Practice shows that when laying sewer systems, 110 mm pipes are the most popular. These products are used for installation of various parts of the pipeline. The connector for connecting the toilet to the sewer has exactly the same diameter, which can be said about some outlets for bathtubs and showers. In general, sewer pipes are made today from different materials, namely:

- plastic;

- ceramics;

- concrete;

- metal;

- asbestos.

What pipes should you pay attention to?

Among pipes with the same diameter, the main competitors are plastic and metal. But the former are being forced out of the market by metal products, because PVC has many advantages. Firstly, they are resistant to corrosion. Secondly, they are not afraid of alkalis and acids. Thirdly, they are light in weight. They are inexpensive, and the likelihood of blockages is much less, because the inner surface is very smooth.

The material is resistant to high temperatures, products made from it are easy to install, and the pipes themselves have an aesthetic appearance and do not require painting. Plastic pipes have many advantages, which is why their popularity is constantly growing. The only downside is the fear of frost. When exposed to low temperatures, products may change their size and burst. Therefore, it is recommended to use them for internal installation, while for external installation the system requires insulation.

Advantages of plastic

Any structural element made from the above materials has the following advantages:

- Resistant to a variety of chemicals, for example, solvents or alkalis.

- Strength , allowing the part to be immersed in the ground at a distance of up to 16 m.

- a smooth surface inside , creating an obstacle to the formation of plaque.

- Low weight . With a length of one hundred centimeters, an element with a circumference of 110 mm weighs about 1.5 kg.

Specifications

A fairly important parameter when choosing is the size of the sewer pipe. 110mm is the diameter you should pay attention to when purchasing. However, there are other performance properties that are important to the consumer. Among others, strength should be highlighted. If you have a corrugated pipe in front of you, then it consists of three layers and can be laid to a depth of up to 8 m. Temperature limits for operation vary from + 65 to - 10 ˚С. The internal pressure that the pipe can withstand is equal to the limit from 6 to 16 bar. The final value depends on the wall thickness and design.

Material

Sewer pipes and fittings are made by hot extrusion from polypropylene, a copolymer obtained by polymerization of propylene and ethylene. The estimated service life of sewer pipelines is more than 50 years.

Basic mechanical and thermal characteristics at 20°C

| Name | Methodology | Unit measurements | Meaning |

| Density | GOST 15139-69 | g/cm³ | >0,91 |

| Linear expansion coefficient | GOST 15173-70 | 1,5×10´ | |

| Tensile yield strength | GOST 11262-80 | MPa | 25—28 |

| Tensile strength | GOST15173-80 | MPa | 28—35 |

| Elongation at break | GOST/1262-80 | % | >100 |

| Thermal conductivity | GOST23630-79 | W/m °C | 0,26 |

Dimensions

Pipe sizes are regulated by technical specifications. If you have a 110 mm pipe in front of you, then you can use it when laying non-pressure networks. The length of such products can vary from 500 to 6000 mm. The outer diameter is 110 mm. You should also be interested in the other sizes of 110 mm PVC sewer pipes. This should also include the internal diameter, which in the described case is 103.6 mm. The wall thickness remains unchanged, it is 3.2 mm.

Among the dimensions of a 110 mm sewer pipe, the length of the socket should also be highlighted. It can be normal or extended. In the first case, the length is 58 mm, in the second - 313 mm. Weight depends on diameter. For example, one linear meter of pipe will have a mass within 1 kg.

Connection methods

Connecting such pipes is possible in three ways:

- Socket welding.

- Butt to butt welding.

- Using a coupling.

Socket welding involves inserting a small pipe into a larger pipe. The connection using a coupling is carried out using an additional part. The coupling is a small cylinder at the ends of which rubber bands are inserted inside and is put on the two ends of the connecting pipes. These connection methods are considered for pipes with a diameter of not more than 63 mm. If the diameter is larger, the butt-to-butt welding method is used. It is no worse than the previously described methods.

What to look for when choosing

When choosing the product described, you should pay attention to the wall thickness. This parameter will depend on the installation location. For external sewerage, greater thickness will be required. Otherwise, the pipe will not be able to withstand earth pressure and temperature changes. In order to increase frost resistance, manufacturers often use a multilayer pipe, which can have two or three layers. The space between the layers is filled with foam material. The product eventually takes on the name sandwich. All this increases strength and resistance to low temperatures, but increases the cost of the product.

When considering other sizes of 110 mm PVC sewer pipes, you should pay attention to the wall thickness. When laying internal networks, products with a smaller thickness are suitable. This is due to the fact that the system in this case is not subject to critical loads. Some craftsmen, trying to improve the functionality of the pipeline, install pipes with greater wall thickness in places where this is not necessary. This is impractical and can only lead to additional expenses.

SDR Ratio

This abbreviation is often found in labeling codes. Spelled as SDR . Indicates the standard dimensional ratio, in English - Standard Dimension Ratio.

This is the ratio of the outer diameter of the pipe to its wall thickness. For example, let's find the SDR for the indicators:

Here D is the outer diameter and S is the wall thickness. Both values are in mm. The calculation formula is:

Round up for a whole number and get:

The lower the coefficient, the thicker the pipe wall. This means it is stronger.

It is clear that it is rarely possible to use just one pipe. They have to be connected to each other. Therefore, there is a classification according to the type of connection:

Under the O-ring.

The most common pipes are those with a socket for a ring. For a reliable connection, it is enough to insert a straight section into the socket.

Reviews of sewer pipes made of other polymers

The dimensions of the 110 mm sewer pipe socket, which were mentioned above, are not all that you should know when purchasing such products. It is also important for the consumer to take into account that the basis may not only be polyvinyl chloride. Along with it, other plastics are also used. According to consumers, the most common is PE polyethylene. It is used only for pipes through which cold water will be transported.

As for cross-linked polyethylene, according to consumers, it is good because it is resistant to ultraviolet radiation. Such pipes can withstand heavy mechanical loads and have a fairly high temperature threshold. Such products can be used at temperatures up to + 95˚С. The connection is made by soldering, and cross-linked polyethylene pipes can be used to transport hot and cold water.

You now know the dimensions of a 110 mm plastic sewer pipe. However, it is also important to know what polymer the products are made from. It may be based on PPE polypropylene. Such pipes are widely used in various industries, because, according to buyers, they have good mechanical and chemical properties. On sale you can also find pipes made of cross-linked polyethylene, which is called PB polybutylene. Such products are not durable enough, therefore, according to home craftsmen, they are not so popular. The structure has defects, the surface may have peeling and cracks that appear after just a few years of use.

Such pipes are produced in small quantities. PVDF pipes have excellent chemical, physical and mechanical properties. It is a semi-crystalline thermoplastic that is even used in the pharmaceutical industry for pumping drugs. Taking into account all of the above, it can be noted that many plastic pipes provide serious competition to classic PVC products, but in terms of their set of advantages, cost/quality, they have no competitors.

Types of accessories for plastic sewerage

The socket installation system has become widespread for its simplicity and reliability. If you don't yet know what this is, then look at the following diagram.

Socket connection of cast iron sewer pipes

Plastic pipes have the same connection system as cast iron pipes. A socket is an expanded neck of a pipe into which the main diameter of the product fits tightly, as shown in the figure above.

In plastic pipes, the seal is created by a rubber ring installed inside the socket in a groove.

O-ring inside the pipe

All pipes and fittings used together with them have such sockets.

Below is a table that lists all the main types of fittings.

| Fittings, photo: | Description: |

Coupling | It is used for straight pipeline sections where it is necessary to connect two pieces of pipe that do not have sockets. There is a limiter rib in the middle of the products. When installing pipes, they must be rested against this rib, otherwise it will create additional resistance to the flow of water, and dirt may be deposited on it. |

Reduction | Couplings can be one-size or transitional - the latter are used as adapters from one pipe size to another. They are also called reductions. This type of fitting is used for transitions from cast iron pipes to plastic ones. |

Plug-in coupling | This part is also called a bell restorer. It is not difficult to guess its purpose - it is installed in pipes that do not have a socket at the ends. |

Audit | A sewer inspection is necessary to clean pipes. They usually place it on risers and on long horizontal sections every 10 meters. This is a short piece of pipe, from which a pipe with a screwed-on cap extends at an angle of 90 degrees; by removing it, you gain access to the system. This window is enough to insert a cable for cleaning. |

Double socket tee | If it is necessary to insert into sewer pipes, these tees are used. They are similar to the revision, but instead of a plugged pipe there is a second outlet with a socket for connecting a new sewer section. There are three types of tees - 45, 67 and 90 degrees. The choice between them is made according to the sewerage project. |

Two-way cross | A geometrically complex part used to connect two sewer branches with a riser at once. There are many types of this fitting. The outlets can be adjacent at angles of 90 and 45 degrees relative to the riser. The side sockets themselves are positioned relative to each other only at an angle of 90 degrees for installation in a corner. The entrances in the cross can be of different sizes, for example, on one side there will be a 50 mm socket, and on the other, 110. |

Single-plane cross | Like the previous option, it can have differently inclined exits, only they are all located in the same plane. The purpose of the parts is similar, but they are used in different places. These are placed on horizontal areas. |

Retraction | Bends are needed to make sewer turns. They come in 45 and 90 degrees. They try not to use the latter, as they are less passable. When designing a sewer system, it is better to reduce the number of turns and connections at 90 degrees to a minimum, since blockages occur more often in these places. If such turns cannot be avoided, then it is better to install pipes in them of a larger diameter. |

Stub | Sewage pipes eventually run out. These plugs are installed at the extreme points of the system. They are installed at the top point of the riser where there is no provision for a drain pipe. Or in bells that are not yet used, but will be used in the near future. |

Expansion pipe | If the length of the main pipe is not enough, or a very short section of the pipeline needs to be laid from the tee, these short compensation pipes are used. They can also be called extension cords. |

Double socket outlet | This part combines the functions of a coupling and a tap at the same time. It is used in the same place as the outlet, but is installed on pipes without sockets. |

Check valve | Here is a more complex part of the sewer system, which includes an internal mechanism. The check valve is designed in such a way that it is capable of allowing water to flow in only one direction - as soon as the water rushes back, it closes. Such valves are installed in sections of the pipeline where the current is forced, for example, a toilet is installed in a plinth, which is located below the level of the main sewer pipe. |

Fan air check valve | Air leaks through this valve when water is drained. It is installed on a drain pipe, the end of which can be brought to the roof of the house or left indoors. Such devices are needed for the following reason. When a volley discharge of water occurs (in a residential area this is the flushing of water in the toilet), zones of low pressure are formed in the sewer pipes - in other words, a vacuum. Our world does not accept emptiness, so the pressure tends to equalize, drawing water from the siphons in the sinks, which act as a water seal, resulting in loud and unpleasant “squelching-smacking” sounds. If there is such a valve in the system, then instead of water the vacuum will be filled with air. These devices operate silently and unnoticed. The dimensions of the sewer drain pipe can be any, the main thing is that the valve can cope with the load. If the drain pipe goes to the roof, the valve does not need to be installed. Instead, a regular umbrella is used. The valve is used indoors to prevent unpleasant odors from the sewer system from penetrating into the house. |

Pipe cost

You now know the dimensions of a 110 mm sewer pipe. However, before purchasing, it is important to also inquire about the cost. This question is the most interesting part for the consumer. For a pipe with the mentioned diameter you will have to pay 165 rubles. per linear meter. Prices for PPE pipes will be almost three times higher, although with a greater set of advantages. In this case, we can say that there is an excess of advantages, but whether to pay for them is up to you.

The final price of the sewer system will be calculated with an eye to the installation of the system and sometimes adds unexpected somersaults to the estimate. For an initial assessment, you can take the option of calculating the construction of a sewerage system in a dacha. So, you will have to pay 1,500 rubles for pipes and their installation. The cost of a drainage well in the composition is 37,000 rubles. This includes two rings, pump installation, concrete and excavation work. Additional costs for laying the system, commissioning, transportation costs, backfilling the station and removing soil will cost 15,600 rubles.

Advantages of metal parts of the waste system

- Durability. The service life of cast iron is at least 60 years.

- Strength. With such elements you can build a riser of any size.

- Easy installation due to the presence of sockets.

Metal drain pipes cannot boast such a range of material choices for production. Such parts are made exclusively from cast iron. However, this metal can boast certain advantages:

Of course, metal parts are much heavier than their plastic counterparts. However, this disadvantage is more than compensated for by reliability and safety margin.

Since plastic elements can be of three types, when installing such products you should understand their technical as well as basic differences. The only constant parameter for each type of plastic is the diameter.

By the way, this circumstance allows you to use several types of material at once when arranging a drain.

Characteristics and reviews of the red trumpet

The dimensions of the 110 mm red sewer pipe will be the same as those mentioned above. Additionally, it can be mentioned that the length will vary from 1 to 6 m. The wall thickness reaches 14.6 mm. The minimum value is 3.2 mm. Such pipes are fire resistant; they are not capable of conducting electric current, which means that additional electrical insulation is not required.

Consumers emphasize that when using such products there is no risk of corrosive disintegration under the influence of liquids or groundwater. The material is resistant to aggressive environments, including solutions of salts, alkalis, acids, gas and oil refining products. The dimensions of a 110 mm sewer pipe are not all you need to know before purchasing such products. As buyers emphasize, the pipes have higher mechanical strength and rigidity compared to polyethylene pipes. Such products have a low melting point. They are able to remain operational when heated to + 120 ˚С. If this value is exceeded, the form will be lost and hydrogen chloride gas will begin to be released, which is harmful to humans.

The first signs of deformation will begin to appear below the mentioned temperature level, when heating reaches 65˚C. It is for this reason that polyvinyl chloride products are not used for laying hot water plumbing systems.

Calculation of construction of sewer risers taking into account diameter and length

The materials and plumbing equipment on which plastic sewer systems are constructed are mostly standard with an already calculated permissible water flow rate. Therefore, preparing to build a plastic riser comes down to comparing diameters, joining angles, lengths and throughput.

The length of sewer pipes varies from 1m to 6m. This parameter also affects the rate of wastewater discharge. Thus, PVC pipes for sewerage measuring 1 m and 5 m, with a diameter of 110 mm, installed with a working riser, have a throughput capacity of 10.6 and 3 l/s, respectively. The flow speed of risers, the length of which increases, decreases due to the overcoming of non-uniform fluids by friction against the walls with the resistance of air masses.

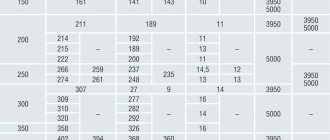

Table No. 2 summarizes the throughput indicators of plastic components with the ratio of the diameters of the riser, bends and joining angles according to SNiP.

table 2

| Internal diameter of bends, mm | Deviation when connecting the branch and the riser, deg | Pass. capacity, l/s of risers with outer diameter, mm | |

| 50 | 110 | ||

| 36,4 | 45 | 1,24 | 8,96 |

| 60 | 1,15 | 8,26 | |

| 90 | 0,77 | 5,55 | |

| 46,4 | 45 | 1,08 | 8,41 |

| 60 | 1,01 | 7,81 | |

| 90 | 0,67 | 5,21 | |

| 104,6 | 45 | — | 5,91 |

| 60 | — | 5,41 | |

| 90 | — | 3,61 | |

The dependence of the pipeline capacity on the length of the riser is presented in Table No. 3.

Table 3

| Riser length, m | Deviation when connecting the branch and the riser, deg | Pass. ability, l/s risers with outer diameter, mm and outer diameter of bends, mm | ||||

| 50 | 110 | |||||

| 40 | 50 | 40 | 50 | 110 | ||

| 1,0 | 45 | 1,61 | 1,81 | 8,81 | 9,51 | 10,61 |

| 60 | 1,54 | 1,71 | 8,51 | 9,11 | 10,11 | |

| 90 | 1,46 | 1,66 | 8,10 | 8,41 | 9,51 | |

| 2,0 | 45 | 0,97 | 1,13 | 5,41 | 5,81 | 6,81 |

| 60 | 0,92 | 1,06 | 5,11 | 5,51 | 6,41 | |

| 90 | 0,90 | 0,99 | 4,71 | 4,96 | 5,91 | |

| 3,0 | 45 | 0,73 | 0,81 | 3,81 | 4,01 | 5,01 |

| 60 | 0,68 | 0,75 | 3,51 | 3,71 | 4,61 | |

| 90 | 0,59 | 0,66 | 3,21 | 3,31 | 4,11 | |

| 4,0 | 45 | 0,53 | 0,61 | 2,81 | 3,01 | 3,71 |

| 60 | 0,49 | 0,57 | 2,61 | 2,71 | 3,41 | |

| 90 | 0,43 | 0,49 | 2,31 | 2,41 | 3,01 | |

| 5,0 | 45 | 0,52 | 0,61 | 2,11 | 2,26 | 3,01 |

| 60 | 0,48 | 0,56 | 1,96 | 2,06 | 2,71 | |

| 90 | 0,43 | 0,49 | 1,78 | 1,86 | 2,41 | |

| 6,0 | 45 | 0,52 | 0,62 | 1,78 | 1,86 | 2,36 |

| 60 | 0,49 | 0,56 | 1,68 | 1,71 | 2,11 | |

| 90 | 0,43 | 0,49 | 1,43 | 1,52 | 1,81 | |

The table shows that the more the joining angle deviates from 0 degrees, the less the riser’s ability to drain waste. Even if you increase the diameter, the throughput of the pipe will be lower compared to an analogue of a smaller diameter installed to the riser at a small angle.

Regardless of the diameter of the pipes, they must be laid in accordance with a strictly calculated slope

When calculating the construction of a sewer system, right angles should be avoided when joining branches; this creates unfavorable conditions for the operation of the sewer system. Steep trajectories greatly reduce the speed of water movement, there is a risk of clogging, and the pipe does not have time to clean itself. In areas of the pipeline with minimum speed, an increase in diameter is necessary.

For self-cleaning of non-pressure sewer systems, a slope must be observed during network installation, since the wastewater flows under the influence of gravity. The size of the plastic outlets influences the determination of the level of inclination. The optimal slope is:

- 3 cm per 1 m pipe dia. up to 50 mm;

- 2 cm per 1 m pipe dia. up to 100 mm;

- 1 cm per 1 m pipe dia. up to 200 mm.

When creating a slope, it is necessary to take into account that the wastewater contains inclusions of varying hardness, fat, which solidifies when the temperature of the liquid decreases (the average temperature of sewer water is 40

O

C), therefore, a small slope will lead to traffic jams, and a large slope will lead to rapid water flow and settling of solid waste.

Pressure sewer networks are equipped with a pumping station with a cutting mechanism for grinding solid waste. It ensures complete drainage of wastewater without any blockages. In this case, it is possible not to maintain the slope by using unplasticized PVC pipes of smaller diameter.

The length of the pipes connected to the riser should not be more than 1.5 m for the toilet and 3.5 m for other plumbing fixtures. Extension requires the installation of plastic outlets of a larger diameter using an aeration valve, otherwise, when flushing, a vacuum will occur, water from the water seal devices adjacent to the riser will be sucked out, all this is accompanied by a disgusting smell, sound, and breakdown.

Imported plastic sewer products often have dimensions listed in inches. The main thing here is not to make a mistake and install it correctly. It’s easier to choose the right diameter by converting it to millimeters (1 inch = 25.40 mm). Fractional values are often found, such as 1⅜″= 32.0 mm; 2 ⅛″ = 54.0 mm.

Whatever design decisions are implemented, there are sewerage rules that must be followed. A good solution when choosing a material and its further installation would be to contact a specialist. The independent option always begins with studying the issue and careful calculations.

Pipes of the largest diameters are used for the construction of urban sewer systems, where wastewater is collected in very large volumes

This is interesting: Connecting pipes without welding and threading: couplings, flanges and clamps

Hardness criteria for red pipes

You already know the price and dimensions of 110 mm sewer pipes. But before purchasing, it is also important to ask what category the product belongs to in terms of rigidity. It can be thin-walled, light, medium-hard, or thick-walled, hard. The first type belongs to class L and has a rigidity index of 2 kN/m2. Thin-walled pipes of medium hardness belong to class N. In this case, the stiffness parameter is 4 kN/m2. The third type is related to class S, and the rigidity indicator is 8 kN/m2.

Ring stiffness classes

Sometimes in the tables there will be letters and numbers that are unclear at first glance. For example, SN 2 . This is the ring stiffness class. It is measured in kN/m2.

The parameter makes it clear how much the pipe can withstand vertical loads without deformation.

Let's give some brief characteristics:

SN 2. Withstands pedestrian traffic only.

SN 4 . Able to cope with passenger vehicles.

SN 8 . They do not get “flattened” by trucks.

The weaker the soil is compacted, the larger the number should appear after SN .

Installation nuances

Before carrying out installation work, I advise you to draw up a diagram of the entire system, additionally measuring all distances. It is necessary to avoid connections at right angles; it is better to make a rounding of several bends, for example 2 at 45°.

In places of bends, I recommend installing a tee with access to the surface and closing it with a plug. This will provide access for cleaning in case of blockage.

If in the future you plan to connect any plumbing fixture, then it is better to install a tee with a plug in such places. This will not affect the sewerage itself, but if you really need additional drainage, it will be much easier to do it.

How to choose?

When selecting the optimal size of PVC sewer pipes, the main parameter is calculated - the expected volume of wastewater that passes through the pipeline. In a private household, the amount of liquid drained depends on the number of people living. The more drainage points there are in the house, the wider the receiving drain pipe. External sewerage cannot be less than 11 cm in diameter. For internal wiring in an apartment, it is enough to choose sewer pipes with a small diameter of up to 7.5 cm. When discharging wastewater into a riser, the size of the circle should not be less than the diameter of the common main. For buildings with five floors and below, this figure is 11 cm; if there are more floors, then the diameter reaches 16–20 cm.

Use common sense to select the optimal size of pipes at various drain points. You should not install a bulky sewer network with high throughput in low-rise buildings and apartments. Efficiency will increase slightly, but the cost and location area will increase significantly.

Sewage pipes are selected according to the following criteria:

- by diameter;

- by wall thickness;

- along the length of the free end.

The internal cross-sectional size or diameter determines the discharge load into the sewer system. Each sewage discharge point requires the use of a diameter of up to 50 mm. The drain hole under the toilet has a diameter of at least 10 cm, since solid particles go down the drain. In a private house, a pipe with a diameter of 110–200 mm is suitable for installing an external sewer system. For sewerage coming from a multi-storey building, the cross-sectional diameter must be more than 20 cm. The size of the outlet to the sewer well in the courtyard area can be 30–50 cm.

The thickness of the walls determines the strength class of the structure. The thickness must be selected according to the expected load on the pipeline. Lightweight pipes with walls of 1.2–2.2 mm are suitable for installation in systems with gravity drainage with minimal load in the internal sewer system. Typically, the diameter of such pipes does not exceed 11 cm. They can be installed to drain sewage from the kitchen and bathroom in apartments and private houses. Pipes must be freely accessible or covered with a box.

Pipes with strength class SN4 are the most common and are used for internal and external sewerage. The minimum diameter for pipes is 5 cm with walls of 2.6 mm. For a diameter of 11 cm, the thickness is 3.2 mm. Medium-heavy pipes are installed for the common house riser and outlet to the external drain. Such pipes are also used in external gravity sewerage in private and multi-apartment construction.