 2898 | 5508 | 11196 | 17352 | 35100 |

| 140,0 | 1400,0 | 220 | 511 | 943 | 2059 | 3143 | 5976 | 12132 | 18792 | 38160 |

| 160,0 | 1600,0 | 234 | 547 | 1015 | 2210 | 3373 | 6408 | 12996 | 20160 | 40680 |

| 180,0 | 1800,0 | 252 | 583 | 1080 | 2354 | 3589 | 6804 | 13824 | 21420 | 43200 |

| 200,0 | 2000,0 | 266 | 619 | 1151 | 2488 | 3780 | 7200 | 14580 | 22644 | 45720 |

| 220,0 | 2200,0 | 281 | 652 | 1202 | 2617 | 3996 | 7560 | 15336 | 23760 | 47880 |

| 240,0 | 2400,0 | 288 | 680 | 1256 | 2740 | 4176 | 7920 | 16056 | 24876 | 50400 |

| 260,0 | 2600,0 | 306 | 713 | 1310 | 2855 | 4356 | 8244 | 16740 | 25920 | 52200 |

| 280,0 | 2800,0 | 317 | 742 | 1364 | 2970 | 4356 | 8568 | 17338 | 26928 | 54360 |

| 300,0 | 3000, | 331 | 767 | 1415 | 3078 | 4680 | 8892 | 18000 | 27900 | 56160 |

The average pressure in most risers varies from 1.5 to 2.5 atmospheres. The dependence on the number of floors is regulated by dividing the water supply network into several branches. Injecting water through pumps also affects the change in flow speed.

Also, when calculating the water flow through a pipe using a table of pipe diameter and pressure values, not only the number of taps is taken into account, but also the number of water heaters, bathtubs and other consumers.

Hydraulic calculation according to Shevelev

To most accurately identify the indicators of the entire water supply network, special reference materials are used.

They define the running characteristics for pipes made of different materials. An example of a good example for calculations is Shevelev’s table. This is a voluminous reference book. You don't have to go to the library to use it. All the necessary data can be found on the World Wide Web. In addition, there are electronic programs based on Shevelev tables. It is enough to enter the required parameters to get the finished result.

Application of formulas

The use of different formulas depends on the known data. The simplest of them is: q = π×d²/4 ×V. In the formula: q shows the water flow in liters, d is the cross-section of the pipe in cm, V is the speed indicator of the advance of the hydraulic flow in m/sec.

Speed parameters can be taken from the table:

| Type of water supply | Speed (m/sec) |

| City water supply | 0,60–1,50 |

| Main pipeline | 1,50–3,00 |

| Central heating network | 2,00–3,00 |

| Pressure system | 0,75–1,50 |

When connecting additional injection devices, it is necessary to take into account the coefficient of pressure created. It is listed in the user manual.

Knowing what characteristics pipes have is necessary to correctly connect plumbing fixtures. With the correct selection of data, there will be no reason to worry that when you open the tap in the bathroom, the water in the kitchen will stop flowing or its pressure will decrease.

Why do you need to correctly determine pipe parameters?

Of course, it is clear that in a complex technical system everything must be accurately calculated. However, the question remains about what bad things can happen if the pipes are not properly sized.

Use of polypropylene pipes Source www.tk-stroyresurs.ru

The water consumption and drainage system in an apartment is highly interconnected. An open faucet in the kitchen can reduce the flow of water in the bathroom or stop the flow of water to flush the toilet. It is important to understand that this can be caused not only by improper installation of equipment, but also by clogging of pipes over time.

For example, metal products rust over time and become coated on the inside with deposits from insufficiently clean water. Plastic ones do not have this drawback. They do not become dirty or destroyed over a long period of time.

If pipes are too narrow, drainage problems may occur. Excessive pressure in the water supply network will lead to leaks and increased accident rates.

Calculation of pipes is important when supplying water and drainage for a multi-story building. In this case, the pipes must correspond to each other. Suitable outside and those through which water flows inside.

Metal-plastic pipes are known for their reliability and durability Source images.ua.prom.st

When paying utility bills, companies and organizations do not always use meters. In these cases, the bill is usually presented according to the patency of the pipe.

Pipes in a home can serve various functions. They relate to the supply of hot and cold water, pressure or non-pressure sewerage, natural gas supply, and heating. In each of these cases, they are presented with requirements that they must meet.

Communications in the house will work without creating problems if their bandwidth is determined correctly. Otherwise, you will have to repair them.

What is the power in the DHW and cold water systems?

The water pressure in multi-storey buildings connected to the central water supply network is not constant.

It depends on factors such as the number of storeys in the building or the time of year - so in the summer season, especially in multi-storey buildings, the lack of cold water becomes especially noticeable, which at this time is used for watering house or garden plots.

Municipal services in practice try to keep the level at an average of 3-4 atmospheres, although not always successfully. The minimum indicators at which the pipeline of a house can function (for both cold water supply and hot water supply) are 0.3 bar per floor.

The pressure of hot and cold water supply is slightly different in favor of the latter (a difference of up to 25% is allowed).

This is explained simply - cold water is used more actively, since it is needed for the functioning of the sewage system. Therefore, the maximum indicators for cold water supply will be 6 atmospheres, and for hot water supply – 4.5 atmospheres.

What determines the permeability of a pipe?

To determine the rate at which water is consumed, several different factors must be taken into account. At first glance, it may seem that for this we can limit ourselves to taking into account only the diameter of the pipe.

When calculating pipe parameters, it is necessary to correctly determine the internal diameter Source stroyobzor.info

In practice, it is necessary to take into account a number of factors:

- It is necessary to take into account the length of the pipe segment through which the liquid moves. The importance of this parameter is based on the presence of friction between the walls and the liquid. The longer the pipe segment used, the more it can slow down the flow of fluid.

- Although the initial pressure plays an important role, the slowing flow of the liquid will not allow new portions to enter the pipe for some time.

- The diameter affects the flow rate. However, it affects the liquid in several ways. When using narrow pipes, the degree of deceleration increases sharply.

- Various materials can be used for the walls. In plastic pipes, water flows at a higher speed than in metal pipes of the same diameter.

PVC pipes do not overgrow from the inside during operation Source aquaplast.ru

- The time during which the pipes are in use. This parameter does not have a significant effect on plastic pipes, but is important for metal ones. Over time, they become overgrown from the inside and rust. This negatively affects their cross-country ability.

- Different segments are connected using fittings, forks, and adapters. They slow down the passage of water. The braking they provide must be taken into account in calculations.

If, when determining cross-country ability, you ignore at least one of the above features, this can change the calculated value several times.

Tables for determining diameter and wall thickness Source vse-o-trubah.ru

Factors affecting calculations

Determining pipe patency and, accordingly, maximum water consumption depends on many factors:

- Length of water main. The longer the length, the lower the speed capabilities of the water flow due to the action of friction.

- Pipe section. The walls of narrow pipelines provide increased resistance. The smaller the internal diameter, the lower the ratio of the speed value of the water flow to the surface area in a certain area, which means the cross-country ability will be worse. In large cross-section lines, fluid flows faster.

- The presence of turning areas. The complex configuration of the pipeline slows down the speed of water flow through it. The same applies to shaped elements. Any taps, adapters and couplings slow down the movement of liquid.

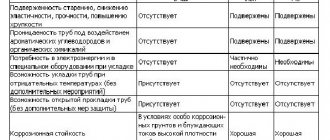

It is also important to take into account the material of the pipe sections. Both the throughput of the network and the service life depend on this. Metal water pipes tend to deform over time under the influence of rust, accumulate corrosive and lime deposits from the inside, which greatly reduces throughput. The latter is typical not only for steel, but also for cast iron pipes, although they are less susceptible to corrosion.

How to calculate pipe patency

When it becomes necessary to make calculations, it is possible to use the following methods:

- Use tables. There are various options that suit the purpose of the pipes.

- Apply formulas. There are several calculation options. Simplified options are often used that do not take into account all the essential features of the plumbing system.

- There are software products designed to carry out the calculations in question. They usually give the most accurate results.

- Online calculators may be used. In order to use them, you must go to the appropriate page and enter the required data in accordance with the instructions.

Below we consider several ways to carry out calculations.

Tables for determining bandwidth Source ytimg.com

See also: Catalog of companies that specialize in utilities and installation of swimming pools

Using a simplified formula

Thus, based on knowledge of the pipe diameter and flow speed, permeability can be determined. To do this, you can use the following formula.

q = (V*Pi*d^2) / 4

The following notations are used here:

- q – permeability, expressed in liters per second;

- V denotes water speed;

- d represents the inside diameter of the hole.

In most cases, the speed is in the range of 0.8-1.5 meters per second. If a pump is used, the pressure and flow rate it produces are indicated in the technical data sheet.

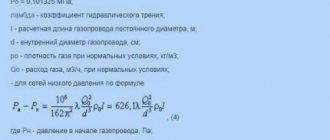

More accurate formula

In this case, it is necessary to use the Darcy formula. It takes into account:

- Length of pipe segment used (L).

- A coefficient that expresses the degree of flow inhibition due to wall friction, the use of various types of fittings, wall curvature and turbulence. It is called the roughness coefficient (lambda).

- The value of liquid viscosity (rho).

Table of roughness coefficient values for each type of pipe (lambda) Source ok-t.ru

The formula looks like this.

PN = lambda * (L/D) * ((V^2)/(2*g)) * rho

The following notations are used here:

- PN represents the head loss. The calculated water consumption should be reduced by this amount.

- L is the length of the pipe through which water flows.

- D is the internal diameter of the pipe.

- g is equal to the magnitude of the acceleration due to gravity.

Using the Darcy formula, you can take into account the characteristics of pipes, but for this it is necessary to determine the “lambda” and “rho” coefficients.

Using online calculators

In order to calculate the pipe capacity, a calculator is easy to find online. To do this, you can use Google, Yandex or others search. To do this, in the search bar you need to type the line “how to calculate the permeability of a pipe, calculator” or similar.

To calculate water flow by pipe cross-section and pressure, the calculator will ask you to enter the following data:

- Material for production.

- Type (design features). Here you need to make a selection from the drop-down list.

- Next, you need to indicate the purpose of the calculation. One of them is calculating water consumption.

When calculating the pipe diameter based on water flow, you will additionally need to indicate the pressure drop per meter, the internal diameter of the pipe and the length of its section. After clicking the button, the desired result will appear on the page.

Example of a calculator interface for hydraulic calculation of a pipeline Source calc.ru

In the second case, before calculating water consumption by pipe diameter and pressure, it is necessary to prepare data on the type of water supply system, structural features of the pipe, length, diameter, material of manufacture, temperature and pressure.

An example of a calculator interface for calculating pipe capacity Source trubanet.ru

Publications

Added: 02/13/2017

The construction of a swimming reservoir is always accompanied by the laying of pipelines and the installation of embedded elements, such as return nozzles, bottom intakes, skimmers...

If the diameter of the pipes is smaller than required, the intake and supply of water will occur with increased friction losses, causing the pump to experience loads that can cause it to fail.

If pipes are laid with a diameter larger than required, the costs of constructing a reservoir increase unjustifiably.

How to choose the correct pipe diameter?

How to choose the correct pipe diameter?

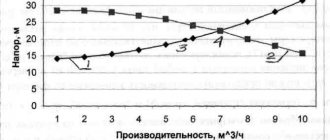

Return nozzles, bottom intakes, skimmers, each have a connection hole of a certain diameter, which initially determines the diameter of the pipes. Typically these connections are 1 1/2″ – 2″, to which a pipe with a diameter of 50 mm is connected. If several quenching elements are connected in one line, then the common pipe must be larger in diameter than the pipes suitable for it.

The choice of pipe is also influenced by the performance of the pump, which determines the speed and amount of water pumped.

The capacity of pipes of various diameters can be determined from the following table:

Capacity of pipes of various diameters.

| Diameter, mm | Internal area section, mm2 | Capacity in m3/hour at speed | |||||

| Outer | Interior | 0.5 m/s | 0.8 m/s | 1.2 m/s | 2.0 m/s | 2.5 m/s | |

| 16 | 10 | 79 | 0,14 | 0,23 | 0,34 | 0,57 | 0,71 |

| 20 | 15 | 177 | 0,32 | 0,51 | 0,76 | 1,27 | 1,59 |

| 25 | 20 | 314 | 0,57 | 0,91 | 1,36 | 2,26 | 2,83 |

| 32 | 25 | 491 | 0,88 | 1,41 | 2,12 | 3,54 | 4,42 |

| 40 | 32 | 805 | 1,45 | 2,32 | 3,48 | 5,79 | 7,24 |

| 50 | 40 | 1257 | 2,26 | 3,62 | 5,43 | 9,05 | 11,31 |

| 63 | 50 | 1964 | 3,54 | 5,66 | 8,49 | 14,14 | 17,68 |

| 75 | 65 | 3319 | 5,97 | 9,56 | 14,34 | 23,90 | 29,87 |

| 90 | 80 | 5028 | 9,05 | 14,48 | 21,72 | 36,20 | 45,25 |

| 110 | 100 | 7857 | 14,14 | 22,63 | 33,94 | 56,57 | 70,71 |

| 125 | 110 | 9506 | 17,11 | 27,38 | 41,07 | 68,45 | 85,56 |

| 140 | 125 | 12276 | 22,10 | 35,35 | 53,03 | 88,39 | 110,48 |

| 160 | 150 | 17677 | 31,82 | 50,91 | 76,37 | 127,28 | 159,09 |

| 200 | 175 | 24061 | 43,31 | 69,29 | 103,94 | 173,24 | 216,54 |

| 225 | 200 | 31426 | 56,57 | 90,51 | 135,76 | 226,27 | 282,83 |

| 250 | 225 | 39774 | 71,59 | 114,55 | 171,82 | 286,37 | 357,96 |

| 315 | 300 | 70709 | 127,28 | 203,64 | 305,46 | 509,10 | 636,38 |

To select the turbo diameter, we need knowledge of the following quantities:

| Speed of water in the pipe by gravity | 0.5 m/s |

| Water speed in the collector pipe | 0.8 m/s |

| Average speed of water in the pipe at the pump inlet | 1.2 m/s |

| Average speed of water in the pipe at the outlet of the pump | 2.0 m/s |

| The maximum possible speed of water in the pipe | 2.5 m/s |

Let's look at the technology for selecting pipes using specific examples of piping embedded elements.

Pipe diameter for connecting return nozzles.

For example, the movement of water in the system is provided by the EcoX2-16000 pump, with a maximum capacity of 16 m3/hour.

The water is returned to the swimming bowl through 4 return nozzles - Nozzle for connecting a vacuum cleaner (connection 2″ external thread), each screwed into the wall passage with connection D 50/63.

The nozzles are located in pairs on opposite sides. We will select the required pipeline.

The water speed on the supply line is 2 m/s. The nozzles are divided into two branches of two each. Capacity for each nozzle is 4 m3/hour, for each branch – 8 m3/hour. Let's select the diameter of the common pipe, pipes for each branch and turbos for each nozzle. If the table does not have an exact match of performance for a specific flow speed, we take the closest one. According to the table it turns out:

- with a productivity of 16 m3/hour (in the table the closest value is 14.14 m3/hour) – the pipe diameter is 63 mm;

- with a productivity of 8 m3/hour (in the table the nearest value is 9.05 m3/hour) – the diameter of the turbine is 50 mm;

- with a productivity of 4 m3/hour (in the table the closest value is 3.54 m3/hour) – the pipe diameter is 32 mm.

It turns out that a pipe with a diameter of 63 mm is suitable for the general supply, a pipe with a diameter of 50 mm is suitable for each branch, and a diameter of 32 mm is suitable for each nozzle. But since the wall passage is designed to connect 50 and 63 pipes, we do not take a pipe with a diameter of 32 mm, but connect everything with a 50 mm pipe. The 63rd pipe goes to the tee, the wiring is with the 50th pipe.

Diameter of pipes for connecting skimmers.

The same pump with a capacity of 16 m3/hour takes water through skimmers. The skimmer in filtration mode usually takes from 70 to 90% of the water from the total flow that the pump sucks in, the rest falls on the bottom drain. In our case, 70% of productivity is 11.2 m3/hour. The skimmer connection is usually 1 1/2″ or 2″. The flow speed at the pump suction line is 1.2 m/s.

From the table we get:

- for this case, a pipe with a diameter of 63 mm is sufficient, but ideally 75 mm;

- in case of connecting two skimmers, we branch with the 50th pipe.

Diameter of pipes for connecting the bottom intake.

30% of the performance of the EcoX2 16000 pump is 4.8 m3/hour. According to the table, a 50 mm pipe is sufficient to connect the bottom drain. Usually, when connecting a bottom drain, they are guided by the diameter of its connection. The standard bottom drain has a 2″ connection, so choose a 63 mm pipe.

Calculation of pipe diameter.

The formula for calculating the optimal pipeline diameter is obtained from the formula for flow:

Q=(P*d2/4)*v

Where:

Q – flow rate of pumped water, m3/s d – pipeline diameter, m

v – flow velocity, m/s

P - number pi = 3.14

Hence, the calculation formula for the optimal pipeline diameter:

d=((4*Q)/(P*v))1/2

Please note that in this formula the flow rate of pumped water is expressed in m3/s. Pump capacity is usually indicated in m3/hour. In order to convert m3/hour to m3/s, you need to divide the value by 3600.

Q(m3/s)=Q(m3/hour)/3600

As an example, let's calculate the optimal pipeline diameter for a pump output of 16 m3/hour on the supply line.

Let's convert the productivity to m3/s:

Q(m3/s)=16 m3/hour/3600 = 0.0044 m3/s

The flow speed on the supply line is 2 m/s.

Substituting the values into the formula we get:

d=((4*0.0044)/(3.14*2))1/2≈0.053 (m) = 53 (mm)

It turned out that in this case the optimal internal diameter of the pipe will be 53 mm. Let's compare with the table: for the nearest productivity 14.14 m3/hour at a flow rate of 2 m/s, a pipe with an internal diameter of 50 mm is suitable.

When selecting pipes, you can use one of the methods described above; we have confirmed their equivalence with calculations.

Based on materials from the sites: waterspace com, ence-pumps ru

We recommend that you read:

Spouts for waterfalls: performance calculation, selection.

Equipment selection. Choosing a pump for an artificial reservoir

Source: https://gidrologia.ru/publikatsii/plavatelnyy-vodoem-podbor-truboprovoda-nuzhnogo-diametra.html

How is the water supply arranged in an apartment or house?

Although the internal diameter is essential when calculating water consumption, it can sometimes be difficult to determine. Special tables may be used for this purpose, but information may not be found here for all brands of equipment.

Installation of water supply Source san-kras.ru

If it is possible to directly measure the desired value, then it should be used for calculations. However, this method is convenient when using plastic or metal-plastic pipes.

If we consider metal ones, then over time they become overgrown from the inside, and this happens unevenly. Therefore, in this case, it is difficult to directly calculate water consumption. Usually, to compensate for the narrowing, pipes of a slightly larger diameter are taken compared to the calculated one.

Video description

You will see how to choose the correct pipe diameter in this video:

In practice, in apartments or private houses, they usually use products with a diameter of 10 or 15 mm for water pipes, and 20 or 25 mm for risers. If equipment with dimensions specified in inches is used, values close to those specified are used.

It is generally accepted that the maximum permissible flow rate of water in a water supply system is 2 meters per second. The diameter is selected depending on the length of the pipe:

- In cases where this value does not exceed 10 meters, it is sufficient to use a pipe with a diameter of 20 mm.

- In the case where its length ranges from 10 to 30 meters, using a pipe with a diameter of 25 mm is suitable.

- When the pipeline section is longer than 30 meters, you can take a product with a diameter of 32 mm.

- For a length of more than 50 meters, pipes with a diameter of 50 mm are suitable.

- For even larger sections of the pipeline and in the presence of numerous water intake points, the required value reaches 100 mm.

Expansion tank calculation

To calculate an expansion tank for a closed heating system, it is necessary to find out how much the volume of liquid increases when it is heated from room temperature +20 ºС to operating temperature, which is in the range of 50-80 ºС. This task is also not an easy one, but it can be solved in another way.

It is considered quite correct to take the volume of the tank as a tenth of the total amount of water in the system, including radiators and the water jacket of the boiler. Therefore, we open the equipment passports again and find in them the capacity of 1 section of the battery and the boiler tank.

Next, the calculation of the volume of coolant in the heating system is carried out according to a simple scheme: the cross-sectional area of a pipe of each diameter is calculated and multiplied by its length. The obtained values are summed up, passport data is added to them, and then a tenth of the result is taken. That is, if there are 150 liters of water in the entire system, then the capacity of the expansion tank should be 15 liters.

Video description

What is pressure loss and how to determine it - watch in this video:

When calculating the pipeline capacity, all points in the house where water consumption occurs and consumers that can be connected simultaneously to the water supply system must be taken into account. These include not only residents, but also devices that consume this resource. For example, this applies to the dishwasher and washing machine.

At the same time, to calculate the pipe capacity depending on the diameter and water pressure, it is necessary to take into account the peculiarities of the situation when the family is small, although there are many taps. It must be remembered that people will not be able to consume water through all taps at the same time.

For simplicity, we can assume that a fully open tap flows 6 liters of water per minute. Based on this, you can see what the maximum water consumption in the house is expected and based on this, calculate the diameter of the pipes that supply water to the house or apartment.

What affects water consumption?

Some parameters are directly related to water consumption.

For example, the following parameters depend on the expected consumption:

- pipe diameter, which is determined based on the expected throughput;

- pipe wall thickness, which is determined based on the expected internal pressure.

One can even say that of all the “pipe geometry”, only the length of the water pipeline does not depend on water flow. In addition, some pipeline parameters are affected not directly, but indirectly, by the expected water flow.

So, calculating the water flow through a pipe of a known diameter will help determine such characteristics as:

- Type of construction material used to construct the pipeline;

- The type of technology used in the process of assembling the water pipeline.

After all, these characteristics are related to the maximum permissible pressure inside the pipeline, which, in turn, depends on the water flow.

Different types of pipes

Various piping systems are used in a house or apartment. Requirements and calculation methods for them may differ.

For example, the calculation of pipeline capacity in terms of diameter and pressure for a sewer pipe is based on the following parameters:

- Pipeline diameter.

- Average flow rate.

- The hydraulic slope (l) under which the pipes move.

- The degree of filling of the pipe with contents (h/d). When determining this parameter, the concept of hydraulic radius is used.

Physical version of PS determination

The physical method of determining throughput includes carrying out calculations using special formulas. Depending on what type of system is being designed, the calculation formulas will vary. To carry out an independent (physical) calculation of the pipeline PS, the following indicators are taken into account:

- Roughness.

- Inner diameter.

- Pipeline slope.

- Resistance value.

- Degree of overgrowth.

According to the outdated formula, only three main parameters were taken into account: diameter, pressure and roughness. It will be quite problematic for a person who has never encountered this to make the calculation independently.

Video description

This video talks about the drop in pressure when a pipe narrows:

Hydraulic slope refers to the angle at which the pipe is located, satisfying a certain condition. If the sewer pipe is located in this way, then under the influence of gravity its contents should drain in such a way that self-cleaning occurs. This value is determined on the basis of special tables.

When calculating the hydraulic radius, they are based on the actual diameter of the pipe and the degree of its filling with contents. So, for example, for a completely filled product these two radii will be equal, but with partial filling the hydraulic radius will be smaller. It is calculated based on appropriate formulas or tables.

Properly designed and installed sewer pipes will ensure good drainage and eliminate the risk that they may become clogged.

When calculating the throughput of a gas system pipe, it must be taken into account that a gaseous, not a liquid, substance spreads through them. One of the important differences is the high compression ratio.

The pipe diameter must be selected correctly Source otoplenie.site

When transporting gas, the pipe capacity depending on the diameter is calculated using the following formula.

Q = DN * 0.67 * p

This formula uses the following notation:

- Q represents the maximum capacity of the gas pipe;

- DN is equal to the nominal diameter of the gas pipe;

- p is a value equal to the operating gas pressure, which must be increased by 10%.

The throughput of a gas pipeline can be calculated using the formula given here or using a table compiled on its basis. This formula is used to calculate the parameters of pipes in residential buildings and apartments.

For calculations in industry, a different formula is used.

Q = DN2 * 196.386 * (p/z) * T

The following notations were used here:

- Q is the pipeline capacity;

- DN2 indicates the diameter of the pipe;

- z – compression ratio;

- p – pressure in the pipeline;

- T – gas temperature.

Heating pipes Source woodmaster-shop.ru

If the temperature increases, this will lead to increased pressure on the pipe walls. Therefore, when using gas, it is necessary to take into account climatic conditions, which significantly affect the permeability of the pipeline. Using a diameter that is too small increases the risk of increased gas pressure and pipe damage.

Engineering assistance

Coolant velocity in the pipeline at: G = 0 kg/h; ρ = 1000.54 kg/m3

| Conventional passages (nominal sizes) according to GOST 28338-89 | ||||||||||||

| Dn (Du) | 10x2.2 | 15x2.8 | 20x2.8 | 25x3.2 | 32x3.2 | 40x3.5 | 50x3.5 | 65x4.0 | 80x4.0 | 90x4.0 | 100x4.5 | Legend |

| v , m/s | Pipe 20 x 2.8 GOST 3262-75 | |||||||||||

| Oventrop Metal-plastic pipe “Copipe HS” PN 10 (at 95oC), PN 16 (for cold water supply) | ||||||||||||

| Copipe HS (Oventrop) | 14×2.0 | 16×2.0 | 20×2.5 | 26×3.0 | 32×3.0 | 40×3.5 | 50×4.5 | 63×6.0 | – | – | – | Legend |

| v , m/s | – | – | – | “Copipe HS” Ø20 x 2.5 | ||||||||

| Rehau Molecular cross-linked polyethylene PN 10, t = 90oC | ||||||||||||

| RAUTITAN flex, his, pink (Rehau) | – | 16×2.2 | 20×2.8 | 25×3.5 | 32×4.4 | 40×5.5 | 50×6.9 | 63×8.6 | – | – | – | Legend |

| v , m/s | – | – | – | – | RAUTITAN flex Ø20 x 2.8 | |||||||

| Uponor Cross-linked polyethylene PE-Xa, eval PE-Xa, PN 10, t = 95oC | ||||||||||||

| Uponor PEX series S3.2 (Uponor) | – | 16×2.2 | 20×2.8 | 25×3.5 | 32×4.4 | 40×5.5 | 50×6.9 | 63×8.7 | 75×10.3 | 90×12.3 | 110×15.1 | Legend |

| v , m/s | – | Uponor PEX series S3.2 Ø20 x 2.8 | ||||||||||

| Valtec polypropylene pipe, glass fiber reinforced, PP-FIBER PN 9, t = 95oC | ||||||||||||

| Valtec PP-FIBER PN 25 (Valtec) | – | – | 20×3.4 | 25×4.2 | 32×5.4 | 40×6.7 | 50×8.3 | 63×10.5 | – | – | – | Legend |

| v , m/s | – | – | – | – | – | Valtec PP-FIBER Ø20 x 3.4 |

* Symbol: steel pipes – nominal bore x wall thickness; polymer pipes - outer diameter x wall thickness. ** Operating pressure PN is indicated at the corresponding temperature

Source: https://helpeng.ru/programs/heating/water_speed.php

Briefly about the main thing

Determining the capacity of a pipe depending on the diameter and water pressure is a complex task. For this purpose, formulas, special tables, online calculators or specialized programs can be used.

Correctly selected pipes will ensure the quality and durability of the plumbing and other communication systems in a house or apartment. When calculating pipe parameters, it is necessary to take into account the magnitude of the pressure, make allowances for its drop, and take into account the length and service life of the pipes.

Ratings 0